News

Biomedical engineering is continuing its amalgamation of individual disciplines of engineering, fusing it into one discipline that has the health of humanity as its core focus.

A host of startups and companies are developing technologies that will assist the healthcare sector and keep people healthier. United States company, Neocis, is one of those companies. They specialize in Precision Healthcare Robotics.

The Vice-President of Operations and fellow co-founder Juan Salcedo has over a decade of experience in manufacturing and mechanical design for the medical device industry. He holds a Bachelor of Science in Mechanical Engineering and a Master of Science in Biomedical Engineering from Florida International University. The Director of Software, the Director of Manufacturing, and the Director of Clinical Marketing have backgrounds in mechanical engineering too.

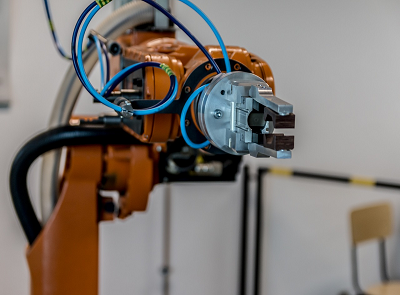

One of the robots they have engineered is a dentistry assistant named Yomi, who is particularly gifted at doing dental implants. Starting with a CT scan of a patient's mouth, the robot can analyze the image and find the exact area where an implant is needed.

And now, the first dentist in the world to use a robotic assistant has feedback.

Dr. Eddie Kotary is from State College and has opted for the dental assistant.

Kotary, however, does appreciate the concern people might feel about a robot inspecting the inside of their mouth. Nonetheless, the dental robot is not yet artificially intelligent and performing operations by itself, it is merely used for assistance — the professional is still crucial in the equation...for now. He said:

“A common misconception among patients is that the robot does surgery. I still perform the surgery and the machine helps to guide my direction.”

Kotary has done 10 surgeries and all have been successful. He has compared the robot to a Tesla vehicle — instead of driving for you, it helps you drive more accurately. According to Centre Daily, the robot ensures that a patient recovers quicker than traditional surgery, and it drives the cost of an implant down by US$500.

The South Florida Center for Periodontics and Implant Dentistry in Boca Raton, Florida, have just taken on their own Yomi robot after undergoing training to use their new robot assistant.

In rural areas, orthodontics, dentistry, and general healthcare is few and far between. Robots could potentially be implemented in third-world countries to provide dental healthcare. But for now, the Yomi Robot is a sizeable investment for a dental healthcare company to make, as it carries a hefty price.

Mechanical engineers could be crucial to the designing and implementing of surgery-assisting robots. If they are involved in every step, they could bring down the cost of these robots and help rural areas get access to the kinds of robotics that could save their lives, or at least their teeth.

Works Cited

Romanowski, Isabel. “Yomi, Oh My! A Local Dentist Is the World's First to Use a Robot Assistant.” Centredaily, Centre Daily Times, www.centredaily.com/latest-news/article217524480.html

https://www.neocis.com/

As the seasons change and the Northern Hemisphere gets a taste of what the Southern Hemisphere was feeling during winter, commuters on London's Underground could not be more ready for winter than right now.

In the month of August, London observed a sweltering heat wave that scorched the region for days on end.

To quell the effects of the immense heat on one's body, travelers could opt to go underground and use the Tube to get around. Except, Londoners have been complaining about the heat in the Tube too — it has been running for so many years that the earth surrounding it can no longer absorb the heat it emits.

The Tube's construction began in the 1800's, with the Bakerloo line opening in 1906. The initial marketing strategy included a line about how it was the ‘coolest place to be' in hot summer weather.

But all that has changed. Travelers have reported that the temperatures inside the Tube on the Central Line have skyrocketed, making for an uncomfortable commute. So, why is it so hot?

Basically, the heat felt in the tube comes from the train's mechanisms itself.

Rail Engineering's Brian Tinham compiled a report entitled ‘Cooling the Tube' in December 2007, that directly pointed out the sources of heat causing discomfort for passengers. They wrote:

"A little detail: primary heat sources are 38% breaking losses, 22% mechanical, 16% drivetrain, 13% train auxiliaries, 4% tunnel support systems, 3% passengers in trains and 4% passengers on stations."

The London Tube tunnels were dug under Subterranean clay. The clay has been heating up, essentially turning the Underground into a clay oven, with little space for air conditioners. Trains are hot, and in a clay oven, they are even hotter.

More worrying is the expansion of the tube. Engineers are currently rolling out the Elizabeth line, which is set to open in the autumn of 2019. The overarching problem with this new expansion is that more trains equals more heat. The older lines are deeper with less ventilation. The issue is, the hot trapped air is being absorbed by the walls, but the earth does not seem capable of absorbing much more heat than it already is. Temperatures inside the tube reach up to 30 degrees Celsius (86 degrees Fahrenheit).

In 2003, the mayor of London at the time, Ken Livingstone, offered a prize of £100,000 to the mastermind who could come up with a good solution to cooling down the Tube. But it seems that prize has gone unclaimed.

The layman's solution to this would simply be installing a lot of air conditioners to keep the tunnels cool. But, Rail Engineering says, ‘not so fast'. Transport for London (TfL) Cooling the Tube programme director Kevin Payne told Rail Engineering that it is a bit more complex than just putting air conditioners in.

“Payne estimates that removing heat from the network this way costs the upper end of 10 to 50 times as much as putting it in. Partly, also, it’s because warm air from the heat exchangers would have to go somewhere and, given the restrictions on building new ventilation plants across central London, it simply can’t.”

Another problem on the Central Line is that the trains run too deep and don't leave enough space for air conditioners. Engineers have, however, promised that a more sophisticated air conditioning system is coming, but only in 2030. In the meantime, they have introduced an experimental fan-based cooling system at Paul's Tube station. A report by Wired explains how it works:

"The system, which was designed by London Underground's crack cooling squad, pulled fresh air from the street and pumped water around pipes at a rate of 16 liters per second to cool the air by seven degrees before pumping it out at platform level. As a result, St Paul's has gone from one of the hottest stations on the Central Line to one of the coolest."

Passengers have taken to social media to express their disdain with the temperatures inside the carriages of the Underground. The temperatures even rose past the EU guidelines for transporting cows and sheep. The end of the heat of the Central Line is not in sight just yet, so, it falls to engineers to be the light at the end of the tunnel and fix the heat woes in London's Underground.

Works Cited

Temperton, James. “Why Is London's Central Line so Hot? Science Has the Answer.” WIRED, WIRED UK, 10 July 2018, www.wired.co.uk/article/central-line-temperature-london-weather-heatwave.

Rail Engineering, Cooling the Tube, as reported by Brian Tinham : http://www.plantengineer.org.uk/article-images/23757/cooling.pdf

The 4D printing era has officially arrived.

Four-dimensional printing is characterized by a 3D printed object's ability to change shape.

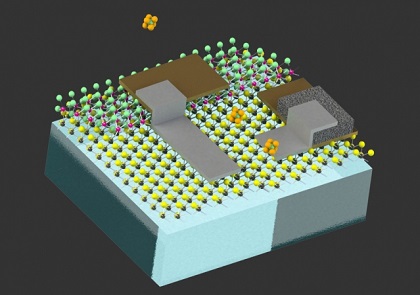

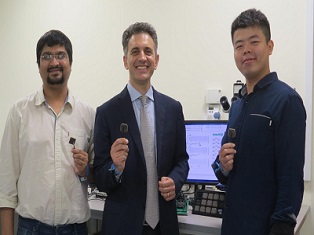

Mechanical engineering researchers at City University of Hong Kong believe they have developed a world-first. They are debuting a ‘ceramic ink' for 3D printers. This means a mixture of elastic polymers and ceramic nanoparticles can be passed through a printer. The object that is produced is then able to be molded into any shape. The researchers published their findings in the Science Advances journal.

Previously, printing with ceramic-based resins produced rigid structures that couldn't change shape. However, this new ceramic ink allows for the production of malleable shapes, similar to origami structures. This signals further evidence of the origami movement that's occurring within the mechanical engineering sector. The title of the research the engineers published was: “Origami and 4D printing of elastomer-derived ceramic structures.”

The ceramic precursors can be ‘stretched three times beyond their initial length' when heated up during the printing process, according to the researchers. Professor Lu Jian, the Chair Professor at CityU's Mechanical Engineering Department — who spearheaded the research — told reporters:

"With the versatile shape-morphing capability of the printed ceramic precursors, its application can be huge. One promising application is electronics. Ceramic materials have much better performance in transmitting electromagnetic signals than metallic materials. With the arrival of 5G networks, ceramic products will play a more important role in the manufacture of electronic products."

The researchers are also confident that there could be impressive aerospace applications in the future. The researchers believe this new process will begin a new chapter of cost-efficient 3D printing with flexible structures.

Works Cited

EurekAlert. “CityU Develops the World's First-Ever 4D Printing for Ceramics.” EurekAlert!, www.eurekalert.org/pub_releases/2018-08/cuoh-cdt081518.php.

“The World's First 4D Printed Ceramics Take Shape Thanks a Team of Mechanical Engineers.” Interesting Engineering, 19 Aug. 2018, interestingengineering.com/the-worlds-first-4d-printed-ceramics-take-shape-thanks-to-a-team-of-mechanical-engineers.

Concrete batteries? It seems that civil engineering and mechanical engineering have met in the middle for a new type of energy storage.

A Swiss startup named Energy Vault has showcased an unorthodox experiment — they have stacked concrete blocks via an electric crane, and in doing this, stored energy.

The startup compares the phenomena to pumped hydroelectric energy storage. Quartz reports that 96 percent of the world's energy storage capacity comes from pumped hydro. This means whenever there is a surplus of electricity, the excess is used to pump the water up into a dam. Then when there is a demand for electricity to be generated, the water falls with the help of gravity. As it descends, the water turns the turbines to produce potential energy.

However, this method can be problematic. What about areas that don't have access to dam water and the subsequent turbines that enable pumped hydro? Well, Energy Vault says stacked concrete could be the answer.

Simply put: when you elevate something against gravity, it stores energy. When it falls, you recover that energy. This is the theory behind Energy Vault's

new system. A crane, with an electric motor, picks up concrete blocks and stacks them in a tower, storing excess energy. Then, the blocks can be dropped from the stack while the motors are run backward and a generator shaft is used to produce the electricity. The startup envisions a 120 meter (400 foot) tall crane that lifts and stacks blocks all around it. The crane is powered by renewable energy like solar or wind — a computer then tells the crane where the concrete blocks are, and a camera assists, too. The block is then lifted, and a stack of concrete blocks begins.

The total energy in a full tower of concrete blocks as pictured above is 20 megawatt-hours (MWh). Quartz reports that it's enough to ‘power 2,000 Swiss homes for a whole day'. The startup is confident that a lower quality concrete can be produced for the plants specifically so they can continue generating energy all day long.

The experimentation is still in its early stages and being performed on a small scale. But, any energy storage applications that could be applied worldwide would be welcomed by governments who are trying to rely less and less on fossil fuel technologies to keep the lights on.

Gravity trains

Some electrical engineers on social media have questioned how viable the concrete block stacking is. Some other engineers point to train regenerative braking as a better option. In California, a company named ARES (Advanced Rail Energy Storage System) has implemented a grid-scale energy management system that is capable of providing utility balance when it is needed.

The system utilizes 300-tonne autonomous train-like vehicles on a train track. When a power utility is in need of power, the vehicles - who would have made their way uphill when the utility had an excess of power - would begin their descent downhill. Their motors then become energy generators and generate electricity in the act of traveling downhill and then braking. The cabs have rocks in them so that they are weighted down and faster when coming downhill.

Here is an example of what it looks like:

Works Cited

Rathi, Akshat. “Stacking Concrete Blocks Is a Surprisingly Efficient Way to Store Energy.” Quartz, Quartz, 30 Aug. 2018, qz.com/1355672/stacking-concrete-blocks-is-a-surprisingly-efficient-way-to-store-energy/.

“Surplus Energy Rides the 'Gravity Train' - BBC News.” BBC, BBC, 28 June 2018, www.bbc.co.uk/news/av/technology-44549962/surplus-energy-rides-the-gravity-train.

Engineers are exceptionally skilled at designing products that assist people who are disabled. But it's not often that we see a disabled person engineering for those who are able-bodied.

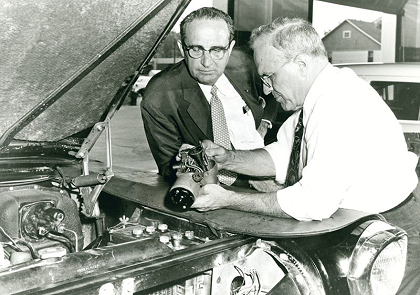

While millions of people use cruise control every day, many wouldn't know that it was invented by a blind engineer. His name was Ralph Teetor.

When he was five-years-old, he was blinded in an accident involving a knife. He then suffered from sympathetic ophthalmia — the other eye went blind as a result of the trauma to the first.

Ralph had a knack for engineering from an early age. He would tinker with parts in his father's workshop, from ten-years-old. He developed a talent for feeling mechanical objects and designing parts despite his disability. His hands had become his eyes. He believed he could have a future in engineering.

After high school, many universities refused his applications based on his disability. Nonetheless, he eventually got enrolled at the University of Pennsylvania in the mechanical engineering department.

He graduated from university and went to work in the U.S. Navy, where he performed engineering maintenance on warship steam turbines. After leaving the Navy, his father and three of his uncles recruited Ralph for their piston ring production company named Perfect Circle. He eventually became the President of the company and tinkered away on his own small projects too.

He also became the President of the Society of Automotive Engineers (SAE).

During World War 2, war rationing forced motorists to drive 35 miles-per-hour so that they could save on gas. Consequently, Ralph began work on a mechanism that could assist motorists in sticking to one speed during a commute, without having to regulate it themselves.

In 1948, the ‘Speedostat' was born. A decade later, they finally finished engineering a prototype that could confidently be used in vehicles.

The first prototype included a vacuum-driven piston capable of stopping the gas pedal from being pushed far enough.

Nonetheless, true cruise control would have to keep the driver at a constant speed, not just slow it down. That's when Ralph added a ‘speed lock' mechanism with the help of an electromagnetic motor. Upon the tapping of the breaks, the speed lock would be canceled out.

By 1958, Chrysler wanted the Speedostat in their cars and started adding it as an option to their luxury cars. By the 1960s, all General Motors' Cadillacs had it - and its name changed to ‘cruise control.' Then in 1973, when the Organization of Arab Petroleum Exporting Countries (OPEC) decided to stop selling oil to the United States due to political factors at the time, cruise control was lauded as an oil-conserving savior.

Ralph Teetor's legacy proves that despite disability, engineers can defy the odds and create something that completely revolutionizes technology and improves lives. It shows that anyone can overcome a setback and still contribute to humankind.

The invention of cruise control made people wonder how much further vehicles could be automated at the time. Fast forward to today, and we are on the verge of driverless cars.

Works Cited

“The Inventor of Cruise Control Couldn't See.” YouTube, 31 July 2018, youtu.be/298Rb9wNwMg.

Sears, David. “The Sightless Visionary Who Invented Cruise Control.” Smithsonian.com, Smithsonian Institution, 8 Mar. 2018, www.smithsonianmag.com/innovation/sightless-visionary-who-invented-cruise-control-180968418/.

A full rotation of the earth around its own axis produces patterns and rhythms in nature known as the diurnal cycle. Ever since human beings could perceive that the sun rose in the East and set in the West, the assumption was that there was a passage of time.

Then came the measuring of time. Lunar cycles were observed, sundials and water clocks became commonplace in some societies. These all pointed towards evidence that the telling of time could be linked to the diurnal cycles of the earth. By the 14th century, in Europe, mechanical clocks were invented, leading to the engineering of the grandfather clock in 1657. Consequently, the world saw a rise in the ordering of human life around the clock.

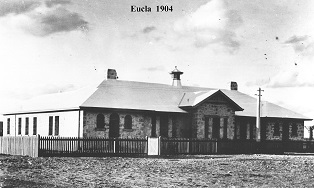

With more and more humans telling time, and governments trying to agree on what the real time was, there was a worrying trend developing in the United States. In the 1880s, each American town had established their own local times based on their reading of the sun. And this caused a headache for the railroad industry. Specifically, the coordinating of trains.

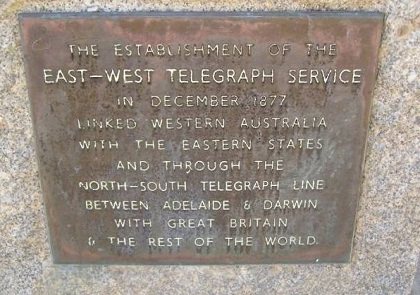

Great Britain resolved in 1840 to begin adhering to a standardized time for their railways. It would be known as the Greenwich Mean Time (GMT). From 1846 to 1848, the railroad stations across Great Britain were all synchronized according to the GMT time. America was having troubles too.

Bafflingly, when it was 6:28 am in Los Angeles, it was 9:28 am in New York. Thus, if each town had its own time defined within its own borders, going cross-country in a train would prove dangerous because two trains traveling on one railroad would want to arrive at the same time — but with the train drivers thinking it was a different time. Metaphorically and literally, it would have been a train crash waiting to happen.

The different states in America realized they would not be able to solely rely on their state-specific reading of time.

In 1918, the American Congress heard and accepted the idea of a standard railroad time. Eastern, Central, Mountain, and Pacific times. Congress eventually passed the Standard Time Act in 1918 and standardized time.

Since then, the rest of the world became dependent on timezones collectively defined with the lesson of railroad travel in mind. GMT has been spun-off and refined into Coordinated Universal Time (UTC), utilizing the advent of atomic clocks which tell time much more accurately. America still adheres to their four time zones that were standardized in 1918.

The change trains and railroads brought to the world, and human life was characterized as the ‘annihilation of space and time’ - engineers had achieved a physical change to the world that had never been observed before. A psychological shift followed - humans became accustomed to a world of travel, speed, and power. And as a result, led to more technological expansion. Many technologies like global positioning systems and the computers that have given rise to them rely on an understanding of atomic time in the present moment.

The world is now observing the fourth industrial revolution. An advancement of technology that could once again disrupt our perception of time, space and energy. As quantum physics’ exploration continues and gives rise to technologies like quantum computing, nanotechnologies, and more, the boundaries of possibilities are growing further and further outward. What this will mean for the majority of engineering industry still remains to be seen - however, the effect is poised to be significant.

How will engineering change human perception of the natural environment next?

Works Cited

“How Did Trains Standardize Time in the United States? - William Heuisler.” YouTube, 5 Feb. 2013, youtu.be/UBpTohx1BOc.

“The Order of Time by Carlo Rovelli.” Penguin Books, www.penguin.co.uk/books/301539/the-order-of-time/.

“The Railroad Journey and the Industrial Revolution: Crash Course World History 214.” YouTube, 1 Nov. 2014, youtu.be/GYAk5jCTQ3s.

What is a side-hustle?

It's really anything that you can do on the side to make money while pursuing higher education or employment. It may be a hobby you are trying to monetize for a little bit of extra cash, it may be a serious venture you are working to pursue but unable to generate an income from just yet, or it may be something you've already started that is producing some extra income for you.

Some qualified engineers take it a step further. Many understand that the traditional trajectory of getting qualified, finding a big company to fit into and staying there for 40 years is a thing of the past.

Some engineers are becoming part of the gig economy. The gig economy is a ‘labor market characterized by the prevalence of short-term contracts or freelance work as opposed to permanent jobs.' And some people have side-gigs to supplement their income while they continue to search for a more permanent position elsewhere. Prospective engineers are learning to become resilient.

Engineers are noticing that they can also create several side-hustles that generate money they can use to achieve even bigger things later on in life.

In the engineering world, the side-hustle usually culminates in a startup idea that requires the input of some like-minded team members. Nonetheless, when you pursue a side-hustle, it's important to make sure you still have the backup plan.

Previously, the backup plan might include a ginormous time investment of going to a brick-and-mortar tertiary institution and putting the side-hustle on pause. Starting a side-hustle while sticking to a strict schedule of classes and examinations is a tall order.

Early on, some engineers fail to realize that their engineering course may be teaching them the business principles they need to become an entrepreneur. Albert van Wyk is a South African industrial engineer. At the age of 22, he was already investing in property and building side-businesses that began generating an income. He became one of South Africa's youngest millionaires.

Albert went on to write a book titled: ‘How to become a Millionaire at 22.'

But it was the skills he was learning in his engineering degree that improved the business-side of his side-hustles. He has started a podcast named ‘Millionaire Insights with Albert van Wyk,' where he inspires like-minded engineers and entrepreneurs in South Africa, to become better businesspeople whilst upskilling and acquiring formal qualifications.

In the latest episode of his podcast, he said:

“I studied Industrial Engineering. I actually completed my degree in four years and became an industrial engineer. And then, I worked for one year in the industry as an engineer before I quit my job to become a full-time entrepreneur. One of the key terms that we learned in industrial engineering is called a value chain analysis. You take each process, each activity, in your chain of events that creates value for your business, and you analyze each of them.”

Industrial automation engineering can teach that, even in business, a person can produce an efficient chain of procedures that leads to the creation of a valuable outcome. But even mechanical engineers are obtaining their qualifications, then swimming against the tide.

Inaam Khan is a mechanical engineer from Manchester, Connecticut in the United States of America. His motto, and advice to prospective entrepreneurial engineers is: ‘Aim high, don't be shy.' He founded his own sock company after graduating. He aptly named the company I-Khanic. In an interview, he said:

“My parents have been very supportive, first of all. They never cared that their son had an engineering degree and was out there selling socks.”

Turning the side-hustle into the main-hustle takes grit and determination. It is recommended that students and graduates continue to upskill themselves — so they are job-ready and educated — while trying to be as entrepreneurial as possible.

Works Cited

Nyberg, Ann. “Manchester Mechanical Engineer Inspired by Social Media Launches Sock Company.” WTNH, WTNH, 14 Aug. 2018, www.wtnh.com/on-air/nyberg/manchester-mechanical-engineer-inspired-by-social-media-launches-sock-company/1366407095.

“Millionaire Insights with Albert Van Wyk.” Iono.fm, Https://Iono.fm/p/360, iono.fm/c/3590.

Electrical engineering professionals will have to roll with the punches as new technology takes over the quarrying business and sends the industry into the future. Volvo Construction Equipment and partner Skanska are testing an Electric Site project — a quarrying operation of the future that will look completely different to anything that has come before it.

It's all going down at Vikan Kross quarry. The group is experimenting with new concept machines, work methods, and brand new site management systems, which have never been tested at a quarry before. They are focusing on electromobility and automation to meet new emissions targets — a move that will set the bar for the mining industry for some time to come.

Gunnar Hagman, CEO of Skanska Sweden said:

“This is the first time that anything like this has been attempted in the quarrying industry and, if successful, Electric Site could serve as a blueprint for transforming the efficiency, safety and environmental impact of quarries around the world.”

On 29 August 2018, the engineers were ready to debut their new Electric Site. For ten weeks, the autonomous Volvo machines will engage in production. They will only emit 95 percent of the emissions that a normal mining setup would produce. The companies will also spend 25 percent less than they would have with the old technology. The engineers have electrified each level of the transport stages in the quarry. Hagman said:

"We have to completely rethink the way we work and how we look upon machine efficiency — pushing the boundaries of our competence. The total site solution we developed together with our customer Skanska is not a commercial solution for sale today and we will evaluate the outcome of the tests but we have learnt so much already, elements of which will be fed into our future product development."

The quarry is utilizing eight prototype HX2 autonomous battery-electric load carriers. These fully electromobile vehicles will carry the extracted resources from the quarry. The engineers had initially tested out a first iteration of the load carrier called HX1. Once they had confirmed the electric drivetrain was capable of being driven by the battery technology they went ahead with producing the HX2.

The engineers then went on to fit previously emission-emitting technologies with electric motors. A primary crusher excavator prototype was born, ready to work on the site. One benefit of electric motors is that the site is much quieter than a normal quarrying site. But Chief Project Manager for Electric Site at Volvo CE Uwe Muller explains just how complicated an electric upgrade to an excavator is:

"To fit the new components in the machine without increasing its size required a significant amount of repackaging work. However, in terms of the operator interface and controls, nothing has changed - it's operated in exactly the same way as a conventional Volvo extractor. If the cable is connected, the machine will automatically start in electric mode. If it's not, it will start in diesel mode. Because the machine will be relatively static - only moving a few meters once or twice a day as the excavator works its way through the blasted rock - it's ideally suited as a fully electric machine on a cable."

The thinking behind this reflects the kind of renewable energy setups at mining setups. Some mines have solar panels and diesel setups so that when the renewables cannot pick up the slack, it can default back to diesel generators and continue powering the mining operation. Muller continues:

“This has allowed us to make it a zero-emission excavator when it’s plugged into the grid. However, we’ve designed it with flexibility in mind, so that we can have the option of using the diesel engine when it’s needed, for example, to reposition the machine or quickly movie it prior to blasting.”

Works Cited

Casey, JP. “Volvo and Skanska Begin Tests at Prototype All-Electric Mining Site.” Mining Technology, 4 Sept. 2018, www.mining-technology.com/news/volvo-skanska-begin-tests-prototype-electric-mining-site/.

“Testing Begins at World's First 'Emission-Free' Quarry.” Volvo Construction Equipment, www.volvoce.com/global/en/news-and-events/news-and-press-releases/2018/testing-begins-at-worlds-first-emission-free-quarry/.

ZipRecruiter, one of America's top job recruitment sites, has reported that the most in-demand jobs are in the electrical engineering industry. The site is visited by millions of people every day, and the most searched for positions — in fact, the top five searches — were all pertaining to electrical engineering.

The searches ranged from entry-level electrical engineering jobs for advanced diploma holders, up to the kinds of jobs that require Professional Engineer recognition. ZipRecruiter confirms many of the inquirers are looking to be electricians on construction sites. Other inquiries are for particularly specialized positions within electrical engineering.

But, mostly, skilled workers are looking for any jobs they can get in the electrical engineering field. Furthermore, ZipRecruiter has indicated that these job seekers are often looking for a promotion.

The report interestingly stated:

“Given the high demand for and low supply of these workers, it’s likely that most of these job hunters are already employed and looking to level up into higher-paying positions.”

Worryingly, the supply of workers cannot keep up with the pace of electrical engineering jobs being listed in the US. The site has its own ZipRecruiter Opportunity Index which takes a look at the availability of workers versus how many jobs had been listed. The index in electrical engineering resulted in a 1:4 ratio. There is one worker to every four listed electrical engineering jobs on the website. Moreover, for electricians, the ratio was 1:5.

Those ratios are the averages across the entirety of the United States. The numbers in state-specific data sets seem to look even more concerning.

Start studying (and working)

The numbers have highlighted a big need for qualified and skilled individuals in the United States. ZipRecruiter says the data also indicates that electrical engineers and electricians should be open to relocating. For example, in Ann Arbor, Michigan there were nine electrical engineering jobs open to one applicant at a time. In the New York metropolitan area, the highest number of applicants existed. Detroit apparently had the biggest labor shortage of all.

The data is also telling a poetic story about the situation throughout the rest of the world. Students are encouraged to examine the job listings for a particular country and assess which engineering disciplines are in demand, before picking a discipline to pursue. They are also encouraged to upskill and gain qualifications for the available jobs they could qualify for.

Shortages across Australia

CNBC reports that Australia is also seeing a rise in job listings for site engineers and electrical foreman. The construction and property market is purportedly on the rise, and that means that electrical systems for new developments will be required.

According to an article written by the Dean of Engineering at the University of New South Wales (UNSW) Sydney, and an Associate Professor in UNSW’s School of Minerals and Energy Resources Engineering, electrical engineers in Australia currently make a median salary of US$46 693.72 per year.

Works Cited

“Electrical Engineers, Electricians in High Demand in These Markets.” The Bay State Banner, 15 Aug. 2018, www.baystatebanner.com/2018/08/17/electrical-engineers-electricians-in-high-demand-in-these-markets/.

Gilchrist, Karen. “These Are the Best Jobs in Australia Right Now.” CNBC, CNBC, 4 Sept. 2018, www.cnbc.com/2018/09/04/best-jobs-careers-australia-teaching-tech-construction-healthcare.html.

z3524864. “Mining Bust's Gone and the Boom's Back: We Need Engineers.” UNSW Newsroom, 29 Aug. 2018, newsroom.unsw.edu.au/news/general/mining-bust’s-gone-and-boom’s-back-we-need-engineers.

China was abuzz at the 2108 World Robot Conference 2018 in August. Manufacturers from around the world descended on Beijing to showcase their latest robotic endeavors. China is stepping up its robotic output and intends to increase manufacturing operations as we approach 2020.

Xin Guobin, China’s vice minister of industry told media officials:

“Robots are the jewel in the crown for the manufacturing industry...a new frontier for our industrial revolution.”

According to Interesting Engineering, China intends to have most of its industrial robots engineered on home soil by 2020. China is currently the world leader of engineering and selling robots — in 2017, they sold 141,000 industrial units.

China has launched an initiative, called ‘Made in China 2025’ to upgrade its industries. They hope that by 2025, they will be the world leader in intelligent manufacturing and smart factories.

Attendees of the World Robot Conference were surprised that many of the robotics manufacturers had debuted robots that were seemingly inspired by nature.

The new design frontier indicates that robotics engineers are trying to figure out how to design robots that are more flexible, speedy, responsive, and intelligent. One of the robots that made journalists curious was named the BionicFlyingFox.

The BionicFlyingFox is an intricately designed robot that mimics the flight of a bat. It has been designed with intelligent kinematics and can replicate unbelievable flying maneuvers. A motion tracking system ensures that it doesn't hit any walls or veer off and crash. This makes the robot semi-autonomous, but needless to say, one day it will likely fly on its own.

The robot was created by Festo, a German multinational industrial control and automation company. They produce and sell pneumatic, electrical control and drive technology for factory or process automation.

While their BionicFlyingFox robot is impressive to look at, it’s a statement of how well-designed their other industrial technologies are. Creating agile robots is imperative to the future of robotics. In biomedical engineering, we are already seeing the rise of robots that can perform maneuvers humans are unable to replicate. As robots replace the repetitive jobs that humans have done in the past, ensuring robots are as agile and flexible as possible is important work.

And they need to be lightweight in the future as well — the fox only weighs 580 grams. And it’s getting smarter. Engineers are utilizing motion tracking systems, which are hooked up to a computer that evaluates and learns from the data of each flight. The robot can aptly alter its course on each individual flight based on the findings of its previous flights.

It seems that the time of flexible, agile, autonomous, intelligent robotics has truly come.

Works Cited

Kirstel, Evan. “Evan Kirstel (@Evankirstel).” Twitter, Twitter, 4 Sept. 2018, twitter.com/evankirstel/.

“Our Favorite Robots From China's 2018 World Robot Conference.” Interesting Engineering, 20 Aug. 2018, interestingengineering.com/our-favorite-robots-from-chinas-2018-world-robot-conference.

In July 1969, Neil Armstrong became the first man to walk on the moon as part of the Apollo 11 mission. In August and September 1977, NASA launched Voyager 2 and then Voyager 1 — space probes with the primary purpose of exploring the outer reaches of the galaxy. Voyager 2 is still the only space probe that has ever visited Uranus and Neptune. The Voyager spacecraft are still exploring outer space 41 years later.

What do the Apollo missions and the Voyager spacecraft have in common? The modern smartphone outranks the computer technology that made those space explorations possible. It took the Apollo 11 missions only four Apollo Guidance Computers (AGC) to get man to the moon.

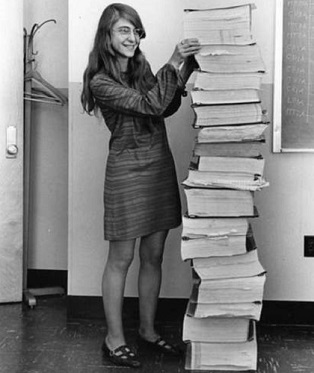

Even more impressive, it was a woman who got man to the moon (sort of). Margaret Hamilton, a systems engineer who wrote the code that defined the Apollo 11 mission, was awarded the Presidential Medal of Freedom by Barack Obama in 2016. The code that was written, when stacked, stood taller than Hamilton.

However, as pointed out by Popular Mechanics, at the time of the missions, the computers utilized were ten years ahead of their time. This was before the microchip ever existed.

IBM assisted NASA in creating the computer infrastructure that facilitated the Apollo missions. Rhuaridh Marr, from Metro Weekly writes:

“The Apollo Guidance Computer directing the rocket was an incredible achievement for NASA -- it was the first computer system to provide real-time information about the spacecraft as it navigated, detailing important stats and allowing for automatic navigation.”

Nonetheless, by the time the Apple II personal computer came out, the technology that guided astronauts through space was outperformed. However, it is undeniably true that NASA ran an entire space exploration program from start to finish with less technology than what’s inside an iPhone. The Apollo Guidance Computer only had four kilobytes of RAM, where modern-day laptops have eight gigabyte RAM sticks. An Apple iPhone’s processor runs at 150MHz, whereas the Apollo computer ran at 1MHz. And they only had 32 kilobytes of storage capacity. Marr writes:

“The Apollo computer took a spacecraft to the moon and back, and it’s 150 times less powerful than a processor that knows whether you’re walking or driving.”

You can now access the exact code that was used on the command and lunar modules that made the Apollo missions possible here.

Not done yet

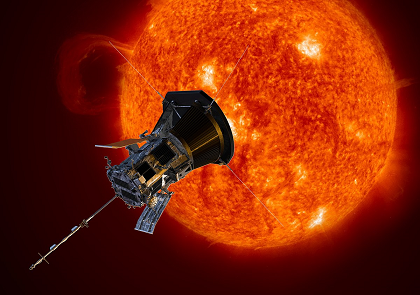

NASA is not done sending probes into space just yet. They have just launched a new probe that is set to ‘touch the sun’.

NASA is sending a probe to fly into the low solar corona. It will comb through coronal plasma and magnetic fields that appear to facilitate the acceleration of energetic particles nearby the sun.

The Parker Solar Probe will be the fastest spacecraft in history. It will also get seven times closer to the sun than the previous record holder, the Helios B. It is expected to get within 3.9 million miles of the sun’s surface. It will orbit the sun 24 times, capturing data that will be pored over down here on earth.

A lot of the information that will be perused will be the data generated on the way to the sun. While researchers are hopeful that data can be generated while the probe is in close proximity to the sun, they say that might not garner any results. The strongest focus will be put on understanding solar wind.

At its optimum speed, the Parker Solar Probe will orbit the sun at 430,000 miles per hour. It will experience temperatures of 2,500 Fahrenheit (1,400 degrees Celsius). A carbon composite engineered shield is what protects the probe from the scorching temperatures of the sun. It also employs a white, reflective alumina surface layer that lessens the absorption of heat. The craft is powered by photovoltaic solar arrays.

The probe will hopefully report back on which segment of the sun is responsible for heating up and distributing the solar wind that is emitted and sent towards earth and other planets. It was engineered by Johns Hopkins University’s Applied Physics Laboratory.

Works Cited

Grossman, David. “The One Way Apollo Computers Still Beat the iPhone.” Popular Mechanics, Popular Mechanics, 15 Feb. 2018, www.popularmechanics.com/space/moon-mars/a25655/nasa-computer-iphone-comparison/.

“To the Moon and Back on 4KB of Memory.” Metro Weekly, 7 Dec. 2017, www.metroweekly.com/2014/07/to-the-moon-and-back-on-4kb-of-memory/.

The automation of mining operations is inevitable. Mining is a high stakes business with costly equipment and a small margin for operational error. Thanks to the digital disruption of the sector, mines are being made safer, more efficient, and productive.

Not many underground mining operations are automated. However, this will soon change. The Syama Mine in Mali is tipped to be the first fully-automated underground mine in the world. Resolute Mining, an Australian company, currently owns the gold mine.

The company intends to completely reorganize the mine with new technologies. An automated fleet of driverless trucks will drive the product around, and a remote monitoring team will be watching everything closely to ensure the mine is working at peak efficiency. Loaders and drills will be automated, too. Sensors will monitor the entire process providing real-time analysis of the health of the operation, and more.

As a result, the mine will not need to recruit or pay any drillers.

Is this a good thing or a bad thing? Africa is a prime candidate for the leapfrogging of technologies and is still a resource-rich continent. Many African workers rely on being employed as drillers in mines so they can put food on the table at home. Would the automation of these mines lead to job losses?

Resolute Mining, the company behind automating the Syama Mine, has said that not many jobs will be lost. And they are advocating for the upskilling of their workers.

What might it mean for the future of the mining industry? How might it disrupt a mining economy? How many jobs will be lost? Resolute Mining managing director John Wellborn says the company has an answer to these pertinent questions. He told ABC News:

“Rather than focusing on putting in wells in local villages and handing out school books, we’re focused on upskilling, training and empowering the local workforce.”

The automation will also save the mining company money — it will slash mining costs by 30 percent. There is also less chance of loss of life as well.

“Automation is often seen through the prism of a vehicle factory where you blow the whistle and sack 200 of your assembly line workers and replace them with robots or a large group of sewing machine operators who can be replaced by a machine. I often get asked about the political impacts of automation in Africa, with the perception that governments will be concerned we’re laying off workers. What we’re doing has very little to do with reducing workforce - it has everything to do with efficiency and productivity.”

The employees of the Syama Mine are waiting with bated breath. They are interested in seeing how automation might change or improve their working conditions, and whether it will mean prosperity for Resolute Mining.

Goldmine blues

Further afield in South Africa, a gold mine is ready and prepared to let a large number of employees go. While a mining surge has been observed in the country, gold production is down. Gold Fields has indicated it must let 1,100 of its permanent staff and 460 of their contractors go at its South Deep mine.

According to Times Live, the mine employs 3,614 full-time employees and 1,940 contractors. The mine had purportedly spent USD 20.2 million more than it had earned in the second quarter alone. Gold Fields has lost USD 275 million in South Africa.

It is not only Gold Fields that is actively pursuing a retrenchment scheme; Impala Platinum is to let 13,000 employees go, and will close 5 of their mines. Gold Fields CEO Nick Holland has previously said that the way gold has been mined for the last 100 years is not how gold will be extracted in the next 100 years.

South Africa seems to be significantly behind in leveraging new mining technologies and keeping the businesses afloat. It’s a widely held belief that Internet of Things technologies are necessary for the sector; the one thing not being said is whether miners and workers will receive upskilling work.

The mines may implement new technology, but the redundant workers might not be aptly skilled to continue working in the mine as it changes. The question remains: What will become of the uneducated driller that currently works at the mine? The answer: Upskilling.

The digitization of industries in South Africa may further intensify an already worrisome jobs crisis. Associate Director of Strategy and Operations at Deloitte, Jan-Adriaan du Plessis, in a discussion on South African radio, said:

“If you look at history, technology advancement, generally, creates more jobs than it destroys. That’s what the studies tell us. The focus should not be on trying to save as many jobs as possible, but to really upskill and repurpose jobs in the required areas.”

Nonetheless, with mining unions trying to protect their workforce, the loss of jobs in an already highly unemployed society does not make for an optimistic outlook. What is clear is that mining employees of past, present, and future, must upskill as much as possible and be ready for the future of mining on a continent that is ready to embrace new technologies with open arms.

Works Cited

Lucas, Jarrod, and ABC Goldfields. “Aussie-Owned African Gold Mine to Be World's First Robot-Only Underground Digs.” ABC News, Australian Broadcasting Corporation, 8 Aug. 2018, www.abc.net.au/news/2018-08-09/worlds-first-fully-autonomous-underground-mine-in-africa/10090932.

Roux. “The Future of Mining, South Africa's Lifeblood (and Employer of 500 000 People).” 702, 17 Apr. 2018, www.702.co.za/articles/300105/the-future-of-mining-south-africa-s-lifeblood-and-employer-of-500-000-people.

Seccombe, Allan. “Gold Fields to Cut up to 1‚560 Jobs at South Deep Mine.” Times LIVE, Sunday Times, www.timeslive.co.za/sunday-times/business/2018-08-14-gold-fields-to-cut-up-to-1560-jobs-at-south-deep-mine/.

The Engineering Institute of Technology (EIT) is pleased to announce that from 03 September 2018, a new application system will be made available to allow interested students to apply online for their course or program of choice.

The implementation of this new online system will make it easier for interested parties to apply to study with EIT and to be kept informed of the status of their application.

We strongly recommend that you contact our qualified Course Advisors before lodging an application so we can counsel you on the suitability of the course and the application requirements. Simply complete the request form on the relevant program page and we will get in touch with you to assist you.

We look forward to receiving your online application to study with EIT in order to help you advance your career!

If you need any assistance, please do not hesitate to contact us:

Dear Colleagues

We wouldn’t have breakthrough discoveries without that wonderful quality – curiosity - from inventing fire, the aircraft to the Google search engine. That magical feeling that goes about investigating new information, pondering on a different way of doing something or simply trying something out new (and often having that incredible ‘Ah hah’ moment) is an innate quality we all have.

No More Boredom

Without curiosity we would have a very boring and unproductive world. It is key to your success in your engineering career. However, many managers and companies fear it as it can be rather disruptive and encourage chaos. Something engineering professionals with their love of order aren’t always fond of. Certainly, you don’t want chaotic curiosity occurring in a bridge design otherwise you may have some catastrophic results.

Without curiosity we would have a very boring and unproductive world. It is key to your success in your engineering career. However, many managers and companies fear it as it can be rather disruptive and encourage chaos. Something engineering professionals with their love of order aren’t always fond of. Certainly, you don’t want chaotic curiosity occurring in a bridge design otherwise you may have some catastrophic results.

Without any question – curiosity is particularly important to engineering professionals and their organisations in lifting one’s creativity and strengths. It improves your performance especially in an uncertain economic environment making you more resilient to the changes coming.

Typical benefits of curiosity include: Fewer errors when making a decision as you are constantly questioning assumptions and stereotypes; driving innovation by being creative and questioning; perhaps reducing conflict as you consider other people’s perspectives and finally more open communications with others as you open your mind to alternatives.

However, in my experience, leaders of organisations often avoid encouraging curiosity. They have huge and often brutal performance targets that your are being measured by. This means that they are absolutely focussed on these targets in their clinical search for efficiency and can’t avoid time for experimentation and curiosity.

How do you increase curiosity in your engineering life ?

A few suggestions (from Francesca Gino modified by my take on engineering):

Surround yourself by curious people. Hire, build your team from and actively move towards curious people. This will have an avalanche effect on your performance and that of your team in lifting your creativity dramatically.

Model yourself as an inquisitive curious person. Ask questions and investigate and encourage others in your team to do the same.

Encourage learning every day all day. Open the opportunities to further study to all your team and certainly yourself. I dedicate an hour early every morning on study and gaining a skill or an appreciation in a new area. Sometimes a painful pursuit as it challenges one’s brain. But it is the only way forward in building and sustaining your engineering career.

Randomly set up regular “What if” and “How Might we” sessions on particular topics with your team.

Remember that Millions saw the apple fall, but Newton asked why.

(Bernard Baruch)

Thanks to Francesca Gino of Harvard Business Review for an interesting take on this topic.

Yours in engineering learning

Steve

Mackay’s Musings – 21st August’18 #677

Another bridge has collapsed and it could have been avoided. Well, that is what at least one engineer thinks. This one came down near Genoa in Italy, just this week. Euronews reports that an engineering professor, back in 2016, had urged the authorities to ‘completely rebuild’ the Morandi Bridge because of deterioration.

On the 14th of August 2018, the bridge came plummeting down causing at least 35 fatalities. And many more are feared missing. In total, 200 meters of the 1.1 kilometer bridge plunged 50 feet taking cars and trucks down with it.

Antonio Brencich, a professor of engineering at the University of Genoa told ingengneri.info:

“The continuous costs for its maintenance suggest that in a few years, these costs will exceed the costs of reconstruction of the bridge; at that point it will be the time to demolish it and rebuild it.”

The bridge, which was constructed in the 1960s, provided a link between France and Rome. It was engineered by Riccardo Morandi, who was renowned for his work with reinforced concrete. While it's a cable-stayed bridge, it utilizes reinforced concrete for the cable stays instead of regular cables.

The lifetime of the bridge was supposed to be 100 years, but Brencich alleged that the east tower of the bridge was not appropriately reinforced. It was, however, the west tower that seemed to give way.

Autostrade del Tronco Genovese, the maintenance authority responsible for maintaining highways and bridges, says that the bridge’s recent checks did not indicate that it was in imminent danger. Recent torrential rain in the area is being considered as a contributing factor to the bridge’s collapse. Other online commenters say that the bridge may have been struck by lightning.

A Genoese architect Diego Zoppi speaking to the ANSA news agency said:

“The problem with the Morandi Bridge is that the tie rods were made of concrete and not metal. In the 1960s they did not expect concrete to degrade and then collapse. Fifty years ago there was unlimited confidence in reinforced concrete. It was believed to be eternal. With the continuous vibrations of traffic, the cement cracks let air pass through, which reaches the internal metal structure and makes it oxidize. For this reason, the bridge has always required extensive maintenance work. It was very expensive to manage.”

The concern now is for other structures dated around the same time as the Morandi Bridge. These will need to be scrupulously checked for any signs of wear and tear, to prevent similar accidents.

Further focus will be given to the loads that the bridge endured over the years; the level of fatigue it had experienced could have been significant. Mehdi Kashani, associate professor in structural mechanics at the University of Southampton, talking to the Independent said:

“The bridge engineering research community should take this seriously in their future research to improve the resilience of our infrastructure under extreme loading.”

Engineering experts say it is too early to confidently attribute cause to the collapse of the Morandi Bridge, but point to the fact that corrosion of the reinforcement in the concrete is a likely explanation. What remains clear is that regular maintenance for bridges should be enforced, and attention paid to experts who indicate that structural issues exist.

Works Cited

Fiorentino, Michael. “Engineer Warned in 2016 That Genoa Bridge Would Need Rebuilding.” Euronews, 14 Aug. 2018, www.euronews.com/2018/08/14/engineer-warned-in-2016-that-genoa-bridge-would-need-rebuilding.

Griffin, Andrew. “Experts Weigh in on Shocking Italian Bridge Collapse.” The Independent, Independent Digital News and Media, 14 Aug. 2018, www.independent.co.uk/news/science/genoa-bridge-collapse-italy-why-did-disaster-engineering-experts-a8491811.html.

The casting of concrete is becoming smarter and smarter by the day.

The digitization of concrete casting has revolutionized the way both architects and engineers do their jobs. It is now possible to 3D print concrete in novel geometric patterns that defy belief and produce artistic results. However, it’s not only for aesthetically pleasing results — the concrete slabs are more lightweight, too.

At their thinnest point, these ‘smart slabs’ are only 20 millimeters thick, making them far lighter than a traditional slab of concrete.

Digital fabrication technology can ensure that a casted slab of concrete holds the structural rigidity of concrete, while showcasing geometrical shaping only a 3D printer and the additive manufacturing process can produce.

Currently, these slabs are being used to build a concrete roof. A three-storey home project, known as the DFAB House, is being built in Switzerland by science, engineering and mathematics scholars from ETH Zurich University.

The process relies heavily on the digital fabrication — the architectural measurements are plugged into the computers, and then the robots begin building. Computer models, CAD software (of which the team have apparently coded their own) and prototyping assists with the fabrication of the elements needed to build the smart structures. CNC milling and 3D printing then finishes the process.

Eleven smart slabs are printed into 7.4 metre long, 78-square-metre segments, individually, and then, joined together on-site.

The project is purportedly the first full-scale architectural project using 3D printed sand printing techniques.

The arrival of digital fabrication means the parts necessary for construction can be produced on demand. This is much quicker than relying on prefabricated parts. In construction, modular fabrication techniques are getting better than prefabrication ever was. Digital technologies and cutting-edge industrial manufacturing equipment makes the process much quicker and ensures the output is of higher quality. On-site fabrication will become the new normal.

Andrew Watts, CEO of Newtecnic, an engineering technology firm, spoke to The Engineer about digital fabrication, and is of the opinion that it is the future. He told the publication:

“Prefabrication is a nice idea, but it doesn’t provide the flexibility needed to put things together where you have a lot of different companies and contractors working together on the same project. There’s often a need to put things together in a sequence where were you don’t just turn up with something, install it and it’s finished. You need to add sequential components later on while there are lots of other people doing work around you.”

Watts believes robots and drones will be familiar sites on-site as well. The digital world and its mechanisms will unquestionably take over the heavy lifting and monitoring on-site in the future.

Works Cited

“The Smart Slab - 3D-Printed Formwork for a Radical New Concrete Aesthetic.” Dbt, dbt.arch.ethz.ch/project/smart-slab/.

Wade, Andrew. “Digital Builds: The Technology Taking Construction to the next Level.” The Engineer, 7 Aug. 2018, www.theengineer.co.uk/digital-construction-technology/.

The war against plastic is gathering force.

Environmentalists have made it clear: the continuing use of plastics bodes badly for Planet Earth. It is gratifying to learn that the initiatives to eliminate or reduce the use of plastics are gathering speed and popularity. For example, Starbucks aim to remove plastic straws from their global stores by 2020. Some restaurants have taken the plunge and are offering customers stainless steel or cardboard straws.

The world’s oceans are filling up with plastic and this can no longer be ignored. Consumers, for the most part, are woefully unaware. Others are indifferent to the knowledge that the array of plastics they use, and then discard, often end up in the ocean. If eradication isn’t on the table, perhaps a better use for the discarded plastic exists — a permanent home other than landfill or the ocean.

Engineers have been busy devising a solution.

200,000 plastic bags and 63,000 glass bottles that would have otherwise been discarded in a landfill, have been used in the laying of a road in Craigieburn, a suburb in Melbourne, Australia.

According to BBC News, there are 40 million kilometers of roads in the world. In most third world countries, road infrastructure could mean continued industrialization and more prosperity. And if plastic could be recycled and used for road infrastructure globally, that could really assist in finding a place for waste worldwide.

What is the best way to recycle plastic and re-use it in road-building?

Engineers have come to the rescue

Scottish engineering start-up MacRebur has suggested turning plastics into pellets and then mixing them into tar mixtures.

Engineer Toby McCartney told BBC:

“How can we solve two world problems? The poor quality of roads we drive on and the waste plastic epidemic that we all see in the world today. We use waste plastics to add into an asphalt mix to create a stronger, longer lasting, pothole free road.”

He was initially inspired by a practice he saw forming in India. People would throw waste plastics into potholes and burn the plastics to plug the pothole.

To improve on the system, his engineering startup began to make plastic pellets out of waste plastics. The pellets are mixed with bitumen and it results in a stronger road that needs less maintenance.

According to Gulf News, in 2017, already 100,000 kilometers of road in India were built using recycled plastic waste. A World Economic Forum report had previously underestimated the number to be 33,768 kilometers.

Remodeling plastic pellets out of recycled plastic waste is a more recent initiative. Unfortunately, McCartney is keeping the company’s method a secret. But engineering genius is broad and engineers determined – a range of approaches to recycling plastics will no doubt emerge.

Safer roads and a use for plastic waste will indeed be another couple of feathers in the caps of creative engineers at work.

Works Cited

Report, Gulf News Web. “Watch: Building Roads from Plastic Waste in India.” GulfNews, Gulfnews, 12 Nov. 2017, gulfnews.com/news/asia/india/watch-building-roads-from-plastic-waste-in-india-1.2122745.

bbcnews. “Can Plastic Roads Help Save the Planet? BBC News.” YouTube, YouTube, 25 Apr. 2017, www.youtube.com/watch?v=cHWYoDKYnQo.

Origami is the Japanese art of folding paper into decorative shapes and figure.

Its use of geometrical shapes makes it a curious art form — one that could inspire mechanical engineering design.

According to Northeastern University researcher Soroush Kamrava, the future solar panels and air bags will be informed by origami designs. The research includes utilizing metamaterials (plastics, metals and rubber) to create complex designs that could produce stronger and more functional products.

Engineers are figuring out how to 3D print origami-inspired structures and introduce new, novel products, but also updated prototypes of products with new structures; such as airbags or solar panels. The researchers are testing out various designs and experimenting with several different angles on everyday shapes.

“Our work is a combination of science and art. So sometimes inspiration comes from a museum, old architecture, or just floor tiles,” says Kamrava.

They are looking to redefine geometry on some of the most renowned engineering designs. The researchers use an origami printer to print out the outline of the folded shape they wish to create. They then fold a paper prototype of what they intend their final print should look like, while working out whether a metamaterial prototype will be structurally sound.

Once they are happy that a geometric shape can sustain the relevant stresses, the engineers begin their print of several parts. They employ metal hinges to get the pieces into the relevant origami shape. The benefit of the origami inspired shapes is that they could be repositioned into new shapes. Creating foldable structures for industries like aerospace could be beneficial, as they’re privy to utilizing deployable structures.

Nothing new under the sun

The practice of using origami as inspiration for engineering design is not altogether new. A year ago, the Brigham Young University developed bulletproof ‘origami kevlar’. They created an origami-based deployable ballistic barrier for police safety during dangerous or hostile situations where gunfire is likely.

The engineers met with federal agents that regularly used the current shields and asked how they could improve the design, to help them safely do their jobs in hostile situations.

BYU Adjunct Professor of Mechanical Engineering, Terri Bateman said:

“Current products out there are about 90 pounds - that’s pretty heavy for one person to carry. And, it only protects one person.”

The engineers worked on reducing the weight to 50 pounds and making it possible to protect two people at once. They used a crease pattern, enabling the kevlar to be collapsible.

Not only is the kevlar aesthetically pleasing, but it also works.

Origami underwater

Engineers at the Wyss Institute at Harvard University have designed a 3D printed, 12-sided origami trap that can be used in the ocean to capture marine life without harming it. The way in which the trap is constructed allows it to fold over the marine life without asserting too much force.

The marine life is then studied by marine biologists. They have dubbed the device the Rotary Actuated Dodecahedron (or RAD). The engineers have pressure-proofed the trap to withstand pressure at 11 kilometers (6.83 miles) deep.

The engineers say their design is well suited for aerospace as well.

Brennan Phillips, a University of Rhode Island professor of ocean engineering attached to the project said:

“We believe that the geometric design can be used for things like deployable solar arrays and mirrors in space, as well as for nanoscale manufacturing. There are likely a lot of other potential applications, but using this high-tech approach to study deep-sea animals is really the best thing, in my opinion.”

A trend of flexible, soft, skin-like exoskeletons for robots and origami-inspired geometrical shapes for product design is currently playing out in the mechanical engineering industry, producing some of the most complex engineering projects the industry has seen for quite some time.

Works Cited

“How Origami Might Reshape the Future of Everything.” Phys.org - News and Articles on Science and Technology, Phys.org, phys.org/news/2018-08-origami-reshape-future.html.

“How Origami Might Reshape the Future of Everything.” News Northeastern Schools Are Safer than They Were in the 90s and School Shootings Are Not More Common than They Used to Be Researchers Say Comments, news.northeastern.edu/2018/08/02/how-origami-might-reshape-the-future-of-everything/.

“URI Engineer: Origami-Inspired Device Enables Easy Capture, Release of Delicate Underwater Organisms.” URI Today, today.uri.edu/news/uri-engineer-origami-inspired-device-enables-easy-capture-release-of-delicate-underwater-organisms/.

A new ‘quantum battery’ could charge devices in less than a second, making your uncharged phone a thing of the past.

The University of Adelaide’s newest Ramsay Fellow Dr James Quach is currently researching this new technology. His previous experience in quantum mechanics could help him turn this theory into reality.

He said that while ordinary batteries take the same amount of time to charge no matter how many you have, quantum batteries should charge faster in larger quantities.

“If one quantum battery takes one hour to charge, then two would take 30 minutes, three would take 20 minutes, and so on. If you had 10 thousand batteries, they would all charge in less than a second.”

While it may seem counterintuitive, this is possible due to a feature of quantum mechanics called entanglement.

“Quantum mechanics deals with interactions at the very smallest of scales, at the levels of atoms and molecules – at this level you get very special properties that violate the conventional laws of physics,” Dr Quach said.

“One of those properties is ‘entanglement’. When two objects are entangled it means that their individual properties are always shared – they somehow lose their sense of individuality.

“It’s because of entanglement that it becomes possible to speed up the battery charging process.”

The University of Adelaide green-lit this project in the hope that these quantum batteries could eventually replace their conventional counterparts in small devices such as mobile phones, watches and computers. However, these batteries require very specific conditions in order to be created.

“Entanglement is incredibly delicate, it requires very specific conditions – low temperatures and an isolated system – and when those conditions change the entanglement disappears,” said Dr Quach.

“With the support of the academic community in Adelaide, interstate and globally, I aim to extend the theory of the quantum battery, construct a lab conducive to the conditions needed for entanglement, and then build the first quantum battery.”

“The long-term aim is to scale up, to build bigger batteries which will support renewable energy technologies by making it possible for continuous energy supply no matter the weather conditions – rain, hail or shine,” Dr Quach says.

Manufacturing equipment requires maintenance; efficient machines to get a manufacturing job done.

With the arrival of the Industrial Internet of Things (IIoT), modern sensors are able to observe every nook and cranny of a manufacturing plant. Traditionally, the responsibility of improving efficiencies and maintaining the operations in manufacturing was down to the technicians and engineers attached to the plant. Increasingly, however, they are being replaced by PdM (predictive maintenance) and IIoT.

Previously, manufacturing relied on preventative maintenance: technicians would ensure that everything was well oiled and working as it should, until, of course, a fault was detected and maintenance was required. This school of thought is now giving way to predictive maintenance - where faults can be predicted before they cause the equipment to hiccough, allowing for preemptive corrections. In essence, predictive maintenance enables plants to forecast the failing of a piece of equipment and it therefore reduces down-time.

But is predictive maintenance the be-all and end-all? Technicians and engineers need to be on call at these plants in case they observe — or even smell — something that can bring manufacturing processes to a halt. Or do they?

Vice President of Product Strategy at RRAMAC Connected Systems, Tom Craven, believes that the worker, familiar with all of the kinks, rattles and smells of a manufacturing plant can be replaced by predictive maintenance software. He told Design News that a common rattle can now be diagnosed by the software and sensors:

“That rattle that the knowledge worker hears has other symptoms that can be picked up by a vibration sensor. The predictive maintenance system is a combination of sensors and machine learning. The knowledge worker is responding to his five senses and he has the experience to know what to do to correct the problem. The machine learning feeds the system data that knows what to do to correct the equipment.”

The main benefit for companies using predictive maintenance is reduced downtime. Additionally, however, remotely-located devices can be used to diagnose and even solve problems that come up. The result: more efficient and cost-effective processes. In the past, engineers would have to visit remote plants to diagnose and fix machinery problems – an expensive exercise.

Data collection, pre-processing, early fault detection, fault detection, time to failure prediction, maintenance scheduling and resource optimization are all of the things a company can look forward to when they utilize predictive maintenance. There is a more immediate situational awareness of how components are faring during manufacturing operations with predictive maintenance. Craven concludes:

“The machine learning is artificial intelligence applied to a machine. What happens over time is you record data, which includes multiple vibration points, motor current and temperature. You look for anomalies. In some cases it is obvious - motor current issues are easy to associate with a failure. Where data analysis become more complex, is when an anomalous vibration may be normal. Vibrations may vary during the cycles of the machine. What happens in these cases is you look at multiple variables and run a mathematical calculation that can flag the anomaly.”

Whilst artificial intelligence may still need some fleshing out and perfecting, predictive maintenance, assisted by AI software, is already saving companies money and time and increasing productivity. The future is predictive maintenance assisted by the connected sensors of the Industrial Internet of Things.

Works Cited

Spiegel, Rob. “Predictive Maintenance Is Replacing the Plant's Retiring Knowledge Worker.” Design News, 1 Mar. 2018, www.designnews.com/automation-motion-control/predictive-maintenance-replacing-plant-s-retiring-knowledge-worker/186322103658317.

Ulbert, Sebastian. “The Difference Between Predictive Maintenance and Preventive Maintenance.” Field Service Management Software, www.coresystems.net/blog/the-difference-between-predictive-maintenance-and-preventive-maintenance.

The head of states of the BRICS nations (Brazil, Russia, India, China and South Africa) have met for the 10th BRICS Summit in Johannesburg, South Africa. Topics on the agenda were energy, manufacturing, technology, industrializations, and more. But most importantly, deals were being made.

China will be giving US$14.7 billion in investments to South Africa for its advancement. The partnerships across the nations are all part of the BRICS Partnership for the New Industrial Revolution (PartNIR). On top of this, South Africa’s railway and energy utility will be given US$2.8 billion in Chinese loans to assist these state-owned entities overcome the short-comings they have faced in the last few years.

The Summit is an important event for those countries involved as they look to improve the conditions in their countries through technological advancement. President of South Africa, Cyril Ramaphosa, in his official remarks at the BRICS Business Forum in Sandton on Wednesday 25 June 2018 said:

“Quantum leaps in technology and innovation present enormous opportunities for growth, development and human progress.”

President of China, Xi Jinping, is making the deals with these affiliated nations to ensure his Belt and Road Initiative (BRI) continues revitalizing China.

The initiative involves a US$1 trillion plan to revolutionize manufacturing and construction in China and foreign investment is extremely important; 60 percent of the money to be generated will be coming from outside of China.

A (clean) change is coming

A positive spinoff of the current investments into manufacturing and industrialization in China has driven down the costs of solar panels. They are embracing solar in areas where pollution is posing a health risk to the people of China.

In densely populated cities, governments are realizing they have to turn the tide on fossil fuel technologies...and quickly. To confront the pollution generated by public transport China has invested in Battery-electric buses (BEBs).

According to Vox, buses accounted for 20% of the air pollution in Shenzhen, China, despite accounting for only 0.5% of the vehicles. Since 2012, all 16,359 buses in Shenzhen have become electric. Not surprisingly, since 2016 the speed at which the electrification has occurred has sped up - as the world calls for cleaner, more renewable forms of powering the world.

The electric buses ensure that 12 million people go from Point A to Point B every day. In 2017 Shenzhen became the world’s first city with an all-electric bus fleet. The city wants the same to happen to their fleet of taxis. This would mean converting 17,000 taxis - their goal is to have this completed by 2020.

China’s growing population with a large number of people living in urban areas highlighted the problem of using diesel-powered buses in the cities. The Chinese government began by swiftly subsidizing the 350,000 BEB (Battery-electric buses) in 2014/2015.

Subsequently, the buses make up 17 percent of China’s bus fleet.

The vehicle manufacturer behind the majority of the e-Buses is a company named BYD. Founder and chairman of BYD told Strait Times:

“China is now facing large-scale urbanisation, coupled with widespread car ownership. Urbanisation causes us to suffer from big city diseases such as traffic congestion and air pollution. BYD uses electric vehicles to help tackle air pollution and Skyrail to solve the problems of traffic congestion. It’s imperative to carry out the electrification of public transport. China is leading the world in this area.”

Ever since China led the charge on using electric buses, the rest of the world is playing catch up. BYD is hoping to send a fleet of buses to Singapore. Dutch company Arriva has also become one of Europe’s chief suppliers of electric Volvo buses.

China is also lobbying to become a member country of the International Solar Alliance. The alliance, formed upon the signing of the Paris Declaration (the agreement to prevent further global warming), is dedicated to further reducing the cost of clean energy technologies. It seems that China is quite serious about reducing the number of fossil fuel technologies they utilize.

Works Cited

Fabricius, Peter. “China's Xi Promises $14.7bn in Investments in South Africa.” Daily Maverick, Daily Maverick, 25 July 2018, www.dailymaverick.co.za/article/2018-07-24-chinas-xi-promises-14-7bn-in-investments-in-south-africa/.

Roberts, David. “China Made Solar Panels Cheap. Now It's Doing the Same for Electric Buses.” Vox, Vox, 17 Apr. 2018, www.vox.com/energy-and-environment/2018/4/17/17239368/china-investment-solar-electric-buses-cost.

StraitsTimesOnline. “Shenzhen Leads the Way in Switch to Electric Buses.” YouTube, YouTube, 26 Jan. 2018, www.youtube.com/watch?v=hcSu92RfT1s.

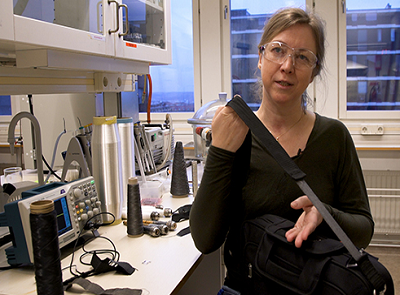

A lot of infrastructure lies underneath bodies of water. Take, for example, the SEACOM Subsea Cable system that provides Internet infrastructure to the African continent — any maintenance on it is done undersea. Presently, a fleet of ships remain ready to be sent out when a fault occurs, with repairs performed by divers.

Underwater bridge and structure inspections are also vital activities conducted by engineering specialists. Oil rigs and wind turbines are no different — they too need to be studied and maintained underneath water.

In future, underwater infrastructure monitoring, maintenance, and repair will — and probably should — be conducted by waterproof robots.

However, what robots face underneath the ocean surface is often treacherous. There are many factors that they have to deal with when undersea, such as; waves, currents and eddies.

Professor of Mechanical Engineering at Stevens Institute of Technology, Brendan Englot, said robots naturally struggle to get their bearings underwater, which presents a unique challenge for artificial intelligence.