News

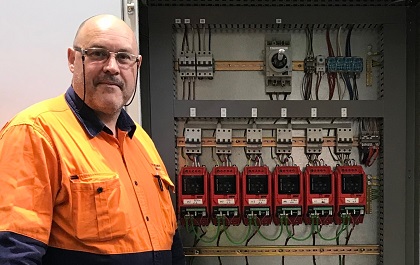

On Friday, 23rd November, at the Engineering Institute of Technology’s Graduate Gala Event in Perth, Brian Lord was awarded the 2018 Graduate of the Year. He recently graduated from the Engineering Institute of Technology’s Advanced Diploma of Applied Electrical Engineering (Electrical Systems).

There are two reasons why this is remarkable: firstly, he now has another qualification under his belt and secondly, he worked full time while he studied. Like many EIT students, Brian had to become an even more astute juggler — he is also a husband, a father of three, a father-in-law and a grandad to two grandchildren.

Brian lives in a small regional city on the Victorian – NSW border in Australia, named Echuca, boasting a population of around 14,000 where he is an electrician by trade.

Despite enjoying his work and having worked Australia wide, he began searching for something that could really challenge him and boost his career. Brian has hankered after becoming an Electrical Engineer, but wondered how he could ever do the required study and retain his job. His employer, Foodmach Pty Ltd, to his surprise, agreed to support his ambitions.

“I’ve never heard of an employer in a small regional city giving a 52-year old employee that sort of an opportunity before; so I grabbed it with both hands, heart, head, and feet,” he said.

Brian applied for EIT’s Advanced Diploma because the learning platform is online and flexible, allowing him to continue working without the need for time off work to attend classes. EIT’s approach to learning is also very interactive; the instructors run tutorials in real-time and students interact with the instructors and each other.

“When I researched every Univeristy I could think of in Australia there was 'not one' that had this complete online platform for Electrical Engineering. I’d almost given up until at the request of my manager Gavin Alder, I researched for one more week,” he said.

“Low and behold I found the Engineering Institute of Technology online AND they offered 'exactly' what I’d been looking for.

“As much as my employer Foodmach was already prepared to support me, this also really helped to sway them all the way, without any worries about labour re-scheduling for schooling time off.”

Brian describes the course as the 'light bulb' that changed his electrical life and opened his mind. Having covered variable speed drives, induction motors, mathematics and much more, he reflected back to his trade school days and wondered why they hadn’t included some of EIT’s modules.

“The knowledge and skills alone, gained with the completion of the Advanced Diploma of Applied Electrical Engineering, has given me a considerable boost in confidence at work as a Trainee Electrical Engineer,” he added.

“I now find others, whom I consider more experienced in the electrical field, regularly seeking my advice; this has given me added confidence.”

Watching his progress through the course and noticing his growth in knowledge and skills, his employer tasked him with the electrical design of three new, small to medium sized projects.

Like most EIT students before him: holding down full time work and embarking on a new qualification, Brian found the new academic lifestyle something to get used to.

“A huge challenge for me as a 52-year old, going back to study whilst working full-time, was arranging and organising my time much better.”

The online delivery of EIT’s modules was an interesting beast to tame, but Brian eventually got the hang of it. He built up a rigorous study routine which included extensive note-taking during webinars, re-watching webinars three or four times, and attempting to ensure he had a clear understanding of all the information he was being presented with.

His resilience and determination resulted in him achieving some of the highest marks in his class.

Brian’s successes prove that you can indeed teach an old dog new tricks. He concludes:

“I’m absolutely stoked to now call myself an 'Associate Electrical Engineer'; recognised by Engineers Australia and to add these post-nominals after my name, Grad AIE Aust. This now helps me get into the next stage of my career; studying a Bachelor of Science to become an 'Electrical Engineer'.”

Now at 53-years of age, Brian appears to be as motivated as ever to achieve; part of the reason why EIT has honored him with the award. And we wish him all the very best with both his career and the next phase of his studies.

On Friday 23rd November the Perth team at the Engineering Institute of Technology was all dressed up and in celebration mode: we were delighted to be gathered to congratulate our 2018 Australian graduates.

A number of these clever people had convened, from all around Australia, and were also joined by Algate Mtemah, a student who had flown in from South Africa.

We not only celebrated the graduates themselves, their persistence and hard work, but also their incredible families and friends. It is their love and support which helps our online students through the gruelling hours of study, before or after their working days.

All of our students deserve recognition, but the Australian Graduate of the Year was ultimately awarded to Brian Lord. He graduated with an Advanced Diploma of Applied Electrical Engineering and this is what he said about it: “It was the ‘lightbulb’ that changed my electrical life and opened my mind.” He went on to ask, “…why a good portion of the study wasn’t taught to us at Electrical Trade school? It was highly relevant and would’ve opened my mind many years ago.” Despite being 53 years old he is filled with renewed confidence and looks forward to starting the BSc in Electrical Engineering.

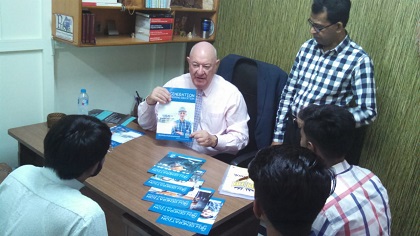

The graduates were addressed by a number of speakers. The Dean of Engineering at EIT, Dr Steve Mackay, reminded them to hone their communication skills and keep abreast of developments in their fields.

Mr Ron Manners, Chairman of the Mannwest Group and the Mannkal Economic Education Foundation, has life and business experiences which are legendary. He encouraged the students to always find perspective; he reflected on our ability to smile at our earnest endeavours when we look back.

The students also heard from Mr Cameron Norsworthy who spoke of ‘flow’- those moments when work flows efficiently and effectively, free of interfering doubts. He conceded that being well-prepared was a prerequisite.

One of our lecturers, Partha Dev, pointed out that despite their dedication and love for all things technical, engineers need to nurture their emotional intelligence - a critical asset in all our professional and personal lives.

Finally, Engineers Australia was ably represented by Mr Paul Young, President elect of the Western Australian division. His experiences in the engineering trenches proved valuable to the students.

It was a lovely evening celebrated at the newly opened EIT campus in East Perth. And it was fitting, therefore, to welcome some of our on-campus students to the event, to help us congratulate the graduates. Two of our young students were then surprised to receive awards for excellence, Victor Onoja and Binod Tamang, studying towards their Bachelor and Master degrees respectively.

Congratulations to all our EIT graduates, wherever you are based, and thank you for selecting to study through EIT. Please keep in touch with us - let us know what you are up to and how you are faring in your engineering careers.

Johannes Kapeuasha is a graduate from the Engineering Institute of Technology and at our 2018 African Graduation Gala in October he was awarded Graduate of the Year.

After completing high school in 2007 he enrolled at a college in Bulawayo, in Zimbabwe. Here he completed a certificate in computer science (database systems) and then another one in 2009 which certified him to work as a computer technician. He worked in the field for a year, but felt he needed to learn more and kick-start his career. He said:

“I decided that I wanted to be part of the robotic and artificial intelligence revolution. For me, to be part of this revolution, I immediately realized that I either had to do software engineering, electrical engineering, or mechanical engineering. I ended up choosing electrical engineering.”

He joined the Namibia Institute of Mining and Technology (NIMT) and began studying towards the Electrical Engineering Millwright Trade. At the same time he began an internship at Namibia Dairies where he was exposed to the industrial side of the industry. In the last year of his internship in 2014, just before his trade test in 2015, he enrolled for a National Diploma in Electronic Engineering at a South African college named INTEC College.

He passed his trade test on his first try and graduated from INTEC in 2016.

Johannes is a true believer in the opportunities that education offers (and is certainly not afraid of hard work). He has since graduated from the Engineering Institute of Technology; he completed the Advanced Diploma of Applied Electrical Engineering (Electrical Systems).

While studying with EIT (which is structured to allow students to also work full time), he realised that there was something preventing him from thriving. He said:

“The job market in Namibia at the time was not favourable. It was really hard to get jobs at that time; however, I was able to make a living as a private electrical contractor, until the situation became so desperate that I was not able to get small jobs anymore.”

As a result, Johannes settled for a security guard job for a local company named Inter Africa Security Services and then later, Omega Security, which helps protect one of the busiest malls in Windhoek, in Namibia. While with this company, this year, Johannes’ luck turned around: Omega Security promoted him to the Industrial Security System Technician role. And he is enjoying his work:

“I love hands-on tasks. I love solving technical problems and having a chance to work in the field that brings me fulfilment each and every day. Technology is really growing fast, and changing everything around us and how we interact with our environment. I am truly fortunate to be part of one of the recent developments - remote arming of home security systems.”

At our Graduation Gala in South Africa, Johannes was overjoyed to be named 2018 Graduate of the Year. He is pleased to have been rewarded for his efforts in the face of overwhelming financial hardship and challenging time constraints.

“What my engineering career has taught me, if I were to sum up my career thus far, is not to be afraid and to work hard. Do not look at other professions and look down at them. Every industry needs an engineer. If you believe in something, go for it - do not let anyone say you cannot do it. You can achieve great things; all you need to do is just believe. I am living proof that anyone can achieve anything they put their minds to. Do not be afraid to dream...dream big.”

Johannes is determined and believes in himself, but these alone have not been enough to enable him to achieve all that he has. He makes it clear that without the support of those closest to him none of this would have been possible.

He wanted us to include a “special tribute to the people who made me who I am today.” His special thanks go to his mother, Mrs. Menete Kapeuasha, to his sister, Josephina Kapeuasha, to his faithful best friend, Ms. Bella Kavungo, and to his manager, Mr. Francois Van As.

Congratulations Johannes, from all of us at EIT, and our heartfelt thanks also go to your wonderful support team.

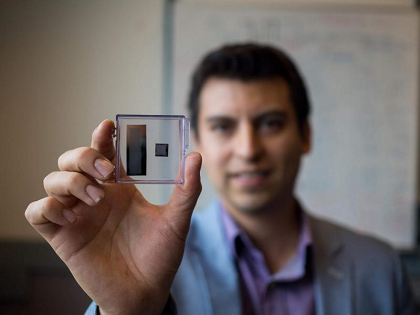

At TEQSA’s third annual conference in Melbourne, at the end of November, Dr Steve Mackay presented a paper on the Development of a Career Advisory Site; it summarised his research to date - applying machine learning techniques to millions of job adverts around the world. Caroline Patterson also attended the conference and interacted vigorously at the QA Online Learning Forum.

Despite the software still being in its infancy, Steve’s presentation (his latest project) involves the creation of a site which is able to collate and update real time job postings.

He believes it will have varied applications, but trusts it will also provide education regulators, including TEQSA and ASQA, with an objective means of measuring and assessing the value of proposed courses - courses that are currently relevant in the marketplace and courses which will enable graduates find work in their fields of study.

With the chatter about jobs being hollowed out, in an age when technologies are changing rapidly, Steve also anticipates the site becoming a useful guide to students, and indeed to those already working. It will provide them with an idea of the existing and emerging job opportunities wherever they live in the world.

The reputable marketing analytics company, Burning Glass, estimates that up to 85% of jobs are now posted online. It was this statistic which spurred Steve on. He realised that sophisticated ‘web spidering’ and machine learning techniques had the capacity to access up-to-date job information, for each key location in the world, and provide a real time source of data.

He has used the ubiquitous Python language, with its machine learning libraries, to classify the huge array of engineering and technology job data.

Natural language processing was then used to identify specific skill and knowledge requirements. This has been useful in summarising what a specific job requires in one city versus the same job, but with different requirements, in other cities.

Then, to ensure readability, Steve used a simple dashboard to include the job title, occupation details, proposed salary, the employer and the location. This will be released in a full online version in late December 2018.

In our modern world immediacy and convenience are expected. This career advisory site will tick both boxes for educators, regulators, would-be students, graduates, job seekers and those looking for a career change. They will have - at their fingertips - access to current information on job vacancies, across the different disciplines, worldwide.

The technological advancement in education has lagged behind other industries. Yet there are technologies available that would transform the classroom, the lecture hall, or even a person’s home, and ultimately transform learning.

The Future of Management Education Alliance wants to bring these technologies to the learners of the 21st century. The alliance is headed up by the Imperial College Business School who plan to introduce hologram technology to their MBA students.

The Imperial College Business School has an educational technology lab (Edtech Lab) that assists the school find the kinds of technologies that would better train the students at the institution.

David Lefevre, director of Imperial’s Edtech Lab said: “This gives our teaching staff a sense of presence when talking with students. Otherwise we might as well run a lecture on Zoom.”

Zoom is video conferencing software employed by some institutions to reach their students via the internet and conduct lectures virtually.

Emmanuel Métais, Edtech Labs’ dean told Financial Times:

“This initiative reflects our commitment to be at the forefront of innovation, not only to provide students with a better learning experience but to make them succeed in a fast-changing world. At Edhec, we believe that excellence and innovation are the two pillars on which our people build their own personalities and careers to make an impact on the world.”

Built by engineers, for engineers?

The hologram technology was developed by Canadian company AHRT Media.

Holographic technology can be leveraged to teach students while a lecturer is on the other side of the world. And the technology has come down in price.

It is not inconceivable to think that students may be taught by lecturers who would appear as holograms. And engineering scholars might need it most. Through simulation technology (virtual and augmented reality) engineers can be taught in virtual spaces.

Even though the technology has not been directly targeted at engineering education, it will be in the next few years. Lefevre concludes:

“Introducing hologram technology to the classroom will break down the limitations of traditional teaching by creating an interactive experience that benefits both students and academics. Rather than replacing or reducing real-life lectures, the hologram technology will provide greater flexibility for academics by enabling them to continue teaching whilst travelling, ensuring consistency and quality for students.”

Works Cited

Moules, Jonathan. “MBA Students to Be Offered Hologram Lectures.” Financial Times, Financial Times, 1 Nov. 2018, www.ft.com/content/01749584-dcf9-11e8-8f50-cbae5495d92b.

Singleton, Laura. “Imperial College Business School to Offer Live Lectures via Hologram | Imperial News | Imperial College London.” Imperial News, 2 Nov. 2018, www.imperial.ac.uk/news/188851/imperial-college-business-school-offer-live/.

2018 marked 100 years since the end of World War I. On the eleventh day, of the eleventh month, of the eleventh hour in 1918, the Allies of World War I and Germany signed a treaty that ended the war.

World War I was a turning point in warfare. In its time, it was the most significant war with the most modern warfare equipment ever invented — Mortars, machine guns, rifles, poison gas and the surprising entrant of the flamethrower. But it wasn't just the handheld equipment and biological weapons that were new.

Even light railways were set up between the trenches upon which petrol-powered locomotives could ride and transport both soldiers and weaponry. But the British still needed something that would give them the upper hand on the Germans.

A stalemate on the Western Front, where endless trench warfare was taking place, had produced the need for a new land-based, cross-country vehicle that could breach enemy lines.

The British army then received a shipment of heavy artillery that they had never seen before.

Director of the Lord of the Rings trilogy Peter Jackson has captured some of the mysticism surrounding the arrival of the tanks in his latest documentary on World War I named ‘They Shall Not Grow Old.' Real soldiers whose stories were captured by the Imperial War Museums and sampled in the documentary relayed their stories:

"They were on the roadside covered with tarpaulin sheets. You could see nothing except a square outline."

"And then the officer said, ‘these are supposed to be hush-hush,'" another soldier recalled.

Another said, “When we asked what it was, the simple reply was: tanks. Knowing the shortage of water we had actually assumed water tanks and thought we were getting reserve supplies. It was one of the best kept secrets.”

The engineering of the tank ushered in a new era of mechanized warfare that has continued until today.

Fiction becomes fact

In 1903, H.G. Wells wrote a short story named ‘The Land Ironclads.' In the fictional story he writes about 100-foot-long armored fighting vehicles that would carry key army personnel across enemy lines. Thirteen years later, Wells’ prediction that ironclad machines impervious to machine gun fire would traverse the battlefield came true.

It was actually a young Winston Churchill - who at the time was the First Lord of the Admiralty - that had a hand in the commencement of the engineering of tanks. He set up a top-secret collective in February 1915 named the Landship Committee.

After a spot of trial and error — and a few prototypes went wrong — Sir William Ashbee Tritton (a British expert in agricultural machinery) and Major Walter Gordon Wilson (a mechanical engineer) were the designers behind the world’s first tank. It was named Little Willie, intentionally mocking German Imperial Prince Wilhelm.

The caterpillar tracks fitted on to the first iteration of the tank was good for traversing over land but got stuck when it tried to ride over any of the parapets (a protective wall or earth defense) in front of the German trenches.

The second iteration of Tritton and Wilson's invention was a more rhomboidal shape that had tracks going all the way around the hull. A mock battlefield with a trench even wider than those in the actual war was set up, and the tank was tested. It surpassed expectations. This was the prototype they sent off to the war.

David Lloyd George, who in 1916 became the secretary of state for war wrote: “At last, we have the answer to the German machine guns and wire.”

Another two prototypes were eventually released toward the end of 1917 and mid-1918 respectively. Nonetheless, the tank had woken up the militaries of the world, and in the wars to come, everyone would want one. The rest, as they say, is history.

It is estimated that nearly one million British and Empire servicemen were killed between 1914 and 1918. The total number of military and civilian deaths in the entire war was determined to be between 15 to 19 million people.

Works Cited

“How Britain Invented The Tank In The First World War.” Imperial War Museums, www.iwm.org.uk/history/how-britain-invented-the-tank-in-the-first-world-war.

“They Shall Not Grow Old.” IMDb, IMDb.com, 9 Nov. 2018, www.imdb.com/title/tt7905466/?ref_=nv_sr_1.

With the festive season just around the corner, it might be time to start planning your next vacation. While on holiday, you might be able to admire some impressive feats of civil engineering. That much is true if you're visiting the Maldives this year.

A structural engineer from Auckland is making news around the globe. His name is Michael Murphy, and he has built a hotel...underwater. Murphy is world-famous for his work on aquariums and underwater restaurants. He graduated with a Bachelor of Engineering in civil engineering at Auckland University in 1971.

The new underwater hotel villa has officially opened in the Maldives as a new addon to the Conrad Maldives Rangali Island. It’s named the Muraka. The top level is above water, and the bottom is fully submerged under the sea.

It provides the patrons willing to pay US $55,000 per night, a night's sleep 16 feet down on the Indian ocean floor.

For the hefty price, patrons get access to a 24-hour team of staff, ready to assist guests during their stay. Allegedly, there is access to a personal yacht as well.

The structure cost US $22 million to build. "It's one of the most challenging projects I've had. And super exciting at the same time," Murphy told reporters. It is now considered to be the world's first underwater hotel.

Constructing underwater

Constructing a hotel room underwater was no easy feat. The structure was prefabricated in Singapore. Three sections were assembled atop a barge that was then towed to a crane ship, which was waiting to begin construction at Rangali Island.

Steel piles were embedded into the seafloor, and after that, the two cranes atop the crane ship planted the prefabricated sections of the hotel room onto the steel foundation. The hotel was in the planning phase for 13 years. Finally getting the designs implemented on the ocean floor was challenging. Even marine biologist staff members were part of the process to ensure that the marine world below wasn't damaged by the building of the room.

Murphy told Hotel Designs:

“Site conditions are paramount. This includes tidal range, water depths, protection from storms, storm wave heights, wind loads, type of soil for driving piles, access for big crane ships etc. This dictates freeboard heights, the depth of undersea unit below the sea level, height of stairwell, piling design and everything else. The greater the volume, then the more water displaced, which means more buoyant uplift, which means more weight to hold the unit down so that it doesn’t float.”

The room just happened to be the maximum weight that the cranes could handle; it weighs in at 600 tonnes. A spiral staircase leads from the top level to the bottom level, revealing the 180 degree view of the bottom of the ocean.

Fancy sleeping with the fishes? It is now possible.

Works Cited

Undersea Villa | THE MURAKA | Conrad Maldives Rangali Island Luxury Resort, www.conradmaldives.com/stay/the-muraka/.

Kilburn, Hamish. “Designing the World's First Luxury Underwater Hotel.” Hotel Designs, Hamish Kilburn Https://Secure.gravatar.com/Avatar/2edcad40930314dca244a6a9d0589916?s=96&d=Mm&r=g, 7 Aug. 2018, hoteldesigns.net/industry-news/designing-the-worlds-first-luxury-underwater-hotel/.

Umbers, Lee. “Sleeping with the Fishes... Kiwi's $73,000 a Night Underwater Hotel.” NZ Herald, NZ Herald, 10 Nov. 2018, www.nzherald.co.nz/travel/news/article.cfm?c_id=7&objectid=12156573.

President of the United States, Donald Trump, phoned American Navy service members on Thanksgiving to discuss their aircraft catapult system.

On the phone with the commander of the USS Ronald Reagan aircraft carrier, Trump asked a few questions about the system they were using. Catapults are used to get the aircraft airborne which would otherwise be impossible with the short runways the ships have. The USS Ronald Reagan is a nuclear-powered aircraft carrier, utilizing a steam-powered aircraft catapult. The catapult diverts steam from the ship's nuclear reactor and uses it to launch the planes.

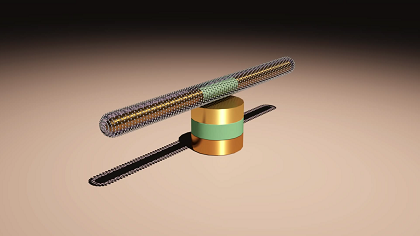

However, the U.S. Navy is in a phase of transition from steam to electromagnetic systems on some of their carriers. They are called Electromagnetic Aircraft Launch Systems (EMALS), and they are developed by an organization called General Atomics for the United States Navy.

In the last two years, the USS Gerald R. Ford was fitted with four electromagnetic catapults.

The system forgoes the steam piston and instead relies on a linear induction motor. The change seemingly helps accelerate and launch aircraft in a much smoother fashion when compared to the steam catapult systems. The steam catapults date back to World War II and require a significant level of maintenance from engineers.

The linear induction motor in the electromagnetic catapults utilizes electric currents, creating a big surge of electricity to propel the plane. But, the President thinks it isn't worth its weight in salt. He pressured the Navy to ditch the new EMALS. Speaking to Time Magazine in 2017, Trump recapped the conversation he had about the system with a member of the Ford:

"You know the catapult is quite important. So I said what is this? Sir, this is our digital catapult system. He said well, we're going to this because we wanted to keep up with modern [technology]. I said you don't use steam anymore for catapult? No sir. I said, "Ah, how is it working?" "Sir, not good. Not good. Doesn't have the power. You know the steam is just brutal. You see that sucker going and steam's going all over the place, there's planes thrown in the air."It sounded bad to me. Digital. They have digital. What is digital? And it's very complicated, you have to be Albert Einstein to figure it out. And I said–and now they want to buy more aircraft carriers. I said what system are you going to be–"Sir, we're staying with digital." I said no you're not. You going to goddamned steam, the digital costs hundreds of millions of dollars more money and it's no good."

Fast forward to the Thanksgiving 2018, Trump once again brought up the doubt he had with the electromagnetic launching systems. Speaking to an official on the USS Ronald Reagan, over the phone, Trump once again cast doubt into the electromagnetic catapults. He said:

"Steam is very reliable, and the electromagnetic — I mean, unfortunately, you have to be Albert Einstein to really work it properly."

To which the Navy service member on the other side of the phone replied:

“You sort of have to be Albert Einstein to run the nuclear power plants that we have here as well, but we’re doing that very well.”

What’s the deal?

While it seems Trump lacks the formative knowledge regarding which catapult system is best for the Navy, the electromagnetic systems have gone through some trial and error. The initial tests done on the USS Ford were a failure in 2015. It was only much later that they moderately perfected the launching system.

According to Popular Mechanics, the engineers atop the Ford were worried about the move to electromagnetic due to the first failed tests. They allegedly ‘briefly considered' going back to the steam catapults for the USS John F Kennedy and USS Enterprise which were under construction at the time.

Steam catapults, over time, are more destructive on the airframes of the aircraft it launches. EMALS would, therefore, be a better investment. But, the Navy Times reported in January 2018 that EMALS ‘may not be ready for the fight.'

The Director, Operational Test and Evaluation report states:

“Poor or unknown reliability of the newly designed catapults, arresting gear, weapons elevators, and radar, which are all critical for flight operations, could affect the ability of the carrier to generate sorties, making the ship more vulnerable to attack, or create limitations during routine operations. Based on current reliability estimates, CVN78 is unlikely to be able to conduct the type of high-intensity flight operations expected during wartime.”

Nonetheless, some of the lieutenants are reporting that the steam catapults make for a very violent takeoff experience, a problem that the EMALS don't seem to have. The EMALS could reduce the amount of bouncing the plane does before it gets launched off of the runway, which would be an advantage. However, the urge to rapidly digitize the ships has some in the Navy, and the US President himself saying, "not so fast."

Works Cited

Miller, Zeke J. “Donald Trump: TIME Interview on Being President.” Time, Time, 11 May 2017, time.com/4775040/donald-trump-time-interview-being-president/.

Mizokami, Kyle. “Donald Trump's Problem With the Navy's Electromagnetic Airplane Catapult, Explained.” Popular Mechanics, Popular Mechanics, 15 Feb. 2018, www.popularmechanics.com/military/weapons/a26478/donald-trump-emals-steam-catapult-aircraft-carrier/.

Ziezulewicz, Geoff. “Report: EMALS Might Not Be Ready for the Fight.” Navy Times, Navy Times, 16 Feb. 2018, www.navytimes.com/news/your-navy/2018/02/16/report-emals-might-not-be-ready-for-the-fight/.

It's the year 2021. You are on a cruise ship, soaking in the sun, inhaling crystal clean air, and drinking a cocktail. While you're on this vacation, it never occurs to you that the very ship you are on is being powered by rotten fish.

Yep. The Norwegian cruise liner group Hurtigruten is planning to power their ships using biogas, liquified natural gas (LNG) and solar-powered battery packs. Biogas is made with organic material like dead plants and animal waste. The company will speed up the decomposition of organic waste and capture the methane it produces.

The group intends to have these ‘fuels’ in place and ready to power their fleet by 2021.

Hurtigruten CEO Daniel Skjeldam told the Telegraph:

“What others see as a problem, we see as a resource and a solution. By introducing biogas as fuel for cruise ships, Hurtigruten will be the first cruise company to power ships with fossil-free fuel. While competitors are running on cheap, polluting heavy fuel oil, our ships will literally be powered by nature. Biogas is the greenest fuel in shipping, and will be a huge advantage for the environment. We would love other cruise companies to follow.”

The company says that it will be utilizing the cutaways from fisheries and other organic waste will soon be used in the ships. It is quite clear that the electrical engineer on the cruise liners, is going to be seeing some of the world’s first alternative powering methods for ships.

The move will cost the company US $826 million over the next three years, to fit six of the 17 ships in the fleet with the new technology. The company is buying three new vessels that will be run only on clean electricity technology. But they will have diesel engines as a backup.

Skjeldam told media that his ship's crew members have seen how ‘glaciers retreat' due to climate change, possibly caused by emissions. He adds that the crew members say they also observe too much plastic on beaches where the ships land. Consequently, Hurtigruten confirmed that they will do away with single-use plastics.

Powering ships while docked

It is not the first time clean energies are being implemented in the cruise liner business. Siemens has developed a technology for when ships are docked at the harbor to ensure they do not create unnecessary air pollution.

Most cruise liners still utilize diesel generators that power their vessels. At a harbor, however, the air quality is a concern. Therefore, running a ship for a prolonged time while docked increases the chances for emissions to degrade the air quality at the harbor.

To combat this problem, Siemens developed the first European onshore power supply for cruise ships back in 2015. The system allows the ships to turn off their diesel generators while in the harbor. They have dubbed it the SIHARBOR shore connection system.

Berthed ships of all kinds can benefit from this setup due to how flexible and straightforward it is. A simple cable management system it all it takes to connect the ship to an onshore source of power. Siemens has their own patented robot arm that feeds the cable system to the boat, specially designed for the tidal range of the ocean.

The trend rising of powering cruise ships offshore and onshore with clean power is encouraging to observe. Ninety percent of the world's goods are transported via ships — making them cleaner will be good in a world craving fuels that emit fewer carbon emissions.

Works Cited

Featherstone, Emma. “Hurtigruten Cruise Ship to Be Powered by Rotten Fish in World First.” The Telegraph, Telegraph Media Group, 19 Nov. 2018, www.telegraph.co.uk/travel/cruises/news/rotten-fish-to-be-partly-used-to-power-hurtigruten-cruise-ships/.

“Forum for Science, Industry and Business.” How Are Cells Held Together?, www.innovations-report.com/html/reports/energy-engineering/siemens-builds-the-first-european-onshore-power-supply-for-cruise-ships.html.

For 15 years, the city of Gweru in central Zimbabwe has been increasingly dry, with water failing to flow into one of their reservoirs. However new water infrastructure would cost the council US $10 million. Since Zimbabwe is enduring extraordinarily tough economic times, an expense of this magnitude was daunting.

As is so often the case, a group of engineers managed to save the day! With little in their public coffers, the Zimbabwean government enlisted the help of the German Development Cooperation-GIZ-Ausaid. GIZ-Ausaid’s head of urban water and sanitation, Mr Stephen Lidsber told the Herald newspaper:

“We asked them what was wrong with the old infrastructure. We decided to fly in a team of German engineers to look at the problem. They spent a good two months looking at ways of getting the water into the city’s reservoir. They discovered it was just a single valve that was malfunctioning. So they opened the valve and they are now able to pump water into the Kopje reservoir tanks.”

Instead of the anticipated $10 million, the German engineers cost the Zimbabwean city US $60,000.

The German Ambassador to Zimbabwe, Thorsten Hutter, praised the city’s frugal approach to the problem. He said:

“Maintenance is always cheaper than buying new equipment. As a local authority, it is important you invest in maintenance. This partnership shows good cooperation based on mutual respect and I hope it will last for a long time.”

Can we fix it? Yes, we can

A culture of consumerism has, unfortunately, become the norm; even fashionable. It has resulted in many industries intentionally engineering products that break more quickly than in the past. This approach has turned us into a throw-away society — it encourages us to replace products rather than consider alternatives.

However, the old culture of repair is at last re-emerging and will, in time, replace our tendency to discard engineered products.

It is a significant shift, particularly for those nations having to eke out scarce resources.

And then there is the issue of landfill.

According to the North London Waste Authority (NWLA), in the UK 22 million pieces of furniture, 11,000 bicycles, and over 28 million toys are thrown away every year when in reality they could be repaired. The NWLA’s Clyde Loakes told Sky News:

“We’ve got ourselves into a bit of a rut and it’s not just a London thing, it’s not just a UK thing, it’s a global thing. We buy things for a certain period of time and when it breaks, because we’ve lost the skills to fix things, we just throw those items away and it’s just easier and more convenient to just go and buy a replacement.”

Several groups or clubs are starting up in Europe (and indeed elsewhere); they encourage meetups to assist with repairing technology. Some groups like ‘The Restart Project’ host parties and promote volunteerism in the repairing industry. Their website indexes repair parties across England. It says:

“Come to one of our free community repair events, where our volunteer fixers will help you learn how to repair your broken or slow devices - and tackle the growing mountain of e-waste.”

The Culture of Repair Organization’s website targets a wide audience; with some of their educational resources for those still at school. It is likely that curricula encouraging a culture of repair will become commonplace in the next few years.

One startup, the Fixit Clinic, is training the designers and engineers of tomorrow to manufacture longer-life products. The clinics hope to influence the way designers and engineers design and create products later on in their careers.

The culture of repair supports the environmentalist: where the world of manufacturing becomes more sustainable and is in sync with other, but related environmental principles: reuse, reduce and recycle.

Works Cited

“Educator Resources.” Culture of Repair, www.cultureofrepair.org/educator-resources/.

Herald. “The Herald.” The Herald, The Herald, 16 Nov. 2018, www.herald.co.zw/.

Vittozzi, Katerina, and Sky News. “We Throw Away Millions of Items That Could Be Repaired.” Sky News, Sky News, 4 Nov. 2018, news.sky.com/story/we-throw-away-millions-of-items-that-could-be-repaired-11544441.

Can a construction crew finish building a house in a week?

What about in 24 hours?

Winsun (also known as Yingchuang Building Technique) is a Chinese construction company that can 3D print a house in 24 hours. The company is at the forefront of 3D printing architecture. Founded in 2003, Winsun currently holds 151 national patents pertaining to their construction materials.

The company has also been recognized as an essential contributor to the ‘one belt one road' policy. The Chinese Government's infrastructural policy aims to connect Asia, Africa, and Europe. It's inspiring sustainability in construction, energy, and transportation.

The 3D printing technique employed by Winsun could go global, considering the Belt and Road Initiative's influence is expected to reach up to 70 countries.

In Jiangsu Province, the company has been printing structures that embody Chinese history and culture, while providing a look into the future of creating Chinese homes, business offices and more.

The process is relatively new. It utilizes a 3D printing cement ink that combines cement, sand, and fiber together with an additive resin that allows layer by layer printing. What the company essentially created was ‘Special Glass Fiber Reinforced Cement.'

Senior Engineer at the Shanghai Research Institute of Building Sciences, Ya Beihong, told CGTN that the 3D printed material has better anti-crack properties than traditional cement. This is due to the added fibers that are pushed through the printing nozzle.

As a result, the houses should be durable, and assuage the many critics who have wondered how sturdy they would be.

Winsun first made news headlines in 2013 when they claimed to have printed 10 houses in 24 hours. Then, in 2015 they printed a six-story apartment building, which only cost US $160,000 to produce.

Ma Yihe, the CEO of Winsun said, "industrial waste from demolished buildings is damaging our environment, but with 3D-printing, we are able to recycle construction waste and turn it into new building materials."

Yihe says that developer costs are cut by 50 percent when buildings are 3D printed. Moreover, with robots taking care of every part of the house's fabrication, a construction crew is not technically necessary — and will be even less essential as the technology develops.

The company says they will be printing bus stations, public toilets, and affordable houses in China soon.

Winsun was the construction company behind the first 3D printed office that was printed in Dubai. The UAE is looking to rely on 3D printing buildings as a part of their 2030 mandate to have most of its construction works done via 3D printing.

The 3D printing building technique could also have positive spin-offs for the globe. If housing is a fundamental right for all humans, the printing method could create housing at a much more affordable rate for those in the world needing shelter. Every level of the construction process is digitized and ultimately futuristic.

Works Cited

About Winsun-Yingchuang Building Technique (Shanghai)Co.Ltd. (WinSun), www.winsun3d.com/En/About/.

Dubai Future Foundation. “THE OFFICE OF THE FUTURE.” 3D PRINTED OFFICE - DUBAI FUTURE FOUNDATION, www.officeofthefuture.ae/.

“Living in the Future: 3D Printing Shaping the Construction Sites of Tomorrow.” YouTube, 2 Nov. 2018, youtu.be/XEVkosH_-gQ.

Friday 30 November is Systems Engineer Day!

A systems engineer's job is to create and manage complex systems. They ensure that the system has a good life cycle and that all systems are running efficiently.

This celebration debuted in 2012, lauding the engineers who, through design and implementation of digital solutions, make a difference in the many workplaces globally. On the day, everyone is encouraged to high five their systems engineer and show their appreciation.

Systems engineers are becoming increasingly valuable to companies as the Fourth Industrial Revolution brings about complex networks to facilitate the Internet of Things. These system engineers are vital and essentially — at least in the interconnected technological industry— make the world go round.

Systems engineers have to work tirelessly to understand user experience. They need to tailor their systems to what they think other people will enjoy and consider efficient.

Dice Insights, an institution which provides advice for tech professionals, reports that systems engineers with an extensive understanding of Linux systems specifically, could be looking at a bigger salary per month.

How to become a systems engineer

According to Dice Insights, the best path to becoming a systems engineer starts with a degree in computer science, information systems, or engineering. They write:

“As systems engineers gain experience, they’ll learn the tools and techniques necessary to manage systems at scale--for example, a senior systems engineer (i.e., systems engineer III) will not only need experience in designing and implementing the overall architecture of a software system, but must have tactical knowledge of virtualization, containers, systems design tools and languages, and analytics.”

Systems engineers need to be fully aware of what networking technologies are available. They should also anticipate the release of new ones that they can implement.

System engineers can go by many names, according to SystemsEngineerDay.com. They can be called systems engineers, infrastructure engineers, system integrators, architects, system analysts, and more.

It’s therefore clear that systems engineer can be present across most of the disciplines of engineering. With engineering becoming more and more interdisciplinary, education institutions are creating new qualifications to formalize the domain expertise moniker of ‘systems engineer.' Boston University has a minor qualification, MEng, MS, and Ph.D. in Systems Engineering.

They say that their graduates can work in a plethora of industries that include but are not limited to:

- Developing computer simulation packages for software providers

- Building and evaluating models for communication, computer and sensor networks

- Developing effective air traffic management systems

- Analyzing the feasibility of relying on teams of autonomous vehicles for military and civilian applications

- Developing, enhancing and maintaining quantitative stock selection models that are used to pick high-performing stocks for clients

- Developing and supporting software that optimizes a company’s global supply chain operations and provides multiple-year production plans based on various supply, demand and capacity scenarios.

- Inventing new scheduling and production control algorithms for manufacturing enterprises.

- Developing a pairing optimizer and crew controller, to provide crew pairing and rostering for more than 30 airline companies all over the world.

- Designing innovative algorithms and software to direct user traffic across the internet, optimizing the end-user experience.

The Engineering Institute of Technology’s Dean of Engineering, Steve Mackay, says that adding systems engineering into the career mix is a wise decision. Systems engineering, in his opinion, represents the function of teaching the old engineering ‘dog’ new tricks. He writes:

“Systems engineering would appear to be mainly in the aerospace and military sphere but it is across all fields of engineering ranging from car manufacturing, building plants & infrastructure, oil and gas, mining and transport and in many newer areas. A great example of a growing field of systems engineering is the smart grid - dynamic, complex with many different disciplines involved in its creation coupled with a high degree of uncertainty and a great opportunity to optimize. Or smart self-driving cars - the number of different disciplines here are mind boggling.”

Consequently, if you know someone working towards becoming a systems engineer, who can grapple with all of the technological development that the convergence of engineering disciplines has produced, celebrate them this Systems Engineer Day.

Works Cited

KolakowskiNovember, Nick. “Systems Engineer Salary Rises Even Higher with Linux Experience.” Dice Insights, Dice, 16 Nov. 2018, insights.dice.com/2018/11/13/systems-engineer-salary-rises-even-higher-with-linux-experience/.

“What Is Systems Engineering?” Family and Medical Leave Act (FMLA) | Human Resources, www.bu.edu/eng/departments/se/prospective-students/what-is-systems-engineering/.

“What Is Systems Engineering?” Family and Medical Leave Act (FMLA) | Human Resources, www.bu.edu/eng/departments/se/prospective-students/what-is-systems-engineering/.

“Systemsengineerday.com.” Systemsengineerday.com, www.systemsengineerday.com/.

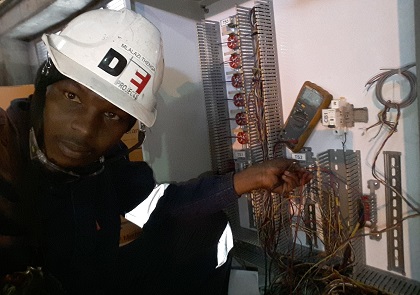

Mthulisi Mlalazi Thenga is a 28-year old, qualified Control & Instrumentation technician. He mainly specializes in system integration & automation. In 2005, Mthulisi graduated from high school in Zimbabwe, but decided to migrate to Botswana. He would visit Kgalagadi Breweries in the region and be fascinated by the automated processes at the plant. He ended up spending some time in the technical departments there assisting with the electrical, control and instrumentation technologies.

As a child Mthulisi found he had a profound love for machines. He was also keen to discover how electricity was generated. Clearly he was already actively – but perhaps even unconsciously - trying to find which niche of engineering and technology he would fit into as an adult.

“Finally I realized my loyalty was in Control Engineering. I went back to Zimbabwe to start my tertiary education at Bulawayo Polytechnic College. I worked hard and excelled,” Mthulisi said.

As a result he qualified as an electrical technician and a registered qualified specialist in the following disciplines:

- Industrial communication.

- Networking and high speed nonmetallic communications.

- Control systems engineering.

Through EIT, he completed further studies and graduated with an Advanced Diploma in Electrical & Instrumentation (E&I) Engineering of Mining and an Advanced Diploma of Applied Electrical Engineering.

During his apprenticeship Mthulisi’s work included the maintenance of heavy industrial equipment; since then he has moved up into system integration and automation.

Incredibly, he has had a hand in either modifying or commissioning projects at thermal power stations in South Africa, at the Unilever plant in Kenya, at the Dundee Precious Metals smelter in Namibia, at the First Quantum Minerals Kalumbila mine in Zambia, and more.

And he says of his work, “I automate and breathe life into chemical plants, water treatment plants, manufacturing firms and mineral processing plants,” he said. “I am passionate about control systems and I have been on teams that have worked hard to make the world a better place.”

The online platform that EIT employs must be scrutinised and who better to do this than the students using it.

Mthulisi’s assessment is insightful; he does not hesitate to outline the challenges faced by someone working long, hard shifts and studying online at the same time. He warns people off, “if you have problems with motivation, procrastination and need lots of individual attention from an instructor.”

On the other hand he states, “Online training is the future”. He believes it teaches students to become “survivors”, “…it taught me how to plan and how to be responsible”.

He loved the flexibility and savings – with a computer and internet he was able to study anywhere and, because he did not have to commute to and from a campus, he saved time and money.

He was kind enough to describe the EIT online platform as “outstanding” because of the uniqueness of its remote labs, student access to library resources and the live streaming of the webinars twice daily (which are also recorded for revision purposes).

Mthulisi did, however, point out something that EIT is poignantly aware of: “Some content isn’t ever offered in an online format. For example, you can watch a hundred videos on welding, but until you have that welder in your hand, you’re never going to master your technique”.

In closing, the following advice from this proactive, driven and passionate young man is also worth sharing: Keep in touch! Listen to business and engineering leaders on LinkedIn and on other social media forums! And actively contribute! He believes this helps him “grow and transform day by day”.

The Engineering Institute of Technology was delighted to welcome representatives from the Universiti Putra Malaysia, on the 29th October 2018.

The delegation was made up of a wonderfully enthusiastic group of ten students, the university’s principal, Dr B.T. Hang Tuah Baharudin, and the students’ chaperone.

For an education provider dedicated to engineering we are conscious of the need to lure females to this largely male-dominated industry. It was very exciting, therefore, to meet these ten visiting students, all of whom were women!

Over a morning tea the students were welcomed to EIT by the Compliance and Accreditation Manager, Ms Caroline Patterson. She gave them an overview of the college and proudly encouraged them to visit Perth’s beautiful sites while here.

The visitors then gave short presentations. Each student outlined her study focus and career dreams, post-graduation, in engineering.

Thereafter Mr Paul Celenza, the College Manager, provided the students with an insight into EIT’s unique approach to engineering education. He explained how engineering experts from around the world reach and teach EIT students in 146 countries, using a live online approach.

The visitors were fascinated when Paul recalled the story of an EIT student (and scientist), who was able to continue his studies while working in Antarctica!

Mr James Theodosiadis (Engineer, Lecturer, Laboratory Coordinator) gave the visitors a taste of the remote labs (connected to real equipment), the virtual labs and the simulations that EIT students access for their practical applications. The visiting students enjoyed that they shared, with James, the same engineering vernacular.

Dr Milind Siddpura, Learning Support Officer and Lecturer, then welcomed the students onto the EIT campus. He outlined the blended form of learning used for our on-campus students.

Back row: Ms Miriam Munitz, (in charge of EIT Student Services)

and Mr Victor Onoja, EIT Master student and Academic Assistant

At the end of the day the Malaysian students were put to work! Mr Victor Onoja, a Master student at EIT and Academic Assistant, had them participate in a maths evaluation quiz. They were excited by the opportunity and their confidence (as they illustrated their solutions on the board) was well-founded; they all did exceptionally well.

Our visitors were extremely appreciative of EIT’s hospitality and demonstrated this with a range of lovely gifts.

All of us here at the Engineering Institute of Technology wish our Malaysian visiting students everything of the best in their studies. We know that they will indeed make impressive engineers in time, ably contributing to their Malaysian communities.

Future generations will judge us for not taking the necessary precautions to offset the effects of climate change on our world. The blame will inevitably involve our reticence to cut down on fossil fuels. In reality, however, the task is massive and will rely on science, technology, engineering and government all committing to solving the problem.

Mark Lynas, a British journalist and environmentalist, has been issuing warnings since 2007. He explains what will happen to the world if the earth continues to warm, Six Degrees: Our Future on a Hotter Planet.

In one chapter he writes about the Palmer Drought Severity Index — a computerized forecast run by the Hadley Centre at Britain's Meteorological Office. This computer model calculates the likelihood of drought in the century to come. In 2007 he wrote the following:

"The results were deeply troubling. The incidence of moderate drought doubled by 2100 — but worst of all, the figure for extreme drought (currently 3 percent of the planet's land surface) rose to 30 percent. In essence, a third of the land surface of the globe would be largely devoid of fresh water and therefore no longer habitable to humans."

This prediction is based on global warming of higher than one degree. And according to a recent study published in the Nature Journal, the Panel on Climate Change (IPCC) believes that by 2100 the temperature will rise by 2 to 4.9 degrees Celsius.

Adrian Raftery, the author of the study, said:

"The likely range of global temperature increase is 2.0-4.9 (degrees Celsius) and our median forecast is 3.2 Celsius. Our model is based on data which already show the effect of existing emission mitigation policies. Achieving the goal of less than 1.5 C warming will require carbon intensity to decline much faster than in the recent past."

Importance of education and teamwork

Experts believe that if engineering disciplines come together to figure out a path forward, the looming water and energy crises can be solved. However, with universities still catering to individual subjects, a shake-up in education needs to occur.

This, according to a study entitled, Adapting to Engineering Education Vision 2020, published by the Multidisciplinary Digital Publishing Institute.

The authors say that in many countries universities have pursued curricula that teach students ‘soft skills' instead of the ‘professional skills' required for engineers. And yet the world needs competent engineers if they are to solve existing and growing crises.

Technological advancement is making it easier for humans to solve the world's most pressing issues. With the right education people will be well placed to manipulate these new technologies to create positive outcomes.

The authors of the report write:

“It is not possible without putting the emerging bio, nano, and info technologies together in power and energy research laboratories under interdisciplinary and trans-disciplinary approaches. Electrical engineers badly need the supportive hand of energy scientists and technologies to overcome global power, energy, food, and water crises. Engineers and scientists often find it difficult to tolerate each other and usually end up with duplicate resources without presentable output which requires motivation to develop teamwork spirit to succeed.”

The authors believe students who have an affinity for energy in chemistry subjects will eventually work in new fuel cells or solar cells. This would provide a great opportunity for engineers and scientists to work together. They say that scientists and engineers are stuck in ‘discipline defense politics' and are squandering this chance to collaborate.

Interdisciplinary curricula within degree programs are helping to equip students to tackle current world problems. The authors of the study point out that an updated engineering curriculum might see the following modules present in the coursework: renewable energy, molecular electronics, polymer solar cells, solar paints, and photochemistry.

The authors conclude:

“Future energy supply to society is a big challenge that individual disciplines cannot harness alone without developing a spirit of interdisciplinary research and development. Keeping in view world energy sources and global power needs, we must readjust our energy wasting attitudes and prepare our generation to cope with future power and energy crisis.”

Works Cited

Raftery, Adrian E., et al. “Less than 2 °C Warming by 2100 Unlikely.” Nature News, Nature Publishing Group, 31 July 2017, www.nature.com/articles/nclimate3352.

“Six Degrees by Mark Lynas.” Goodreads, Goodreads, www.goodreads.com/book/show/227477.Six_Degrees.

Yasmin, Musarat, et al. “Adapting to Engineering Education Vision 2020.” Proceedings, vol. 2, no. 21, 2018, p. 1365., doi:10.3390/proceedings2211365.

By all accounts engineering remains a male-dominated industry.

In 2015, the U.S. Department of Commerce reported that women fill 47 percent of all jobs, while men take up the other 53 percent.

However, according to more recent figures from the National Science Board, women only filled 24 percent of STEM jobs in 2018. And the industry in which women are least represented? Engineering.

TechCrunch writer Dr. Ioannis Miaoulis, president and director of the Museum of Science in Boston, says the numbers are ‘startling.' He writes:

“At a young age, girls internalize long-lasting stereotypes that tell them that boys are better at engineering and computer science, and that girls simply aren’t engineers. And during these formative years, they never have an opportunity to imagine themselves as engineers.”

Dr. Jordan B Peterson, a professor of psychology at the University of Toronto, explains why that might be:

“Women are tilted towards empathizing and males are tilted towards systematizing. That seems to fall into alignment with other observations suggesting that, the biggest gender difference between adult humans is interest preference. Women are much more likely to express interest in occupations that involve a lot of social contact, whereas men are more likely to manifest interest in occupations that have to do with things.”

Peterson points out that even in the Scandinavian countries — considered the most gender equal societies in the world — the most striking gender differences exist, based on occupation. He reports that the ratio of male nurses to female nurses is 1:20, and the ratio of female engineers to male engineers is also 1:20.

Breaking boundaries

Dr. Ioannis Miaoulis notes that even with the advocacy groups and the many institutions prepared for increasing numbers of female engineers, the results are disappointing.

The Engineering Institute of Technology has seen more women apply to the institution as the boundaries of entry for women lowers in the education sector. A 24-year old female Advanced Diploma of Civil and Structural Engineering graduate from EIT, Oyama Khanyisile Vundla, is a driven young woman ready to take on the Engineering world. She says:

“Media plays a huge role in people’s perceptions of how men are equipped for engineering and women are not. Even the movies we watch display men as engineers, people end up believing that women can’t survive in these industries. I would definitely advise young women to pursue this industry and cast away all the negative spin that says we can’t survive in this industry.”

What else can the world collectively do to inspire more females to join the Engineering workforce?

Apparently the answer is to play video games!

A study published in the journal Computers in Human Behavior reports that girls who play a plethora of video games between the ages 13 and 14 are more prone to investigating STEM job opportunities in their future.

Through the demographics of the women polled in the study, it was clear that a majority of the women who identified themselves as gamers were studying STEM subjects at degree level.

The study conducted by Director of Ph.D. in Higher Education at the University of Surrey,

Anesa Hoesin said:

“Our research shows that those who study STEM subjects at degree level are more likely to be gamers, so we need to encourage the girl gamers of today to become the engineering and physics students and pioneers of tomorrow.”

Hosein is trying to pressure educators to introduce gaming to girls at a young age so that they become familiar with interacting with technology at a high level.

We could also use platforms such as YouTube to get girls interested in a digital future where an equal number of men and women are engineers. A YouTuber named GoldieBlox features a young female engineer showing off her skills to a wide audience of 561,345 subscribers.

Goldieblox is a digital media, publishing and consumer products company that is helping inspire girls in STEM fields. They target their content towards young girls, in the hope of encouraging them to pursue STEM opportunities in the future.

Currently, only 11 percent of engineering faculty in the US is women. The key to improving this statistic seems to revolve around getting girls involved in engineering at a younger age. New strategies must be tested so humanity can benefit from the contribution women could bring to the engineering industry.

Works Cited

“'Geek Girl' Gamers Are More Likely to Study Science and Technology Degrees.” University of Surrey, www.surrey.ac.uk/news/geek-girl-gamers-are-more-likely-study-science-and-technology-degrees.

Miaoulis, Ioannis. “We're Addressing Gender Disparity in Engineering Way Too Late.” TechCrunch, TechCrunch, 26 Oct. 2018, techcrunch.com/2018/10/26/were-addressing-gender-disparity-in-engineering-way-too-late/.

Ramble. “Jordan B Peterson: Why so Many Male Engineers and Female Nurses?” YouTube, YouTube, 7 Aug. 2017, www.youtube.com/watch?v=d7uZOAzVRgU.

The EIT remote and virtual lab platform

The EIT lab hosting platform, Electromeet, connects students with lab computers in real time using TeamViewer software. Once connected, students will have access to a wide range of engineering software and connected hardware, which will be used in practical assessments throughout their course. Utilizing the Electromeet scheduling system, students are able to pre-book exclusive access to the required labs for when they are needed. The labs consist of:

- Virtual labs; computers hosting software for a multitude of engineering applications, including: modelling and analysis, science education, programming, power network design, construct models, design and drafting, project management, industrial process control, and virtual plant field operations.

- Remote labs; computers connected to physical equipment and sensors equivalent to the traditional university engineering lab. These practicals are interactive, controllable, variable, and viewable over webcams in real-time, with examples including; data communication and protocols, scientific instrumentation, physical experimentation, the control and observation of circuits, systems and machinery, and robotic automation.

Electromeet online lab hosting provides EIT students with on-demand access to professional engineering software and lab equipment, from anywhere in the world, subject to an internet connection. The booking and access page stipulates which software and physical equipment is available on each lab. Access is via the website: https://lab.electromeet.com/Home

EIT remote and virtual labs are hosted primarily in Perth, Australia, but additional labs are located in Johannesburg, London and Singapore. If a lab is offered in more than one of these locations, for an improved experience, EIT strongly suggests selecting the lab in the location which has the lowest latency for the student.

Demonstrable industrial experience

Embedded within the EIT Bachelor of Science and Master of Engineering curriculums is the requirement to complete 240 hours of engineering discipline-specific industrial work experience, with one or more companies, under the supervision of a professional engineer. Students are required to attend a site visit prior to independently undertaking industrial experience.

The primary objective of this requirement is to ensure that students have had the opportunity to learn about real situations in engineering practice; by working both independently, and in groups, and contributing to professional work related to their engineering specialisation in a meaningful way. Work experience may be achieved in numerous ways ranging from roles as junior members of teams, to tasks that form part of discrete engineering projects.

Through participation, observation, and engagement, students will: enhance their understanding of how organisations function, put engineering theory and concepts learned in the classroom into practice, develop their professional competencies, gain perspective on the realities of practice, and develop their judgement, innovation and problem solving skills.

In addition to understanding the company structure and activities, the student will be exposed to organisational policy and culture, interact with employees and other engineering disciplines, familiarise themselves with organisational communication procedures, and obtain insight and practical aptitude regarding projects; from the planning phase to completion.

For school leavers, the concept of networking and applying for industrial experience can be very daunting. EIT provides assistance to on-campus students in communication and presentation skills, contacting companies, arranging a site visit, and accessing a network of local engineering companies in order to meet the course requirements and pursue vacation work opportunities.

Students who already possess significant industrial experience in their engineering discipline of study may apply for recognition of prior learning to meet this requirement.

EIT also readily engages with distinguished industry guest speakers who are able to share their experiences and expertise.

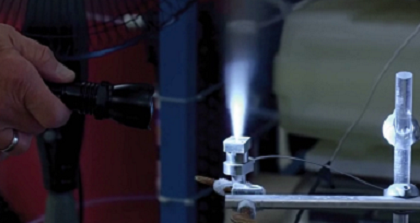

Hands-on with engineering equipment and experimentation

Demonstrable practical hands-on work is a requirement of many professional engineering societies and accreditation agencies around the work and is an essential component of the EIT Bachelor of Science and Master of Engineering programs.

Whilst these programs include contextualised remote and virtual labs; equivalent to, or considerably more comprehensive than a traditional classroom-based program; it is essential to verify that students are competent in hands-on work skills, including; practical tool usage, workplace safety, physical measurement, experimentation, construction, assembly and working in an engineering team, within the context of their discipline. The workshops commence with a first aid course and each session requires students to undertake a job safety analysis. In total, there are four workshops for Bachelor’s students and five for Master’s students.

The Hands-on workshops are also conducted to provide the supplementary exposure to the course units. For example, the Hands-on Workshops cover laboratory experiments related to Physics as well as Chemistry; mechanical workshops apply theoretical concepts related to mechanisms, machines and processes; civil workshops relate to materials, surveying and construction; industrial automation workshops relate to instrumentation and controllers; and electrical workshops relate to circuits, switchgear, transformers and electrical motors. The latter workshops foster high-level technologist drafting and design skills and the Master’s workshop has engineering project teams working on a discipline-related comprehensive industrial case study.

On-campus and online students will elect to attend one of the annual workshop deliveries, at an EIT campus, but no sooner than having completed three semesters of full-time equivalent study to ensure sufficient prerequisite knowledge and skill. Subject to demand, workshops are run over four weeks in Perth and Johannesburg, commencing in January and November each year, with a fifth week for Master’s students. On-campus students may also choose to complete the initial workshops over the course of a semester.

Students who already possess significant industrial experience in their engineering discipline of study may apply for recognition of prior learning to meet this requirement. Master’s students who possess an accord-recognised undergraduate qualification are exempt from the first four workshops.

At the foot of the pyramids of Giza, a new museum is taking shape.

Five thousand Egyptian civil engineers are hard at work to complete the Grand Egyptian Museum. Construction began 16 years ago, and the doors are expected finally to open in early 2019.

One of the firms attached to the build is Buro Happold Engineering. They say the museum will be a construction where ‘mathematical precision meets elegant vision.'

The initial call for proposals for the museum was in 2002. The winning designers were Heneghan Peng from Dublin, Ireland. They worked alongside Arup, an independent firm of designers, planners, and engineers. The exhibition design was completed by Metaphor and Cultural Innovations Ltd.

It is expected to assume a 50 hectare stretch of land and will go down as one of the most audacious museum builds in world history. Director General of the museum, Tarek Tawfik told CNN:

“This will be the museum of the 21st century. All means of modern technology have been taken into consideration in order to make this an unforgettable experience for the visitor, but at the same time provide the best possible environment for the artifacts.”

The museum's construction is expected to cost US $1 billion. Inside it are the country's most marvelous relics and artifacts of the past. The Colossus of Ramses II, weighing in at 121 tonnes, (already transported across Egypt) is to be moved to the Grand Egyptian Museum. He will be standing tall above the visitors at the museum’s entrance.

A Horus God statue has also been transferred from Al-Masalah Garden in Zamalek to the Grand Egyptian Museum.

The building has been constructed to resemble a chamfered triangle — a homage to the pyramids. Built on a sand hill, engineers had their work cut out for them. Tawfik said:

“This made it a bit more difficult to prepare the location, but it had the big plus point that there was no fear to stumble over antiquities here because the ancient Egyptians didn’t build any temples or carve any tombs into sand.”

Another feat of civil engineering will be an 800 meter long, 40 meter tall translucent stone wall, erected just in front of the museum. When tourists approach from the Cairo side, the translucent stone will produce a natural, inviting entrance to the museum. An 800-seat auditorium is also to be opened inside the museum.

The museum is downwind from the Giza pyramids and perfectly adjacent to the Giza pyramids, just two kilometers away. Another phase of the construction includes building a Conservation and Energy Center (CEC) that will house a conservation center, conservation plant, and a fire station.

Conservation

While being an impressive feat of civil engineering, the museum will also be an enigma of conservation.

The museum will also include King Tut-Ankh-Amun's Treasure — the only complete set of royal belongings in Egyptian antiquities collections.

Two-thousand-and-six of King Tut's 5,300 possessions will be shown off in the Grand Egyptian Museum. Conservationists are in the process of polishing the artifacts with specialized techniques, ensuring not to cause any damage.

One of King Tut's sandals was said to be beyond restoring, yet it has been done and is now present in the collection. Consequently, the museum's construction has also spurred one of the most significant restoration projects in the world.

Other attractions include artifacts from Queen Hetepheres I’s tomb; these antiquities were discovered in 1925.

The museum's visitors will have the chance to look at artifacts that date back at least 3,500 years. The Egyptian government is hoping that the opening of the museum will reinvigorate its tourism industry after the instability caused during the 2011 Arab Spring.

Works Cited

The Grand Egyptian Museum, www.gem.gov.eg/index/Museum -Museum Building - Facade & Entrance.htm.

“Egypt's New $1 Billion Museum.” CNN, Cable News Network, 5 June 2018, edition.cnn.com/style/article/grand-egyptian-museum/index.html.

“Grand Egyptian Museum.” BuroHappold Engineering, www.burohappold.com/projects/grand-egyptian-museum/.

Mechanical engineers are flexing their eco-friendly and business savvy muscles in the startup industry. Pratheek Palanethra was a mechanical engineering student in Bengaluru and is also passionate about cricket.

During his student years - studying for his Master of Technical Entrepreneurship at Lehigh University in Pennsylvania – he was sad to discover that there was really no cricket culture in the US. He struggled to find students who wanted to practice cricket with him. Instead of allowing it to perturb him it inspired him; he decided to engineer something to enable his practice.

He enlisted the help of his roommate Justin Jacobs, who was studying civil engineering at the time, and they began work on an affordable, non-electric bowling machine.

“We really wanted to be innovative the cricket market. Everyone’s going high-tech, we are going low-tech,” Justin said.

Usually, cricket bowling machines are quite expensive. In South Africa — where cricket bowling machines would be in high demand — a Paceman Pro Bowling Machine costs approximately US $932.

A new product ready to fly

Pratheek and Justin’s new mechanical engineering startup soon announced their eco-friendly, affordable answer to the bowling machine; they called it the Freebowler. The bowling machine is free from batteries, cords, and has no electricity ports on it.

What they produced was a purely mechanical product, fitted with a throwing arm operated via a spring, a ball cup, and more.

"The ball in the cup can be set at different angles and orientation using a knob that enables the batsman to play variations of lengths and swings," said Pratheek.

"The machine has wheels at the bottom to maneuver and is thus portable. It can be placed shorter than the normal 22-yard distance from the batsman. This way it enables the batsman to play different length and bounce at higher speeds."

The Freebowler costs approximately US $434. The Freebowler also matches, and in some cases, trumps other bowling machines' output speed: the Freebowler can launch balls at up to 140 kilometers per hour (87MPH). The Freebowler weighs in at only 23 kilograms. It's a perfect product for remote regions which do not have access to electricity or cannot afford conventional bowling machines.

The machine can take old cricket balls, new balls, indoor cricket balls, baseballs, and tennis balls.

Mechanical engineering for the betterment of sports could indeed be an area of growth with the Freebowler as the inspiration. The Freebowler website states:

“Machines that have this capacity to contort in a unique way, combined with an amount of storing convenience, environmental consciousness and adjustability not only show how far technology has come, but it also enhances the sport’s overall value.”

Works Cited

“Cricket Bowling Machine | Non-Electric Training Equipment.” Freebowler, freebowler.com/.

“This Startup Is Batting for Cricket Lovers with Its Portable Non-Electric Bowling Machine.” YourStory.com, 28 Oct. 2018, yourstory.com/2018/10/startup-batting-cricket-lovers-portable-non-electric-bowling-machine/.

As 2018 comes to a close, the industrial automation market is preparing to further digitize and automate industries into 2019.

McKinsey Global Institute (MGI) reports that by 2030 about 15 percent of workers around the world will be displaced by automation. However, they also note that employees are unaware that eight to nine percent of them will work in jobs that don't yet exist.

Consequently, automation will not only replace repetitive jobs, but also create new opportunities in many industries. This is why a culture of life-long learning is critical; a willingness to upskill and cross-skill.

Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, believes emphatically that automation will preserve the engineer, not replace him/her. However, Steve notes that they should take responsibility for their futures, by being aware of the changes occurring in the industry.