News

Did you now an interactive LEGO brick exhibition has arrived in Perth?

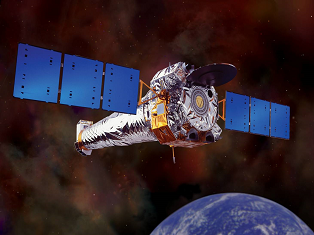

That’s right, Brickman Awesome will be showcasing the tallest LEGO model in the Southern Hemisphere — a NASA SLS rocket, which was constructed using more than 450,000 bricks and measures in at 7.5 metres tall. It took exhibition curator Ryan McNaught more than 500 hours to build the model and it even features a lighting display which creates the illusion that the rocket is blasting off into space.

The exhibition also features a life-sized Toyota Camry, the only life-sized LEGO Harley Davidson motorbike ever built and the world’s largest LEGO Caterpillar 797 dump truck. For the science-fiction fans, there is a life-sized TARDIS from Doctor Who and a light-up Back to the Future DeLorean. A full-sized Australian saltwater crocodile, weighing 60 kilograms and comprising of 40,000 LEGO bricks is also on display. Don’t forget to check out the LEGO Kangaroo, Koala and Orca too!

In total, there will be 38 brand new LEGO models, which have been created using more than 2 million bricks and took the team more than 5000 hours to construct. Ryan McNaughton is the only LEGO Certified Professional in the Southern Hemisphere and one of only 14 in the entire world!

Visitors also have a chance to show off their building skills. There’s the opportunity to help the Brickman team expand their colony of Emperor Penguins. You can also build your own time machine and contribute to Australia’s longest LEGO model, by adding new sections to the snake!

This event is being held at the Perth Convention Centre until July 22.

Some highways (and most sidewalks) in the United States are made out of concrete. Mark Weaver, a Professional Engineer in California, writing on website Quora, explains:

“The main reason is that highways have much higher volumes of traffic than surface streets. Highways also have much heavier vehicles traveling on them than surface streets. The combination of higher volumes and higher weights of vehicles causes serious durability issues for asphalt concrete pavement.”

The problem with concrete? It isn’t very flexible. For building roads, the material of choice is usually asphalt due to its flexibility - but concrete is cheaper to install. A lot of other U.S. infrastructure is made with concrete - and it is starting to show its age.

The brittleness of concrete is not one of its favorable attributes, but what if engineers could cheaply install concrete and it could last longer than any rival material?

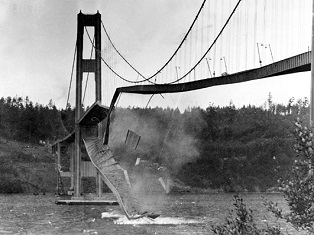

Bendable concrete would contribute to more stable bridges and it would help prevent them from collapsing. Sometimes it’s not the older bridges that are in trouble of collapsing, but the new ones.

In March 2018, a bridge collapsed at Florida International University in the United States that unfortunately led to loss of life. Engineers had discussed a crack that had formed on the bridge hours before the bridge collapsed. The crack has still not been confirmed as the root cause of the collapse, however, a bendable concrete that could survive more stresses may have prevented a collapse. The bridge is said to have been built via a quicker construction method and utilized a new form of concrete known as ‘self-cleaning concrete’.

Solutions

Engineers at the University of Michigan believe they have the answer to offsetting the brittleness of concrete. Their discovery was inspired by seashells. In their Conversation article, they write:

“To develop ductile concrete, our laboratory borrowed ideas from nacre, also known as mother of pearl - the iridescent material on the inside of abalone shells.”

Mimicking the nanoscale architecture of an abalone shell - which the engineers say looks like a brick wall - makes what seems to be a small shell, quite rigid.

“The ‘bricks’ are thin layers of aragonite platelets, and the ‘mortar’ between them is a natural polymer that is very elastic. The polymer holds the rigid aragonite layers together, but allows them to slip from side to side under stress. This structure makes nacre both strong and flexible.”

Their new concrete has been given a name: Engineered Cementitious Composite (ECC) or strain-hardening cementitious composite. When using tiny fibres within concrete that is under pressure, the composite emulates the flexible rigidness of the nacre.

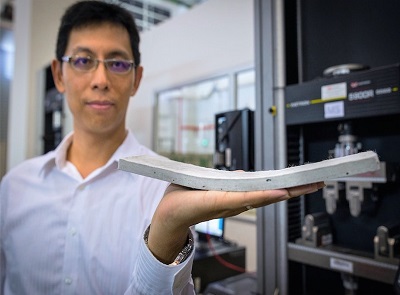

Scientists in Singapore’s Nanyang Technological University have also been experimenting with putting ‘thin-as-human-hair’ fibres into their mix of concrete. The result? A new material known as ConFlexPave. The distribution of the polymers reportedly makes the concrete stronger and more durable.

The researchers say instead of pouring the concrete on site, the concrete could be prefabricated at a factory and transported to the construction site and simply laid in place. The engineers will test the concrete around their campus over the next three years.

Professor Yang En-Hua from NTU’s School of Civil and Environmental Engineering, leading the charge on the research said:

“The hard materials give a non-slip surface texture while the microfibres which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in a concrete that is tough as metal and at least twice as strong as conventional concrete under bending.”

Works Cited

Coxworth, Ben. “Next-Gen Concrete Bends Instead of Cracking.” New Atlas - New Technology & Science News, New Atlas, 17 Aug. 2016, newatlas.com/bendable-concrete-sidewalks/44950/.

Li, Victor C. “Bendable Concrete, with a Design Inspired by Seashells, Can Make US Infrastructure Safer and More Durable.” The Conversation, The Conversation, 11 June 2018, theconversation.com/bendable-concrete-with-a-design-inspired-by-seashells-can-make-us-infrastructure-safer-and-more-durable-93621.

Weaver, M. (2018). In the United States, why are most highways made of concrete, while most streets are made of asphalt?. [online] Quora. Available at: https://www.quora.com/In-the-United-States-why-are-most-highways-made-of-concrete-while-most-streets-are-made-of-asphalt [Accessed 11 Jun. 2018].

We had a very good response to the seminar which the Engineering Institute of Technology ran in Midrand, South Africa, on the 19th June.

During the

The theme of the presentation, in a nutshell, was the disruption being caused by the increasingly digital/automated world. The topic may have been confronting

Perth is surrounded by some amazing destinations that are only a couple of hours out of the city. If you’re looking for something to do during your study-break or on the weekend, why not explore some more of Western Australia? Here are some of our favourite day trips.

Araluen Botanic Park

This stunning park is home to 59 hectares of native Australian bushland and 14 hectares of manicured gardens showcasing exotic plants. In the spring, it features more than 100,000 tulips in full bloom against a backdrop of eucalyptus trees. Visitors can take a train ride around the park to take in the scenery and learn about Western Australia’s native flora. Located in Roleystone, it is only 35km south-east of the Perth CBD.

Yanchep

This is the perfect place to spot koalas and kangaroos in their natural environments. There are also a number of walking trails, where you can relax and take in the beautiful scenery. If you’re looking for something a bit more adventurous, why not visit one of the natural caves?

Gnomesville

Thousands of gnomes live amongst some trees on the side of the road, approximately 195km from the Perth CBD. How Gnomesville originally came into existence is still a mystery; however some people believe one gnome was placed there on its own and then others were added to keep it company. Since then it has become an attraction for both tourists and Perth locals, with visitors from all over the world adding to the community.

Serpentine Falls

Best visited in winter, you can watch the water from the Serpentine river cascade down a granite cliff here. Why not pack a picnic and enjoy lunch surrounded by grey kangaroos? There are also a number of hiking trails in the area that can take from 15 minutes to five hours to complete, depending on how far you want to walk. The falls are located in the Serpentine National Park, which is 55km south-east of the Perth CBD.

The Pinnacles

Thousands of natural limestone sculptures cover this dessert. Known as the Pinnacles, they can stand up to 5m tall. The best time to visit is at dusk or dawn as the shadows cast by these formations create incredible shapes and patterns across the sand. You might even be lucky enough to spot a wild emu.

Lake Clifton

This lake is home to thousands of thrombolites, which are tiny micro-organisms believed to be some of the earliest life-forms on earth. Follow the boardwalk to get an aerial view of these creatures. They resemble rocks, despite the fact that they’re actually alive. Located in the Peel region, it’s only a short drive from Mandurah and Bunbury if you’d like to continue exploring the state further.

This winter, get your skates on and brave the cold at winter wonderland events in Fremantle and Elizabeth Quay. If you’re not too keen on ice skating, there will be snow-man building, inflatable slides,

food stalls and markets.

Winterworld

This outdoor ice skating rink in Fremantle will be complete with falling snow. There will also be a giant inflatable slide and a snow pit, where you can build your own snowman. If you’re feeling cold, don’t worry — inside the National Hotel is a warm and cosy Cabin Bar. You can relax here with a warm hot chocolate, roast marshmallows around a fire pit, or visit local producers and retailers showcasing their wares at the marketplace. There will also be food trucks serving food, perfect for a cold winter’s day.

Australia’s largest open-air ice skating rink will be open from 23 June – 15 July at the Fremantle Esplanade Park.

Skating At Festival

This open-air ice skating rink is located in the heart of the city at the picturesque Elizabeth Quay. The pop-up rink is ideal for people of all ages and skating abilities. If you’re looking for a dose of adrenaline, you can race your friends down a slope on a snow tube. There will also be a giant inflatable slide and a bouncy castle, plus food trucks selling snacks and hot drinks.

This attraction will also be open from 23 June – 15 July at Elizabeth Quay.

What modern curriculum vitae should look like is a question that prospective employees are asking themselves all over the world. For those seeking employment in the engineering industries this is a particular challenge because it requires some creative aptitude – not always something that comes naturally to technical gurus.

And yet, fierce competition in the modern workplace means that perfecting a CV and marketing oneself as the best possible candidate is critical, despite being tedious.

Thankfully there are some basics that graduates can apply to their CVs that will help them at least be considered by employers.

Steve Mackay, the Dean at the Engineering Institute of Technology, believes that the rules of CVs have changed. What used to work in the past does not necessarily work today. He said:

“First of all, ensure your CV is designed for the particular job you are applying for. Most people think they can use a generic resume because they have to apply for lots of jobs. This is not advisable. If you feel it is a good fit then use it, but then ensure your cover letter is specific and thorough. Your CV should use plain English and the information should be laid out simply and logically…and leave lots of white space. Grammar and spelling must be one hundred percent accurate. Avoid too much detail; the CV that is 20 pages long is not acceptable. An executive summary at the top of the resume is a good idea. Be specific! Focus on the job you really want. Your CV should also include business strengths and business wins.”

What is available for those needing to build a CV?

On some college campuses students organize events to assist others who aren’t well versed in putting their CVs together.

And services like Microsoft Word and Google Docs, which are often underrated, have templates that people can utilize for their CVs.

The reality is that many people don’t know where to begin, but do engineering professionals have it harder than others when trying to show off their experience?

One engineer has an interesting take on it. When talking to social media site Reddit he showed what he thought the modern resume could look like. He has created an entire website to show off his experience. The site serves as a portfolio of things he has designed, worked on and perfected in the past. It also links to all of his social media, and even his GitHub repository.

Take a look at it: http://julian6alvarez.strikingly.com/

He breaks up his website resume into four sections:

Engineering - Design - Experience - Contact

Evidently he had worked at some cutting-edge aerospace engineering companies; involved in both the design and engineering of many projects.

Back to basics

Nonetheless, there are many companies that prefer the no-frills approach to CV submissions. Unless otherwise asked, send the company an age-old, basic CV. Consider the following table of ‘Dos and Don’ts’. It is from an assortment of engineering experts on creating effective CVs.

|

Do |

Don't |

|

Leave white space. Make it easy on the eye. Presentation is everything. |

Use weird and wonderful fonts. Avoid hand writing at all costs. |

|

Keep it succinct. NO PARAGRAPHS. |

Add unnecessary images. |

|

Double check your grammar. |

Add outdated skills. |

|

List all relevant experience. |

Use slang or colloquial language. |

|

Tweak your CV based on which employer you are applying to. |

State your salary expectations. |

|

Refer to most relevant, important skills. Put them closest to the top. |

Make your CV longer than two pages. |

|

Investigate which keywords to include in the CV. |

Add information that you cannot verify. |

|

Add major achievements. |

Add unnecessary personal information. |

|

Save the resume in multiple formats. |

Deviate from a neat and tidy format. |

Works Cited

Bloomfield, Georgina. “How to Write the Best Engineering CV There Is.” Engineering & Technology Jobs, Engineering & Technology Jobs, 20 Apr. 2017, engineering-jobs.theiet.org/article/how-to-write-the-best-engineering-cv-there-is/?utm_source=Adestra&utm_campaign=Jobseekers Non Members 05/06/2018&utm_medium=Advertising - Recruitment E&T Jobs&utm_content=E&Tj Job Seekers campaigns&utm_term=https://engineering-jobs.theiet.org/article/how-to-write-the-best-engineering-cv-there-is/.

“Do's and Don'ts for Developing a CV | Independent Jobs.” The Independent, Independent Digital News and Media, independentjobs.independent.co.uk/article/do-s-and-don-ts-for-developing-a-cv/.

Can leadership be inherited? Can leadership be learned?

In a study published in 2013 by Science Direct, the answer to both those questions is ‘yes’ - but learning how to lead significantly outweighs the likelihood of the former working without some input. The researchers of the paper entitled, Born to lead? A twin design and genetic association study of leadership role occupancy, believe that inheritance contributes little to leadership qualities:

“Employing twin design methods on data from the National Longitudinal Study of Adolescent Health, we estimate the heritability of leadership role occupancy at 24%”

The study would go down as the only study to ever use genotypes to determine whether or not humans could inherently be born with a leadership gene. The result was that leadership is more easily taught than inherited.

In engineering the likelihood of being thrust into a position that involves having to manage a team is high. So those new to leadership may find solace in the fact that it can be taught.

This is indeed heartening when one considers that engineering projects do fail when the teams involved are not managed ably.

A prominent clinical psychologist from the University of Toronto, Jordan Peterson, has been delivering presentations based on his new book, 12 Rules for Life. Talking to SpeakerSpotlights about management and leadership, Peterson suggests that those in charge must encourage their team members to take control of their lives and strive towards achieving their goals. He explained:

“If you have a vision for the direction of your life, and your job is serving that purpose, then instantly your job becomes motivating. People are motivated when they are undertaking an act that is associated with a goal that they desire.”

He also emphasizes the need for a positive atmosphere within a team as it will result in a unified group who work actively to achieving the same goal or project outcomes.

Become a leader

Elizabeth Powitzky, a writer for the Forbes Financial Council, has penned her responses to the study by Science Direct; she has come up with six strategies that could turn a manager into a leader:

1. Identify gaps and strengths. To be a truly effective leader, figure out what’s hindering or helping you, and then take action.

2. Surround yourself with diverse thinkers. Leaders constantly confront difficult problems and no one person typically has the answer. It is important to seek out people who think differently from you -- and from one another.

3. Understand that words matter. People often dissect a leader’s words, looking for nuance and hidden meaning. Think carefully about what you’re saying and how it’s being perceived.

4. Question and test decisions thoroughly. Imagine explaining each one to a client, your team, or other leaders in your organization.

5. Observe others and keep growing. You have to be a lifelong learner in all aspects of life, but particularly if you want to grow as a leader. Study critically what others say and do.

6. Seek feedback and act on it. Ask others to share their perceptions of you and how they would describe you to others.

The Engineering Institute of Technology (EIT) has a Diploma of Leadership and Management and a Professional Certificate of Competency in Project Management for Engineers & Technicians. These courses offer the kind of training that familiarizes students with ‘people skills’ and teaches a range of skills including scheduling, cost control and risk management.

Drawing on his years in engineering, the Dean of Engineering at EIT, Steve Mackay, has articulated his thoughts on dealing with conflict in engineering teams. He believes a manager who is able to diffuse difficult situations makes a good leader. Consider his ideas in the following:

Works Cited

“Born to Lead? A Twin Design and Genetic Association Study of Leadership Role Occupancy.” Egyptian Journal of Medical Human Genetics, Elsevier, 10 Sept. 2012, www.sciencedirect.com/science/article/pii/S1048984312000811?via=ihub.

Powitzky, Elizabeth. “Great Leaders Are Made, Not Born: Six Strategies For Becoming A Better Leader.” Forbes, Forbes Magazine, 25 May 2018, www.forbes.com/sites/forbesfinancecouncil/2018/05/25/great-leaders-are-made-not-born-six-strategies-for-becoming-a-better-leader/2/#35abb68d25d2.

speakersspotlight. “On Leadership and Direction | Dr. Jordan Peterson.” YouTube, YouTube, 8 Aug. 2017, www.youtube.com/watch?v=I_wVDdJ0JQk.

110,000 Australian homes are to be powered by renewable energy sources before the end of 2018. Much of this is thanks to Partners Group - the global private market investment manager. They will be investing a total of AUD$700 million in a renewable energy platform named the Grassroots Renewable Energy Platform.

The investment will, over four years, help add 1.3GW of new wind power, solar power, and battery storage projects in Australia. It is not the first time Partners Group has thrown their weight behind the Australian renewables sector. In 2015, they pledged AUD$450 million for the building of the Ararat Wind Farm in Victoria. The local developer utilizing the funds and building the farms is CWP Renewables. They are in the business of delivering energy, and powering communities.

Then in 2016, the investment firm pumped a further AUD$250 million to complete the 270MW Sapphire Wind Farm in New South Wales. This particular wind farm is going to be the most important player in the new Grassroots Renewable Energy Platform the company plans to perfect in Australia. It is thought that the wind farm would be paired up with an upcoming solar and battery storage project.

This cash injection is changing the face of power generation in Australia. The Head of Private Infrastructure Asia-Pacific at Partners Group Benjamin Haan said:

“When we invested in Sapphire Wind Farm, one of the key attractions for us was the project’s potential to anchor an Australian renewable energy platform. Partners Group and CWP have a project in the pipeline of 1.3GW in generation capacity across wind and solar power, offering the scope to be selective and develop Grassroots into a quality renewables platform of significant scale. We look forward to working with the CWP team to further support the generation of clean energy in Australia.”

CWP boss, Alex Hewitt, believes that the platform will undeniably help Australia transition from a fossil-fueled electricity industry to one powered by renewables at ‘very affordable prices’. An added benefit of bringing the wind farms online will be a marked decrease in carbon emissions.

Not stopping there

An extra 55,000 homes will be getting clean power in 2019 when the second project, the Crudine Ridge Wind Farm, is completed. That farm will produce 135MW in Mudgee, New South Wales. And of course power isn’t the only thing being generated – jobs are too. By September of next year the General Electric wind turbines will be erected, producing 75 full time jobs.

Partners Group adds that over its lifetime, the Crudine Ridge Wind Farm, will offset eight million tonnes of carbon emissions.

And if all goes well, with continued innovation in renewables, the Grassroots platform could indeed become an Australian clean energy superpower. Talking to Clean Technica, Haan concluded:

“In Australia’s energy market, a significant transition away from fossil-fuel power is now underway. The compelling economics of renewables and the age of older coal plants is driving that change, the speed of which is ramping up. While it is true that political instability has delayed the transition in the past and the sector is still somewhat fragmented, the Grassroots platform is aimed at this transition and its business plan is robust enough to deal with any likely outcomes from the current political debate. We believe Grassroots has the scale and competitive edge to succeed and become a significant renewable IPP in Australia.”

Works Cited

“Partners Group to Invest AUD 700 Million in Australian Renewable Energy Platform; Announces Imminent Construction of Crudine Ridge Wind Farm.” Private Investors, www.partnersgroup.com/en/news-views/investment-news/current/detail/article/partners-group-to-invest-aud-700-million-in-australian-renewable-energy-platform-announces-imminent-construction-of-crudine-ridge-wind-farm/.

“Swiss Equity Firm Commits To 1.3 Gigawatt Australian Renewable Energy Platform.” CleanTechnica, 29 May 2018, cleantechnica.com/2018/05/29/swiss-equity-firm-commits-to-1-3-gigawatt-australian-renewable-energy-platform/.

Paul Celenza is the College Manager at the Engineering Institute of Technology (EIT); he has worked for the college for eight years. Upon a recent visit to South Africa, Paul reflected on eight years of change and innovation in the education sector and revealed more about EIT’s novel approach to the future of engineering education and training

EIT’s sister company, IDC Technologies, began offering courses to students over 25 years ago; short engineering professional development courses, on site and in classrooms around the world – a branch of the business which still exists today.

With the reach of the internet and emerging online technologies EIT began offering these short certificate courses online. The platform is live and interactive and provides students, in all corners of the world, with access to engineering and technical training. The college also now awards Australian qualifications in a range of diplomas, advanced diplomas, BSc and Master degrees for those in, or heading into, the technology and engineering industries.

These qualifications have been designed by EIT with teams from industry, to ensure the content is relevant and driven by the demands in industry. Celenza says the college has been able to nimbly adjust its offerings to keep up with the changing nature of technology:

“Traditional engineering is morphing. Some positions in industry are becoming more niched, whereas others require a range of engineering disciplines. The education behind these professions needs to change as the technology changes.”

For example one of the college’s signature degrees is the Bachelor of Science in Industrial Automation Engineering. Apart from covering the specific technologies relating to it, it incorporates mechanical and electrical engineering; it provides students with the requisite skills for a profession which is critical to the fourth industrial revolution.

Celenza commented further:

“The whole world is talking about STEM - we want to facilitate student careers in technology and engineering across the globe.”

EIT already reaches students in over 140 countries, but felt a campus would benefit school leavers. To this end the first EIT campus opened in Perth, Western Australia in February this year. Students passionate about engineering and technology, from Australia and abroad are being welcomed. The on campus learning is blended, using EIT’s local and international lecturers; academics and engineering experts from industry.

The Commonwealth Register of Institutions and Courses for Overseas Students (CRICOS) makes the process of bringing students into Australia possible. Higher education institutions and their unique course are listed in the register, and international students are encouraged to apply. Celenza said:

“Our first intake has been small, which is good – we have learned much from this band of learners; they have encouraged us to expand in Perth and open others in Australia and abroad. With all that EIT offers, we are really building the hybrid college of the future.”

Paul spearheads the recruitment of students in the VET (Vocational Education and Training) sector of EIT - where all training is delivered online. This option to study online, for those working full time and with family commitments, is a massive advantage to students. The need to do further study has become increasingly important in our fast-paced world and the online platform of learning is the facilitator.

In the VET courses and higher education degrees EIT ensures all content is designed with the demands of the workplace in mind and it is continuously improved. Celenza explains:

“Universities, with mammoth campuses, often teach obsolete skills to students. They graduate with little or no practical work experience; it becomes lost in the academic world. Students with access to hands-on experience which is underpinned by technology translates into more valuable, employable workers.”

EIT, Celenza says, is consolidating and improving all of the technological requirements of a modern day education and training institution. They are providing their students with remote labs that can be accessed from all over the world and creating virtual simulation canvasses for students to experiment on.

Furthermore, the institution is utilizing a new, novel, cloud-based approach to student management. Celenza’s recent trip to South Africa, from EIT’s Australian head office was motivated by this. He was tasked with guiding the institutions’ Learning Support Officers (LSOs) through the technological processes of upgrading their student management framework.

EIT, on the road to 2020, is in a consolidation phase of strengthening their offerings in both the VET and higher education sectors - steadily building the foundation of future learning so that they can be the futuristic institution that modern day students are seeking.

Paul notes that as a College Manager he comes into contact with EIT students from many cultures, from all over the world. He admits proudly that he provides support to many of these learners who are determined to improve their employability and their lives through gaining qualifications via a globally relevant institution.

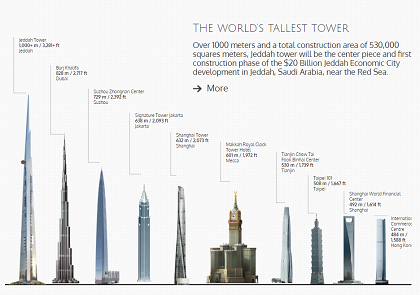

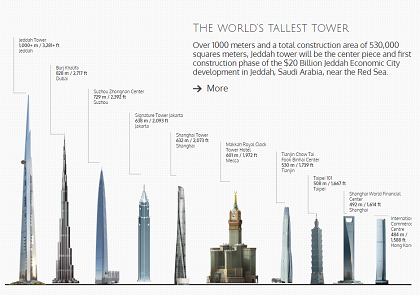

The world’s tallest building, the Burj Khalifa in Dubai, is about to be dethroned. 1,200 miles away, a new tower is nearing its completion in Saudi Arabia. In 2020, the tallest building in the world, the Jeddah Tower measuring in at one kilometer, will open. That is if engineers can complete the audacious towering skyscraper on the desert sand.

The tower’s construction is estimated to cost the Kingdom Holding Company around US$1.5 billion. Jeddah Economic Company website initially reported that the tower would stretch “over 1000 meters” but Engineering360 says those plans have changed. Nonetheless, the tower will also have the world’s highest observatory deck ever built.

The tower will also be the centerpiece of an almost Singaporean city, a center for business and commerce. This city will be called the Jeddah Economic City. The entire district is to cost US$20 billion. It will include a new airport and cutting-edge infrastructure, replacing the dated and aging infrastructure Saudi Arabia has become synonymous for.

Building on sand

Whilst building a kilometer high building is obviously an engineering challenge, another engineering conundrum is how to build on the fine sand in Saudi Arabia. Civil engineers have had to closely study the 5 subsurface layers of the sand in Jeddah.

Geographically the tower is near the Red Sea.

Roger Pink from IEEE Global Spec’s Engineering360 explains:

“The first layer, varying from half a meter to 2 meters thick consists of silty sand. The next 40 to 50 meters is coralline limestone, followed by a 2 to 10-meter thick mudstone/gravel layer. Next comes a poorly constituted sandstone layer about 35 to 50 meters thick, followed by another 3 to 9-meter gravel layer. Finally, below all of this is a sandstone layer as far as 200 meters.”

The unique challenges have been figuring out how to utilize the architecture blueprints and build sturdily according to those designs. The architect for the project is American born Adrian D. Smith - coincidentally the architect behind the Burj Khalifa in Dubai. He is also responsible for the Trump International Hotel & Tower in Chicago, the Jin Mao Tower in Shanghai and the Zifeng Tower in Nanjing.

The engineers have created a three-winged load-bearing design. This design also has to account for wind and the pressures that it brings. The project began construction in 2013, but a series of delays has led to the most recent end-goal which is 2020.

One of the delays arose because of the height of the Jeddah Tower. Civil engineering experts advised the architects that the higher up they go, the more unstable the concrete becomes. That high up, the wind load would cause the concrete to shrink under the pressure. (This has also meant the construction has had to be as aerodynamic as possible.)

Specialized concrete pumping equipment with thin, pressurized pipes is being utilized to counteract the forces of gravity on the concrete. Pumping wet concrete a mile in the sky is allegedly the most challenging element of the construction.

The engineers have had to work later in the evenings at lower temperatures. This allows the concrete - being pushed out a single tube - to set. However, concrete is not the only thing that needs particular attention - transporting humans to the top of the tower will be a challenge too.

Bart Leclercq, head of structures for WSP Middle East, explains:

“You have to make sure a tower is not too flexible and people aren’t getting nauseous in high winds. You have to put enough stiffening elements in your building. For example, sheer walls in combination with concrete cores in the case of a concrete building.”

A novel approach to an elevator system is being drawn up to ensure the elevators do not suffer under the wind loads and the building sway. The tower is expected to have a wholly different elevator system - the first of its kind in the world.

The engineering challenges and the feasibility of a mile-high tower have meant that the architect’s original plans have, in some instances, changed to accommodate the actual construction of the tower.

Hisham Jomah, chief development officer at JEC, told the Times of Oman:

“Between theory and application: what has been designed and what is actually on site is quite another world.”

This year, over 50 percent of the construction is reportedly completed. Here is a video of the progress made on the tower in the first half of 2018:

To see how six cranes will contribute to the construction of the Kingdom Tower Jeddah, take a look at this construction simulation:

The entire project is a marvel of engineering from construction phase to completion. And as far as tall buildings go, in 2020 this tower will have reset the bar. It does, however, make one wonder at the significance of it all?

Works Cited

“Home Page.” Times of Oman, NEWSPAPER_NAME, timesofoman.com/.

Pink, Roger. “Jeddah Tower - Building a Skyscraper on Sand.” A Water Treatment Alternative to Chlorine? | Engineering360, insights.globalspec.com/article/8791/jeddah-tower-building-a-skyscraper-on-sand.

_TWIITERID. “Jeddah Economic Company | Home.” Http://Www.jec.sa//, www.jec.sa/.

Ephgrave, Oliver. “Tall Order.” ConsrtuctionWeekOnline.com, www.constructionweekonline.com/article-13533-tall-order/.

A startup in Melbourne, Australia, has introduced the world’s biggest 3D printer. The company in question is

They boast that they also have the industry’s fastest metal 3D printing production line.

They specialize in titanium, of course. They print for an assortment of industries. They produce and manufacture metals for space ships, automobiles, skyscrapers, bicycles, military marine vessels, yachts, wheelchairs, mining equipment, and offshore oil and gas drilling stations.

Their 3D printer stands at 1.5 meters high, has an area of 9 meters and is 3 meters wide. The 3D printer can produce 45kg (99lb) of printed material per hour. Smaller machines, CEO Jeff Lang says, can only do 1kg (2.2lb) per 24 hours. The size and efficiency of Titomic’s machine

CEO of

The printer has a printing function the company has dubbed

In short, the process uses kinetic fusion instead of melting metals to build.

The company has begun utilizing their new fusion methods to create seamless titanium bicycle frames. They produce a new bike every 30 minutes with a smaller machine utilizing the same fusion methods the larger 3D printer employs.

The process was created in collaboration with the Australian federal scientific research agency CSIRO. Business Insider reports that the previous title owner of ‘biggest 3D printer’ was GE’s machine - which could print metal objects of up to one cubic meter.

Here is a timelapse of Titomic’s machine printing a sign in four minutes:

Why titanium?

The benefit for bikers is immediately apparent. Titanium bike frames are more durable than those made from carbon fibre. The golf club company, Callaway, is also very interested in this very capable printer.

However, titanium isn’t the only metal the company is looking to use.

CEO of

“When we look at carbon fibre parts they generally make a hollow part called a monocoque construction. We’re sort of at the stage now where we can achieve that with metal,

Lang believes that their printer signals the birth of a new industry for metal manufacturing. He says now, with

The printer, Lang says, is creating titanium at a level that is “very close” to the strength of titanium when created using traditional methods - but concedes that more can be done to improve its printing methods. The printer has shown how efficient the process of additive manufacturing

Works Cited

Farquhar, Peter. “A Melbourne Manufacturer Just Fired up the World's Largest 3D Metal Printer.” Business Insider Australia, Business Insider Australia, 16 May 2018, www.businessinsider.com.au/a-melbourne-manufacturer-just-fired-up-the-worlds-largest-3d-metal-printer-2018-5.

Quick, Darren. “World's Largest Metal 3D-Printer Scales up Additive Manufacturing.” New Atlas - New Technology & Science News, New Atlas, 18 May 2018, newatlas.com/titomic-worlds-largest-metal-3d-printer/54667/.

If you aren’t utilizing a service that delivers your groceries to your door now, you most likely will use one in the future. Thanks to automation, you won’t have to cast your mind to the nonexistent workers that are packaging all of your groceries up for you - because all of the workers will be robots.

If it sounds like a persuasive brochure from a futuristic sci-fi novel, it isn’t. It’s already happening. Ocado warehouse in Hampshire, England, utilizes hundreds of robots on a metal grid, speedily transferring groceries from holding cell to packet to your front door. And we have engineers to thank for that.

The warehouse where the robots perform their gymnastics is completely unmanned. Pick-and-place robots are abundant, carefully lifting and then putting down items that will be shipped to the demanding customer.

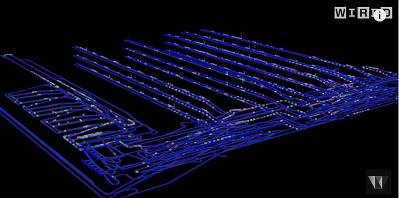

It is all made possible through an automated solution named the Ocado Smart Platform Automated Fulfilment Solution. The graphical representation of what is going on in the computers’ brains as it fulfills an order looks like this:

The whole robotic ‘ecosystem’ is orchestrated through a 4G-based wireless protocol system that is running the whole system in real-time and can optimize the operation on-the-fly. The company says the system is the most advanced system for logistics in the world.

Thousands of little specks on a digitized warehouse blueprint map show what the robots see - items ready to be fetched and delivered. It is called a resource map.

440 other specks (the robots) then need to travel into the interior of the warehouse and pick the items up. The 4G network makes the magic happen - it communicates at 10 interactions per second with each robot.

The robots need to know where to be at the appropriate time. The system can handle 3 million routing calculations per second. Something that quantum computing, upon its arrival, will more than quadruple. It is an ecosystem of robotic automation, working in complete harmony - something human workforces are hard pressed to perfect.

source:wired

Talking about efficiency, the grid that Ocado has designed ensures that all possible warehouse floor space is utilized so that there is no wasting of resources whatsoever. The company says that the grid can be retrofitted into existing warehouses.

The robots themselves can carry tens of kilograms and can move at several meters per second - there is no doubt that the robots are efficient. They are so efficient they have dubbed their robot battalion a ‘swarm’ of robots. Traversing a grid the size of several football fields, the robots communicate via a cloud-based solution and continually generate data that gets plugged into an analytics program named BigQuery.

It is a data and communications tour de force. Experts say the data communications network the company is running is the first of its kind and is the ‘first deployment of unlicensed 4G spectrum for warehouse automation’. The warehouse can handle up to 1,100 robots.

Thus, it is a glimpse of the not too distant future for all warehouses.

However, Ocado isn’t the only company utilizing robots in warehouses. Amazon has a staggering 45,000 robots currently whizzing around in 20 fulfillment centers - grabbing the relevant items customers have ordered, and transporting it to the delivery departments. From 2016 to 2017, they doubled the number of robots that was working for them. Amazon purchased the robot company Kiva Systems in 2012, and has been using warehouse robots ever since.

It is no secret, automation is replacing the pick-and-place workers in warehouses. What has been kept secret are the incredible data communications systems in place to ensure the most efficiency for a warehouse. Companies are looking to automate more efficiently than the next company, and it seems Ocado - with their own novel software and systems - is pulling ahead.

Works Cited

“Ocado's Robot Swarm.” New Electronics, 23 May 2018, www.newelectronics.co.uk/electronics-news/ocados-robot-swarm/174218/.

Shead, Sam. “Amazon Now Has 45,000 Robots in Its Warehouses.” Business Insider, Business Insider, 3 Jan. 2017, uk.businessinsider.com/amazons-robot-army-has-grown-by-50-2017-1?IR=T.

Food and beverage processing has been achieved by

With the rise of

Fast food giant,

Four MIT engineering graduates have gone into the restaurant business and shown the world the future with their automated kitchen. It is the brainchild of Michael Farid, who during his Masters in Mechanical Engineering, found that he had almost no time to cook himself meals.

He recruited Braden Knight, Luke Schlueter and Kale Rogers to acquire the technology they would need for the project of creating an automated kitchen. They, too, agreed that they couldn’t find a decent meal at an affordable price point as students. They subsequently began their work on the restaurant of the future. ‘’

In 2015, they took their idea to MIT’s Global Founders’ Skills Accelerator program. They had officially become a startup. They gave the restaurant they would open a name: Spyce.

When they had all the robotics figured out, they had to get a menu going. Therefore, they brought in a gentleman named Daniel Boulud, a Culinary Director and Michelin-Star Chef. Michael Farid guessed Boulud’s email address and asked if he wouldn’t mind creating a menu for their automated kitchen. Boulund says the robotic kitchen brings ‘precision’ and ‘consistency’ to the kitchen - something which humans struggle with.

They eventually opened the restaurant in downtown Boston on May 3rd, 2018. What’s on the menu? An assortment of stir-frys. So how does the restaurant work?

Customers are ushered in by a host. Food is ordered via an automated kiosk. The automated kitchen then gets to work after which the

Every bowl costs US$7.50. Patrons can opt to add proteins for an extra cost.

The

To see how it all came together, check this video out:

The replacement of human workers in the food industry is already causing some consternation in the industry. Members of Las Vegas’ Culinary Workers Union recently went on strike to force employers to amend their contracts to protect their jobs from being replaced by automated technologies.

But Luke Schlueter, the head mechanical engineer on the project, has made assurances that only one or two processes have been automated in their kitchen and that humans are still as vital as ever. He said:

“Our robotic kitchen was designed to be a tool. At our restaurant, our robotic kitchen allows our managers to focus on making our bowls look beautiful, applying the finishing touches, and being creative. We also have a commissary team that preps our ingredients for the robotic kitchen. We’ve designed the robotic kitchen to work in harmony with

Works Cited

Coxworth, Ben. “Restaurant Keeps Its Prices down – with a Robotic Kitchen.” New Atlas - New Technology & Science News, New Atlas, 29 May 2018, newatlas.com/spyce-restaurant-robotic-kitchen/54818/.

“Las Vegas Food Service Workers Are Going on Strike so They Don't Lose Their Jobs to Robots.” Futurism, Futurism, 29 May 2018, futurism.com/las-vegas-food-service-workers-strike-automation/.

“Spyce Restaurant Opens with Robotic Kitchen Ready to Serve.” Should the Federal Government Raise the Minimum Wage to $15? - MIT Sloan School of Management, mitsloan.mit.edu/newsroom/articles/spyce-restaurant-opens-with-robotic-kitchen-ready-to-serve/.

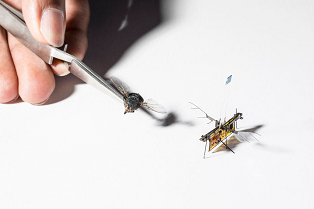

Ahead of the International Conference on Robotics and Automation in Brisbane, Australia, a group of engineers from the University of Washington have announced something that might have tongues wagging at the conference.

They are releasing a study they have conducted that will show the feasibility of wireless, flying, robot insects.

Looking like something out of the film ‘Eye in the Sky’ the engineers have created the world’s first wireless flying robot insect. The engineers have said this is “one small flap for a robot” and “one giant leap for robot-kind”.

The video they have released shows the robot flapping its wings quicker than the eye can see. When slowed down, the robot’s wings look eerily similar to that of a fly’s wings. And have aptly dubbed the robot, ‘RoboFly’.

How it flies

The methodology behind how it flies (how it is powered) is impressive. The engineers have devised a scheme whereby a laser beam is pointed at a photovoltaic cell positioned on the fly’s back.

The assistant professor who co-authored the study, Sawyer Fuller, works in the University of Washington’s Department of Mechanical Engineering. He said:

“Before now, the concept of wireless insect-sized flying robots was science fiction. Would we ever be able to make them work without needing a wire? Our new wireless RoboFly shows they’re much closer to real life.”

Enlisting the expertise of the Electrical Engineering department at UW, the robot utilizes a specially designed circuit that takes the current being produced by the laser beam and the photovoltaic

Johannes James, the lead author, explains how the wings use all of the produced energy:

“To make the wings flap forward swiftly, it sends a series of pulses in rapid succession and then slows the pulsing down as you get near the top of the wave. And then it does this in reverse to make the wings flap smoothly in the other direction.”

Refining how the fly uses its wings will be the main focus going forward. Because of its size, the robot is unable to use any other method of levitating - the wings are its only low-weight solution. Nonetheless, the progress that the University of Washington’s engineers

“You could buy a suitcase of them, open it up, and they would fly around your building looking for plumes of gas coming out of leaky pipes. This is inspired by real flies, which are really good at flying around looking for smelly things. So we think this is a good application for our RoboFly.”

Developing these kinds of robots is important

Works Cited

Grossman, David. “Watch a Laser-Powered Robotic Fly Take Its First Flight.” Popular Mechanics, Popular Mechanics, 16 May 2018, www.popularmechanics.com/technology/robots/a20717355/robotic-laser-fly/.

“Wireless Robot Fly Undertakes First Independent Flight.” Interesting Engineering, 17 May 2018, interestingengineering.com/wireless-robot-fly-undertakes-first-independent-flight.

If you start an engineering company today a lot of your operations - both on-site and at the enterprise levels of your business - are vulnerable to being hacked. This is due to the number of technologies which are connected to a cloud-based or internet-connected framework.

The infrastructural technologies of the world are not the only entities under attack - the data the technologies generate and the general data that

The topic of data protection became compelling when companies like Facebook - who have the data of more than 1 billion people - allowed data to be sold to bidders. The issue, therefore, needs to be two-pronged; companies need to establish an ethical approach to handling data and a new band of engineers, the data protection engineers, need to carefully secure data so that it cannot be stolen.

Protecting individuals

Whilst complex security solutions for utility-scale technologies are designed and implemented, individual data - that we humans freely give to every new app that emerges - is undergoing new levels of protection.

You may have received an onslaught of emails recently from the services you have signed your data away to. This would have been due to the European Union’s new General Data Protection Regulations (GDPR). And whilst it may seem that only Facebook and Twitter need comply with the regulations, the company you work

The regulations insist companies have clarity on the location of their stored data and who has access to it. The personal data of individuals within companies has to be adequately protected unless they want to risk being fined by the relevant authorities.

Companies doing business with clients and customers in the European Union need to, as PricewaterhouseCoopers puts it, “make changes to their data privacy, technology and oversight processes”.

Similarly, those investing in a company need to be protected.

Under the new regulations, individuals may ask a company to remove any of their details from databases unless their details are legally required.

If a cyber-attack occurs, and data is compromised, a company must alert authorities within 72 hours.

The new regulations essentially ensure a client’s right to be forgotten when they cease being a client. The party involved can contact the company and ensure that all traces of their data are eradicated from all servers the company has.

Non-compliance could lead to fines of up to 4% of a company’s annual worldwide revenue. PwC reports that in the United States, 3 in 4 companies will invest up to US$1 million in an effort to be GDPR compliant.

Companies who believe they already have a reasonable level of protection for the personal data of their staff and clients can rest easy for now.

Works Cited

Nadeau, Michael. “What Is the GDPR, Its Requirements and Deadlines?” CSO Online, InfoWorld, 23 Apr. 2018, www.csoonline.com/article/3202771/data-protection/general-data-protection-regulation-gdpr-requirements-deadlines-and-facts.html?page=2.

PricewaterhouseCoopers. “SA Companies Doing Business with EU Customers Need to Consider Making Changes to Their Data Privacy.” PwC, www.pwc.co.za/en/press-room/sa-companies-

While Perth is known for its beaches, wildlife and hiking trails, the cold and wet weather doesn’t always make these activities seem so appealing. So, we’ve come up with a list of things to do which will keep you warm and dry this winter.

AQWA

The Aquarium of Western Australia is passionate about generating respect for marine life through their education programs, rehabilitation of sick and injured animals and conservation efforts. Their exhibits feature marine life from five different zones: the great southern, shipwreck coast, Perth coast, the far north and the danger zone. These include one of the world’s largest living coral reefs, fish, sharks, rays and turtles. It also features Australia’s largest walk-through aquarium tunnel.

There are a number of experiences on offer at AQWA as well. These include diving, snorkelling and behind the scenes tours.

AQWA is located at Hillarys Boat Harbour, approximately 20 minutes north of the Perth CBD.

Perth Mint

The Perth Mint was opened in 1899 in response to the discovery of gold deposits in Kalgoorlie and Coolgardie. It was used for gold refining up until

The Gold Exhibition tells the story of the search for gold in Western Australia through a series of photographs, artefacts, multimedia presentations and gold mining legends. Meanwhile, you can also watch a traditional gold pour in the original 1899 melting house, during which the molten gold transforms into a solid bar.

Another major attraction is the Guinness World Record-holding Australian Kangaroo One Tonne Gold Coin. This is the world’s largest and most valuable coin, made out of 99.99% pure gold and measuring 80 cm wide by 13 cm deep.

Girls School Cinema

The people behind Fringe Festival and Rooftop Movies are opening a new pop-up cinema this winter, and it will be showing a combination of blockbuster, classic and arthouse films. Located in one of Perth’s most beautiful buildings atop the highest part of East Perth, it was formerly a girl’s school and police station. The castle-like structure is iconic for its Egyptian Art-Deco grandeur.

Just like at Rooftop Movies there will be plenty of food trucks, this time offering up foods perfect for winter including toasties, soups and popcorn.

The Swan River Colony was settled in 1829, and in its first 60 years Western Australia made little progress. In 1881 the state had a population of less than 30,000 people, however by 1911 the

population had grown to 282,000. This was a result of the gold mining in the eastern “desert” from 1893, which drew people from across Australia and the rest of the world. The scarcity of water in the Goldfields area caused many deaths and the rapid spread of disease, so the government decided they needed to implement a scheme to address this problem.

Western Australia’s Engineer-in-Chief C. Y. O’Connor proposed the construction of a 30 metre high dam, 521 kilometres of steel pipeline and 8 steam-driven pump stations with associated reservoirs. He was met with criticism due to the cost of the project and the fact that many people believed this plan wouldn’t work. However, construction of the Mundaring Weir and Coolgardie Pipeline still went ahead.

One of the reasons this project was considered significant by Engineers Australia was because the construction occurred during a time when Western Australia lacked its own resources. This meant the cement, steel and machinery had to be imported from Europe and timber had to come from the United States. As a result, it took between six weeks and three months for the materials to arrive. Despite this, it took just under five years for the project to be completed. This was due to the successful leadership of those directing the construction and the large workforce who contributed.

There were also no tertiary or technical education facilities in the state at the time; however those working on the construction of the pipeline utilised innovative technologies. For example, this construction developed the practice of using thin-walled steel pipes to deliver water to remote areas with arid conditions, typical of Australia.

On completion, the dam was the largest in the southern hemisphere and the pipeline’s length was unprecedented. The project ensured the viability of the settlement in the Goldfields area by providing a reliable water supply. This greatly boosted the development of Western Australia.

Today, the Mundaring Weir is still in use and located in the Darling Ranges escarpment. It’s a popular picnic spot and close to natural hiking trails in the surrounding Perth Hills.

Perth is home to many natural attractions, including bush walks, beaches and waterfalls. Here are some of the top places you can visit for free.

Kings Park and Botanic Garden

This is one of the largest inner city parks in the world, boasting a total area of 400.6 hectares. The landscape is made up of a combination of cultivated gardens and natural bushland, featuring 319 species of native plants and approximately 80 bird species. There are a number of attractions you can enjoy at Kings Park , such as taking a guided tour to learn more about the area, or following one of the trails. The Lotterywest Federation Walkway takes visitors through the botanic gardens and up into a canopy of trees. The trail begins at ground level and then travels up into a glass and steel footbridge, with a maximum height of 16 metres. It offers a panoramic view of the city and the native flora throughout the park.

The park also features a number of places which honour Indigenous culture , such as the Aboriginal Art Gallery, the Beedawong amphitheatre and the Boodja Gnarning Walk. There are also a number of memorials and honour avenues —the most famous one is the State War Memorial Cenotaph, which attracts over 40,000 people for the annual ANZAC Day Dawn Service.

Free City Walking Tours

These walking tours are helpful for people who are new to the city and looking for an orientation, or those who would like to learn more about the history, arts and culture in Perth. The iCity Information Kiosk is located in the Murray Street Mall and the volunteers are available to provide visitors with information about events, activities and attractions. They also offer brochures for self-guided tours.

Stirling Gardens

When the Swan River Colony had first settled, this spot was established as an acclimatisation garden, where plants were raised from seeds. This included grapes and other fruits. In 1845 it was opened as a botanical garden and some of the original trees still remain here today. It underwent reconstruction work in 1965, to add a retaining wall and shallow pools of water. It’s now the oldest public garden in Perth and features a number of artworks and sculptures.

Bells Rapids

This natural attraction is located in Brigadoon in the Swan Valley and features picnic areas and bush walking trails alongside streams and waterfalls. It’s also a prime location to watch the annual Avon Descent White Water Race, although swimming is not permitted in the area. The grey kangaroo can be spotted here at certain times of the year.

Lesmurdie Falls

This waterfall is located in the Lesmurdie National Park in the Perth Hills and is considered to be one of the most spectacular features of the Darling Ranges escarpment. The trail begins at the top of the falls and can be followed down to the base, where there is lush vegetation and a picnic area. At the top of the falls there is a lookout, so you can get a perfect view of the area. The trail is considered moderate in difficulty and is approximately 2 kilometres long.

Mount Dale Walk Trail

This 2.5 kilometre trail allows hikers to walk up to Mount Dale’s peak, so they can get panoramic views of the Darling Ranges in the Perth Hills and experience the beauty of the natural jarrah forest. The circular walkway goes up through bushland to the lookout, before meeting up with the Bibbulmun Track upon descent. It is considered to be of moderate difficulty.

Visit one of Perth’s Beaches

Perth is known for its sunny weather and beautiful coastline, so why not visit one of the many beaches? There are fantastic beaches from Fremantle to Burns Beach, however the most popular are Cottesloe, Trigg, Scarborough, Leighton and City Beach.

Swan River Loop

Cycle around the Swan River and take in the sights of Elizabeth Quay, Barrack Street Jetty and the South Perth Foreshore. This is a great way to see Perth city and enjoy the outdoors at the same time. The pathway is considered easy and can even be completed on foot. Remember, it’s compulsory to wear a helmet if you do cycle.

Sunset Coast Cycleway

A 14 kilometre cycleway follows Perth’s stunning coastline from Marmion to Burns Beach. This half-day cycle takes you past highlights including the Marmion Marine Park, Hillarys Marina and Mullaloo Beach. You can also walk or jog sections of the path.

The port city of Fremantle is located approximately 25 minutes from Perth’s CBD and has played a large part in Western Australia’s history. In 1829, Captain Charles Fremantle claimed the West Coast of Australia under the British Crown. That same year, the first British settlers arrived on the shores of the Swan River and began to establish a colony, led by Governor James Stirling.

The Swan River Colony was unique, because it was built by free-settlers — civilians and military — rather than convicts. However, the colony struggled and manpower was needed to build the infrastructure required to ensure its success. As a result, convicts were sent to Western Australia from 1842 and constructed some of Fremantle’s most distinguished heritage buildings, including Fremantle Prison and Fremantle Arts Centre. During this time, the colony expanded 20 kilometres from Fremantle to Perth. Fremantle is also home to two of Western Australia’s most impressive engineering feats : the Stirling Bridge and the Fremantle Harbour.

The Stirling Bridge

Since the colony’s inception, a key focus was on building a bridge over the Swan River to connect Fremantle and the Perth township. Without one, the only way to cross between the two banks was by ferry. The first bridge was built out of timber by convicts in 1867 and named the North Fremantle Bridge, which was later changed to the High Level Bridge.

The first stage of the Eastern Railway was constructed in 1881, linking Guildford and Fremantle. As part of this project, a railway bridge was built in 1880. It was built with much stronger timber trusses than the High Level Bridge to carry the weight of the tracks. Fremantle experienced an economic boom in the late 1800s as a result of the gold rush and significant wheat production and the port became a gateway to the goldfields and agricultural lands. In 1895 a second railway bridge was built to carry stone from the quarry. These bridges were replaced by a new railway bridge in 1964, which is still in use today.

The economic boom led to increased commercial traffic, so a wider and stronger bridge was constructed just downstream from the High Level Bridge in 1898 — it was named the Low Level Bridge. However, it was designed as a temporary structure to replace the High Level Bridge while it was being renovated and widened. These renovations took place in 1909 and the temporary bridge was closed as a result. The High Level Bridge lasted for a total of 73 years, before finally being decommissioned after the Fremantle Traffic Bridge was constructed in 1939. It was eventually demolished in 1947.

In 1974, Fremantle’s newest bridge was constructed 3 months ahead of schedule and received two awards and one award nomination for its design. The Stirling Bridge’s construction was considered significant because it was the first time a computerised wave formula was used to confirm a structure’s properties in a major civil engineering project in Australia. Another noteworthy point about the structure is all 292 of the segments were precast offsite to ensure each one was constructed within tight measurement constraints. As a result of this planning, not a single unit was rejected. The Stirling Bridge was also praised for its aesthetic design, which was achieved through analytic advancements in calculating shear transfer. At the time of its construction it was the longest bridge in Perth.

Fremantle Harbour

When the first British settlers arrived at the Swan River Colony they took shelter at Garden Island to protect their boats from gale winds. This emphasised the need for a breakwater to be built at Fremantle, however for the first 60 years the colony’s growth was hindered due to the lack of a harbour.

There were two jetties built at Fremantle in 1832 and 1854 respectively, yet the first substantial structure wasn’t built until 1872. It was named the Ocean Jetty. In 1891, C. Y. O’Connor was appointed Western Australia’s Engineer-in-Chief and he proposed a scheme for the development of a harbour at Fremantle . This was becoming progressively more important as the gold rush in Kalgoorlie significantly increased trade through this port. In 1892, the project began. It involved dredging a rocky bar to create a channel and dredging the river bed to create a deeper basin. Two moles were also constructed at the entrance of the harbour. The Ocean Jetty was extended to 1100 metres in 1896. The entire project was completed in 1897.

This project is considered significant by Engineers Australia because it’s “an example of superior assessment of oceanic factors.” For example, the breakwaters were the first case of large scale use of random tipped rocks in Australia. This project also introduced a major construction plant to Western Australia and required the management of a large-scale construction force and integration with the infrastructure of the small colony. It exceeded most other Australian ports of its time. Perhaps the most impressive part is that it hasn’t required any major maintenance or modifications in the past 100 years, despite ship growth and variety.

With population numbers expected to rise exponentially, and the global growth of the middle class to continue, the topic of the sustainability of resources becomes more pertinent. More cities are needed, functioning infrastructure must be available, and it must all reflect the hallmarks of modern civilization.

However, it has become apparent that populations are growing faster than cities can be constructed.

Some philosophers and thinkers have started looking to the sea to solve some of these problems. And if their ideas are to become reality, it should present civil engineers some unique challenges. The main challenge: how to build a floating city.

The result is a futuristic movement blending civil engineering and marine engineering; seasteading.

A case for floating

Blue Frontiers, a Singaporean startup has linked arms with a California-based nonprofit named the Seasteading Institute to make seasteading a reality in the near future. They are formalizing their efforts on a project dubbed ‘The Floating Island Project’.

Thanks to their unique governing frameworks, these floating cities will create utopias, says the company’s promotional material.

“Seasteaders plan to provide you with the technology to found your own floating nation on the ocean. And seasteading is already happening,” said president of the Seasteading Institute Joe Quirk, at a futurism conference named Voice & Exit in 2015.

Quirk explains that floating cities are not a new idea - engineers have been engaged in building floating communities for a variety of reasons.

Shell has a floating liquefied natural gas (FLNG) facility 475km north-north east of Broome, Western Australia. It is the largest floating facility ever built and is an indicator that a floating life at sea is possible. The floating facility employs 260 local workers. The facility will produce liquefied natural gas for the next 25 years.

Similarly, cruise ships are commonly referred to as floating cities. The existence of floating nuclear-powered military submarines, ships and even floating nuclear power plants are becoming a reality.

“Nearly half the world’s surface is a blank slate, unclaimed by existing governments, and we want to create a thousand startup governments on the sea,” Quirk said. A floating city might also have a unique advantage that may just attract the environmentalists; solar power.

Engineers are currently building an energy producing system utilizing a process known as ocean thermal energy conversion (OTEC). Essentially, it turns the ocean into one big solar panel.

With seawater absorbing a lot of the sun’s emitted energy, the thinking is that the heat at the surface of the ocean can be captured and converted into electricity. The process includes deep cold seawater, heat exchangers, refrigerants, and a turbine. The lead engineers of Makai Ocean Engineering explain in this video:

Soon a reality?

In January 2017, the Seasteading Institute and the government of French Polynesia signed a Memorandum of Understanding, setting the stage for a seastead to be constructed. Blue Frontiers, the company spearheading the project, alongside the Seasteading Institute, must, however, raise all the funds.

The company in charge of constructing the floating city s a company named DeltaSync. Quirk says that humanity could be uplifted because of future floating cities. He is advocating a mantra of ‘ocean first, space second’.

He also reflects on rising sea levels in French Polynesia, thanks to global warming. A future which includes floating cities could save entire communities from being swept away by the ever encroaching sea.

“Is it doable? We walked on the moon 45 years ago. It’s easier to float than fly. It’s cheaper to build seastations than space stations.”

Blue Frontiers has even created its own crypto-currency for the floating city they plan to build in French Polynesian waters. They hope to have a functioning example by 2020, but still have a long way to go and a lot more money to raise before the project truly sees the light of day.

Quirk believes they could have a functioning floating city completed by 2050 if all goes according to plan.

However, Silicon Valley billionaire investor, Peter Thiel, is a little skeptical, he feels that the seastead is “not quite feasible from an engineering perspective”. He previously invested $1.7 million into the Seasteading Institute but has since extricated himself from the project.

Nonetheless, engineers are at the forefront of creating sustainable solutions to the world’s most pressing problems. With technological growth experiencing great leaps every decade, which in turn is making technology much more affordable, solutions to dire infrastructural problems are being presented.

Works Cited

“Atlantis Rising: Why Floating Cities Are the Next Frontier (Joe Quirk).” YouTube, 16 Mar. 2015, youtu.be/Jr8Iw4o7Gic.

“Prelude FLNG.” Shell Global, www.shell.com/about-us/major-projects/prelude-flng.html.

As Vladimir Putin gets another six years in the seat as the Russian President, Russian engineers tow something through the Baltic Sea, something the world has never seen before.

The metal giant in tow has the symbol of an atom tattooed to its exterior, which onlookers know can only mean one thing; it’s nuclear. The Russians correctly assert that it will be the world’s only functioning floating nuclear power plant. Floating nuclear technologies are not new, but this is an impressive feat of engineering.

Russia’s state nuclear power company Rosatom is behind the construction of the unit.

Construction on the unit began in 2009 - the first stage of the build does not include any nuclear fuel. But, in 2019 it will reach stage two. The Deputy Head of the Directorate for the Floating NPP Construction and Operation Dmitriy Alekseenko said:

“At the first stage, the FPU with no nuclear fuel on board will be towed from the territory of Baltiysky Zavod to the landing of Atomflot FSUE in Murmansk. Then, at the second stage - roughly in the summer of 2019 - it will be sent from Murmansk to the seaport of Pevek, loaded with nuclear fuel and with the crew on board.”

Its final destination will be the Arctic town of Chukotka.

Critics abound

Russia is not a stranger to media coverage, much of which is overly negative. As a consequence this new floating nuclear power unit has been dubbed the ‘floating Chernobyl’. Greenpeace went as far as calling it ‘Chernobyl on ice’.

Some critics have said taking a nuclear reactor to an Arctic town may pose a danger to the environment. But Rachel Becker, writing for the Verge, makes a pertinent point - some critics are making risk assessments on the project, but conveniently overlooking the fact that submarines have been powered by nuclear means for 60 years.

Furthermore, experts warn that judging one nuclear plant by heavily publicized historical plant meltdowns is damaging the future of an energy source that should be part of a country’s energy mix.

Usefulness

According to Rosatom, the floating nuclear unit would be providing electricity for 100,000 people through its 70 megawatt capability. After the nuclear unit goes live in the coastal town of Pevek, it will be the most northerly located nuclear plant in the world.

The Russian government doesn’t intend slowing down; the Akademik Lomonosov is one of many mobile transportable low-power units planned to provide electricity. The mobile units can be used to power “remote industrial plants, port cities” and offshore gas and oil platforms.

The mobile unit currently traversing the Baltic Sea is a Floating Nuclear Thermal Power Plant (FNPP). The nuclear reactors the plant will utilize include technologies first devised in 1980 to power Russian icebreaker ships.

Bringing ship building and nuclear technologies together is now the pride of Russian engineers. To attempt to quell critics of the technology, the engineers of the state-run nuclear company put out some assurances in a press release:

“The FNPP is designed with the great margin of safety that exceeds all possible threats and makes nuclear reactors invincible to tsunamis and other natural disasters.”

Works Cited

Becker, Rachel. “The Scary Part of the Russian Nuclear Power Plant Isn't That It Floats.” The Verge, The Verge, 2 May 2018, www.theverge.com/2018/5/2/17313174/floating-nuclear-power-plant-russia-academik-lomonosov-chernobyl-titanic.

“The World's Only Floating Power Unit 'Akademik Lomonosov' Takes the Sea.” Benefits of Nuclear Energy, www.rosatom.ru/en/press-centre/news/the-world-s-only-floating-power-unit-akademik-lomonosov-takes-the-sea/.

A vast number of jobs are potentially on the chopping block in South Africa: engineering professionals, senior project managers, energy storage specialists, coal truck drivers, technicians, asset managers, operations officers, and others. They are seriously threatened if the state-owned power utility, Eskom, restructures its operations.

Presently it powers 95 percent of South Africa, but it is not looking good. It is struggling to weather historical maladministration, a failed nuclear deal with Russia, crippling debt and a change of presidents. Electricity distribution is once again under the microscope.

The situation is looking particularly dire as the country moves into their winter months. Three managers at the company were recently suspended, deemed responsible for coal shortages, and the utility is also without a CEO at the moment.

Up for debate?

To ensure an ongoing electricity supply in the country an open public debate was held in Johannesburg earlier this month. It was tasked with asking the pertinent question: ‘Should Eskom be restructured and if so how and when?’

Frans Baleni, the Deputy Chairman of the Development Bank of Southern Africa and former Secretary-General at the National Union of Mineworkers (NUM) argued that the utility has served South Africa well; he believes it is impossible to turn back from the network footprint it has.

He says that Eskom has a solid fleet of generation plants, but concedes that they are now aging and need to be upgraded.

He says that Eskom has a solid fleet of generation plants, but concedes that they are now aging and need to be upgraded.

He warns that a complete restructuring of the utility would put 40,000 jobs at stake. He proposes that the utility deals with governance issues, focuses on building investor confidence and deals with corruption decisively, so that business performance can be prioritized.

Miss Nelisiwe Magubane was also one of the speakers at the debate. She is a Non-Executive Director of Eskom and Former Director-General at the Department of Energy. She is an electrical engineer with 25 years of experience. She is a key player in energy policy in the energy sector. She has also been named as one of the top 50 most influential people in the energy sector in South Africa.

She commented that those countries with a more privatized energy sector had superior systems, when compared to the vertically integrated state-owned utility business model. However, she thinks the terms and conditions surrounding the privatization of the energy sector in South Africa should depend on whether a private system would lead to the lessening of inequality and poverty.

She said:

“What kind of industry structure is going to meet our objectives? You need skills, you need drive, you need financial astuteness. We need to have a proper governance of the energy sector. It needs to be beneficial for all South Africans.”

Dr Grovè Steyn, a graduate from the University of Cape Town and the University of Sussex, was the last speaker at the event.

Steyn started his career as an Industrial Engineer at Eskom. He went on to become a leading infrastructure and regulatory economist in South Africa. He is currently the Managing Director at Meridian Economics. He says undoing the 95 year institutional model of Eskom is going to be a tough process, but it has to be done. He explained:

“This institutional model has long since outlived its usefulness. It has now become critical for South Africa to embrace the technological disruption and address the environmental imperatives in the power sector.”

Steyn says Eskom’s ‘abuse of dominance’ in South Africa has led to ‘managerial moral hazards’. Citing numerous studies, Steyn highlighted the ‘human cost’ of coal power stations - explaining that coal power reportedly kills 2,000 people in South Africa per year.

Steyn advocates for clean, renewable energy sources. He notes that the reduction of costs in technologies such as solar and energy storage means governments have little choice but to use the cleaner alternatives in new energy project builds.

He also wants the energy sector to open the industry up to new players, to move away from the state-owned monopoly. More choice, more competition and a democratized energy industry can’t be a bad thing.

“It is now globally recognized that electricity generation is best organized as a competitive sector. And our own experiences with our IPP program supports this very strongly.”

Where are the jobs being created?

Power sector talks, which are now a national conversation, are pressing for the sector to be overhauled. South Africans need to ensure they are skilled-up to deal with the newer power generation technologies, and the jobs that are created through them.

Some of the traditional jobs will begin to dwindle; coal truck drivers are particularly concerned that they will be made redundant. Already Eskom has said it wants to shut down four coal power stations by 2020. In their stead the country is asking renewable energy providers to apply for tenders to create renewable plants in South Africa.