News

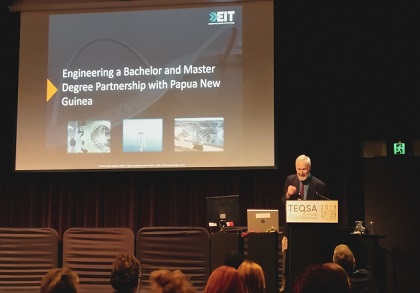

EIT recently embarked on a roadshow through southern Africa, covering hot trends in engineering, job prospects across the engineering disciplines, and troubleshooting tips.

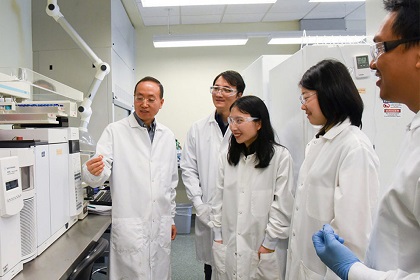

Dean of Engineering Dr. Steve Mackay and Edwina Ross presented an interactive seminar on ‘engineering as a noble profession’ to aspiring engineers and industry professionals in South Africa, Namibia, and Botswana.

In the crowds were EIT alumni, current students, prospective students, and curious engineering enthusiasts. The seminars did focus on the noble profession of engineering and its immutable age-old principles. However, Dr. Mackay also demonstrated how the industry is changing thanks to globalization and advanced technologies.

In the crowds were EIT alumni, current students, prospective students, and curious engineering enthusiasts. The seminars did focus on the noble profession of engineering and its immutable age-old principles. However, Dr. Mackay also demonstrated how the industry is changing thanks to globalization and advanced technologies.

“We are hyper-connected: mobile apps, emails, social media, and a quickly updating web. Analytics and predictive models are appearing. One of the great programming languages is Python. There are incredible tools you can use in your career. Everything is in the cloud; you can derive huge resilience by working under the cloud. If it weren’t for the cloud, we wouldn’t have a college,” Dr. Mackay said.

He noted that engineers are finding employment in a plethora of industries they might never have considered before due to the changing nature of the industry, learning, and training under the fourth industrial revolution.

“Engineering is increasingly driven by technology, and these technologies change rapidly. In response, engineers need to become more versatile. There is downward pressure on repetitive jobs in industry today.

“You have to take ownership of your education and training. That’s why you guys are here because you’re proactive in your learning. We believe that engineering skills are becoming more and more generalistic. Today you have to go cross-disciplinary and become a highly-skilled generalist.”

EIT as a solution to conquering the automation future

“EIT is a creature of the fourth industrial revolution,” Dr. Mackay said. The seminar highlighted EIT’s Industrial Automation qualifications, which have been specially created to conquer the challenges brought about by the technically demanding fourth industrial revolution.

In a wisdom-of-the-crowd practical exercise, seminar attendees were divided into groups to come up with automation solutions for several industries. They had to devise innovative solutions for automating a service station, a pizza shop, and an iron ore mining operation. The exercise demonstrated how cross-disciplinary the engineering solutions are to some of the world’s most complex technological problems. It also inspired the participants to think above and beyond what the role of the traditional engineer is.

The participants displayed immense creativity, which provided a fantastic insight into how the advent of automation has transformed the minds of both working and prospective engineers.

Dr. Mackay encouraged the attendees to explore the development of their critical thinking and investigate becoming shrewd entrepreneurs. His mantra is: “Experience together with life-long learning is critical for your career.”

A plethora of options with EIT

EIT’s College Manager Paul Celenza attended the seminar in Johannesburg, South Africa. He spoke to the crowd about EIT’s many study options to suit students of all different walks of life. He also described the methodology of how the institute delivers its courses.

“We have a whole gambit of different courses we provide to different students. We have live webinars where we link up students with lecturers in real-time. We have academically qualified instructors that have years and years of industry experience. They speak the same technical engineering languages that you do. We are ready to host you and get you fully equipped to thrive in your career.”

Representatives from EIT travel the world to demonstrate our unique online and on-campus delivery modes. These both make use of live and interactive webinars, an international pool of expert lecturers, dedicated learning support officers, and state-of-the-art technologies such as hands-on workshops, remote laboratories, and simulation software. Students can study online from anywhere in the world, or they can study select degrees on campus in Perth or Melbourne. Our supportive blended learning model and small class sizes allow you to advance your technical knowledge and remain engaged in your studies while forming global networks and balancing life and work commitments.

Representatives from EIT travel the world to demonstrate our unique online and on-campus delivery modes. These both make use of live and interactive webinars, an international pool of expert lecturers, dedicated learning support officers, and state-of-the-art technologies such as hands-on workshops, remote laboratories, and simulation software. Students can study online from anywhere in the world, or they can study select degrees on campus in Perth or Melbourne. Our supportive blended learning model and small class sizes allow you to advance your technical knowledge and remain engaged in your studies while forming global networks and balancing life and work commitments.

On this trip, EIT was seeking to prove to the participants that we can provide them with high-quality engineering education and training. Prospective students were most interested in the EIT programs that are accredited by Engineers Australia and therefore are recognized under international engineering accords.

“Our visit was exceedingly valuable. The African continent is hungry for education and innovation. The continent is brimming with resilient engineers. The region’s technological capabilities have grown by leaps and bounds. More Africans than ever are connected to the internet, and that is ensuring that they can come and study with EIT and fulfill their work responsibilities at the same time,” Dr. Mackay concluded.

March 8th marks International Women's Day 2020, a global day that celebrates the social, economic, cultural, and political achievements of women. We wanted to take this opportunity to highlight the valuable contributions from women at the Engineering Institute of Technology (EIT) and the movements they are making to break through the glass ceiling.

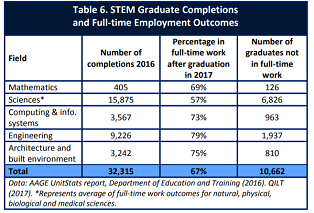

In 2017, the World Economic Forum released its global figures on women in engineering. They reported that around 20% of engineering graduates are women, but only 13% of the engineering workforce is female. A lot has been done to elevate female engineers in the last couple of years, but there is still work to do. Getting girls ready and prepared for the world of STEM work is one of the major challenges of our time.

Thus, the importance of introducing young girls to STEM subjects at an early schooling level is paramount. We consulted our very own Deputy Dean of Engineering at EIT, Indumathi V, to collect her thoughts on the ongoing challenge of getting more women into engineering. She believes that it is essential for young girls to be aware of the various career options and study pathways available to them.

"Education is the foundation to a better society. Engineering is the field that is a pillar in providing economic, environmental, health and security benefits to society. I am a strong advocate for girls and women in STEM. I am encouraged by being a mum of two young girls and a boy myself. It is important that girls are aware of any capabilities that they need to develop from a young age to nurture their interest in the field. I have run some successful initiatives and actively participate in events that promote girls in STEM."

Indumathi is passionate about innovating in the educational space and getting more people educated and trained in engineering. She understands, however, that the prospect of studying towards a career in engineering is a daunting one. Retaining the interest in mathematics in young adults is becoming harder and harder. Indumathi said:

"I was a student who was not very good at maths when I was young. It wasn't until my year 10 when maths started finally making sense, and my confidence grew to pursue Engineering. That making sense led me to understand the importance of a passionate teacher, good pedagogy, good training, well rounded education and how it changed my pathway. Both engineering and education share synergies of making a positive impact on the future generation and society."

Revolutionizing the way education is delivered is necessary to include girls and women, particularly in developing nations, in engineering education and training. Indumathi is currently pursuing her Ph.D. on the topic of Engineering and Education at the University of Southern Queensland.

Her research work includes looking at how institutes can combine technologies to assist students and teachers in the learning environment. After joining EIT in January 2019, Indumathi has helped the institute grow from strength to strength as the institute looks to ways to revolutionize the dissemination of engineering education and training.

"EIT has grown very strongly since I started at the beginning of 2019. Their innovative approach to accessible, flexible, and high-quality education is like no other in the world. The success is strongly attributed to the passionate team of lecturers and staff here at EIT.

"We are always looking at ways to do things better and are very student-centric. While we have a young growing on-campus program, we are growing strongly every day and have achieved some great recognition via professional accreditation of our programs and via our staff and student publication list growing strongly."

Works Cited

Hutt, Rosamond. "Why Do so Many Women Leave Engineering? Probably Not for the Reason You're Thinking." World Economic Forum, www.weforum.org/agenda/2016/11/why-do-so-many-women-leave-engineering?utm_content=buffer43a1f&utm_medium=social&utm_source=facebook.com&utm_campaign=buffer&fbclid=IwAR2z4QcvQV23dIrMlaP1N8l_jSjUUQN0ifpNAfdTgU7xINGywP6qhjHw6sw.

Transformative technologies demand flexibility in the modern era. Consumers demand that technologies be smaller, thinner, wearable, fireproof, bendable, etcetera. On top of all that, the battery still needs to hold a charge.

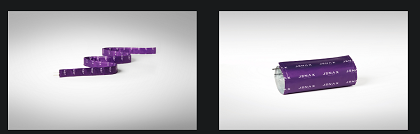

In Busan, South Korea, a company named Jenax has been hard at work at revolutionizing the lithium-ion battery. They are ensuring a battery can scrunch, bend, flex, and more. The battery is called the J-Flex. And it looks like this:

Jenax says they have batteries as small as 0.5 millimeters that could power sensors, with their biggest battery being a 200mm by 200mm battery. The company says after 1,000 charge-discharge cycles, the cells retain 90% of their capacity.

Creating ultra-flexible batteries that can twist and turn increases the chances of flammability. Lithium-ion batteries are prevalent in many of the technologies that we plug-in to charge every day. Most notably, our smartphones, smartwatches, and tablets.

Jenax has created a non-flammable liquid electrolyte solution for their batteries. Lithium-ion batteries are well known to suffer from a phenomenon known as thermal runaway once the battery gets too hot. The company has 100 patents related to its flexible battery technology. Jenax is keeping mum on how they achieve their level of flexibility, and rightly so, due to the market heating up.

Director of Jenax, EJ Shin, said in a statement, “Liquid is the best conductor for ionic movement, which means it delivers the best battery performance. But because liquid can also be a tremendous fire hazard, many manufacturers try to use solid state electrolyte instead. They sacrifice efficiency and in the case of wearables, comfort and usability, for safety. Jenax has always been focused on delivering the greatest combination of safety and performance. With this non-flammable electrolyte - we’re taking both to the next level - providing peace of mind manufacturers and consumers need with the high performance they deserve.”

Here is a safety test that demonstrates how other lithium-ion batteries fair when undergoing stress tests:

The company says their battery can be used to revolutionize the following battery-powered technologies:

IT wearables

- Smart Watch

- Smart Glasses

- Headset

Health

- Fitness Band

- Medical Device

Fashion

- Smart apparel

- Accessories

Military

- GPS Tracker

- Military Helmet

- Wearable Robot

The company recently showcased their flexible batteries at the Consumer Electronics Show which took place in Las Vegas from Tuesday the 7th of January to the 10th of January 2020.

Jenax showed their willingness to see their battery tech installed into other companies’ applications. They reportedly powered a sensor-lined football helmet developed by HP1 Technologies. Engineers are being called to see where they could implement the flexible batteries in their daily applications.

On the eve of their appearance at CES, EJ Shin explained, “Too many connected products fail to attract customers because they are awkward, uncomfortable, or difficult to use. Hardware designers often tell us that traditional battery limitations - including rigidity, thickness and lack of flexibility - are getting in the way. We created J-Flex specifically to help innovators overcome these challenges and meet consumers’ needs.”

Works Cited

“Jenax Announces Snack & Demo Sessions on Ultra-Flexible Batteries at CES 2020 | Markets Insider.” Business Insider, Business Insider, markets.businessinsider.com/news/stocks/jenax-announces-snack-demo-sessions-on-ultra-flexible-batteries-at-ces-2020-1028719460.

Zenopa. “Jenax Announces a Non-Flammable Liquid Electrolytes Solution.” Recruitment Within Pharmaceutical Jobs, Medical Jobs, Scientific Jobs, Tech PR Jobs, Zenopa, 3 Jan. 2020, www.zenopa.com/news/1976/jenax-announces-a-non-flammable-liquid-electrolytes-solution.

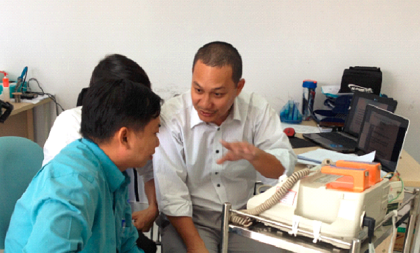

Armando D. Ngojo is an Engineering Institute of Technology graduate who recently completed our 52705WA - Advanced Diploma of Biomedical Engineering.

Currently working in the healthcare engineering industry for a company that maintains and manages medical equipment, Armando has spent fifteen years in the technological side of the medical industry. However, Armando’s interest in engineering began at a young age.

“When I was younger, I was very fascinated with the functionality of the transistor radio. I opened it up and saw a lot of small things and components which fired up my curiosity. I was amazed at how a television worked. How a refrigerator cooled the items inside of it intrigued me.”

In his secondary school years, he pursued his love for technology further by enrolling in an elective that covered electricity & electronics. After high school, he began to pursue a career in Electronics Engineering. However, Armando’s road to an engineering career was not an easy one.

“When I was in college, I went through a lot of ups and downs. Initially, in 1996, I was a freshman scholar with tuition discounts but it was abruptly terminated after the first semester only. I failed the cut-off grades to maintain the discounted fees,” explained Armando.

“I was also out of university the following year due to financial issues. In order for me to continue my studies in the year after my hiatus, I became a working student and helped my family survive while pursuing my degree.”

In college, Armando had the opportunity to work with simple medical equipment like suction machines and OT lights in conjunction with his studies at college. It was in that role where his interest in the healthcare engineering industry was sparked.

After graduating from college, Armando got a job at a local medical sales and service company in the Philippines as a Biomedical Service Engineer. This role unlocked a world of opportunities, which resulted in Armando working full-time in Malaysia for seven years, Vietnam for one year, and Abu Dhabi and Dubai for more than five years.

After many years of working in the industry, Armando felt that he wanted to take the next step in advancing his career. He went on a search for a biomedical engineering course that would allow him to upskill even further, and that is when he discovered EIT. He noticed our Advanced Diploma in Biomedical Engineering was exactly what he needed.

“I took the course because although I was already working in the healthcare industry for the last 15 years, I lacked a proper school qualification. This is due to my home country; in the Philippines, no university was hosting a real course in Biomedical Engineering in my time.”

Since he has graduated, Armando has found that his daily responsibilities at work have become easier to manage.

“Professionally, I got a promotion within my company and was given more responsibilities, and of course, better remuneration. My newly acquired qualification also opened up a lot of opportunities for me. Being an EIT graduate was a power credential in my portfolio.”

He is now waiting for EIT to begin hosting a Master’s Degree in Biomedical Engineering so that he can continue building on his knowledge base in the technological realm of the healthcare industry. He concluded:

“I am very interested in pursuing further studies in this field due to the fact that with my current job requirements, the face to face interaction with medical officers like nurses, lab technicians, radiographers, and doctors are always imminent. I need to learn how to converse with them using medical terminologies they understand. I am talking to them with more self-assurance after graduating with EIT.”

Armando is fascinated by the developments occurring in the biomedical engineering industry. He says that the emergence of AI and 3D printing of organs has been particularly interesting to watch. He says the course through EIT delved into some of those topics and opened his eyes to the development occurring in the space. As the industry continues to grow, he sees his career growing.

“My career maturing in the upcoming years is a definite! I know that the industry that I am currently in will become very competitive in the coming years, but I am very confident that I will survive because my years of extensive experience in the industry are already backed up by my proper and formal school qualification achieved through one of the best technical schools in Australia: EIT.”

Islam Sarwat graduated from EIT in 2015 with a 52742WA - Advanced Diploma of Plant Engineering. Before completing the program, he was an in-training operation and mechanical engineer. He noticed that he had some spare time on his hands and a dream to attain a senior engineering job in the future.

Islam chose this particular program because, he says, it was comprehensive and covered a lot of material that would improve his knowledge and enhance his skills. He also knew it would help him find direction in his career.

“My studies helped orient me in choosing which engineering industry to go into. The engineering industry has a lot of different varieties and disciplines. Instead of one particular field, it includes many different fields.”

Islam found that the pathways to being hired in a high-level job became more likely after completing the plant engineering program.

“Life was better. I felt that I did what should be done to enhance my skills. I extracted immense value from my studying with EIT. The course definitely added to my skill set in my work environment.”

After three years of studying, he got what he was hoping for: Islam was appointed as a project lead in the new extension of the plant for the company he was working for in the Industrial Gases industry. His daily responsibilities include:

- Process optimization

- Efficiency enhancement

- Preparing reports regarding plant performance

- Preparing maintenance and operation budget

- Carrying out preventive and corrective maintenance

- Implementing production plans

Islam is looking forward to the future challenges his career in engineering may throw at him. And now, he is looking to the next career challenge of leveling up to more senior (and managerial) positions.

“I have met the challenges that have come as my career has matured. I overcame these challenges, developed my skills, and improved myself by studying and training in my field. I for sure, have a better future. I plan to improve my managerial skills to shift from the technical world to managerial positions.”

Legal Wise, a law institute in South Africa, defines retrenchment quite aptly, “Retrenchment is a form of dismissal due to no fault of the employee, it is a process whereby the employer reviews its business needs in order to increase profits or limit losses, which leads to reducing its employees.”

In some instances, automation has meant that some jobs no longer require human intervention. For example, in the banking sector, many physical branches have closed down or downsized as Internet banking takes over.

In the engineering world, mining companies have also been badly hit. For example, in September 2019, mining conglomerate Sibanye-Stillwater indicated that 5,270 jobs (or roughly 6% of their workforce) would have to be cut after financial losses at their mines. In 2017, Platinum producer Lonmin announced that it would lay off 12,600 workers over three years.

In the engineering world, mining companies have also been badly hit. For example, in September 2019, mining conglomerate Sibanye-Stillwater indicated that 5,270 jobs (or roughly 6% of their workforce) would have to be cut after financial losses at their mines. In 2017, Platinum producer Lonmin announced that it would lay off 12,600 workers over three years.

However, while some jobs are no longer as in-demand as they once were, advances in technology mean new roles are being created all the time. Here are some tips for surviving retrenchment.

Tweak your CV and get back to job hunting

Updating your curriculum vitae to be in line with modern recruitment practices is essential. Our Dean of Engineering at EIT, Steve Mackay, has a few tips on where to begin with your CV.

“First of all, ensure your CV is designed for the particular job you are applying for,” he said.

“Your CV should use plain English and the information should be laid out simply and logically…and leave lots of white space. Grammar and spelling must be one hundred percent accurate.

“Avoid too much detail; the CV that is 20 pages long is not acceptable. An executive summary at the top of the resume is a good idea. Be specific! Focus on the job you really want. Your CV should also include business strengths and business wins.”

You can also utilize your network here. Check up on previous employers, see if they have any vacant positions you could fill. Talk to colleagues and friends you have amassed along the way in your career. Your next job could be a phone call away.

Upskilling for the future of work

Growing your skillset is imperative. Many industries are automating more and more of their operations, which may leave the role you are performing redundant. Therefore, undertaking professional development in cutting edge areas of the engineering industry is essential.

The Engineering Institute of Technology provides professional certificates of competency, diplomas, advanced diplomas, and bachelor’s and master’s degrees in crucial engineering disciplines with updated curriculums that prepare you for the technologies you can expect to see in the workplaces of the future.

Entrepreneurship

Market your skills as a freelancer or an independent contractor to get work after you have been retrenched from a company. Depending on where you are in your career, you could continue doing that for a reasonable amount of time. In fact, some engineers are noticing that they can also create several side-hustles that generate money they can use to achieve even bigger things later on in life.

Retrenchment doesn’t have to be the end of the world for you. It can be the beginning of a new chapter in the book of your career. Keeping a level head and carrying on with making the most of the skills you have amassed, or looking into educating yourself further, are all important mechanisms to surviving any tough patch.

Works Cited

Retrenchment Tracker: South Africa's Big Corporate Job Losses in 2019 - so Far, www.businessinsider.co.za/total-number-of-job-losses-south-africa-retrenchment-corporate-job-losses-2019-6.

“Retrenchment Process and Procedure: QuickLaw Guide.” LegalWise, www.legalwise.co.za/help-yourself/quicklaw-guides/retrenchment.

Lucinda Krige is a South African inspiration. She is a qualified Marine Engineer Officer who, since 2003, has been working for renowned seafood processing company Sea Harvest. She currently works as a HR Business Partner in Learning and Development at Sea Harvest.

She was the first woman to qualify as a Chief Engineer in the fishing industry in South Africa. The sector produces 80 million tons of food and employs 40 million people across the globe.

Sea Harvest is a company that was established in 1964 on the Atlantic West Coast of South Africa. They are headquartered in Saldanha in the Western Cape. They catch and package seafood, exporting it to 22 countries.

Lucinda, being the first female engineering cadet in the fisheries industry to rise up the ranks to become a Chief Engineer, is a role model to the many unemployed youths in South Africa who are desperately seeking the kinds of opportunities she has worked for.

Lucinda, being the first female engineering cadet in the fisheries industry to rise up the ranks to become a Chief Engineer, is a role model to the many unemployed youths in South Africa who are desperately seeking the kinds of opportunities she has worked for.

Lucinda started with Sea Harvest as an engineering cadet in 2003. Sea Harvest, at the time, was recruiting cadets via the newspaper. Lucinda’s father drew her attention to the article, saying she should perhaps pursue it.

“I asked him what it was about - he didn’t know, and neither did I,” she said.

“But, I applied and was successful. When I boarded my first vessel, that is when I started to discover what marine engineering was all about, and life at sea - the rest is history.”

At the age of 20, Lucina began the grueling process of practically learning the ins and outs of the technologically advanced trawler vessels used in the fishing industry. She had to learn everything from the operation to the maintenance of the fishing vessels during her time as a cadet. Almost every single time she boarded a ship, she was the only woman on board.

“When you start out in the field, you start as an engineering officer, that’s the first level,” she said.

“You start with the basic knowledge of various disciplines. That is where your workshop training comes in, because those are your hand-skills, that you have to get under the knee.

“For instance, your winch system onboard the vessel includes hydraulics, pneumatics, and electronics. Then there is refrigeration, electrical, engines — which is the mechanical part, and controls section. You start out with a cluster of skills that you need to familiarize yourself with.”

For a detailed look at the five years of of theoretical training and work experience Lucinda conducted to obtain her qualification as chief engineer, watch her chat with me here:

Breaking the glass ceiling

Lucinda and her father took a keen interest in stories of female engineers in the newspapers. This, coupled with her love for mathematics and science, led to her pursuing a career in the engineering industry. She says working in a male-dominated industry was not too intimidating to her.

“The funny thing about my career choice is that when I was little, my father would always ask what I wanted to be when I grow up. This was back in the 80s. I had this thing of wanting to be a policewoman. My father asked why I wanted to do it, and I said it was something that I didn’t see a lot of women doing.

“When I was in primary school, I came home with the newspaper that had an article in it about the first female civil engineer in South Africa that was part of a bridge project. That’s when I decided I wanted to do engineering.”

It has been eleven years since Lucinda was sea-bound as an engineering cadet with Sea Harvest. She now chuckles when she says she has ‘hung up her overalls’ for an on-shore job.

She now heads up the technical and maritime training at Sea Harvest’ Saldanha headquarters. She ensures that the curriculum is up to date in accordance with the vessels so that the ships can be safely manned.

The training helps both those who have no formal qualifications and those who do, level up in the maritime industry in the country. Lucinda sits on advisory committees and is a fishing industry representative that speaks at government events as well. Sea Harvest takes in unemployed youth in South Africa and puts them through an apprenticeship program that helps them become artisans in the fishing industry in South Africa.

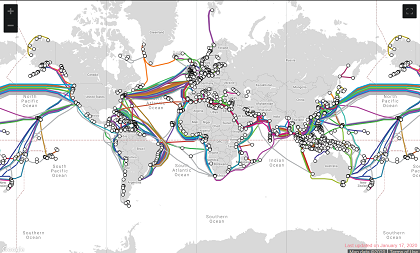

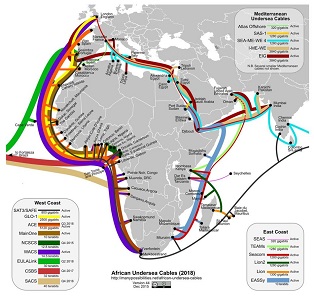

While the Engineering Institute of Technology has campuses in Perth, Western Australia, and Melbourne, Victoria, we predominantly run as an online institute that sees thousands of students logging in and out every day. For students who are part of our online learning cohort, internet connectivity is imperative.

We are proud to have students from all over the world who have earned Australian accredited diplomas and degrees through our unique online delivery model. We are, however, aware of the challenges many countries face with limited internet connectivity.

According to Internet World Stats, there are 525,148,631 internet users in Africa. The continent’s population is said to be 1.216 billion people, according to estimates compiled in 2016. About 690 million people are, therefore, without access to life-changing internet technologies.

According to Internet World Stats, there are 525,148,631 internet users in Africa. The continent’s population is said to be 1.216 billion people, according to estimates compiled in 2016. About 690 million people are, therefore, without access to life-changing internet technologies.

In 2017, the United Nations (UN) reported that more than half of the world’s population still does not have access to the internet, with Asia and Africa facing the lowest connection rate. It has now set a goal for universal access to the internet — which would equate to 90 percent of the world population — by 2050.

Facebook and Amazon have been experimenting with the research and development of internet-for-all technologies. Engineers are deeply involved in how nations connect to the internet. While philanthropic companies undertake the challenge of creating new, still-to-be-debuted, mobile internet technologies, the tech that connects the world to the internet has its fair share of maintenance issues.

How is the internet provided to the world?

Ninety-nine percent of international internet data is transmitted through a series of submarine cables spread across the ocean floor across the globe. There are 300 undersea cables transmitting data underwater, ensuring nations get internet connectivity.

However, when these connections become damaged, the internet traffic from the directly affected countries is rerouted through working cables. This impacts speed and accessibility.

For example, on the west coast of Africa, the West Africa Cable System (WACS) and South Atlantic 3 (SAT3) form international links that connect southern Africa to the world.

WACS connects South Africa with the United Kingdom. The SAT3 cable connects South Africa to Portugal and Spain. Both of these cables were damaged by gale winds earlier this year, impacting the entire collection of southern African internet service providers.

On the east coast of Africa, the SEACOM and EASSy cables are receiving rerouted international internet traffic from the western parts of the country where the cables are down.

This meant internet service providers had to continue buying international bandwidth from SEACOM to keep international traffic ticking along for their consumers.

The future of internet connectivity

Are undersea cables set to be the norm for internet connectivity a century from now? Is South Africa’s cautionary tale of gale-force winds and broken undersea cables enough food-for-thought for engineers to come up with more innovative ways of connecting the world to the internet?

Some internet service providers in southern Africa offer competitively priced high-speed satellite internet. Satellite internet is useful, especially in rural areas that do not have fixed and wireless internet infrastructure. South African born Elon Musk’s aerospace company SpaceX, has recently launched a satellite network named Starlink that will help provide low-cost internet to remote locations.

The U.S. Federal Communications Commission (FCC) has given the company clearance to launch 12,000 small satellites and may allow them to push the number to 42,000 in the future. Around 242 satellites are already in space. Ongoing research and development of internet technologies, such as SpaceX’s Starlink, are going to have to go into hyperdrive to meet the UN’s target of 90% of the earth’s population being connected by 2050.

Works Cited

“Africa Internet Users, 2019 Population and Facebook Statistics.” Internet World Stats, www.internetworldstats.com/stats1.htm.

Mann, Adam. “Starlink: SpaceX's Satellite Internet Project.” Space.com, Space, 17 Jan. 2020, www.space.com/spacex-starlink-satellites.html.

South Africa needs more medium-skilled workers. The youth graduate unemployment rate in the first quarter of 2019, according to Stats South Africa, was 31 percent. The hope is that the first quarter of 2020 may see improvement.

The Minister of Higher Education, Science and Technology, Blade Nzimande, is encouraging matriculants who just received their results in January to consider enrolling in Technical Vocational Educational and Training (TVET) colleges.

He said most students aim straight for university after completing the twelfth grade, “TVET colleges play a pivotal role in addressing South Africa’s skills needs and cater for a wide spectrum.”

He said most students aim straight for university after completing the twelfth grade, “TVET colleges play a pivotal role in addressing South Africa’s skills needs and cater for a wide spectrum.”

Blulever Education, a new South African higher education group, reports that there is a shortfall of 40,000 people in the artisanal space in the country. The situation is further worsened with unqualified artisans purportedly flooding the market.

In their latest report on the sector, they write, “We found that this is a system with pockets of excellence and institutions that are doing things well in various ways, but that overall the artisan ecosystem is dysfunctional and in need of many interventions. Some issues are systemic, and need to be addressed by large-scale policy or governmental interventions, while others present opportunities for institutions to introduce solutions.”

Nzimande says that 156,800 new studying opportunities are available in the 2020 academic year to students who wish to undertake engineering, general, or business studies. The TVET sector in the country also has its own shortfalls - and that’s where EIT comes in.

EIT is well positioned to help South Africans reach their potential and empower them to get qualified as a technologist or technician. EIT provides an opportunity for these students to graduate with a locally and globally relevant qualification.

The unique online delivery model means students can learn while seeking and undertaking employment. The importance of redefining study and work is clear from the whitepapers in South Africa, and EIT is meeting the challenge head-on.

EIT’s Dean of Engineering Steve Mackay, who will be visiting three South African cities in February, said, “I think in the daily haze of software, theory, paperwork, standards, regulations, procedures, policies and systems we operate in; we tend to forget this as engineering professionals.

“Despite all the changes in engineering today, the engineering craftsman is still a key contributor in the engineering team and should always be accorded enormous respect.”

The Department of Higher Education (DHET) has been nudging students towards artisan education and training since 2014, under a campaign called ‘The Decade of the Artisan.’ The success of this campaign will be measured in 2024.

The DHET is continuing its efforts to motivate students to join the medium-skills industry, and are hoping the economy may be revived through this sector.

EIT is poised to continue helping students in South Africa and beyond reach their education and training goals while gaining work experience. With every passing year, distance learning, coupled with work experience, is becoming the norm. We are dedicated to helping train artisans in the engineering industry up for this ‘decade of the artisan’ and the next.

Works Cited

“Blulever.” Blulever, blulever.com/.

Mafolo, Karabo. “HIGHER EDUCATION: Blade Nzimande Urges Students to Apply to TVET Colleges.” Daily Maverick, www.dailymaverick.co.za/article/2020-01-16-blade-nzimande-urges-students-to-apply-to-tvet-colleges/.

Australia’s fire season has been the most damaging in living memory. The skies have been tinged red by the earth-scorching fires that have burned up about 12 million acres of land in Australia.

The bushfires, which are usually observed between October to March, have been raging since September 2019. They are the worst in the country’s history. Each state has been affected in a variety of ways, but it is New South Wales and Victoria that have been most severely hit by the fires.

As Australia picks up the pieces, while still blazing fires as temperatures soar, engineers are both assisting where they can and wondering how to prevent another disaster like this in the future. Each engineer in every engineering discipline could use their technical studies to the country’s benefit to mitigate future fire events.

Back in 2016, a Research Scientist at IBM, Anna Phan, asked the question: Can we outthink natural disasters? IBM’s artificially intelligent systems could be a potential solution to future flare-ups in the bushfire season in Australia.

On an article posted to LinkedIn, she wrote, “At IBM, our researchers are applying science and technology to tackle problems like predicting which areas and properties are most at risk of bushfires, investigating evacuation plans in hypothetical scenarios, or recommending the best evacuation route in a crisis.”

One of the elements of fire spreading that IBM had to account for as they began their research in 2016 was ember attack. Ember attack happens when burning foliage, twigs, and other flammable materials become airborne after gusts of wind. Larger fires create more embers. Therefore, Australia has seen runaway fires continue to develop.

The civil engineering implications in the aftermath of the fires could be significant. Updating building standards with future fires in mind will be imposed.

Ian Weir, Head of Landscape Architecture at the Queensland University of Technology, who is researching bushfire-affected architecture, spoke to NPR. He explained that in Australia, conventional homes that do not comply with the latest building standards are more flammable. A remedy for that has been cutting away vegetation to create buffer zones for properties. However, with embers spreading over the landscape, conventional homes catch fire in any case. Hence the need for future retrofitting and construction regulations to protect properties from fires in the future.

Newer automated technologies can play a part in prevention, mitigation, and disaster relief.

Anna Phan writes, “By using big data and analytics such as fire spread simulations and traffic modeling, IBM’s researchers have also developed an evacuation planner. This can provide answers to how long it will take to evacuate an area, the impact of road blockages and what shelters are available to help town councils and emergency services better prepare for bushfires.”

Electrical engineers will also be learning vital lessons for future disasters, as the bushfires have threatened electricity distribution. In New South Wales, the bushfires blazed through a link connecting the state’s electricity link with Victoria. Some transmission lines were reduced to rubble which led to pleas from the government to limit power consumption.

Two substations in the Snowy Mountains region were closed, causing 900MW to be lost from the grid - but impressively, electrical engineers managed to keep the lights on thanks to emergency backup sources of power. However, there were some regions, specifically from South Nowra to Moruya, Tumbarumba, and others where power was non-existent due to the ravaging fires.

The crisis is ongoing and will be remembered for years to come. However, the resiliency of the Australian firefighters during this crisis will be most remembered. The world will continue to celebrate them. Their job is not yet complete as they continue to battle fires, which are expected to continue burning. Moreover, the heroic stories of everyday Australians’ survival will number in the thousands after the dust has settled on these bushfires, and each deserves an equal measure of attention.

Works Cited

Hersher, Rebecca. “Australian Fires Prompt Questions About Protecting Houses From Embers.” NPR, NPR, 7 Jan. 2020, www.npr.org/2020/01/07/793991736/australian-fires-prompt-questions-about-protecting-houses-from-embers.

PhanFollowResearch, Anna, and Anna PhanResearch. “Can We Outthink Natural Disasters?” LinkedIn, www.linkedin.com/pulse/can-we-outthink-natural-disasters-anna-phan/.

Sefiwa Monyamane is an engineering professional and Engineering Institute of Technology graduate from Botswana. Currently working at a state-run electricity utility company, Botswana Power Corporation, Sefiwa is a scholar of the world of electrical engineering. But why did he choose the world of electrical engineering and more specifically, EIT?

“New inventions are ever-changing in complexity, especially in power utilities. As an innovative individual, I thought this was the right course and the right field to express my interest in the technologies of the industry.”

Sefiwa first began to pursue a career in electrical engineering many years ago. He attended Shashe River School between 1999 and 2000. There he received his Botswana General Certificate of Secondary Education (BGCSE) in Physical Sciences. Soon after, he enrolled for a Diploma in Electronics and Electrical Engineering at the University of Botswana, receiving his diploma in 2003.

In 2005, he went on to work in Broadcasting Services as a Transmission Technician. Three years later, he would join the Botswana Power Corporation as a Commercial Technician, working there from 2008 to 2016. It was during this time that Sefiwa enrolled for EIT’s 52727WA - Advanced Diploma of Electrical and Instrumentation (E&I) Engineering in Mining.

Sefiwa enrolled in the program after the profession he was pursuing began demanding that he continue to develop his skills in the industry.

“I have come to understand the entire scope of work across the power industry in the particular sector I am in. It was covered by the modules in EIT’s course. The course captured every aspect of power from generation to distribution, which was useful because now I utilize the knowledge in my daily work.”

In 2016, he found himself fulfilling a role as an Operations and Instrumentation Coordinator at Serviceline Engineering. He remained in that role until rejoining Botswana Power Corporation in 2019, this time, and he worked as Planning Technician for the state utility. His day to day responsibilities include load forecasting and network extensions to cater for future scenarios at the utility.

Sefiwa is looking forward to the remainder of his ever-expanding career and is currently considering enrolling for the Bachelor of Science (Electrical Engineering) with EIT. He is also keen on learning more about renewable energy technologies as he notices the power generation industry moving away from coal-based generation to solar energy. EIT caters to that too — students can seek out the 52764WA - Graduate Certificate in Renewable Energy Technologies.

Sefiwa’s career progression and academic journey is proof that he is an individual dedicated to serving his community, improving lives, and working towards a better future.

“With the dream of obtaining my bachelor's degree, I foresee a change in the way our utility generates its power - especially because the world is embarking on utilizing green technologies. And I want to be ahead of the learning curve when it comes.”

Dear Colleagues

The debate is now moving to whether the current coronavirus (as I write this, more than a hundred people have died) is more virulent than the earlier SARS virus with suggestions that it is even spreading before symptoms are evident. Some comparisons are also being made about the influenza pandemic in 1918 when between 20 and 40 million died near the end of World War I. (More people died in a single year here than in the horrendous Black Death Bubonic Plague from 1347 to 1351).

And we have Cyber Viruses of course

Naturally, there are a plethora of millions of cyber viruses being spread on a second-by-second basis through the internet. These are absolutely horrendously destructive to electronic media and have been known to shatter longstanding businesses and careers. But fortunately, with training and varied isolation techniques combined with a dose of common sense and pro-activeness, they can be kept at bay.

Working Online is a Win-Win-Win on So many Levels

In addition to avoiding the spread of biological viruses, the rapid growth in broadband, the need to reduce travel and accommodation costs as well as reduce harmful emissions (from travel), makes the whole topic of working and learning remotely very relevant today. It’s good to collaborate remotely without the need to physically travel — you can increase productivity, save time and money while reducing your company’s carbon footprint. As well as (today) avoiding spreading harmful diseases.

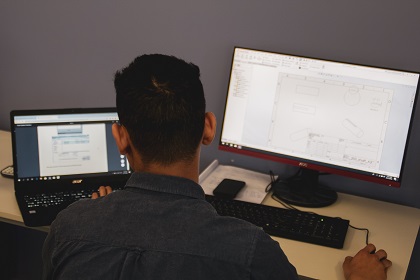

A Growing Need for Remote collaboration and Online Learning

With the growth of working online, there is a growing demand for remote configuration and testing of systems often performed by teams of engineering professionals collaborating virtually, while scattered at geographically remote locations. Admittedly, there are technical challenges of remote control and configuration on a real-time basis and there is a heightened risk of security breaches with catastrophic consequences for a remote automation project for example. However, the field of remote collaboration and configuration is growing fast.

Needless to say – if you can collaborate online, you can undoubtedly learn online. This is resulting in an explosion in online training and education.

Working in Teams

As engineering professionals, we tend to work in teams. This is often the sales pitch used to encourage the use of a new family of tools allowing for communication, collaboration and coordination. Without the requirement for physical travel.

The market of remote collaboration can be segmented by price and bandwidth requirements and ranges from (at the low end of bandwidth) email/instant messaging/phone calls/audio conferencing / webcasting/web conferencing/video conferencing and the big one – telepresence. The web conferencing is the tool that offers particularly useful features at an affordable cost.

Three Main Functionalities of Remote Collaboration

Remote collaboration is not only just about technology but has three main functionalities:

* Communication – the ability to exchange information between participants

* Co-ordination – the ability to coordinate tasks among the geographically scattered team

* Collaboration – the ability to achieve team goals.

Typical tools range from Gotomeeting, Livemeeting, Electromeet and WebEx. These allow typical web conferencing at an affordable cost. The main methods of delivery of web conferencing are typically using slides, audio, text chat, video streaming, use of a whiteboard, sharing of programs, file transfers and web touring.

In addition, the feature of simultaneously performing remote configuration and testing of a remote site is an added benefit in some of them, and this is the area that really interests me with our research and work. This is especially helpful for our online education using remote labs scattered around the world which our students can access wherever they are located.

The benefits of remote collaboration and testing include:

* Stops the spread of biological viruses

* Good for minimizing harmful emissions

* Convenience

* Easy to use

* Expertise available to more sites

* Higher availability of equipment

* Access to specialized equipment

* No geographical barriers

* Minimisation of travel and accommodation costs – lower greenhouse gases

* Considerably lower costs

How can you take advantage of these tools?

* Think seriously about using remote collaboration, testing, and configuration for your next project

* If you have access to broadband on your remote sites, this makes the decision easier

* Your younger staff would be familiar and comfortable with these tools

* Pay attention to the security of your connections

* Training is required to ensure everyone is skilled at using these tools

Naturally, everyone is not going to go across to 100% remote collaboration. Agreements and contracts often need a personal touch. Informal discussions during tea breaks are difficult to replicate through the sometimes clinical internet. And naturally, critical tests and interfacing with equipment where an expert is required physically on the spot are still essential. And as we all know, in many locations, internet connections are not possible, impossibly slow or tenuous. So as with everything – there is a trade-off required between the online and physically-on-the-spot worlds.

On the topic of remote control, John Alejandro King made the joking remark, which could be one day true: If you're not scared or angry at the thought of a human brain being controlled remotely, then it could be this prototype of mine is finally starting to work.

Yours in engineering learning

Steve

Ijaz Ali is a graduate of the Engineering Institute of Technology based in the United Arab Emirates. He completed his 52724WA - Advanced Diploma of Civil and Structural Engineering in March 2019. He has recently embarked on his journey of acquiring a Bachelor of Science (Civil and Structural Engineering) with EIT.

He chose to study these qualifications because of the industry he works in; he works in the field of Transportation Engineering, which is a subcategory of Civil Engineering.

To get to where he is today, he started his journey in 2007 when he did a CAD certificate and worked with an Engineering Consulting office. His affinity for engineering in his day to day work is apparent.

“I chose this field as I was fascinated by how easily and systematically one can solve complex issues through engineering. It is a very well-structured field with proper procedures and standards that govern it, and this is the main reason why I like it.”

Ijaz already had close to eight years of experience in the Transportation Engineering industry before he began building on his skills with EIT.

In those eight years, Ijaz has seen immense development creep into the industry. He has seen mobility as a service, like Uber, become a societal norm. He has seen engineers hypothesize multi-national road traffic safety projects to eliminate all fatalities and serious injuries on roads, otherwise known as Vision Zero. And he has seen the incredible development in the autonomous driving industry. At his current job, he forms part of the ITS & Transportation Team.

“I am involved in the design and studies for different ITS strategies such as the Traffic Control System, Road Weather Information System, FOC Network and CCTV Connectivity. I support the team in preparing drawings, feasibility reports, and traffic studies. Previously I was also involved in the design and studies for Internal Roads, Highways, and Parking areas. I was also involved in obtaining their approvals from the local authorities. I also prepared longitudinal and ROW sections for the same along with the Stormwater, Sewerage & Streetlight design. I also proposed utility corridor designs for it. In addition to that, I have worked with the QS and Project Management team for cost and schedule estimation, for forecasting UpToDate.”

Ijaz now works at the Surface Mobility Consultants head office in TECOM Dubai, where he mostly works on projects with Integrated Transportation Center (ITC – DOT) for the implementation of Plan 2030. He has equipped himself further with Transport Engineering and Project Management short courses to ensure that he remains as proficient in his trade as possible, and gaining domain expertise as he goes along.

“I am still part of EIT as I have continued my studies through the bachelor's program, but I can say that after obtaining my Advanced Diploma, I am now officially recognized as an industry professional and I am also in the process of being recognized by Engineers Australia at the Engineering Associate Level.”

Ijaz has gotten this far in the industry and intends to go even further. He says that the elephant in the room nobody wants to discuss in the industry is the effect of the massive carbon footprint that the transportation industry creates - something he wants to contribute towards fixing.

Sometimes Ijaz tries to fit in some reading into his busy schedule. He encourages people to pick up a copy of ‘Seven Habits of Highly Effective People’ by Stephen Covey. He also encourages young people to pursue a career in engineering as it is ultimately a rewarding career path. He concluded:

“Engineering is an ever-evolving discipline that affects our day to day activities and sustains the system we are currently living in. This is why I would highly encourage young people to consider pursuing a career in this field.”

Autonomous and efficient data-collecting systems will continue to revolutionize engineering industries throughout 2020. The development of these cyber-physical systems is what is enabling the data and sensor-driven efficiency of the fourth industrial revolution forward.

The most cutting-edge of industrial setups in the world are combining cyber-physical systems with large amounts of data, paired with machine learning, in one big interconnected network. This means factories can run with almost no human interference.

Jon Excell, the Editor of The Engineer Magazine, ended his first Editor’s Note of the January 2020 edition by highlighting how engineering innovation and data generation is transforming a plethora of industries.

“Few areas of industrial endeavor are untouched by digitalization...engineering innovation - whether it’s destined for the high seas, the operating theatre or the farmer’s field - is increasingly reliant on the intelligent use of data,” he wrote.

“And, as we look further ahead, the degree to which this drives different sectors to collaborate and learn from each other will surely become one of the defining characteristics of modern engineering.”

To get ahead of the ever-expanding automation industry, the Engineering Institute of Technology (EIT) delivers industrial automation programs to students around the globe via a unique online methodology. It makes use of live and interactive tutorials, an international pool of expert lecturers, dedicated learning support officers, and state-of-the-art technologies such as hands-on workshops, remote laboratories, and simulation software.

The supportive blended learning model and small class sizes encourage students to advance their technical knowledge and remain engaged in their studies while forming global networks and balancing life and work commitments.

Students can also apply to study applicable degrees in Australia at their campuses in Perth and Melbourne.

A new cohort of industrial automation students are set to familiarize themselves with the Internet of Things and other technologies that are automatizing the workplaces of the future, thanks to EIT.

EIT also offers short-courses that provide working technologists and engineers with professional development opportunities. These courses all have a specific focus and are designed to help engineers upskill and cross-skill to keep their knowledge relevant as technologies continue to develop and change the nature of their work.

For instance, practitioners working in the industry can opt to do the three-month-long Professional Certificate of Competency in Industrial Data Communications to continue to grow their proficiencies with the kinds of technologies that are embodying the fourth industrial revolution. EIT hosts many other professional development courses, including: ‘Practical Machine Learning using Python for Engineers and Technicians’ and ‘Programmable Logic Controllers (PLCs) & SCADA Systems.’

A technology significantly propped up by the automated systems defining the fourth industrial revolution is industrial robotics.

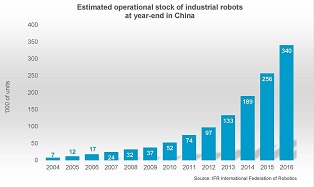

Robots: From China to the rest of the world

China is a country that is seeing a significant uptake of industrial robotics. The International Federation of Robotics back in 2016 were predicting big things for the year we currently find ourselves in.

They wrote, “China has rapidly become a global leader in automation. From 2018 to 2020, a sales increase between 15 and 20 percent on average per year is possible for industrial robots... China intends to forge ahead and make it into the world’s top 10 most intensively automated nations by 2020. By then, it’s robot density is targeted to rise to 150 units - this being the number of industrial robots per 10,000 employees.”

A report by the Wuhan University of Quality Development Strategy predicts that if China’s goals are met, by 2025, automation will replace at least 5% of the Chinese workforce. The report purportedly surveyed 2,000 companies in China. This trend is expected to be observed at varying levels globally.

The onus is thus on students to grow their skill sets, and pepper their careers with creative and entrepreneurial endeavors within their industry. This will ensure that they stay ahead of the curve as automation replaces the repetitive tasks of the past. The advent of automation was also never intended for the mass-replacement of workers. It is being spearheaded to open up new avenues for workers to do much more meaningful work.

Nonetheless, the need for skills development still stands. Companies have a new responsibility to keep workers skilled, but workers too are expected to keep on developing themselves as the job markets change around automation. Will you rise to the automation challenge in 2020?

Works Cited

“BACK ISSUES |.” The Engineer, www.theengineer.co.uk/back-issues/.

Papadopoulos, Loukia. “By 2025 Nearly 5% of China's Workforce Will Be Replaced by Robots, Reveals New Survey.” Interesting Engineering, Interesting Engineering, 23 Dec. 2019, interestingengineering.com/by-2025-nearly-5-of-chinas-workforce-will-be-replaced-by-robots-reveals-new-survey.

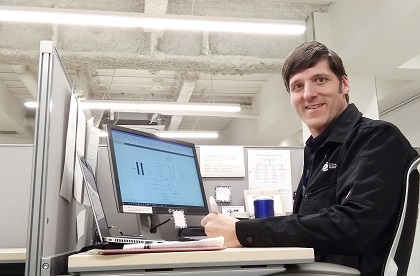

Ryan Smith is an Engineering Institute of Technology graduate who earned his 52705WA - Advanced Diploma of Biomedical Engineering in 2018. First working in the audio engineering industry, Ryan now works for an American multinational conglomerate in the healthcare industry. His engineering journey proves that, regardless of the discipline, you can go cross-disciplinary based on your passion for technology alone.

After completing a Diploma in Audio Engineering in 2011, Ryan spent six years in the professional audio industry. However, Ryan always had a predisposition to technology, and this keen interest led him to apply for an apprenticeship in electronics.

From that apprenticeship, Ryan was granted a trade qualification in Electronics and Communications. Now equipped with expanded electronic knowledge, he found employment within the biomedical industry. His work now saw him repairing, maintaining, and installing medical equipment.

Answering why he chose the engineering industry, Ryan said, “I pursued a career in the engineering industry to satisfy my curiosity for technology and problem solving. It’s incredibly fullfilling to be a part of something that benefits the wider community, and I love seeing a challening project come to successful fruition.”

Working in the biomedical field sparked Ryan’s curiosity even further, soon enrolling for the 52705WA - Advanced Diploma of Biomedical Engineering through EIT.

“I chose biomedical engineering to compliment my background in electronics and further understand how technology interplays with anatomy and physiology. The course impacted the way I interact with clinical stuff, empowering me to confidently understand the medical lexicon. I gained a higher appreciation for the devices I work with and their impact on people’s lives.”

His daily responsibilities include installation, repair, and servicing of medical devices in the fields of invasive and diagnostic cardiology, anesthesia, ultrasound, patient monitoring, and maternal-infant care. He is responsible for ensuring new systems are installed to Australian and global standards before clinical use. After installations have been done, he has to ensure those machines keep on functioning — which includes preventative maintenance and corrective repairs.

Life after EIT

Ryan is now actively building on his skills set within the biomedical sector. He has started an Associate Degree in Science, focusing on biological and information technology.

“I have an elevated level of confidence in my day-to-day work life, thanks to my qualifications. It’s opened up various avenues for my career and inspired me to continue studying in the biomedical sciences field.”

Ryan says that employers have reacted positively to his qualification from EIT. He says it has increased his visibility in the biomedical field and has opened various avenues for his career progression. EIT’s novel online training methodology allows students to progress in their careers while also gaining their qualifications.

When he is not busy at work in his engineering role, he fills his spare time with being an engineering hobbyist, keeping fit and reading. He says he enjoys designing PCBs for audio devices, long distance running and his favorite author is Dostoevsky.

When asked if he would recommend a career in science, technology, engineering, or mathematics to young people, Ryan said, “Absolutely! Technology is constantly changing. A career in these fields keeps your mind constantly engaged and developing new skills and knowledge.”

Thanks to the qualification from EIT, and his appetite for continued studying, Ryan’s career prospects are looking brighter and brighter. It seems that the biomedical industry has inspired him to continue trying to utilize technology to make people’s lives better. When asked about how he sees his career maturing in the upcoming years, he said:

“In the upcoming years, I see myself involved in training and development in the biomedical field. One thing I love about learning things is being able to pass that knowledge on. Teaching and development is a strong way to reinforce your own learning and constantly keep yourself in check.”

Tesla has officially announced that its lithium-ion home batteries, named the Powerwall, will be available in South Africa in 2020.

They have sent surveys to prospective South African customers inquiring about their home energy usage.

The questions the company put to the eager respondents were:

- Do you have a Solar PV system currently installed at this property?

- Do you own this property?

- When would you like the installation to occur? (Within six months or 6-12 months)

- Why do you want to install Powerwall or Solar Panels?

Tesla will send this feedback to a Certified Third Party Installer company who will make contact with the customer. This means there are companies with electrical engineers in South Africa, who are ready to install the solar panel arrays and the Powerwall.

Therefore, future electrical engineers in South Africa should be learning the tools of the renewables trade so that they, too, can find employment in the industry as it is set to blossom.

The consumer solar photovoltaic industry has been stymied for quite some time in South Africa. However, due to ongoing electricity load shedding in the country by the state utility, renewable energy is gaining in popularity.

According to My Broadband, a company named Rubicon is one of the companies importing the Powerwall to South Africa. They confirmed the pricing for South Africans to be:

- Powerwall: R120,000 (USD $8,203.92)

- Backup Gateway: R19,900 (USD $1,360.46)

- Installation cost: R10,000 to R15,000 (USD $683.65 to USD $1,025.48)

Those in rural areas of South Africa can expect to pay significantly more in installation costs. Nonetheless, the availability of the Powerwalls to metropolitan areas in South Africa is a positive step in the right direction for a country urgently seeking to create and store electricity, powered by the African sun.

Powerwall 2, the second iteration of the Powerwall technology, can provide a consumer 13.5kWh of stored energy ready to use. It is a fully integrated AC battery system for residential or light commercial use.

To solve South Africa’s energy crisis, however, more solar companies are having to throw their hats in the ring. Lamo Solar has highly impressed the President of South Africa, Cyril Ramaphosa. The President, at a recent investment conference, acknowledged the work the solar company is doing and encouraged more small and medium-sized enterprises to enter the renewable energy space.

South Africa is looking for innovative solutions to bringing electricity to the masses in 2020, as the government figures out what to do with the ailing state utility. President Ramaphosa has indicated that he wants to attract the likes of Elon Musk to South Africa so they can bring with them their innovative engineering technologies.

With the changing landscape of electrical engineering, engineers must continue learning and developing their skills.

The Engineering Institute of Technology (EIT) is one of the only institutes in the world specializing in engineering. Through our unique online delivery model, students can study with us from anywhere in the world, to continue their education while maintaining work and family commitments.

EIT offers several electrical engineering programs at different levels, from professional development, through to vocational education and training, and higher education.

Works Cited

Musk, Elon. “Would Love to, but Import Duties Are Extremely High, Even for Electric Vehicles.” Twitter, Twitter, 28 Aug. 2019, twitter.com/elonmusk/status/1166854343770988544?ref_src=twsrc^tfw|twcamp^tweetembed|twterm^1166854343770988544&ref_url=https://businesstech.co.za/news/technology/338275/elon-musk-on-why-tesla-is-not-in-south-africa/.

Vermeulen, Jan. “Tesla Powerwall Is Back in South Africa.” MyBroadband, 2 Dec. 2019, mybroadband.co.za/news/energy/328955-tesla-powerwall-is-back-in-south-africa.html.

Air travel is a major contributor to CO2 emissions and is attracting the ire of environmentalist movements who are campaigning for the industry to look to alternative methods of powering aircraft.

Airbus is looking to nature for inspiration to minimize the carbon footprint their planes create around the world. They are suggesting that planes could fly in V-shape formations — as seen by geese migrations in the animal kingdom — to save fuel and lower emissions.

In the first six months of 2020, Airbus hopes to test the flying formations with two A320 planes. The planes will fly a predetermined route in a configuration that will test the aircraft’s ability to utilize what is known as ‘wake energy retrieval.’

On their website, Airbus writes, “Just like birds, every aircraft creates a wake while flying. Flying together could thus help aircraft to retrieve the lost kinetic energy by positioning a follower aircraft in the air upwash of one of the lead aircraft wakes. Airbus is taking a fresh look at how this flight technique could provide aircraft with free lift, enabling them to reduce engine thrust and fuel consumption.”

Airbus says that air traffic management technology has experienced a leap forward. Historically, the air traffic management tech would have been unable to aptly monitor two planes flying so close together, but Airbus says the technology is now more than capable. The flight engineers at Airbus will be engineering around the idea and demonstrating the company’s proficiency, under a project named Fello’fly.

Airbus says that by flying planes 3km apart from each other, the aircraft can benefit from the wake retrieval energy, which can equate to 5 to 10% less fuel and emissions. The prohibitive factor that could delay this innovative step is collaboration across the industry as a whole. Getting all aircraft companies coordinated and collaborating could be tough.

Nick Macdonald, Fello’fly Demonstrator Leader in a press release, said, “To achieve this evolutionary step in operations, we have to look at the challenge from the perspective of all industry stakeholders. It’s a great opportunity for our industry to demonstrate a joint commitment to reducing our use of fossil fuels.”

Hydrogen-powered aircraft coming soon?

The aviation engineering industry has been around long enough for it to, in a way, return to its roots. Now with the means to meet the zero carbon propulsion vision of the future, the industry is considering a shift back to hydrogen as a potential fuel source.

An engineering team at Imperial College in London has patented a hydrogen storage solution they believe could be implemented in the air travel industry. They are calling it H2Go Power.

Co-Founder and Director of H2Go Power, Dr. Enass Abo-Hamed, initially began work on the technology at the department of chemistry at the University of Cambridge.

“We have developed through the past two years a safe method for hydrogen production and storage for providing power on the movie. Our core technology involves a novel porous catalytic material, which produces, stores and releases hydrogen in a controlled manner. Our unique solution allows for the deployment of Fuel Cells into new markets, such as portable consumer electronics. The potential outcomes include smartphones that last 5x longer than ones that have current battery technology and all-electric vehicles with the same range as combustion engine counterpart.”

The company has subsequently begun working on powering drones with hydrogen fuel cells. The company’s systems work by converting the hydrogen gas into a solid-state, which makes storing the gas that much safer. It is stored in a specially designed 3D-printed tank. Inside the tank are a network of aluminium tubes.

Through one side of the reactor Hydrogen (H2) is pumped through a catalyst, freeing electrons and, in turn, generating the electricity. On the other side, oxygen (O) is pumped in and fuses with the positively-charged hydrogen atoms. The only emission that the process creates is water.

The UK government and the EU are injecting money into the company to continue to develop the fuel cells. Dr. Enass Abo-Hamed said:

“While it takes hours to recharge a lithium-ion battery-powered drone, it could take minutes to do that with hydrogen. Maybe in the next 20 or 30 years, we could even start thinking about how to put this in commercial flights and decarbonize air travel — which is very important for our climate.”

Works Cited

Airbus. “Airlines Are Looking to Reduce Fuel Consumption. Wake-Energy Retrieval Could Help.” Airbus, Airbus, 18 Nov. 2019, www.airbus.com/newsroom/stories/airlines-are-looking-to-reduce-fuel-consumption-wake-energy-retrieval-could-help.html.

“Pioneering Clean Tech. Delivering Safe and Reliable Power Supply for All.” H2GO Power, www.h2gopower.com/.

Jules Bekoka Botomba’s story is an inspiring one. He is an Engineering Institute of Technology graduate who, despite the odds, managed to bring himself out of a difficult situation and turn it into success in the automation world.

He has obtained two qualifications with EIT.

During the Second Congo War in 2001, Jules and his family had to escape the country, effectively becoming refugees. Jules fled, looking for asylum in Johannesburg, the largest city in South Africa. Coming from the DRC, Jules was predominantly French-speaking. He soon found he would have to learn English to communicate with the South Africans.

Jules realized it was going to be tougher to assimilate to South African customs than he initially thought. Asylum seekers who were waiting to be recognized as refugees were not permitted to study or work in the country.

This set Jules — a man who fantasized about having a career in engineering since he was a young boy — considerably back. The prohibitive legislation was only repealed in 2003, but, finally he could get a job. Equipped with only a matric certificate from the DRC, he went to Cape Town to try and find a job. So began his journey to develop his skills so that one day, he could be recognized as an engineer.

Jules bought a newspaper and checked the classifieds, eventually finding an ‘electrician wanted’ position. Without even knowing how to pronounce the English words in the electrical industry, Jules went to the interview for the job. He soon found out that he was to be challenged. The interview for the job consisted of having to fix 100 broken fluorescent light fittings — of which he managed to fix 60.

The employers were impressed, and he got the job with MetroRail Limited, where he worked from 2004 to 2006. In this time, he did an associate’s degree in electrical, electronic, and communications engineering technology through Intec College in South Africa.

Moving from Cape Town to KwaZulu-Natal saw Jules working for Bidvest Logistics as a Technician working from 2006 to 2007.

This is where he came into contact with programmable logic controllers, human-machine interfaces, and general automation technologies. When he began working on these technologies, he knew that in the future, everything would become automated, and if he did not focus on improving his technical know-how in automation, he would be left behind.

Jules then secured his dream job, working as a Port Automation and Control System Engineer with the Liebherr Group. They were working with the KwaZulu-Natal government to expand the piers at the port of Durban. On this job, he met a handful of engineers that reinforced the idea in Jules’ head that automation was taking over the industry. The project that the Liebherr Group did for the government of KwaZulu-Natal helped grow the economy of the region in the seven years they worked on the project.

To further build on his knowledge in automation, Jules enrolled for the 52677WA - Advanced Diploma of Remote Engineering, Mechatronics and Robotics with the Engineering Institute of Technology.

In 2015, Jules decided to look for employment outside of South Africa. This saw Jules working on ports up the coast of West Africa, namely in Nigeria and Togo.

However, he had a feeling that his true engineering potential could be realized in the United States. He began working for Interplex Automation, ArcelorMittal, and finally ended up in his current role.

Jules now works as a Lead Software Design Engineer in PACCAR — a leading truck manufacturing company in Texas. The company produces 190 trucks every 8 hours, and Jules is in charge of making the manufacturing process as efficient as possible.

Jules Bekoka Batomba is a shining example of how to overcome obstacles to get to where you need to be. Arriving in South Africa with nothing to his name but a matriculation certificate, Jules managed to elevate himself thanks to a brilliant work ethic and a hunger for knowledge — specifically in the automation world. The result is a worker who will continue to thrive in the fourth industrial revolution as the world continues to automate and transform the job markets.

Jules has recently graduated again with his Master of Engineering (Industrial Automation) from the Engineering Institute of Technology. He is now pursuing a master’s degree in robotics through the Ancestor Polytechnic Institute. There is no stopping Jules now — he has become what he always dreamed of as a young boy: a fully qualified engineer.

It is no exaggeration to say that technology has taken a giant leap forward in the last decade.

In this decade, Uber revolutionized taxi industries around the globe, 4G networks brought fast internet to the masses, and Whatsapp and Instagram appeared on the world stage.

Who do we have to thank for these incredible contributions to daily life? Engineers, in part.

The arrival of those advents of technology proves that the next decade could be equally as disruptive in the world of engineering. These technologies have sent the dominoes falling in the industry, revolutionizing how we all do business, mobility, learning, networking, and automating.

Naturally, engineers are philosophizing of what could be the next big thing that transforms industry across the world.

Artificial intelligence and self-driving cars are the buzzwords flying around at the moment. However, we could ask: What other engineering innovations could be hiding in plain sight, just waiting for a business plan to set them in motion?