News

In this modern age, we are constantly surrounded by batteries. From TV remotes to hand-held radios, you probably use batteries more than you realize. The lithium-ion battery industry is worth $23 billion alone and is expected to grow to nearly $100 billion by 2025.

Battery technologies have been evolving since their initial creation as our needs have continued to grow. However, as our future is looking increasingly electric, engineers and scientists are now focusing on manufacturing new eco-friendly battery technology on a scale we have never seen before.

The most positive alternative seen so far is aluminum-based batteries, being both light-weight, cheaper to make, and abundant in resources. However, there has been a consistent struggle in making aluminum batteries that compare to the energy content of lithium batteries. As far back as 2015, Stanford University researchers were mentioning that all that’s holding aluminum batteries back was the cathode material that would help increase voltage and energy density.

However, that might be all about to change. In 2019, researchers say an upgraded type of aluminum battery may soon make its debut. The Chalmers University of Technology and the National Institute of Chemistry in Slovenia have worked on a concept for a new aluminum battery they think could revolutionize the battery storage industry.

Their proposal includes replacing the graphite on the battery’s cathode with a carbon-based molecule named anthraquinone. This organic nanostructured replacement will assist the battery’s ability to absorb electrons during operation.

“Because the new cathode material makes it possible to use a more appropriate charge-carrier, the batteries can make better usage of aluminum’s potential,” says Chalmers researcher Niklas Lindahl.

“Now, we are continuing the work by looking for an even better electrolyte. The current version contains chlorine - we want to get rid of that.”

With a better electrolyte, the battery will allow ions to move between the electrodes, which will unlock the higher energy density in the aluminum battery. Therefore, developing the aluminum battery is still a work in progress, but researchers think they are closer than ever.

“The material costs and environmental impacts that we envisage from our new concept are much lower than what we see today, making them feasible for large scale usages, such as solar cell parks, or storage of wind energy,” says Professor Patrik Johansson from the Department of Physics at Chalmers University.

“Additionally, our new battery concept has twice the energy density compared with the aluminum batteries that are ‘state of the art’ today.”

The researchers’ idea is to make the aluminum battery four times as energy-dense as its lithium alternative. For applications such as electric vehicles, the added battery capacity will mean less charging required between trips.

On whether or not aluminum-ion batteries could one day replace lithium-ion, Johansson concluded, “Of course, we hope that they can. But above all, they can be complementary, ensuring that lithium-ion batteries are only used where strictly necessary.

“There remains work to do with the electrolyte and with developing better charging mechanisms, but aluminum is, in principle, a significantly better charge carrier than lithium. Furthermore, the batteries have the potential to be significantly less environmentally harmful”.

Works Cited

Leisegang, et al. “The Aluminum-Ion Battery: A Sustainable and Seminal Concept?” Frontiers, Frontiers, 2 Apr. 2019, www.frontiersin.org/articles/10.3389/fchem.2019.00268/full.

“A New Concept for More Sustainable Batteries.” Chalmers, www.chalmers.se/en/departments/physics/news/Pages/A-new-concept-could-make-more-environmentally-friendly-batteries-possible-.aspx.

It’s a question more commonly asked of architects rather than engineers, how can nature inspire the design of structures? However, designing with or around the environment is becoming a common trend amidst the structural engineering industry. A newly constructed walkway in Denmark has nature as its main focus, and it is turning engineering heads.

High above the tree line at Camp Adventure in Copenhagen, a 45-meter high tower seemingly spirals into the sky above. At the top, an observer can enjoy a 360-degree view of the treetops of the Gisselfeld Klosters Forest in Denmark. The project was completed by Danish architecture firm EFFEKT and masterminded by a Danish NAVY seal named Jesper Mathiesen, who runs Camp Adventure.

A feat of engineering, the structure is a fourteen-story tower that features a spiraling walkway inside leading to the top. The structure is made entirely of weathering steel. The benefit of these steel alloys is that there is no need for painting as it has a natural rust appearance. The walkway within the structure consists of oak, which helps the structure blend in with the trees.

If viewed from far away, the tower has an hourglass shape, which Tue Foged, lead architect from EFFEKT, says is an intentional design that endeavors to respect the existing trees in the forest.

“Nature provides the real experience. We just made it more accessible and offered a series of new and alternative perspectives,” says Foged.

“The tower is shaped to enhance the experience of the visitor, shunning the typical cylindrical shape in favor of a curved profile with a slender waist and enlarged base and crown. This allows for better contact to the forest canopy moving up through the tower.”

The tower, which opened in March 2019, is an example of how structural engineering as an industry is looking back to nature for inspiration. However, this isn’t the first time designing with nature has occurred within the engineering industry. A decade prior, the New York High Line opened with a walkway through the natural environment of its own.

Structural reuse and reintegration

The High Line serves as an example of nature reclaiming its territory inside the concrete jungle. It’s a project that shows that structural engineering can have a secondary use.

The High Line is a 1.45 mile-long elevated linear park, greenway, and rail-trail that runs above a former railroad. It is a spur on the west side of Manhattan on the New York Central Railroad.

Over two hundred species of plants are spread out as vegetation on the former railroad in Manhattan. The High Line last utilized for railroad activities in the 1980s. The initial intention was to demolish the railway, but BuroHappold Engineering and Field Operations worked to reuse and re-integrate the line for its new purpose it serves today.

BuroHappold constructed two structures on the railway. One structure was named the Flyover, which was an elevated steel walkway engineered to appear as a levitating floor. The second structure was called the Cutout: which was a steel mesh deck providing views to the street below.

The High Line is now a park that the public can enjoy and where they can get a new feel for the city that they live in. Once a source of noise as the trains drove by, it is now a tranquil resting space.

The industrial past is now fused into the future-focused metropolis. With views of the Hudson River and the general cityscape, it is a popular destination in New York City. Encapsulating both New York’s heritage and future, while abiding by green construction imperatives, structural engineers have managed to work with the industrial past and bring it into an eco-friendly future.

Works Cited

CBS News. “A Spiraling Walk above the Trees.” CBS News, CBS Interactive, 6 Oct. 2019, www.cbsnews.com/news/camp-adventure-in-denmark-a-spiraling-walk-above-the-trees/.

Frearson, Amy. “EFFEKT Completes Spiralling Camp Adventure Tower in Midst of a Danish Forest.” Dezeen, Dezeen, 15 May 2019, www.dezeen.com/2019/05/12/camp-adventure-tower-effekt-denmark-forest/.

Engineers are the all-encompassing link to most of the world’s observable built environment. They are the backbone of functioning systems all across the globe. They keep the lights on, the water flowing, the robots in sync, the planes in the sky, and much more. So, should you pursue a career in engineering?

Working engineers today will tell you that it is a rewarding career with problem-solving at its core. However, people should get into the engineering industry because they want to further humanity’s progress. Engineering's purpose has long existed to invent new ways of doing things and to continuously increase efficiency. The many technological contributions of engineers throughout human history have transformed the world in which we live.

John Browne was the chairman of L Energy and chief executive officer of BP from 1995 to 2007. That period was known as the ‘golden period of expansion and diversification’ for BP. He received praise for directing the oil company’s attention to alternative renewable sources of energy. He was also the President of the Royal Academy of Engineering from 2006 to 2011.

He is a keen author who makes sense of the engineering world for prospective engineers, encouraging them to make the world a better place through their work. He has just released a new book titled: ‘Make, Think, Imagine: Engineering the Future of Civilization.’ He reckons that humans’ interaction with everyday technology is awakening the engineer hidden inside them. A section of his book reads:

“There is an engineer in every one of us, but we, fortunately, do not require the skills or expertise of a professional engineer to tap into this aspect of our nature — contemporary technologies, such as the Internet and smartphones, give all of us access to an engineering mindset. Now, more than ever, we can use these technologies to solve the world’s problems and shape the society in which we live.”

Engineering is a profession that has traditionally attracted those with an affinity for maths and science. However, the tide is slowly turning to involve more humanities-inspired approaches to engineering.

Bringing new technologies into the world

Engineering has recently been defined as solutions-based problem-solving to replace and automate some of the more repetitive tasks humans engage in. For instance, autonomous vehicles are something many an engineering company wishes it could perfect — that is their idea of progress. However, getting to a finished product has not been easy for engineers.

“Progress is not delivered with an instruction manual spelling out the safe and responsible use of new inventions,” Browne writes.

“Engineering is instead like a game of cat and mouse, in which innovators must continuously act to ensure that the intended consequences of their efforts outweigh the unintended ones.

“Engineered solutions will never be perfect first time because mistakes and misuse are inevitable, and every step forward has risks. Autonomous vehicles will create a revolution inconvenience but, unless properly designed and tested, could kill more people than human drivers currently do.”

Technological progress, while a noble engineering intention, must be first be tested out in a controlled environment so that we can know whether it is feasible. And once its viability can be proven, it needs to be marketed to society and governments at large to show its something the world needs.

Therefore, engineers have to become entrepreneurial. Engineering programs have typically ignored the business side of engineering, but now engineers are seeing that they need to become salespeople of their own innovations to convince the world they need the solution.

“Engineering naturally led me into business, since I realized that no solution was complete unless it resulted in something practical that humanity wanted,” writes Browne.

“Thomas Edison apparently said that ‘anything that won’t sell, I don’t want to invent. Its sale is proof of utility, and utility is success. Engineering is like a head with two sets of eyes: one looks to the fruits of discovery, the other looks to the demands of commerce and customers.”

Being an engineer in the modern world is a balancing act that involves becoming a multifaceted and as skilled as possible. With technology rapidly advancing and automation creeping into industry, an engineer who was eligibe to thrive in the previous industrial revolutions, may not be prepared for the fourth industrial revolution. Hence, engineers must prepare themselves for the new civilization that is already being transformed by the digital revolution and the call to make the world a more environmentally friendly place.

Specialized Engineering Education

The Engineering Institute of Technology delivers engineering programs that are designed by an international body of industry experts, ensuring our students graduate with cutting-edge skills that are valued by employers around the world. Our vocational programs and higher education degrees are accredited by the Australian Government, and we have programs that are recognized under three international engineering accords. Together with our sister organization IDC Technologies, we have trained over 500,000 engineers, technicians, and technologists globally over the last 30 years.

We deliver programs for a range of different levels, from professional development to diplomas and degrees. They are offered across a variety of fields such as industrial automation, electrical engineering, mechanical engineering, civil and structural engineering, industrial data communications, electronic engineering, and engineering management.

We deliver our online and on-campus programs via a unique methodology that makes use of live and interactive webinars, an international pool of expert lecturers, dedicated learning support officers, and state-of-the-art technologies such as hands-on workshops, remote laboratories, and simulation software. Whether you are studying online or on-campus in Australia, our supportive blended learning model and small class sizes allow you to advance your technical knowledge and remain engaged in your studies while forming global networks and balancing life and work commitments.

Works Cited

Bloomberg.com, Bloomberg, www.bloomberg.com/opinion/articles/2019-09-16/engineers-are-the-reason-many-of-us-are-alive

Browne, John. “Make, Think, Imagine: Engineering the Future of Civilization.” Amazon, Pegasus Books, 2019, www.amazon.com/Make-Think-Imagine-Engineering-Civilization/dp/1643132121.

“Careers in Engineering - A Beginner's Guide.” The Engineer, 18 Sept. 2019, www.theengineer.co.uk/careers-engineering-first-steps/

Technological advancements are changing the landscape of the engineering industry by creating gaps in practical knowledge. As a result, engineers need to educate themselves continuously to keep up with these innovations. This is especially crucial for those working in multidisciplinary engineering companies.

Micro-credentials are the key to helping graduates stay up-to-date with new technologies across the industry. The continued industrialization of the world is creating incredible opportunities in the engineering industry.

It also means that educational institutions need to stay on top of these changes so they can provide appropriate training. It is no longer about just delivering major qualifications, such as degrees and diplomas — it is about providing professional development to engineers in every stage of their careers.

As the industry changes and areas such as automation and cybersecurity become so much more critical, qualified engineers need flexible and high-quality short courses that hone in on these specific areas.

Engineering professionals see digital technologies that can interface with the Internet of Things, and general automation technologies, changing the face of their workplaces rapidly. These engineering professionals are seeking to build on their skillset while honoring their initial qualifications.

The Engineering Institute of Technology (EIT) delivers several professional development courses across different engineering industries. All of these courses are designed by an international body of industry experts, ensuring our students develop cutting-edge skills that are valued by employers around the world. They are kept up-to-date to remain current with rapidly changing technology.

We have a unique delivery model that makes use of live and interactive webinars, an international pool of expert lecturers, dedicated learning support officers, and state-of-the-art technologies such as remote and virtual laboratories, and simulation software. Because we deliver these courses via the Internet, already qualified engineers can gain professional development and form global networks, while balancing life and work commitments. The courses help engineers gain new knowledge in three months, supplementing the skills they already have.

Works Cited

“The Surge in Micro Credentials.” Australian Financial Review, 22 May 2019, www.afr.com/news/policy/health/the-surge-in-micro-credentials-20190521-p51po4.

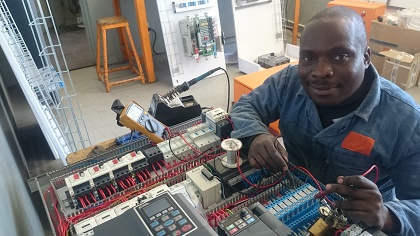

Dominique Mutombo Hoyi is an Engineering Institute of Technology graduate from the Democratic Republic of Congo who is living in South Africa. He was EIT’s Outstanding Student Award Runner-Up for 2017. We caught up with him to find out what he is studying now and to see how his career is maturing with the qualifications he has earned so far.

Dominique studied the 52708WA - Advanced Diploma of Industrial Automation from March 2016 to October 2017. He is currently busy with his Bachelor of Science (Industrial Automation Engineering) with us.

He chose to study automation because he wanted to gain the kinds of skills needed for the process control field and instrumentation industry. When he got a job as a process control system engineer, he realized that he was missing the kinds of hands-on training that his job required. So, he began studying with EIT.

He notes that the advanced diploma helped him better his design skills and familiarize himself with control systems.

Dominique is now working as an Automation Technician at Power Plant Electrical Technologies in Nelspruit in South Africa.

“I am currently in the primary industry, which involves getting raw materials for processes such as mining, farming, and fishing,” he said.

“We are installing, testing, commissioning, upgrading, and maintaining industries like power generating plants, refineries, paper industries, water treatment plants, and mines.”

He spends his time working with technologies like programmable logic controllers (PLCs), variable speed drives, protection relays, and instrumentation and control equipment. Every day there is a new problem to solve or a fault to find, and sometimes he even has to oversee small to medium construction projects. He is also expected to complete technical surveys on electrical, control and instrumentation systems.

Dominique says the course content covered in our Bachelor of Science (Industrial Automation Engineering) has helped him a lot within his job.

As Dominique nears the end of his degree, he envisions the continuation of a fruitful career in the automation space.

“My future vision in my current position is to become a great senior process control and automation engineer; then later, I can join the engineering management within a well-known organization. The project engineers I work with are inspiring — they can solve complex problems in networking, control, power circuits.”

Dear Colleagues

No matter how good you are as a presenter, I am sure you have been in that horrible situation when you can see your audience fast losing interest in your presentation - from furtive looks out of the windows, whispered interchanges, more intensive glances at phones or simply walking out on you - sometimes with not even a muttered excuse. You start feeling desperate at your critical information being ignored and simply lost. You may be passionate about your topic – but sometimes, your audience is bored.

There are a few simple techniques (perhaps, tricks?) that I have used to reclaim my audience and to re-invigorate the presentation. There is at least one positive – you are aware of this drop-off in interest - unlike many presenters who continue droning on and on and essentially wasting their presentation.

The first one is the quickest

The first technique is the quickest to implement. Come out from behind the comfortable podium or central position you are occupying and move to the edge of your stage. I even move into the audience and stand behind them. You do need to be comfortable with your presentation and be happy not to have your notes freely available, though, as it is hard to carry these around when you are dynamically moving around the room. Your audience will often be surprised by this maneuver and start focussing on you - in case you walk up close to them and ask them an awkward question.

Change the Pace

Change the Pace

Change the pace at which you are presenting. If you are presenting fast - slow down and perhaps drop your voice to a whisper. Ask rhetorical questions that you answer after a short silence. The audience will start reconnecting with you as they are uncertain about this change in presentation speed and keen not to lose out.

Throw a Bone out to your would-be listeners

Throw open to the audience a problem which someone can attempt to answer. This is somewhat higher risk as you could lose control, so you may need to be quick to reclaim ground or guide the person solving your problem. The audience will become more interested as they may end up having to join in and there is someone different talking.

A Story is an Age-Old Favourite

Finally, telling the audience an anecdote or story always tends to galvanize their interest. The important point is to be sensitive to your audience and to ensure their time isn't wasted by your message being lost.

Perhaps, Alfred Hitchcock was referring to ensuring good connectivity with your audience with his comment: Always make your audience suffer as much as possible?

Good luck with your next presentation.

Yours in engineering learning,

Steve

Climate change remains one of the biggest problems our world has ever faced, and there are no signs that it will drastically improve any time soon. So engineers and scientists are coming together to investigate a controversial technique to prevent an environmental catastrophe.

Geoengineering may seem like something from a far-fetched science fiction film, with ideas ranging from mirrors in the ocean to reflect sunlight away from earth to space sunshades. However, engineers are now investigating the notion of releasing millions of tons of sulfur dioxide into the stratosphere as a potential solution to reducing the effects of climate change. The idea behind this is the particles will reflect sunlight away from earth and therefore cool the planet.

The notion originated from the eruption of Mount Pinatubo in 1991. This volcano in the Philippines erupted, spewing fifteen to seventeen million tons of white ash and sulfates up to ten kilometers into the sky. Fifteen months later, scientists combing over the data realized the particle cloud had shielded the area from the sun, with temperatures dropping by 0.6 degrees Celsius.

The idea is that aircraft will spray sulfate particulates into the lower stratosphere at 60,000 feet. The process would theoretically be equal to a volcano ejecting sulfates into the sky during an eruption. The sulfur dioxide shot up into the stratosphere forms sulfuric acid drops, which then rotate around the globe for 48 months, and successfully hinder sunlight from penetrating it. The result could be a one-degree temperature drop, which would reverse the global temperature rise of the last century.

This technique, known as stratospheric aerosol injection, is considered radical and opposed by many as they believe the effects of intentionally modifying the climate could be worse than climate change itself. In fact, in 2018, the Global Challenges Foundation published a report on major threats against humanity — and solar geoengineering was listed as one of these, as was catastrophic climate change.

At the Paris Climate Conference in 2015, governments around the world acknowledged that something needed to be done to accelerate anti-global warming effects. They set out several targets, including keeping the global temperature rise this century well below two degrees Celsius above pre-industrial levels. The deal was ratified in 2016; however, the issue remains that governments across the world are realizing they are still not on track to achieving the initial targets set out in the Paris Agreement.

This is why some scientists see geoengineering as a legitimate solution to saving our planet. The Global Challenges Foundation report explains the appeal and the risks.

“Solar geoengineering is the only known technique for quickly stopping or even reversing the rise in global temperatures. Although it does not solve the root cause of climate change, it could be used to reduce the length or the magnitude of a temperature overshoot (beyond the Paris goal) during the transition period needed for massive decarbonization at the global level or provide insurance against a potential ‘climate emergency.’

“However, we don’t know enough about the risks and potential benefits of the technology, and it carries considerable risks – in particular, it may destabilize local and global climate, as well as various elements of the global ecosystem. In addition, a sudden termination of solar geoengineering would lead to rapid and severe global warming, with no time for natural and social systems to adapt.”

The reality is that carbon emissions must be reduced urgently because things will only get worse. The report states that if the temperatures increased by three degrees Celsius, most of Bangladesh and Florida would drown. Other coastal cities would also be flooded, which would then create hundreds of thousands of climate refugees across the world.

As a result, a team of scientists at Harvard University is hoping to implement the first in situ geoengineering experiment to determine whether it is a viable solution. However, they are facing critics who worry that once we start experimenting with these radical ideas, we will be heading down a slippery slope.

To appease those with fears about the result of this experiment, Harvard University has put together an advisory committee to ensure that appropriate steps are taken to mitigate health and environmental risk and ensure they operate transparently.

Scientists first proposed the experiment in 2014. It will see researchers launch a scientific balloon with sensors and propellers 20 kilometers above the earth. They will release between 100 grams and two kilograms of calcium carbonate particles in a kilometer-long plume. This is limestone dust and is less likely to deplete the ozone layer than sulfates.

The balloon will fly through the plume, and its sensors will measure how far the particles scatter, how they interact with other compounds in the atmosphere, and how much light they reflect.

The project’s principal investigator Frank Keutsch explained in a statement that they hope this experiment will inform the feasibility of geoengineering.

“If anything, I’m concerned that the current climate models make solar geoengineering look too good. If we want to be able to predict how large-scale geoengineering would disrupt the ozone layer, or the exchange of air between the troposphere and stratosphere, we need more real-world observations.”

The Carnegie Climate Governance Initiative’s Janos Pasztor is one scientist who has concerns about geoengineering experiments. Such worries include the technology affecting ocean circulation, biodiversity, disease patterns, agriculture, and causing extreme weather.

The Union of Concerned Scientists' climate and energy program’s Shuchi Talati, echoed these sentiments.

"We don't know what the regional impacts will be," Dr Talati said.

"There have been different modeling papers showing different things."

The other major issue is that a global thermostat will need be set to determine a particular global thermal temperature, creating winners and losers. While one region might experience favorable rainfall to help its agricultural industry thrive, another nation might experience devastating drought. There are now fears surrounding security risks, because who gets to control this global thermostat and what happens if it gets breached or hacked?

Mr Pasztor argues that because this technology is cheap enough to be accessible to virtually every country, the fact that it is ungoverned could have horrific political consequences.

"Imagine a situation where China unilaterally goes ahead, and a couple of years later the monsoon fails in India, and lots of people starve, “ he said.

"Even if you cannot link the failure of the monsoon to the stratospheric aerosol injection activity, people in India might think it's because of the Chinese."

Mr Pasztor helped advise on the Paris Agreement and emphasized that geoengineering should not be used to replace cutting emissions, but as insurance in case we do not meet our temperature goals. Other scientists fear that an overreliance on geoengineering will undermine efforts to reduce greenhouse gases.

In a previous news article, we covered what engineers could do to help save the planet. These other geoengineering solutions included marine cloud brightening that would see naval ships spraying salt particles into the air, in turn brightening the clouds hanging over the sea. The brightened clouds would also deflect the sun off the earth.

Many of these advents of carbon mitigation and climate geoengineering have certain checks and balances that slow the process of their implementation. And that is perhaps a good thing. Attempting to engineer the climate raises ethical and political issues. Not to mention, scientists must conduct the experiments in the safest possible ways. However, it is encouraging to see that scientists and engineers are rising to the occasion to combat oncoming climate events that could save thousands, if not millions of lives.

Works Cited

Salleh, Anna. “A Planet-Sized Sunshade? It Sounds Far-Fetched, but Some Scientists Are Seriously Considering It.” ABC News, Australian Broadcasting Corporation, 24 July 2019, www.abc.net.au/news/science/2019-07-24/climate-hacking-to-avoid-a-global-warming-apocalypse/11300460

Temple, James. “Geoengineering Is Very Controversial. How Can You Do Experiments? Harvard Has Some Ideas.” MIT Technology Review, MIT Technology Review, 29 July 2019, www.technologyreview.com/s/614025/geoengineering-experiment-harvard-creates-governance-committee-climate-change

As conserving finite resources becomes an increasing priority, scientists have been consistently successful in discovering alternate renewable energies. One of these alternatives is solar energy. Solar panels absorb powerful rays from the sun and convert them into power resources, which are used in both residential and commercial areas.

However, solar panels still suffer from a list of setbacks that offset their usefulness. One of these ailments is overheating. When solar panels are exposed to too high temperatures, their efficiency and performance is hindered.

Electrical engineers are now busy trying to figure out how to overcome the heating problem and retain efficiency. Researchers at Rice University in Texas think that they may have found the answer. The solution involves capturing the thermal photons that the solar panels release.

Junichiro Kono of Rice’s Brown School of Engineering explains:

“Thermal photons are just photons emitted from a hot body. If you look at something hot with an infrared camera, you see it glow. The camera is capturing these thermally excited photons.”

Solar panels essentially have nowhere to send excess photons, which is why researchers want to reroute the extra heat and convert it into more electricity. Gururaj Naik, an assistant professor of electrical and computer engineering at Rice University, told PV Magazine, “Any hot surface emits light as thermal radiation.

“The problem is thermal radiation is broadband, while the conversion of light to electricity is efficient only if the emission is in a narrow band. By squeezing all the wasted thermal energy into a small spectral region, we can turn it into electricity very efficiently. The theoretical prediction is that we can achieve 80% efficiency.”

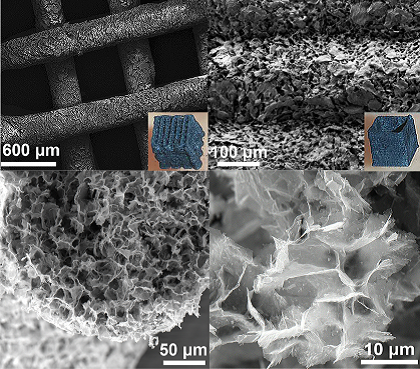

The engineers have created a device that will direct the photons emitted as heat into the narrower band. It utilizes ‘a film of carbon nanotubes,’ which forces the electrons to move in one direction. The researchers say the device can operate at a maximum temperature of 700 degrees Celsius.

They compiled a report entitled ‘Macroscopically Aligned Carbon Nanotubes as a ‘Refractory Platform for Hyperbolic Thermal Emitters’ published in the journal ACS Photonics. The research is only in its beginning phases; however, the engineers are optimistic that panels will soon run at four times the efficiency.

Works Cited

Hutchins, Mark. “Harnessing Heat for 80% Theoretical Efficiency.” Pv Magazine International, 29 July 2019, www.pv-magazine.com/2019/07/29/harnessing-heat-for-80-theoretical-efficiency

“Macroscopically Aligned Carbon Nanotubes as a Refractory Platform for Hyperbolic Thermal Emitters.” ACS Photonics, pubs.acs.org/doi/abs/10.1021/acsphotonics.9b00452

Ishmael Muumbe is a two-time, verging on three-time, Engineering Institute of Technology graduate. He studied both his 52708WA - Advanced Diploma of Industrial Automation and 52726WA - Advanced Diploma of Applied Electrical Engineering through EIT after having moved from Zimbabwe to New Zealand to train as an electrician.

Now a technologist, Ishmael is working within the mines in Western Australia and is embarking on a journey of furthering his skills and education in the electrical engineering world. Ishmael’s story is one of looking for opportunity wherever one can find it, and balancing studies, work, and family life.

Ishmael finished high school at Ascot High in Gweru, a city located in central Zimbabwe. At school, he found that he had an affinity for science subjects. After graduation, he had the chance to do an apprenticeship at a Zimbabwean Alloys Chrome Ore smelter plant in Gweru. There he trained as an Electrical Apprentice.

With the expertise that he acquired from working at the plant, Ishmael decided to explore getting electrician jobs in Zimbabwe. Soon, he was working as an electrician.

For a couple of years, he worked as an electrician, but as he kept working, Zimbabwe began suffering a reversal of economic fortunes. Ishmael consequently decided to relocate to New Zealand to seek greener pastures where he would better be able to develop his skill set. Soon, he found himself in a new country with a rapidly advancing technological industry.

He said, “coming from a third world country, I realized that the technology in electrical engineering was so dynamic and to keep up, I had to further my education. That was not going to be an easy task — finding studies that I could do while working full-time and while providing for my family.”

Ishmael began researching distance learning institutions that could assist with growing his knowledge while gaining the practical experience he was hoping to acquire through working in New Zealand. Soon, he stumbled upon an institution that fit his needs: the Engineering Institute of Technology.

He enrolled for the 52708WA - Advanced Diploma of Industrial Automation and followed that up with a 52726WA - Advanced Diploma of Applied Electrical Engineering. The two qualifications have equipped him with the skills necessary to deal with the automation making its way into the electrical engineering industry.

He then took advantage of the mining boom in Western Australia. He currently works in the mines for Fortescue Metals Group in the Pilbara region in WA. His daily responsibilities include service, repair, and maintenance of the electrical mining processing plant. This consists of all of the crushers, conveyor systems, and all associated automated equipment.

“Studying online has made me manage my life in a great way. I enjoy work life, family time, and study time at the same time. It’s not always easy to study online though. One must develop great time management skills, especially to ensure you stay on top of your studies.”

Ishmael says he would encourage any young person to pursue a job in science, technology, engineering, or mathematics (STEM) industries due to engineering’s role as the backbone of technological innovations.

“The studies I have completed with EIT have made me appreciate and understand how electrical engineering and automation merge,” he concluded.

Ishmael has enrolled for the Bachelor of Science (Electrical Engineering) with EIT, which he will be starting in early 2020.

In August, the Engineering Institute of Technology (EIT) went to Namibia in southwest Africa to meet with prospective and already working engineers. While there, we hosted a seminar about the trends in the engineering industries that are transforming Africa.

The development of skills amongst young people in Namibia is vital. Therefore, EIT visited the Namibian University of Science and Technology (NUST). We were invited by the Dean of Engineering, Dr Samuel John, to share with the faculty of engineering students what EIT is doing to provide engineers with further tertiary education and training.

In the presentation, David Gadjus, EIT’s International Education Manager for the regions of Africa and South America, shared several pathways to gaining higher education, training, and continued professional development through our institution.

Gadjus says the students were interested to learn about EIT’s online delivery methodologies. Online distance learning is rapidly becoming something students in Africa are becoming interested, since networking technologies have advanced on the continent. Now, mobile internet technologies are becoming the norm, and more students are wondering how they can gain knowledge through online means.

“Many potential students are unable to attend full-time or part-time classes due to family or work commitments. Some also work at remote sites and do not have access to physical education institutes.”

EIT then hosted a seminar at the Protea Hotel Furstenhof in the center of Namibia’s capital Windhoek. David was joined by EIT lecturer Deon Reynders who presented on the technical aspects of the engineering knowledge that comes along with enrolling in EIT courses.

“There were so many people who came to attend that we had to arrange more chairs to accommodate everyone. We had some of our current online students who came, keen to stay updated with what is happening with EIT. We had some prospective future students who enquired about our online and on-campus programs. We even had representatives from the Engineering Council of Namibia, including the Vice President.”

The attendees were seemingly most interested in the area of study catering most to the fourth industrial revolution: Industrial Automation. EIT delivers accredited advanced diplomas, bachelor's degrees, and master’s degrees in Industrial Automation. The prospective students were naturally curious as to what jobs they could apply to when graduating through the Industrial Automation courses. EIT recommends that practitioners involved in the following industries would benefit greatly from pursuing the Industrial Automation qualifications:

- Electrical engineers and electricians

- Maintenance Engineers and Supervisors

- Energy Management Consultants

- Automation and Process Engineers

- Design Engineers

- Project Managers

- Instrument Fitters and Instrumentation Engineers

- Consulting Engineers

- Production Managers

- Chemical and Mechanical Engineers

- Instrument and Process Control Technicians

One of EIT’s Namibian students, Festus Tawii, was also in attendance at the seminar. He told the crowds gathered about his positive experience of studying with EIT. Festus currently works with the country’s energy utility Nampower.

Festus is currently studying the 52726WA - Advanced Diploma of Applied Electrical Engineering at EIT. He told the attendees that he was utilizing the knowledge he was gaining in his course in his day to day job in the energy sector.

All in all, EIT is seeing record numbers of seminar attendees in the Southern African regions. The attendance numbers prove that the hunger for the skills of the future and the mastering of rapidly advancing technological industries are in high demand. EIT is looking forward to returning to Namibia and collaborating with educational institutions on the ground to both strengthen their education sector and open students’ eyes to the possibilities and opportunities they can access that could transform their engineering careers.

While solar and wind energy seem to be the primary sustainable energy sources mentioned in the media, tidal energy is actually more predictable. Tides can be timed in perpetuity throughout the year, whereas predicting when the wind will blow and when the sun will shine is far harder.

In a world-first, a data center in Scotland will set the bar for tidal arrays in the future. Renewable energy technology developer Simec Atlantis has turbines capturing the natural flow of water between Scotland’s northeast coast and the uninhabited island of Stroma.

There are reports that Amazon, Google, and Microsoft are interested in utilizing the technology for their data, as well. With all of the data crunching these kinds of companies do, large data centers are necessary. The issue is how much power these data centers need to use to keep our favorite websites and services up and running. Therefore, it makes sense to power them in a renewable way.

Tim Cornelius, CEO of SIMEC Atlantis Energy, said, “data is being touted as the new oil. It is arguably becoming the world’s most valuable resource, and the amount of data requiring storage is increasing at a staggering pace. However, data centres are undeniably power hungry, and the clients of data centre operators are rightly demanding power be sourced from renewable and sustainable sources.”

SIMEC Atlantis’ tidal energy site will be in Caithness in Scotland. It is expected to be the biggest tidal energy project globally once opened in 2024. However, SIMEC Atlantis northeast will not confirm which ‘world-leading data center operators’ they are talking to and signing deals with.

The company leases parts of the seabed off Scotland’s northern coast. They will be installing forty new turbines on the seabed, which will be adding 80MW to the capacity they already have installed. In 2010, the company was granted the option to develop a tidal stream project that would be given license to install up to 398MW of capacity.

They currently have the first phase — MeyGen Phase 1A — operational, which saw the deployment of four 1.5MW turbines. On their website they describe the complexities of their world-leading tidal turbines:

“Each turbine is located on an individual foundation between 250 and 350 tonnes coupled with six ballast blocks weighing 1,200 tonnes, that provide horizontal stability over the lifetime of the turbine. Each turbine has a dedicated subsea array cable laid directly on the seabed and brought ashore via a horizontal directionally drilled borehole within the foreshore bedrock.”

The MayGen array has the potential to influence electrical engineering industries all across the globe and get tidal energy powering critical infrastructure in sectors that make the world turn. Electrical engineers can also sleep easy knowing that new jobs will be opening in the renewable energy industry soon. The CEO of SIMEC Atlantis, Tim Cornelius said:

“At MeyGen we have many of the ingredients to provide clean power to the data center, including a large grid connection agreement, proximity to international fiber-optic connection and persistent cool weather. We also believe that Scotland can play a key role in the global data center industry thanks to its ready access to clean energy and we are eager to play our part at Atlantis to turn this potential into reality.”

EIT offers a range of electrical engineering programs - find out more!

Works Cited

Gardner, Elliot. “Talking Tidal as MeyGen Kicks into Gear.” Power Technology | Energy News and Market Analysis, 27 June 2018, www.power-technology.com/features/talking-tidal-meygen-kicks-gear/.

Thomas, Allister. “Plans for 'World's First' Ocean-Powered Data Centre in Scotland - News for the Oil and Gas Sector.” Energy Voice, 9 Sept. 2019, www.energyvoice.com/otherenergy/207276/plans-for-worlds-first-ocean-powered-data-centre-in-scotland/.

In Southern Africa, aging infrastructure and shortages of much-needed resources are stifling the electrical engineering sector. Powering countries south of the equator is a topic much in focus in the last few years. Both Zimbabwe and South Africa have been seeing a need to balance power loads and load shed at their public energy utilities. However, Zimbabwean companies are starting to get smart with how they manage their power outages.

Econet Wireless Zimbabwe, the largest provider of telecommunications services in Zimbabwe, have resorted to contemporary solutions to their modern-day problems. If Econet’s servers go down, the country suffers economically.

Telecommunications currently plays a vital role in the economy of Zimbabwe. Many people in the country are doing transactions via mobile means. The country is currently experiencing a shortage of physical paper money, and so the transactions are done digitally.

To further exacerbate the problem, in May, Zimbabwe began load-shedding after the government announced it was undergoing power shortfalls due to aging power stations and heavy usage occurring in the winter months. According to reports, the power in Zimbabwe can be switched off for 18 hours a day.

Without Econet’s service, according to Bloomberg, 6.7 million people would be without a way to pay for groceries or tip waiters.

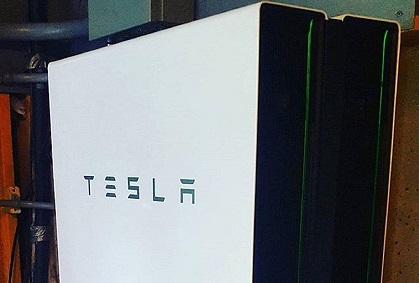

Luckily, southern African born Elon Musk’s company, Tesla Inc, has engineered the kinds of technology that can keep the lights on for the African country and companies. Econet, with the assistance of Distributed Power Africa, have installed 520 Powerwall batteries across the telecommunications company’s 1,300 base stations around the country.

Powerwalls are lithium-ion batteries that can be charged up via photovoltaic solar panels.

Norman Moyo, the chief executive officer of Distributed Power Africa said, “telecommunications have become the lifeblood of the economy. If the telecom network is down in Zimbabwe, you can’t do any transactions.”

Distributed Power Africa is looking at rolling out similar projects to other African countries that are struggling to keep their national grids working. Tesla has been shipping their Powerwall technology out to regions that lose access to electricity to try and keep the lights on for crucial infrastructure.

Before the arrival of the Powerwalls in Zimbabwe, Econet’s base stations were utilizing Diesel generators as backup power when the national grid went down. However, fuel shortages soon arose in the troubled country.

The batteries, costing US $6,500 each can power the service provider’s base stations for ten hours without help from the national grid. Backup generators and the arrays of solar panels can pick up the rest of the hours of the day when the sun is shining, granted there is an 18-hour power outage in the area. In the evening, the Powerwall can kick in and keep the base stations running.

The Powerwall was initially designed for the powering of homes in peak power usage times, but their usefulness in business has also been realized. In the United States, some companies are utilizing the much bigger Tesla engineered Powerpacks — they are essentially many stacked Powerwalls that can power an entire building and its infrastructure.

Engineers around the world are called to familiarize themselves with the battery technologies so that they can one day restore power to the regions that need it. Lithium-ion batteries are changing the way things are powered down south, but more needs to be done to bring traditional electric systems to use carbon-neutral technologies such as the Tesla Powerwall.

In neighboring South Africa, Twitter-ers are asking Elon Musk how long it might be before the country sees Tesla Motors’ vehicles being exported to the southern parts of the continent. Responding to a question on Twitter on the 29th of August, Elon Musk said he would love to bring the vehicle to South Africa, but import duties were far too high — especially for electric vehicles. Something the government has promised to change.

There seems to be a demand for the new electric ways of powering several industries in the southern hemisphere. Zimbabwe utilizing lithium-ion batteries to power their businesses is a huge leap forward and is indicative that African countries are rapidly surging towards a decarbonated, fourth industrial revolution future. Engineers are going to have to study the many facets of this new electrical engineering world they have been waiting to meet.

EIT offers a range of electrical engineering programs - find out more!

Works Cited

Bloomberg.com, Bloomberg, www.bloomberg.com/news/articles/2019-09-01/tesla-batteries-are-keeping-zimbabwe-s-economy-running.

Sguazzin, Antony. “How Zimbabwe Is Banking on Tesla.” BusinessLIVE, Business Day, www.businesslive.co.za/bd/companies/2019-09-02-how-zimbabwe-is-banking-on-tesla/.

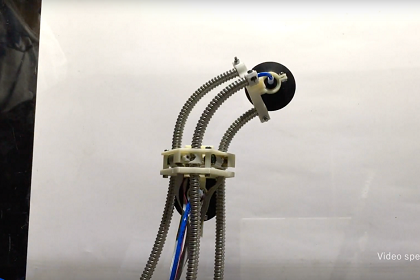

Mechanical engineers have, for a long time, been using the natural world as inspiration for robot design. However, the latest soft-robot that is taking inspired by nature might creep some people out. What started as an inadvertent thought from a mechanical engineering student has turned into a real robot. And it is in the shape of a leech.

This collaborative research project will unsurprisingly be called the ‘LEeCH’ (Longitudinally Extensible Continuum-robot inspired by Hirudinea). Hirudinea is a subclass of parasitic or predatory worms found in nature that belong to the phylum Annelida.

The original idea for the robot came from a Doctoral student in the Department of Mechanical Engineering at the Toyohashi University of Technology. He said, “I came up with the idea in the bathroom of my house. The shower hose went wild as if it had a life when I inadvertently turned on the faucet at maximum. Then an idea occurred to me that if I could manipulate a hose, I might be able to make a robot with the dynamic movement of a living creature.”

The researchers wanted to mimic a leech’s flexibility. The longitudinal muscles are what they are most interested in. The elongating and retracting of the body for the purpose of movement got the researchers designing something that could potentially be as flexible in the future.

The collaboration involves Dr. Tomoaki Mashimo, Associated Professor of the Department of Mechanical Engineering at the Toyohashi University of Technology and Dr Fumiya Iida, Reader in Robotics at the Department of Engineering at the University of Cambridge.

However, if you assumed the robot was completely fleshed out and built with the most cutting edge materials, you would be wrong. The robot is fabricated out of suction cups and shower hoses. But, it is the 3 actuators that do the important work:

Immediately upon seeing what the first draft robot is capable of doing, the potential future uses of these robots become clear. Dr. Fumiya Iida explains, “climbing robots have a wide range of potential applications, including building inspection, maintenance, construction, and search and rescue tasks.

“Climbing robotics is still a challenging research field both theoretically and practically, but together, we have made significant contribution to advanced this field by creating a robot, inspired by leeches that can transition from one surface to another and can climb a vertical wall -- without any constraints.”

According to New Atlas, the leech-like climbing technique — which involves scaling a wall and transferring to the other side of a wall — is a world-first for robots. Climbing robots would be sought out by several engineering industries that desire constant oversight of their machinery even in those hardest to reach areas.

There is more work to do on refining the robot, however. The researchers intend to make the robot’s movement smoother. This means changing how stiff the tubes are by lubricating the inside of the cavity with liquids. The engineers can also work on making the robot much softer and more flexible so that the robot can reach its full potential and one day be used in those countless engineering sectors. And it all started with a shower hose, and a mechanical engineer’s imagination - with a little help from nature too.

EIT offers a number of programs related to mechanical engineering - find out more!

Works Cited

EurekAlert. “壁登りロボットの概要.” EurekAlert!, www.eurekalert.org/pub_releases/2019-05/tuot-iba051019.php.

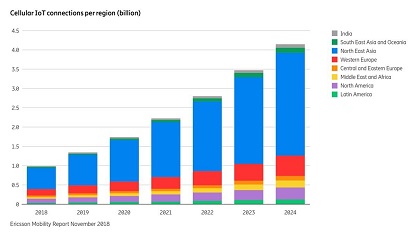

Manufacturers are seeking ways to make their global supply chains more flexible. Luckily for them, wireless Internet of Things technologies are empowering these factories and making processes more efficient than ever before. Ericsson, a giant in automation technology engineering, reported that “IoT connections are set to pass the 4 billion mark by 2024.”

In Ericsson’s blog entitled ‘The future of manufacturing is smart, secure and stable,’ they outline that companies with production lines are trying their best to integrate the Industrial Internet of Things technologies, and the market is heating up with competitiveness.

Essentially, manufacturers who create the most novel interconnected system in their factories, underpinned by Industrial Internet of Things technologies, will get more work done and generate more profits due to the efficiency of their operations. That requires the fastest interconnectivity technology available to the market.

This is where 5G wireless internet technology comes in. 5G promises faster speeds and unparalleled latency for factory-connected equipment, making the technology a bone of contention in global politics — especially in the case of the ongoing trade war between the United States and China. The global rollout of 5G technologies is happening — and fast. For instance, Chinese telecom Huawei’s aim is to ‘build a fully connected, intelligent world.’

Ericsson has published their findings in their Mobility Report. The report casts industry projections while analyzing the latest trends in the mobile data industry with regards to 5G, IoT, fixed wireless access and more. In the report, the graph relating to countries’ uptake of cellular IoT connections, shows that North-East Asia is expected to continue growing the number of operations IoT connections well into 2024.

In the United Kingdom, as the government prepares to separate from the European Union, fiber internet technology and 5G connectivity are going to be a vital mechanism of their efforts to transform factories in the country to enter the market and keep the economy strong.

The UK government is ensuring that even the most rural parts of the country are receiving high masts connecting the areas with 5G technology so that they can begin digitally revolutionizing markets in those regions. On top of that, online education and training is something that rural Britons can also start to pursue from where they are based. The power of mobile internet connectivity can affect many levels of society within any given geographic area.

Broadband service provider EE, in the United Kingdom, have been trying to educate the general populace about the benefits of 5G and how the speeds are equipped to transform several industries in the country:

Companies race to deploy 5G technologies

A survey by research firm Gartner reports that two-thirds of organizations are looking to have their 5G setups deployed by 2020. Organizations are also trying to ensure that they get their entire manufacturing setups with 5G readiness. Gartner reports that 59 percent of organizations surveyed are looking to implement 5G-capable networks by next year.

Sylvian Fabre, a senior researcher at Gartner said, “the figure for IoT communications is surprising, given that other proven and cost-effective alternatives, such as Narrowband IoT over 4G and low-power wide-area solutions, already exist for wireless IoT connectivity.

“However, 5G is uniquely positioned to deliver a high density of connected endpoints -- up to 1 million sensors per square kilometer.”

Manufacturers benefit massively from the ‘high density of connected endpoints’. An entire network of interconnected sensors that take about a millisecond to interface with each other is something that will empower the autonomy of manufacturing systems. Delays in manufacturing plants may be a thing of the past with 5G.

With 5G being normalized rapidly, prospective engineering students should be familiarizing themselves with 5G and the telecommunications technologies surrounding it, because once they graduate, they will likely see the technology in their future workplace. The more and more engineering industries that utilize these technologies, the closer the supply chain gets to being revolutionized through smart-manufacturing.

EIT offers a variety of courses in the industrial automation sector - find out more.

Works Cited

“Ericsson Mobility Report: Read the Latest Report.” Ericsson.com, 30 Aug. 2019, www.ericsson.com/en/mobility-report.

“Gartner Survey Reveals Two-Thirds of Organizations Intend to Deploy 5G by 2020.” Gartner, www.gartner.com/en/newsroom/press-releases/2018-12-18-gartner-survey-reveals-two-thirds-of-organizations-in.

Engineers are collaborating on a project to strengthen energy storage technologies through the use of 3D printers. This project is also highlighting the importance of 3D printing in electrical engineering.

Researchers at the University of Manchester have developed a unique way to convert 2D materials into electrodes that can be stored in devices such as supercapacitors. This requires turning a clay-like substance known as MXene into an ink, which once dried, can conduct electricity.

In 2011, engineers from Drexel University in the United States created MXene. It consists of carbon atoms and transition metals. This substance has two properties which make it particularly useful; it is hydrophilic, which means it can be turned into an ink, and it is conducive for electricity. This means it is more suitable for energy storage than other 2D clays.

MXene has been derived from graphene, the world’s first 2D material which was a better conductor than copper, but one million times thinner than human hair, stronger than steel, transparent, and flexible. The discovery of graphene opened the door for scientists to experiment by creating other 2D inks, each with differing properties.

However, to make effective use of these properties, the inks need to be integrated into devices and structures.

Drexel College of Engineering Professor in the Department of Materials Science and Engineering, Dr Yury Gogotsisaid, “so far only limited success has been achieved with conductive inks in both fine-resolution printing and high charge storage devices.

“But our findings show that all-MXene printed micro-supercapacitors, made with an advanced inkjet printer, are an order of magnitude greater than existing energy storage devices made from other conductive inks.”

University of Manchester researchers have done just that. They put MXene through their 3D printer and showed how they could make the most of the compound.

Team leader Suelen Barg said, “We demonstrate that large MXene flakes, spanning a few atoms thick, and water can be independently used to formulate inks with very specific viscoelastic behavior for printing.

“These inks can be directly 3D printed into freestanding architectures over 20 layers tall.

“Due to the excellent electrical conductivity of MXene, we can employ our inks to directly 3-D print current collector-free supercapacitors.

“The unique rheological properties combined with the sustainability of the approach open many opportunities to explore, especially in energy storage and applications requiring the functional properties of 2-D MXene in customized 3-D architectures."

University of Manchester researchers said 3D printed MXene electrodes could have significant use in supercapacitors. The supercapacitors could store power and weigh less than what is already in energy storage devices today. In future, this could help electric vehicles, solar panel energy storage batteries, smartphones, and other electronic devices deal with electrical charges much more efficiently and expand the energy storage capabilities.

Ph.D. students from the University, Wenji and Jae, said, “additive manufacturing offers one possible method of building customized, multi-materials energy devices, demonstrating the capability to capture MXene’s potential for usage in energy applications.

“We hope this research will open avenues to fully unlock the potential of MXene for use in this field.”

EIT offers a range of electrical engineering courses - find out more!

Works Cited

Greenwood, Matthew. “Engineers Use 3D Printing to Turn 2D Materials into Electrodes.” Engineering.com, www.engineering.com/DesignerEdge/DesignerEdgeArticles/ArticleID/19430/Engineers-Use-3D-Printing-to-Turn-2D-Materials-into-Electrodes.aspx.

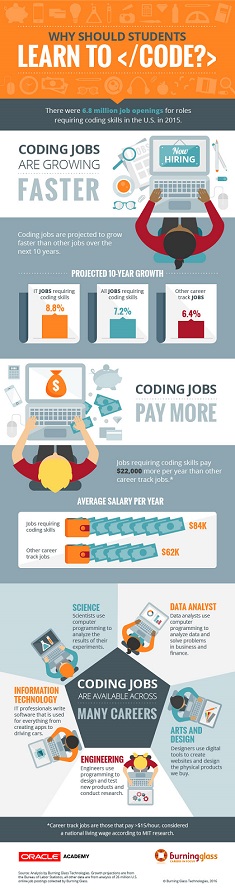

The ability to code in the python language is becoming an increasingly sought-after skill, particularly in the engineering field. In industries underpinned by computer programming, this skill is critical for data analysis and visualizations, artificial intelligence and machine learning, and automation.

Knowledge of python is pertinent with traditional engineering tasks changing across disciplines, as computing technologies transform the way engineers do their jobs. Coding is becoming a much sought-after skill by employers around the world.

In 2016, Burning Glass Technologies suggested that seven million job openings in 2015 were in occupations which valued coding skills. Their report, titled ‘Beyond Point and Click: The Expanding Demand for Coding Skills,’ also predicted that by 2030, 500 billion devices would be connected to the Internet of Things. Therefore, the job openings which value coding skills will likely rise to levels unforeseen back in 2015.

“We live in a digital world. Our phones, our cars, our banks, and our hospitals - nearly aspect of our lives - depend on computer code,” the report stated.

“As a result, coding or computer programming, is becoming a core skill requirement for many well-paying jobs. Coding skills are in-demand across a broad range of careers, not just for programmers.

“The ability not only to use but also to program software is often required of business people who work with data, of designers and marketers who create websites, of engineers who build products and technologies, and of scientists who conduct research.”

With python’s abilities to disseminate and crunch data, the language makes the perfect candidate for overseeing industrial environments. In such settings, you could have many software and hardware elements that need to be controlled in unison. For example, python allows engineers to implement open source SCADA (Supervisory Control and Data Acquisition) systems that can perfectly sync an industrial project.

The coding language can handle large data sets that engineers can develop algorithms around, to meet the ends they require for their setups. Therefore, it is a particularly useful language in machine learning realms. Machine learning focuses on developing systems that can warp and transform around the injection of data into a system — and learn from it. It is being utilized in several industries, which are looking to automate some of their more repetitive tasks to free up their workers and direct them towards more productive tasks.

Python can also be used to actively teach a machine what to look for in a set of input and output data. This alerts personnel when a system breakdown has occurred or when part of a system requires maintenance. In the machine learning world, this is referred to as supervised learning.

Unsupervised learning involves a machine learning from the input data of hundreds of similar projects and putting together a python-activated algorithm that can find and classify the data you want the machine to learn from in your system.

Python is convenient for engineers due to an extensive library of available pre-written code that can quickly be expanded on and implemented within a system. There are over 14,000 python packages available for download, making it a more accessible language than some of the alternatives that need to be coded from scratch. Python also takes up less space than alternative programming languages.

The standardization of the language is what is making some of the biggest businesses all around the world (JP Morgan, IBM, and more) utilize python on their websites and inside their enterprises. Consequently, engineers are being asked to understand more and more of the programmed backend of the companies they are working within. No longer can one set of skills suffice.

The Engineering Institute of Technology is hosting two three-month-long live, online professional development courses in python programming. One of them focuses on python programming and its application within the different engineering fields. The second course looks at how advanced python programming can be used within machine learning algorithms.

Works Cited

“Real-Time Job Market Analytics Software.” Burning Glass Technologies, www.burning-glass.com/.

“Why Engineers Are Learning Python.” LinkedIn, www.linkedin.com/pulse/why-engineers-learning-python-koen-van-viegen.

A railway line near Aldershot in the United Kingdom is set to become the first railway line directly powered by a photovoltaic solar farm.

A 30kW pilot-scheme is currently paving the starting point of the project with renewable energy powering the signaling and lights on Network Rail’s Wessex route.

Whilst there is nothing new about solar panel technology keeping the lights on at train stations, Network Rail’s Aldershot project is the first time a solar array will bypass the electricity grid to plug directly into a railway’s “traction” system.

This groundbreaking solar movement is part of the Network Rail’s plans to completely avoid running trains on diesel. The benefits of this movement include the reduction of air pollution, greenhouse gas emissions, and costs.

It was climate advocacy group 10:10 Climate Action and Imperial College London that got the ball rolling on powering UK railways with solar PV. Their campaign, named Riding Sunbeams, estimates that solar could power 20% of the Merseyrail network in Liverpool, as well as 15% of commuter routes in Kent, Sussex, and Wessex. Their website says:

“Direct solar supply of solar power to rail traction systems has never been done. But it has huge potential - from metros, trams, and railways in the UK and around the world. After extensive feasibility work and research, we’re almost ready to connect the first pilot solar panels to the railway.”

The Department of Transport in the United Kingdom, who backed the project, is keenly awaiting the results of the project’s results - they hope that the straight-solar process could be rolled out to other train stations around the country. They also hope this technology might extend to the tube and tram networks as well.

The directors of Riding Sunbeams say that technology could also transform railway industries in countries that rely heavily on trains. The Guardian reports that India ‘already has 250 trains powered by solar panels attached directly to the roof of the train, but it plans to develop its own trackside solar farms’.

The move would also open up employment opportunities for electrical engineers in the UK who can assist with rolling out the solar arrays for all train stations across the nation. Leo Murray, the director of the Riding Sunbeams project told media:

“Matchmaking the UK’s biggest electricity user, the railways, with the nation’s favorite energy source, solar power, looks like the start of the perfect relationship.”

“Helping to get the railways off fossil fuels in this way will cut running costs and benefit local communities at the same time as helping to tackle the climate crisis.”

Works Cited

Ambrose, Jillian. “Rail Line in Hampshire Is World's First to Be Powered by Solar Farm.” The Guardian, Guardian News and Media, 23 Aug. 2019, www.theguardian.com/business/2019/aug/22/rail-line-in-hampshire-is-worlds-first-to-be-powered-by-solar-farm.

Griffin, Esther. “Taking Solar Railways off the Drawing Board onto the Tracks - 10:10 Climate Action.” 10, 10:10 Climate Action, 8 Mar. 2019, 1010uk.org/articles/taking-solar-railways-off-the-drawing-board-onto-the-tracks.

In 2016, France announced an exciting plan that would hopefully power 5 million homes with electricity. The plan entailed paving over 1000 kilometers of road with photovoltaic panels, generating around 790kWh every day. However, what was supposed to the first step of a revolutionary development ended up being a bitter disappointment.

One kilometer and eight million dollars later, the issues of the road were already piling up.

The solar panels suffered immense wear and tear, to the point where some were completely shattered from the pressure of traveling cars. Some sections also failed to work to their full potential when moving dirt had covered the panels. Their horizontal position on the road also meant they were not directly facing the sun for many hours of the day, adding up to be incredibly inefficient.

The road also generated a strange noise, which forced traffic officials to change the speed limit of the paneled road to 70 kilometers per hour.

Now that the experiment is over, the government’s idea of rolling out 1,000 kilometers of the solar road has ground to a sudden halt. With all of the issues that have dogged the road, the electricity output of the solar road has been abysmal.

Alain Pelleray, a senior regional officer in the department of Orne in Normandy told media:

“As time went on, we realized that on an economic and financial level, in terms of producing electricity, it was a failure.”

The initial projection was that the roadside solar panels would, from December 2016 to March 2019, generate 624MWh (megawatt hours) but it the final results didn’t even make it halfway with the road only generating 229MWh. The plan was to sell the electricity to state-owned power company EDF with an expected 35,000 dollar profit –however, they only sold 13,000 dollars.

Nonetheless, Pelleray says much has been learned from the project and they are looking forward to continuing the experimentation with solar roads. Pelleray said:

“We have no regrets, the department did not spend anything on this and we are talking about applied research. In terms of renown, we hit the jackpot. We’ve had visits by Korean and Chinese tourists and industrialists.”

It is also back to the drawing board for the manufacturer of the panels, Colas, to solve the complications associated with the panels themselves. Colas Group’s Wattway panels were tipped to be the most promising solar roadway technology manufacturers, and they now have to rethink the entirety of their panel engineering. Colas is reportedly working on hundreds of small solar experiments to in an effort to determine how to capture the most sun as possible.

In another part of the world, Chinese industrialists are witnessing their own problems with solar roadways. In 2018, China opened a ‘solar highway’ in Jinan which was said to be longest solar roadway in the world at the time of its opening.

The first issue was vandals stealing portions of the road, and the second was passing vehicles causing layers of damage to the road. The Chinese used a glass-based photovoltaic panel (covered with a layer of concrete) that splintered when heavy items fell from trucks onto the highway. The fractures in the panels got worse when passing vehicles dragged bits of glass down the highway.

The hurdles the solar roads have faced now represent an opportunity for engineers. Engineers can now apply what they have learned and look for ways to strengthen the photovoltaic solar panels.

Works Cited

“China's 'Solar Highway' Was a Victim of Bad Design, Not Thieves.” South China Morning Post, 16 Apr. 2018, www.scmp.com/news/china/society/article/2131241/chinas-solar-highway-was-victim-heavy-traffic-and-bad-design-not.

Jakarta Post. “France to Try Again with Solar Road Plan.” The Jakarta Post, www.thejakartapost.com/life/2019/07/25/france-to-try-again-with-solar-road-plan.html.

Engineers will always be required to design, build and maintain - everything from infrastructure to highly complex systems which run the world’s industries. But as new technologies emerge and disrupt it is critical that engineers skill themselves to remain relevant today and into the future. Many traditional educational institutions struggle to respond to market demand, but EIT has gained momentum as one of the only colleges in the world specializing in delivering industry-driven, applied engineering education. It is no wonder that in July 2019 EIT celebrated the milestone of achieving over 250,000 visitors to its website in 1 month; this represents the largest month in website traffic for the organization since its inception.

Internationally, engineers are the cornerstone of society; they facilitate commercial and industrial applications that meet societal and consumer needs. Increasingly, however, the modern engineer requires multi-disciplinary engineering skill and knowledge to secure future employment.

The World Economic Forum suggests that engineers need to be retrained for the 21st century, an era defined by a sharp rise in computing technologies resulting in automation. They say that, ‘technology has surpassed technological education’.

Miguel Milano, the President of Salesforce, writing for WEF said, “at least 133 million new roles generated as a result of the new division of labor between humans, machines and algorithms may emerge globally by 2022, according to the World Economic Forum. There will also be strong demand for technical skills like programming and app development, along with skills that computers can’t easily master such as creative thinking, problem-solving and negotiating.”

Not only are computing technologies transforming the industrial automation and data & communications industries, but new forms of powering our planet are also transforming the electrical engineering world. And this is aside from their impact on the civil & structural, energy, mining, oil and gas industries.

The Engineering Institute of Technology’s vision is to provide students - throughout the world - with measurable and significant gains in their places of work and in their careers. The college mandate is to provide cutting-edge engineering education to enable graduates to achieve success in the evolving engineering roles of today and tomorrow.

The Engineering Institute of Technology (EIT) emerged in 2008 from the extensive and global foundation established by its sister company IDC Technologies. Since 1991, IDC’s portfolio of 300 industry-targeted professional development courses has been attended by over 500,000 engineering professionals worldwide, with clients such as NASA, UN, Rolls Royce, Rio Tinto and BHP. EIT built on this platform by designing accredited vocational qualifications across the engineering disciplines. Subsequently, and to provide students with seamless academic pathways, in 2014 EIT became a nationally registered Higher Education Provider.

In the higher education space, EIT offers an extensive range of engineering BSc and Master Degrees (with nested graduate diplomas). A professional doctorate, still under development, will soon be added.

In achieving the status of Commonwealth Register of Institutions and Courses for Overseas Students (CRICOS), EIT was able to progress its strategic priority of delivering higher education engineering programs to students on campus in Australia, in 2018. In line with these priorities and market demand, the organization opened a second campus in Melbourne in February 2019.

EIT’s unique online and blended delivery methodologies enable the college to reach students worldwide, but they also assist graduates to become highly skilled practitioners. Two essential components of this approach involve human resources: EIT’s lecturers are subject-specialists, who are industry experts and globally-based, and EIT’s dedicated Learning Support Officers nurture students through to graduation.

State-of-the-art online tools and technologies further facilitate EIT’s online and blended platforms of learning. They include 24/7 access to hands-on remote and virtual laboratories, simulations, a comprehensive student Learning Management System, invigilation software, and a web and video conferencing system which supports live and interactive sessions.

EIT’s innovative online learning approach is critical to students who are working; they can acquire quality education without accessing a campus or having their studies interfere with their responsibilities at work. One of EIT’s Master graduates based in Uganda commented, “It allowed me to gain knowledge in the most flexible way possible for a busy full-time employee. I was able to study without my employer feeling my absence. My class had experienced students in the automation field who could share real work experiences.”

EIT has graduates in 141 countries, including Australia, South Africa, Nigeria, Botswana, Namibia, United Kingdom, United States, Zimbabwe, Zambia, Canada, New Zealand, Ghana, Saudi Arabia, Papua New Guinea, United Arab Emirates, and Ireland.