News

An accomplished Controls Technical Field Advisor, Leticia Oppong is a recent graduate of EIT's Professional Certificate in Programmable Logic Controllers (PLCs) & SCADA Systems. As technology and software in the PLC and SCADA industrial world has developed over time, the need for ongoing education in the sector is necessary. Leticia enrolled with EIT to broaden her expertise in the field and ensure she stays on top of industry developments.

A self-proclaimed natural problem solver, Leticia's journey towards her engineering career began after graduating high school when she enrolled in Electrical Engineering at the Kwame Nkrumah University of Science and Technology.

"I've always had a knack for fixing broken things. I was the child who tore electronics apart and put them together. So, pursuing engineering was a natural progression." Leticia said.

"I've continued in the field because I enjoy navigating the complex systems, with the ultimate purpose of solving problems."

Shortly after graduating, Leticia undertook internships at Vodafone Ghana and General Electric (GE). After completing her internship experience in 2014, Leticia was offered a Controls Engineer position within GE, and in 2017 she accepted a position at FieldCore.

A GE company, FieldCore, is a global industrial field services company that Leticia is still working for today. With the experience she gained over the years, she was able to familiarize herself with power generation technologies. However, she notes that there is increasing development inside the industry.

She points to digital twin technology as a fascinating development in the industry. Digital twin technology is a virtual model of a process, product, or service. Utilizing this technology, Leticia says, helps with predictive maintenance.

"Being able to create a virtual model of a gas turbine to forecast performance issues in time for corrective action, optimizing operations, and having visibility of when a unit needs maintenance is pretty fascinating to me," Leticia said.

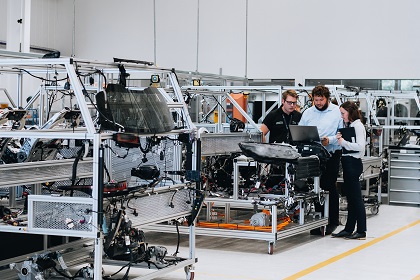

As a field engineer, Leticia works on different projects over a period of time, so the daily responsibilities aren't always fixed. There may always be something new to do. However, she is familiar with gas turbines and their control systems - and those are the constants in her work.

"I'm typically responsible for the installation, maintenance, and operation of the gas turbine's control system. For a new unit, that would include calibration of all instrumentation, panel setup, logic verification, and systems commissioning. For unit maintenance, there's still instrument calibration & inspections, part replacement, and returning the unit back online. And in operations, my job would be to support the customer in keeping things running smoothly: unit monitoring, fault-finding, and issue resolution," she explains.

PLCs and SCADA systems in the industrial world help with the overall control of the industrial system. Mastering the machinery is important for engineers and engineering practitioners. With added automation technologies making the systems more complex but increasingly more efficient, engineers are beginning to face a learning curve.

"Throughout my career, I have worked with a particular control system, albeit with some variation. This year, I decided I wanted to expand my portfolio. After some consultation, a course in PLC and SCADA emerged as the best option to get that foundation I needed to broaden my expertise. Due to my work schedule, attending an in-person class was not on the table, so I started looking for online options. A colleague mentioned EIT, where he had taken a master's some years earlier. So, I went to the website and got enrolled," Leticia said.

Now that she has graduated, Leticia doesn't intend on slowing down whatsoever. "I intend to remain in the engineering space, honing my skill set and ultimately taking on roles in project engineering and plant management," she concluded.

We wish Leticia well in her ongoing engineering career and are immensely proud to have her as one of our alumni.

In this time of global market uncertainty, the one thing that we know for sure is that the world needs energy. It’s not only essential to our daily lives but needed in increasingly larger quantities to support economic and social progress, build a better quality of life, and support a sustainable future.

However, for developing countries, the need for reliable and affordable energy is more fundamental. Reliable energy supply can help improve industry, agriculture, trade, and transportation. These are the crucial building blocks that help people escape poverty and create better lives and communities.

Since 2007, South Africa has experienced widespread rolling blackouts as energy supply consistently falls behind demand. The country’s primary power generator, Eskom, began load shedding in an attempt to prevent the country’s entire power grid from collapsing. This hastily implemented plan has affected energy reliability in South Africa to this day could possibly remain for at least the next “five to seven years.”

Power outages can result in substantial financial losses, quality issues, occupational safety hazards, and time delays that could lead to lost business. As a result of this, many South African consumers quickly invested in diesel-powered commercial standby generators to keep their operations running.

However, the unprecedented 2020 coronavirus lockdown regulations and the sudden increase in the number of people staying at home meant generator manufacturers and installers experienced a significant slow-down in demand. According to sources, some engineers in commercial standby generator installation companies had their wages cut by 30 percent during the lockdown.

As restrictions begin to ease and people begin to return to work, the sector is slowly starting to recover. However, some companies are still opting to let a large portion of employees work from home. This has produced an increased demand for more residential solutions, such as battery-based backup systems.

While generators are a quick short-term solution, battery-based systems are much more effective for long term regular power failures. As they are quick and easy to implement and much quieter to operate, there are several benefits over standard generator systems.

University of Western Cape’s Energy Storage Innovation Lab (ESIL) has been researching how they can improve battery performance to become a viable method of combatting the effects of blackouts. They believe utilizing battery-based backup systems will contribute to GPD growth through meaningful job creation and make use of South Africa’s mineral deposits and mining industry.

“It’s only a matter of time: future batteries and supercapacitors are going to change the world,” says Head of ESIL, Professor Bernard Bladergroen.

“Renewable energy combined with an energy storage device such as a battery that could deliver electricity at the cost of electricity from a power station would be a gamechanger – and the future could be bright for Africa.”

Therefore, residential energy storage that is not run on fossil fuels is a great idea for households that need to remain electrified. The instability of energy grids in a world with a changing climate and global shifting perspectives of the future of work produces more career choices for engineers in the electrical engineering field.

In the field of civil and structural engineering, urban stormwater management is a complex and challenging issue. As cities continue to grow, so does the number of impermeable surfaces — those that do not allow water to infiltrate the ground. From concrete sidewalks to parking lots, excess stormwater runoff from these structures can have serious adverse side effects on the surrounding ecosystem.

In more regional areas, rain can soak into the ground to be absorbed and released by plants. By contrast, when rain hits water-resistant surfaces in urban areas, it causes runoff, and water begins to collect sediment, bacteria, oils, metals, and other known pollutants. It has long been a civil engineers' tradition to direct stormwater into nearby systems to be treated at wastewater facilities or discharged directly into waterways.

However, as cities expand, significant precipitation events are having a higher chance of overwhelming stormwater systems. Scientists are warning that the effects of global warming may cause more rain to fall in one storm than an entire year prior. This means that countries with aging or poorly designed infrastructure are falling behind in their ability to manage runoff.

For example, Mumbai, India, has experienced its wettest monsoon season in more than 61 years. Torrential rains halted city life as many establishments, transport links and homes were submerged in waters waist deep. The coronavirus crisis impacted drain cleaning throughout the city, worsening the effects of devastating floods across the city.

An important legal consideration for most construction projects is to ensure that the final build won’t worsen downstream flooding for a particular area. On the stormwater front of a project, the engineers need to look out for that when runoff does occur, the interventions help:

- Reduce erosion

- Minimize pollution

- Prevent flooding

More water diverting infrastructure is necessary to achieve less flooding and mitigate the amount of water overwhelming a drainage system. One method of stormwater management would be to increase water infiltration through the inclusion of permeable surfaces. This approach would allow stormwater to still reach soil while reducing runoff from urban infrastructure.

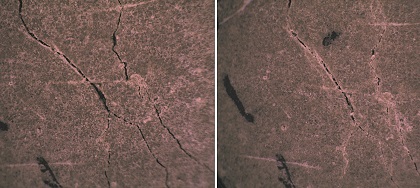

Topmix Permeable is a fast draining concrete pavement solution that rapidly directs stormwater off streets, parking surfaces, driveways and walkways. This efficient approach to stormwater management would help reduce environment impacts, costs and maintenance efforts. Topmix Permeable’s video of their innovative pavement recently went viral online.

Topmix Permeable’s video, while impressive, saw them receiving critique. The concern among some of the online civil engineering community was that sediment buildup would occur rapidly if stormwater and other elements filtered in below the road surface at such speed. They caution that pavement as permeable as Topmix Permeable would require a lot of maintenance, and expert level drainage - making it tough to implement in roadways.

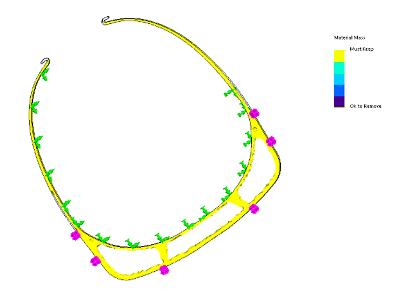

Nonetheless, all permeable pavements should have stone reservoirs below the surface. The stone reservoir is another fine art the engineer must perfect to create effective permeable pavements. The stone reservoir is generally made of uniformly sized stones that create enough gaps underneath the porous surface. It then temporarily stores water when precipitation is occurring and then slowly moves it off. Nevertheless, Topmix Permeable does look like an intriguing development in pavement that could lessen the chance of flash flooding for cities.

The company says their permeable pavement can provide relief to aging stormwater infrastructure inside the cities. Permeable pavement is still considered a new and developing avenue of the civil engineering world. It is to see much more attention as stormwater drainage continues to make headlines due to added precipitation. If some form of it is to be implemented on roadways in the future, it would require careful design features and construction techniques.

Civil engineers will be keeping an eye on the development of permeable pavement. It may appear at their next project build. Several configurations of how to implement permeable pavement are becoming known as engineers try an assortment of different styles. If these kinds of porous pavements can limit the number of floods worldwide, more and more civil engineers will be looking to lay them at their next project.

Prepare for the future of road construction with EIT’s Professional Certificate of Competency in Fundamentals of Road Construction.

Works Cited

Matchar, Emily. “This Concrete Can Absorb a Flood.” Smithsonian.com, Smithsonian Institution, 5 Oct. 2015, www.smithsonianmag.com/innovation/concrete-can-absorb-flood-180956830/.

“Mumbai Records Decade's Highest 24-Hour October Rain, 2nd Highest Monthly Rain in 10 Years.” Hindustan Times, 15 Oct. 2020, www.hindustantimes.com/mumbai-news/mumbai-records-decade-s-highest-24-hour-october-rain-2nd-highest-monthly-rain-in-10-years/story-5DGtX98zNszUW9jkdXMEWK.html.

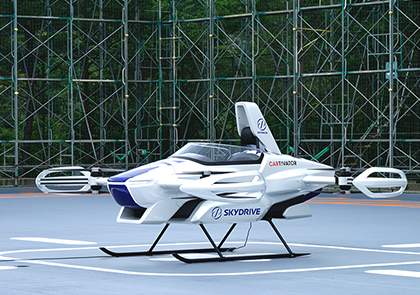

Hailing a flying taxi will no longer be just a concept found in science fiction movies. A Japanese company called SkyDrive recently tested a single-seat prototype straight out of Back to the Future. The company has unveiled its electrical vertical takeoff and landing (eVTOL) vehicle, also known as a flying car. The vehicle looks to be a significant step forward toward the future of air mobility.

On the 25th of August 2020, SkyDrive successfully tested prototype SD-03 at the Toyota Test Field in Japan. The flight saw the vehicle hover a few feet off the ground for around 4 minutes within a protective cage. However, the test's success has now given SkyDrive enough impetus to broaden the testing environment and generate safety data in a larger area. Ultimately, this data will be used to make a case for the flying vehicles in transportation.

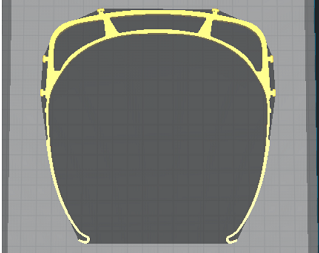

SkyDrive says it has long been their goal to develop the world's smallest flying car model. The SD-03 measures in at just 2 meters high, 4 meters wide, and 4 meters long, making it the smallest eVTOL in the world right now. The one-seater craft takes flight thanks to eight electric motors that power several rotors positioned in four locations around the vehicle's body.

SkyDrive says that if one of the eight motors fail on the SD-03 prototype, the other motors will play a backup role and keep the vehicle flying. The 'car' also has two front lamps and one red tail lamp — the first signs that it might conform to some form of aerial traffic system in the future.

Chief Technology Officer at SkyDrive, Nobou Kishi, has also predicted when he thinks a flying taxi service may come about utilizing their technology.

"The crewed flight that we achieved this time is the culmination of the results that SkyDrive has accumulated so far for technical verification. We have been working step by step, such as designing and testing electric propulsion systems, flight control systems, airframe structures, and introducing equipment for airframe conditions during flight tests. We will continue to work on technological development and type certification so that we can start a safe and reliable flight car navigation service in 2023," Kishi said.

Sky race

Another technology company keenly interested in air mobility is Uber, who just recently launched Uber Air. They have vehicle partners who include Aurora Flight Sciences, Bell, Embraer, Hyundai, Jaunt Air Mobility, JOBY Aviation, Overair, and Pipistrel Vertical Solutions.

Aerospace company Boeing and automobile manufacturer Porsche had also conducted autonomous tests on prototypes of their flying cars back in 2019. They say their vehicle has space for two to four people and a range of 50 miles.

Naturally, due to Boeing's foray into flying car manufacturing, rival Airbus has been tasking their engineers to develop a prototype of their own. There is, therefore, no lack of competition in the air mobility industry. Nonetheless, it is impossible to say which company may go public with a certified consumer experience first.

SkyDrive's two-seater concept vehicle is the company's next focus. The SD-XX is a customer-focused eVTOL that can fly up to altitudes of up to 1,640 feet.

"We are extremely excited to have achieved Japan's first-ever manned flight of a flying car in the two years since we founded SkyDrive in 2018 with the goal of commercializing such aircraft," SkyDrive CEO Tomohiro Fukuzawa said.

"We aim to take our social experiment to the next level in 2023, and to that end, we will be accelerating our technological development and our business development."

Works Cited

sd2020 投稿者: "HOME." 株式会社SkyDrive, skydrive2020.com/archives/3506.

From the online classroom to the world's leading producer of diamonds by value, many EIT graduates are using their qualifications to contribute to the operations of Debswana Diamond Company mines located across Botswana.

Established in 1969 and owned in equal shares by the Government of the Republic of Botswana and The De Beers Group of Companies, Debswana is one of the world's leading diamond producers and Botswana's largest employer with over 5,000 employees and 6,000 contractors.

A self-proclaimed 'people-based organization,' Debswana places great value in its employees' training and development, attributing a large part of their success to their ability to develop and sustain a qualified and skilled workforce.

EIT has helped develop the skills and knowledge of eleven Debswana employees. With graduates coming from a range of EIT programs including our 52726WA - Advanced Diploma in Electrical Engineering, 52810WA – Advanced Diploma of Mechanical Engineering Technology, 52708WA – Advanced Diploma of Industrial Automation, and Bachelor of Science (Industrial Automation).

Our unique online learning experience allows students to develop their engineering skills remotely, meaning Debswana's employees can continue working while gaining globally relevant qualifications that further augment their understanding of the industry they work within.

"I chose this course because I have always wanted to be an electrical engineer. My studying experience with EIT has been consistently good. EIT has a lot to offer and is very capable," says 52726 - Advanced Diplomas in Electrical Engineering graduate, Johnson Itumeleng.

"I have learned a lot, and I am executing my daily work in a much more professional manner with what I have learned from EIT."

Johnson started his career in engineering as an apprentice at the Orapa Technical College in 2007. After spending four years as an apprentice, Johnson was employed by Debswana in the Power Distribution sector. He now works as an Industrial Electrician in Debswana's Orapa Mine.

Discovered in 1967 and in operation by 1971, the Orapa Mine is the world's biggest open cast mine. Orapa is currently mining at a depth of 250 meters and is expected to reach 450 meters by 2026.

Orapa is one of Debswana's four mines, along with the Damtshaa, Jwaneng, and Letlhakane operations. Debswana's vision is to be a global bench-mark diamond business. To achieve this, they are setting increasingly demanding targets, embracing industry change, and making meaningful contributions to communities' development around its mines and Botswana at large.

As plans for Debswana's driven future became clear, 52708WA – Advanced Diploma of Industrial Automation graduate Goratoane Rivaldo Rabodietso began studying to keep up with the digitization and automation that he saw encroaching into the industry.

"The most interesting development in our industry is the use of smart instruments which can be calibrated and operated remotely," Goratoane said.

"The use of smart trucks at the mining pit is amazing as well - it can even perform an alcohol test on the driver to check their fitness prior to the operation, which protects the most valuable assets of the company."

Due to its technical and machine-driven nature, Debswana prioritizes the safety of its personnel and operations. All the sites boast impressive records, such as the Jwaneng Mine achieving one of the lowest disabling injury incident rates in Botswana and the Orapa and Letlhakane Mines achieving 2 million fatality-free shifts.

The continuing success story of Debswana Diamond Company is one of excellence and engineering success. EIT is thrilled to have played a part in equipping some of its workers with the skills and knowledge that further assists one of the most notable companies in Botswana's history.

Ray Crawshaw is an engineer who currently works in the mining industry in Australia. He is also an Engineering Institute of Technology (EIT) alumnus, having studied our 52726WA - Advanced Diploma of Applied Electrical Engineering and our Master of Engineering (Industrial Automation).

Ray has spent his working life pursuing more practical and hands-on jobs and has filled a plethora of roles in several countries and regions. He truly has had a decorated career, with 35 years of experience in the oil & gas, power generation, and mining sectors. Later on in his career, Ray looked to add higher education qualifications to his resume, further building upon his skills and technical knowledge. Nearing retirement age is not slowing Ray down — he is more determined and hungry for growth in his academic and working career than ever before.

A son of a farmer, Ray went to school in a country farming region in New Zealand. When he was 11 years old, his father tragically passed. In 1966, he started living on his uncle’s farm. His uncle encouraged him to take up a trade so that he could find work.

Ray applied for a job as an electrician and was soon employed by a power supply authority in New Zealand. He started as a substation cadet. Ray ended up spending eight years with the Bay of Islands Electric Power Trust (now known as Top Energy). There, he earned a trade certificate in the first two years of his four-year apprenticeship. He still, however, had to complete the 8,000 required hours.

In 1978, Ray moved to Australia for work, which saw him fulfilling an altogether different role. He became a fireman on a train that transported freshly cut sugarcane. A year later, he went back to New Zealand for Christmas and incidentally met his future wife.

Six months later, Ray was married and began working for New Zealand’s only oil refinery, Marsden Point Oil Refinery. Refining NZ, the company that operated the refinery, was spending several billions of dollars upgrading it. He spent two years on the refinery, saving money to buy a house for his family, which was soon to grow.

Back in his hometown, Ray decided to start a business that sold whiteware, such as fridges and stoves. His wife oversaw the operations of the store.

Ray began to do commercial and domestic contracting work. His industrial experience, however, took precedence and saw him constructing mills in the north of New Zealand. Along with a crew of 50, they ran the project from start to finish. Ray then returned to contracting himself out to dairy farmers and abattoirs.

Chasing the boom

Ray and his wife flew to Australia for Christmas in 2007. Looking for a change of scenery, they decided to pursue opportunities during Australia’s mining boom. He was soon working on the electrical systems on a plethora of mines in Australia.

Due to his years of experience, Ray was promoted to supervisor and superintendent roles on the mines. He then was head-hunted while working at one of the mines, which allowed Ray to pivot to the oil and gas industry. He became a construction area manager on Gorgon Barrow Island’s LNG (Liquefied Natural Gas) Plant for a company named Leighton Contractors Oil and Gas. It was the largest LNG plant in the world built at the time; 10,000 people were employed to work on the project, and it cost a total of 60 billion dollars (AUD). Ray was the area construction manager that laid four million kilometers of cable.

A year and a half later, Ray began work for ConocoPhillips — an American oil and gas company — on their Gladstone Curtis Island site in Queensland, Australia. He worked as a Programs Completion Manager working on their LNG project. Soon he was flown out to work on another project, this time for Chevron back at Barrow Island Gorgon.

There was no doubt at this point that Ray was an engineering professional in all sense of the word. However, Ray himself had an overwhelming feeling that he was missing that formalized ‘Professional Engineer’ recognition. He set out to find a way he could become a professional engineer while continuing to work.

The EIT connection

“Since leaving school, I hadn’t done any formal education for over nearly forty years. I just had the trade certificate. I had a lot of experience over the years, had run my own business, and had been in many high profile positions. But, I didn’t have any qualifications to back it up,” Ray said.

In the year that Ray began work on Gorgon Barrow Island in 2012, he enrolled in the 52726WA - Advanced Diploma of Applied Electrical Engineering with EIT, finishing it in the year 2014. Witnessing the encroachment of technology into the engineering disciplines he was interested in, he wondered if he should become more skilled in automation.

Ray had already worked for Chevron for a year when he enrolled in our Master of Engineering (Industrial Automation). He seamlessly integrated what he was doing at work into his thesis for EIT. He became the E&I area construction manager overseeing the construction and pre-commissioning of engineering equipment crucial to the LNG operations on those projects.

“At Chevron, they were testing the gas wells for mercury, and they thought they aligned with international standards, but by the time it got to the plant itself, the mercury levels were a lot higher than the standards,” Ray explained. As a construction manager, he was given the task to go into the plant and install online mercury analyzing equipment. The master’s studies came into good use — Ray found he could consolidate what he was learning in his automation studies to find a more efficient way of detecting mercury levels.

“I thought there must have been a better, less expensive way of testing mercury levels. Using modern technology, I looked into what we could devise that could help us analyze. We ended up using electric devices that would use surface acoustic waves for measuring mercury. And since the master’s with EIT was to do with automation and control, I had to use my knowledge of PLCs and SCADA and HMI. So I correlated the thesis with the work I was doing there.”

Beginning the golden years

Ray entered his sixties in 2017 and was as hungry as ever to continue working in the world of engineering. After he finished at Chevron, he found it was harder and harder to get work — he couldn’t find a job for ten months. As a consequence, he began looking for work overseas, hoping a company might see the benefit of his immense experience.

He managed to snag a job as an LNG plant commissioning manager in San Antonio, Texas, in the United States for a company named BHGE. The job saw him being ported to Port Harcourt in Nigeria as well — a region that was going through a civil war at the time. After a year and a month of working in that role, he moved back to Australia.

In Western Australia, Ray found work again. This time as a project manager for Synergy, Western Australia’s leading provider of electricity and gas. He oversaw projects at the Mungarra Gas Turbine Power Station and the building of Black Start generator for a GE Gas Turbine that supplied the Western Power grid. He was highly lauded in the position and given an award for delivering it on time and under budget.

Ray is currently working at Fortescue Metals Group Mine, a global leader in the iron ore industry. He is working as a construction and commissioning manager on-site, building mining hoppers and shifting them from location to location. He is on-site for three weeks at a time as he is employed on a FIFO (fly-in, fly-out) basis. Ray’s contribution to the engineering world has been invaluable.

“Considering my age, the two qualifications I received through EIT did enhance my career in terms of positions and employment — not only in Australia, but overseas as well. I recommend for anyone to do qualifications with EIT because the online delivery mode is utterly convenient,” Ray said.

“Now, with EIT offering a doctorate, I might consider doing it. I will be nearly seventy by the time I finish,” he laughed. “But it would be worth it.”

The Engineering Institute of Technology (EIT) has alumni from over 40 countries and is one of the only institutes in the world that can boast a truly global spectrum of learners due to its online student body. However, EIT also has two campuses in Australia that are ready and able to welcome both local and international students for on-campus studies in 2021.

The COVID-19 pandemic has caused a delay in international students traveling to Australia. Encouragingly, EIT has the ability to allow students to stay abreast of their studies while waiting for travel restrictions to lift due to its unique, refined, online delivery model. EIT has been conducting and perfecting online engineering education for the last ten years. The Engineering Institute of Technology has therefore remained open throughout the year without disruption, and is offering future on-campus students an option to begin their studies online and finish the qualification on campus in Australia when borders re-open.

The Engineering Institute of Technology has two campus locations in Australia (Perth & Melbourne) and is planning to announce more in the future. The unfortunate reality that COVID-19 has presented international students who wish to complete their degrees on-campus in Australia with are the travel restrictions that have been enacted. However, at EIT, we have over ten years of experience with delivering high-quality engineering education to students around the world via our unique delivery model. For on-campus studies, we currently cater for both bachelor’s and master’s students.

Bachelor of Science degrees in Industrial Automation, Electrical Engineering, Mechanical Engineering, and Civil and Structural Engineering are EIT’s undergraduate programs available for on-campus study in Perth, Western Australia. EIT also offers Master of Engineering programs in the same fields in both Perth, Western Australia, and Melbourne, Victoria.

EIT’s future on-campus master’s students have been able to commence their qualifications via a unique September intake. These master’s students will complete one unit online and then transition to the campus once travel restrictions are lowered.

The benefit of completing one of the units of the master’s degree online will assist students in becoming accustomed to the unique delivery model EIT employs. They will also become immersed and engaged in their academic journey. By the time they reach the campus, they will be ready to hit the ground running.

The Engineering Institute of Technology is monitoring international travel regulations extremely closely. In the event that travel restrictions are still in place for our February 2021 intake, both the bachelor’s and master’s degrees will continue fully online.

Transitioning from online to on campus

Once travel restrictions are lowered, EIT will be welcoming students with open arms. We recently hosted a discussion with one of our master’s students who is currently completing his Industrial Automation qualification through EIT. Felix Okoh is a Nigerian student who went from studying through EIT’s online campus in his home country to relocating to Australia. He is one of our revered master’s students who has taken the option of completing his course on-campus.

In 2018, Felix was looking for a premium education provider that would further build his skills based on his prior experience. He finished two units in his hometown before deciding to open up a world of opportunities by completing his qualification in Western Australia.

“With my experience in the oil and gas industry in Nigeria, combined with a Bachelors in Electrical and Electronic Engineering, I decided Industrial Automation was one of the fields that would keep me competitive within a wide range of industries,” Felix explained. “I chose EIT because of their specialization in Engineering, more affordable tuition fees, and the accreditation of its programs.”

Felix says that he was at first worried about combining full-time work and part-time online studies, but was quickly impressed by the knowledge of the lecturers and how seamless the learning environment worked for him. After successfully receiving his VISA, he managed to relocate to Australia to complete his studies.

“The online platform affords you a lot of flexibility,” Felix said, “But I decided to go on-campus because I read up a lot about Australia and the opportunities the country has. For students who have studied in Australia for two years and above, you can apply for post-study work rights that let you work in Australia.”

Once Felix commenced his studies in Australia, he explains he enjoyed the campus environment and meeting the capable lecturers that he had become so accustomed to on the online platform. He has made friends with other international students on campus and says that he is building a network of colleagues now that he knows he can rely on in the future.

“I am looking forward to having Australian work experience and being admitted as a member of the prestigious Engineering Australia. I encourage students to look into EIT and work toward improving their careers,” Felix concluded.

You can follow in Felix’s footsteps when you apply for an on-campus bachelor’s or master’s degree with the Engineering Institute of Technology.

The Engineering Institute of Technology (EIT) is a unique global institute, delivering online engineering short courses, diplomas, and degrees. Students around the world log into EIT’s synchronous online virtual campus to network with other students and lecturers in real-time. Underpinning this live online academic delivery are EIT’s Learning Support Officers (LSOs), who play a key role in helping students succeed in their studies. They become a student’s trusted advisor and provide guidance and encouragement on a student’s learning journey.

“We are the dot connectors for everything a student needs to complete a qualification or course,” said Holly Ross, an LSO based in New Zealand. Holly has been working with EIT for the last seven years, watching the institute grow from strength to strength. “I have gone from seeing our systems and procedures changing rapidly with the growth of the company and the ever-changing world of technology.”

Learning Support Officers walk alongside students every step of the way as they progress in their course. They constantly check-in with their students and iron out any problems the students may be having. If a student is falling behind, the LSO gently (and virtually) nudges the student to help them progress successfully in their studies.

How it all starts

“My role starts once a student has applied for a Professional Certificate or an Advanced Diploma course. I have specific courses that I manage, so if a student applies for one of those courses, their application comes through to me by email,” explains Thelma Bango, an LSO operating out of the South African EIT office. “I then assess the student’s application for suitability, and I either send them an acceptance email in the course or a request for more documentation to support their application.”

Once students are fully enrolled in the course and begin working to earn their qualification, their various studying styles emerge. The Learning Support Officers face the task of keeping tabs on EIT’s diverse student body. Holly says she tries to encourage students at the start of their courses to take it ‘one step at a time.’

“During the course, we check student progress. We contact students who are falling behind and send them letters stating where they need to catch up. Most would normally do their part to ensure they catch up when they get these letters,” said Isabel Sibanda, an LSO based in Zimbabwe.

For diligent students who more effortlessly rise to the challenge of their online qualifications, LSOs give sprinkles of praise to further encourage them to keep pushing forward with their course. In some cases, students are doing their first online qualification, which may seem like a daunting task, but with EIT’s LSOs, their journey becomes easier. EIT Learning Support Officers understand all too well that many students combine their studies with full-time work and they are well experienced in providing the necessary support to assist those students in staying on track.

“The beauty of our work is that we understand that our students have work, family, and life commitments, so we give them an option to ask for an extension to their assignment submission dates, within reason, of course,” said Thelma.

Across the universe

The Learning Support Officers of the Engineering Institute of Technology assist students from an assortment of countries across the globe, including but not limited to: Canada, the United States, United Kingdom, India, South Africa, New Zealand, and Australia.

“Dealing with students from different cultures, nationalities, and continents reveals just how different people are even though the common goal is the same; to attain a qualification with which one can better themselves,” Thelma said.

The Learning Support Officer also experiences news-making world events that unfold and affect their students’ lives. Sisipho Phakamisa, another of the LSOs in the southern African region, explains that she has learned perspectives from students who this year have experienced Australian wildfires, COVID-19, retrenchments, marriages, births, and everything else in between.

Moreover, the LSOs have to be acutely aware of the various time zones students are in. “I have become accustomed to the time differences between students. As big and far away that the continents and countries are, the interaction with students makes the world feel a little smaller,” Sisipho says.

When a course has run its course

Once a course is on the cusp of being completed, the LSO team at the Engineering Institute of Technology encourages students to reach that finish line. Once the students have graduated from the course, they are in charge of putting together the students’ graduation packs. The pack includes their stamped qualification they just earned.

“At the end of each course, I am tasked with the wonderful duty of graduating students from the intake by compiling and mailing out their graduation packs. There is no greater feeling than graduating your class at the end of an 18-month journey and knowing that someone has an additional qualification under their belt, all thanks to your assistance throughout the course,” said Thelma.

While the LSOs wield much power, students are also encouraged to provide feedback surveys to comment on whether or not they are satisfied with the support they are receiving. Keeping students on track is important work, and takes a balance of compassion but also firmness. The Engineering Institute of Technology’s Learning Support Officers are continually refining the processes they employ to help students achieve their dreams. With this ‘art of support,’ LSOs help students earn a career-changing and life-changing qualification.

EIT’s Academic Resources, Higher Education, and IT departments have been working in the background over the past few months to revamp the EIT eLibrary, hosted on Moodle. We are pleased to announce that the official launch date is 1st October 2020!

What is happening?

We have updated the EIT eLibrary to a new, more user-friendly format. This includes new information to support students throughout their course, easier access to the IDC technical manuals, and a complete overhaul of the Open Access Resources content.

The goal of this update is to improve, modernize, and re-organize the learning resources available to students so that it is easy to navigate and provides more useful content. Some of the major changes include:

- An upgrade to the IDC technical manuals viewer to ensure eBooks are easier to read online

- A complete overhaul of the Open Access Resources content to include a centralized listing of reputable open access publishers as well as lesser-known open access journals

- A new section called Study Support with tips, tricks, and information on report writing, general writing skills, and exam preparation

- An updated library of our master’s graduates’ thesis papers

The new eLibrary will go live on Thursday, 1st October. There will be no changes to student access – everything will still be hosted within Moodle, and students can access the platform in the same way as before. The Academic Resources team will be constantly working on new updates and added content to ensure continuous improvement to the resources we offer.

We hope the new eLibrary will be a welcome improvement for all current and future students.

The industrial facility or smart-factory of the future is, in fact, here today. Automated processes ensure efficiency, and round-the-clock monitoring promises ongoing operations. However, not a lot of consideration is given to the crucial sensors in an industrial set up that makes this possible. Industrial sensors are the smaller but omnipresent element within those industrial facilities and factories, monitoring the entire ecosystem of an industrial operation and making sure those processes continue without a hitch. As sensor networks are brought online and form part of the Internet of Things (IoT) future, keeping them online is imperative. Industrial sensors typically run off of lithium-ion batteries and inevitably need replacing. A new startup is innovating in the space and taking the battery out of the equation altogether.

Smart factories and other industrial operations face replacement costs since sensor batteries eventually deplete. Some sensor batteries can last for up to a year before they need to be replaced.

However, a startup named Everactive says they have the answer to eliminating battery requirements that modern-day IoT sensors have. They are launching a self-powering sensor without a battery that can last up to 20 years.

How does the sensor work?

The sensors have come a long way since their inception. The initial concepts were bouncing around inside the minds of the two future co-founders of Everactive who were attending the Massachusetts Institute of Technology. David Wentzloff and Benton Calhoun focused their academic careers on low-power technologies. The former on low-power digital circuits and memory, while the latter focused on low power radios. Their combined skills have given birth to their new sensor — the Eversensor.

“It’s all enabled by the ultra-low-power chips that support continuous monitoring. Because our source of power is unlimited, we’re not making trade-offs like keeping radios off or doing something else [limiting] to save battery life,” Everactive Co-Chief Technology Officer David Wentzloff said.

Everactive says the ultra-low-power integrated circuits harvest energy from indoor light and vibrations. There is also an outdoor self-powered sensor available that can utilize small collar cells to power the sensors. The Eversensors can be fixed to key infrastructure in industrial operations and can sense when those machines stop functioning. The sensors do this by measuring temperature, acceleration, vibration, pressure, and more.

Everactive says the sensor meets all of the sensing, processing, and wireless capabilities that any battery-powered sensor does. Process optimization and reduced maintenance cost of both the sensors and industrial machinery are just some of the benefits of sensors working around the clock.

“Removing the need for batteries solves one of the key limitations of the IoT and represents a fundamental paradigm shift, allowing our customers to deploy wireless sensors at scale and gain access to new, high-value data-driven insights,” Bob Nunn, the CEO of Everactive, said.

The company is boasting the world’s lowest power radios and are deploying them for some of the biggest industrial companies in the world. With batteryless technologies generating much interest in the world of industrial engineering, more battery-intensive technologies could see new opportunities in a plethora of industries.

Works Cited

“Industrial IoT - Batteryless Sensors Data Analytics.” Everactive, 31 July 2020, everactive.com/.

Zach Winn | MIT News Office. “The Factory of the Future, Batteries Not Included.” MIT News, 20 Aug. 2020, news.mit.edu/2020/everactive-sensors-0820.

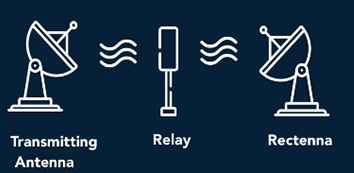

An electricity startup company in New Zealand says they are working toward a launch of a world-first wireless energy transmission system they assert will be opening up the world's access to power. They reportedly will be using tele-energy technology to enable long-range wireless energy transmission that is safe, reliable, and cost-effective. Echoing the work of inventor Nikola Tesla, the company hopes to democratize access to electricity. If the company succeeds in rolling out the technology, it could usher in a new era of electrical engineering.

Nikola Tesla, who famously engineered the alternating current system toward the end of his life, was attempting to engineer a system where electricity could be transmitted to single antennas in consumers' homes. In turn, he hoped the wireless energy would power entire households and give everyone in the world access to electricity — the attempts at figuring out the technology led to the creation of the Tesla coil. Tesla, in the 1890s, managed to light a bulb across a distance of two miles using a Tesla coil.

Since then, wireless electrical transmission has been an elusive technology that no single company has been able to implement at a level that consumers could benefit from. However, a government-backed startup in New Zealand seems to have picked up where Tesla's work left off. Emrod, the startup in question, says they have developed a safe method for wirelessly transmitting electric power across long distances.

The technology utilizes electromagnetic waves to transmit energy wirelessly over vast distances. New Zealand's second-largest electricity distribution company, Powerco, will be first in line to test the new Emrod technology.

Tech entrepreneur Greg Kushnir spearheaded the technology. Surprised by how little development of wireless electricity technology was being worked on in the industry, he set out to recruit scientists and engineers from a company named Callaghan Innovation.

"We have an abundance of clean hydro, solar, and wind energy available around the world but there are costly challenges that come with delivering that energy using traditional methods, for example, offshore wind farms or the Cook Strait here in New Zealand requiring underwater cables which are expensive to install and maintain," said Kushnir.

"I wanted to come up with a solution to move all that clean energy around from where it's abundant to where it's needed in a cost-effective, eco-friendly way. Energy generation and storage methods have progressed tremendously over the last century, but energy transmission has remained virtually unchanged since Edison, Siemens, and Westinghouse first introduced electric networks based on copper wires 150 years ago."

How it all works

The company has patents pending for its technology, so the more proprietary technology the company is using is mostly under wraps for the time being. However, they do say they are working in frequency ranges in the ISM (Industrial, Scientific, and Medical) band - which are typically used in WiFi, Bluetooth, and RFID.

The prototype point-to-point transmission system Emrod engineered, along with Callaghan Innovation, impressed Kiwi government funders. To further demystify the tech the startup is working on, Kushnir spoke to New Atlas.

"Transferring energy with microwaves has been around for decades. In the 70s, NASA showed it could support a helicopter drone in the air, charging it with microwaves from the ground. It's been around for a while. What's changed in the last few years is mostly metamaterials technology. New materials that allowed us to convert the energy back into electricity very, very efficiently. That was what made it viable for commercial use. Before that, it's been around, but mostly used for military purposes," he said.

IT is the proprietary beam shaping, metamaterials, and rectenna technology that Emrod is keeping under wraps for now.

Kushnir goes on to say, "Electromagnetic metamaterials can absorb electromagnetic radiation and turn it into heat, or electricity, or make it go away. It's essentially stealth technology, that's what it's been used for in the military."

The startup assures critics that their system will produce no waves, no radiation, and no environmental impact. They have been testing their tech, sending 'a few watts' between two points spaced 130 feet from each other. The startup ultimately has faith that they are on the right track:

"The statistics are pretty compelling. We are talking about a potential 50 percent increase in sustainable energy uptake, up to 85 percent reduction in outages and up to 65 percent reduction in electricity infrastructure costs due to the Emrod solution," Kushnir concluded.

The startup wants people to imagine the possibilities when power can be accessed anywhere. The startup hopes this technology can finally power rural communities who don't have much access to electricity. If they get wireless electricity for consumers right, the startup might be hailed as one of those that managed to achieve what Nikola Tesla dreamt of over a hundred years ago.

Works Cited

"Press Release: NZ Start-up Launches World-First Long Range Wireless Power Transmission." Emrod Energy, 2 Aug. 2020, emrod.energy/press-release-nz-start-up-launches-world-first-long-range-wireless-power-transmission/.

silvae/Depositphotos, and Emrod. "New Zealand's Wireless Power Transmission: Your Questions Answered." New Atlas, 4 Aug. 2020, newatlas.com/energy/wireless-power-transmission-emrod-interview/.

It is estimated that in the United States alone, elevators travel up to 4.5 million miles every single day. The 31st of July is International Talk In An Elevator Day — it encourages people to engage with someone in an elevator, instead of looking down at their devices and ignoring their surroundings. However, for the first time since ‘Talk In An Elevator Day’ was coined, engineers and scientists are warning against striking up conversations in elevators. The coronavirus pandemic has put the day on pause for 2020 — and there is good scientific evidence as to why.

Amid the pandemic, Richard Corsi, Dean of Engineering and Computer Science and a specialist in indoor air quality at Portland State University in the United States, said: “They should put big signs on the elevator: ‘Do Not Speak.’”

He said this because of the risk run by people who are entering elevators during this time, given the close proximity of occupants. The virus has been particularly widespread in the United States, which recently saw its most significant one-day rise in coronavirus tests; 71,484 tested positive in one day.

Corsi, under the rising coronavirus cases, set out to investigate elevator safety in a pandemic using a method that only an engineer would. He created a model utilizing engineering principles akin to fluid mechanics and cross-referenced them to several kinds of elevators and buildings. Knowing there would be thousands of scenarios, he decided to choose one hypothetical scenario.

In his scenario, a mask-less COVID-19-positive passenger rides the elevator alone from the first floor to the tenth floor. During the ride, they speak on their phone and cough into the elevator car, which spreads the virus around.

When the elevator gets to the tenth floor, they exit the elevator. The doors remain open for ten seconds, close, and then the elevator returns to the ground floor. Taking into consideration the opening and closing of the doors and the subsequent circulation of air, plus the ventilation within the elevator, Corsi estimates at least 25 percent of the particles from the first passenger remain inside.

“The main intent of the exercise was just to show that some level of virus can be sustained in the air beyond an infected person using the elevator. I don’t know whether the dose in an elevator is going to be high enough to pose a significant risk, but I would probably take the stairs if possible,” Corsi told the New York Times.

He tweeted out a hypothetical elevator scenario, including the asymptomatic but infected individual traveling ten stories in a residential building. Evidently, this is an engineer doing their calculations, needing a bit more input from the science still being compiled about the coronavirus. Nonetheless, it is an admirable attempt to work with the facts the public is equipped with at the moment and guesstimating — based on what type of elevator someone is riding - whether or not it may be safe.

Moreover, Corsi’s calculations barely begin to cover the risk the floor number buttons pose to the passengers who touch them. Thankfully, Harvard School of Public Health’s Joseph Allen, an Assistant Professor of Exposure Assessment Science has sound advice on what to do if you do find yourself in an elevator as businesses continue to open up:

- Wear a mask

- Load the elevator in a checkerboard pattern

- Face forward

- Announce your desired floor

- Have the person near the buttons select for everyone, using their knuckles

- No conversations

“Workers want to know whether they can really be safe in an elevator, and building owners want to know whether they get elevator capacity to more than one person at a time. Fortunately, the answer to both is ‘Yes,’” Allen said reassuredly.

Engineers, when probed on elevator safety, are erring on the side of caution due to the constant uncertainty of the coronavirus pandemic. Common sense precautions are becoming more important than waiting for the epidemiologists to aptly inform the global population on the safety of elevator rides. The question about elevator engineering and air circulation and quality is a rare moment where both engineers and scientists can revise some of their studies and come up with answers that can better inform those who ride them.

It was hailed as the next giant leap for personal transportation. Now, it seems, the idea has become redundant. The Segway PT was a one-person electric vehicle that was brought to market in 2001 — with extreme hype and expectation. Nineteen years later, the self-balancing, two-wheeled personal transporter is being discontinued. It seems that lower consumer demand for the vehicle has convinced Segway to pull the vehicle from its assembly lines, to instead focus on other projects in the mobility industry.

The discontinuation of one product and the evolution of another is seemingly the great challenge for consumer-driven engineering companies all over the world. As technology advances and some technologies become obsolete, one can look back at how those technologies laid the foundation for newer, more advanced technologies to enter the market.

The Segway PT, while an attractive prospect for consumers, was dogged with scathing headlines whenever a crash of the vehicle would occur — resulting in its 'fair share' of highly publicized sensationalist coverage. Nonetheless, Segway inventor and founder Dean Kamen was praised by fellow entrepreneurs at the unveiling of the Segway back in 2001. Apple co-founder Steve Jobs said, about the Segway PT, that it was the most significant invention since the personal computer and Amazon founder Jeff Bezos called it 'one of the most famous and anticipated product introductions of all time.'

"Within its first decade, the Segway PT became a staple in security and law enforcement, viewed as an effective and efficient personal vehicle," said Judy Cai, Segway president, in a recent statement on the discontinuation.

"This decision was not made lightly, and while the current global pandemic did impact sales and production, it was not a deciding factor in our decision."

Associated Press confirms that the Segway PT currently only accounts for 1.5% of the company's profits. The company is, therefore, looking to debut new products that may buoy their company from now on. Even though the PT has seen a downward spiral in demand at the consumer-level, the transportation industry continues to make strides forward.

The Segway company is not disappearing into the history books, however. The company has introduced a new vehicle to the personal transport industry at the Consumer Electronics Show in Las Vegas in January. Their new concept is a self-balancing electric wheelchair and is named the Segway S Pod.

The company is also designing and selling several variants of lightweight scooters. They continue to innovate in the space and seek an audience in the personal transportation industry. PT's story is one of demand, after all. Demand forecasting and predicting a product's life cycle in the market is good business practice, and something engineers have to grapple with within companies.

When to discontinue a product

Companies tend to design products with lessons learned from their previous endeavors. Apple is one of those companies. The company went from designing personal computers to music players to smartphones. After the introduction of the iPhone, some of the company's different music-playing hardware products very much fell out of fashion, and some were promptly discontinued. The iPod Classic, Nano, and Shuffle are no longer being engineered.

Companies usually discontinue certain products because they are in the process of introducing a new line of products into the market that will render the previous product obsolete.

Dr. Kenneth Reid, an Associate Professor in Engineering Education at Virginia Polytechnic, and John Estell, professor of computer engineering and computer science at Ohio Northern University put together an engineering design book, "Engineering Design and the Product Life Cycle: Relating Customer Needs, Societal Values, Business Acumen, and Technical Fundamentals." They sum up the entire engineering design and product life cycle in 9 steps:

- Conceptualization

- Feasibility

- Definition

- Implementation

- Introduction

- Growth

- Maturity

- Decline

- Discontinuance

Business management concepts, coupled with product design and engineering life-cycle theory, are vital concepts to impart on up-and-coming engineers who are entering engineering workplaces or founding engineering startups. Knowing when to introduce products to the market, and when to discontinue, is one of the modern-day challenges for a plethora of engineering companies in a wide spectrum of industries.

For companies that prepare products to sell to consumers and clients, starting the product development process with the end in mind is smart business practice. With how fast technology is advancing, being aware of when to begin producing the next product, and discontinuing the one that came before it is becoming an engineering art form. Reid and Estell conclude:

"Even the most successful, earth-shattering, and monumental designs eventually go out of style, lose their significance or usefulness, or are simply replaced by a superior design. In each case, discontinuance from an engineering standpoint implies more than simply throwing something away. We should anticipate the discontinuance in our design."

Works Cited

Ott, Matt. "Segway, Popular with Police but Not the Public, Hits Brakes." AP NEWS, Associated Press, 23 June 2020, apnews.com/3525b9a69569d57dc41a373e82a8f1cd.

Reid, Kenneth J., and John K. Estell. Engineering Design and the Product Life Cycle: Relating Customer Needs, Societal Values, Business Acumen, and Technical Fundamentals. Momentum Press, 2018.

Lighting design brings together art and science: requiring the designer to apply both creative, visually appealing, and effective spaces. Lighting professionals work in a variety of roles and project areas: malls, hospitals, residences, roads, tunnels, sports arenas, and more. The Engineering Institute of Technology (EIT) is offering a 52856WA - Advanced Diploma of Illumination Engineering and Lighting Design, starting in November, that will equip students looking to go into the lighting industry with the fundamentals of illumination and lighting.

Lighting also happens to be essential for crop-growing in greenhouses, which in turn, helps geographical regions develop food security. The growth lights industry has been gaining momentum in the last couple of years as urban farming gains in popularity.

Specialists in the lighting industry are in demand, with farming companies looking to build the best lighting designs to produce bigger harvests. Growth lights are a critical component of the urban agricultural sector in colder countries that lack the hours of sunlight much warmer countries get. The growth lights market is expected to grow at a Compound Annual Growth Rate (CAGR) of 19.5% in the next five years, according to a report by Mordor Intelligence. The industry is well suited for an influx of lighting specialists to continue transforming the sector with new and exciting lighting technologies.

With a rescheduled Olympics happening around this time next year, lighting engineers will be working around the clock to ensure the opening ceremony impresses with fascinating lighting displays. Equally important, stadium lighting allows athletes to operate during the evening hours and keep television audiences enthralled and entertained. Lighting specialists are crucial in this area.

The health sector is also seeing renewed interest in lighting specialists too. Considering how many people may have visited hospitals in 2020, lighting designers have been a vital component in making hospitals more welcoming and habitable for patients. According to HealthDesign.org, 11 academic studies suggest that light is ‘effective in reducing depression.’ Other studies found that facilities with low light levels saw more agitated patients. Hence, well-thought-out and designed lighting systems in hospitals can help keep patients and staff psychologically satisfied — and can lead to better patient wellbeing statistics for hospitals in general.

The International Labour Organization agrees that lighting in all workplaces, regardless of industry, is exceedingly important. The organization says that poor lighting at work can lead to eye strain, fatigue, headaches, stress, and accidents. Lighting specialists measure light levels in LUX - luminous flux per unit area. A bright sunny day measures at 100,000 lux. The general lighting standards for a standard office setup is 500 lux. A good mix of natural lighting and artificial lighting is the delicate balance in a workplace a lighting specialist can help create.

To become a specialist in the lighting design field, you can complete EIT’s 52856WA - Advanced Diploma of Illumination Engineering and Lighting Design, which runs for 18 months. The course will introduce students to the following fundamental elements of illumination engineering and lighting:

- Implementing and utilizing engineering solutions to lighting design and illumination engineering.

- Analysing, planning, designing and providing lighting solutions.

- Preparing complex technical information and concepts to plan, communicate, and implement solutions to a range of illumination engineering and lighting design environments and contexts.

- Designing advanced lighting systems utilizing software and understanding of lighting concepts.

- Managing complex projects and tenders on time and within budget.

- Managing self-autonomy to achieve objectives within organizations that have output based on engineering application and develop professional practice in the field.

Becoming a certified professional in the lighting industry is good practice as the industry continues to innovate in the space. With the arrival of the Internet of Things, interconnected lighting systems with remote control and sophisticated automation is creating new opportunities and diversifying the industries where lighting systems can operate within. Now is the best time to update, or even begin your upskilling in the illumination engineering and lighting industry.

Works Cited

“GreenPower LED Production Module.” Philips, www.lighting.philips.com/main/products/horticulture/products/greenpower-led-production-module.

“Impact of Light on Outcomes in Healthcare Settings.” Impact of Light on Outcomes in Healthcare Settings | The Center for Health Design, https://www.healthdesign.org/chd/research/impact-light-outcomes-healthcare-settings

International Labour Organization, www.ilo.org/.

Market Research, www.reportlinker.com/p05934721/Grow-Lights-Market-Growth-Trends-and-Forecasts.html?utm_source=GNW.

A lecturer and a postgraduate student from the Engineering Institute of Technology (EIT) recently virtually attended the 29th IEEE International Symposium on Industrial Electronics (ISIE2020) from the 17th to the 19th of July. ISIE focuses on advancements in knowledge, new methods, and technologies relevant to industrial electronics - along with their applications and future developments. EIT’s two representatives submitted academic papers at the symposium to report their findings on vitally important topics to the industry. Their contributions will spur innovation in the industry, and provide solutions to engineering problems prevalent in both the energy and renewable energy sectors.

Dr. Seyed Morteza Alizadeh started his position as a Lecturer at EIT’s Melbourne campus in July 2019, conducting classes for our Master of Engineering (Electrical Systems) and Master of Engineering (Industrial Automation) courses EIT offers. Soon after he joined EIT, he was promoted to research coordinator with a strong focus on research activities in EIT’s freshly announced Professional Doctorate program. Dr. Alizadeh this year presented two papers at the 29th IEEE International Symposium on Industrial Electronics (ISIE2020). Both of the papers have now been published in the IEEE Xplore Digital Library - a research database for academics in the computer science, electrical engineering, and electronics industries.

“IEEE has a key role in educating, standardizing, and innovating the electronic development industry. It has provided professional engineers across multiple industries with valuable resources and tools,” Dr. Alizadeh explained. “IEEE has an active portfolio of around 1,300 standards which makes it as a leading developer of industry standards in a wide range of technologies used by people in everyday life.”

One of the papers Dr. Alizadeh presented at the symposium was based on the thesis work of one of EIT’s postgraduate students Samuel Afotey. The student completed his thesis remotely under supervision. Entitled ‘Investigation into the impact of Cable Failure localisation methods on the Underground Cable Life Time in a Medium Voltage Distribution Network,’ it was awarded the ‘Best Paper Award’ at ISIE2020.

Afotey’s paper focused on the use of underground cables essential to power distribution networks. The thesis particularly honed in on the impact of underground cable fault localisation methods on the cable lifetime and proposals on cable testing techniques. The paper utilized data from a use case of an electricity distribution network in an urban region of Ghana.

“The testing practices proposed enable to reduce the adverse impact of fault current and harmonic generated during the cable testing process, which is the significance of the presented over the existing cable testing methods,” Dr. Alizadeh explained. “The work helps guide and enables the engineers and designers to carry out an initial assessment on the major causes of cable failure and provide them with the knowledge on how to minimize the adverse impact of underground cable testing,”

Dr. Alizadeh also had a paper that himself and colleagues prepared on renewable energy. IEEE has published the report he unveiled at the symposium. The report titled: ‘A Mathematical Method for Induction Generator Based Wind Power Plant Sizing and Siting in Distribution Network,’ The papers that have now been published will be accessed by engineers and researchers all around the world.

Furthermore, Dr. Alizadeh chaired a conference session on ‘Power Systems and Smart Grids’ at IEEE’s symposium. He is intrigued by the development of renewable energy-based power plants that are being engineered to minimize the number of fossil fuel burning technologies existing in energy industries worldwide.

“In my point of view, the renewable energy-based power plants have been significantly developed, and there are many large-scale on-going projects in many countries to increase the penetration of renewable energy sources for producing electricity. However, in many countries, the existing renewable energy-based power systems have the capacity of supplying the intermediate or peak load while the base load is still provided by fossil fuel-fired power plants. This has increased the environmental issues such as air pollution and global warming,” Dr. Alizadeh said.

At the conference session he chaired, Dr. Alizadeh was fascinated by an engineer from Bosch Company who presented a paper titled ‘Load Profile Cycle Recognition for Industrial DC Microgrids with Energy Storage Systems.’ The hope is that, especially in developing countries, that renewable energy technologies can form part of the base-load of countries’ energy capacity, so they don’t have to rely on fossil fuels as much.

“The investigation of different aspects of renewable energy power systems, for example, power quality and voltage analysis, frequency stability and technical issues for grid interconnection in the renewable energy-based power systems, is a very exciting research prospect in the power engineering field and much research has either already been completed or in progress,” Dr. Alizadeh concluded.

Phillippus Roedolf (Rudy) Botha is the Managing Director of Victory Business Ventures — a family-owned construction company. He is also an Engineering Institute of Technology alumnus, having completed our 52724WA - Advanced Diploma of Civil and Structural Engineering in 2020. With his career trajectory in mind, Rudy has been working to both gain theoretical knowledge and hands-on practical work experience to achieve more sophisticated and management roles within industry.

Rudy achieved his Matric Certificate at Southdowns College in 2013. Unsure of the career path he wanted to follow, he decided to take a gap year in 2014. The year after that, he enrolled in Damelin College, to study a Diploma in Civil Engineering. Rudy had zeroed in on his newfound passion.

"I have always been fascinated with the structural features of buildings and the manner in which they are created. I have always felt a passion to be able to create buildings and structures of my own that will stand as reminders of my achievements in this industry," Rudy explains.

In 2017, he began working for Kalcon (WBHO) in Botswana at Karowe Mine as a student engineer, where his primary role was quality assurance with regards to civil works. In the middle of the year, Rudy went back to Damelin to rewrite two subjects, which finally earned him his Diploma in Civil Engineering.

At the end of 2017, the Karowe Mine project ended, leaving Rudy to search for a new engineering role. He had his sights set on DRA Global. The company is a multi-disciplinary global engineering group delivering mining, mineral processing, energy, agriculture, water treatment, and infrastructure services from concept, to commissioning and comprehensive operations and maintenance services. He applied to the company and was employed soon after.

He began working for DRA Global at Bisie Tin Mine in the Democratic Republic of Congo as a Junior Site Supervisor. His role was to supervise the contractors doing civil and earthworks.

"While I was with DRA Global, they mentioned an opportunity to work in a management role at the head office if I furthered my studies," Rudy explained.

"I decided that I wanted to advance my studies in the engineering industry while providing myself with better working opportunities." Consequently, he set out to begin developing his skill set and gain new insights into the management of civil engineering projects. He registered with the Engineering Institute of Technology at the start of 2018, and began earning his 52724WA - Advanced Diploma of Civil and Structural Engineering.

At the end of 2018, the civil and earthworks department was nearing completion at Bisie Tin Mine. Even though Rudy’s future with DRA Global looked promising, he saw potential in the family business in Botswana. In 2019, he decided to take over his father’s construction company in Botswana. He was also approached by Fresh Camp Services to take the role of Construction Manager in where they constructed flatpack units at the Khoemacau Mine in Botswana. He agreed to the project and worked with Fresh Camp Services under the family business until the contract came to an end in April 2020.

Now working with his family's business, Rudy is in charge of tendering for various new construction projects. He also has a role in the planning, costing, and management of the projects his company is involved in. Rudy notes that one of the most fascinating developments in the civil engineering industry has been the updating of design software that has made the entire construction process more efficient.

In Rudy's mind, the future's looking bright. He is an engineering professional who has taken charge of the development of both his qualifications and his work experience. He has boots-on-the-ground since finding his passion for the construction industry. He continues to find ways of innovating in the industry and ensuring the family company keeps finding success.

"I see my company taking on various new projects and leading the construction industry in Botswana, while being open to other international opportunities that may arise. I am looking to study further in order to obtain a Bachelor of Science (Civil and Structural Engineering), which will once again diversify the job opportunities that are available to me and my company," Rudy concluded.

When engineering equipment fails, the consequences can be severe or even catastrophic. Jan Croucamp has dedicated his career to ensuring the ongoing integrity and reliability of plants and equipment in the engineering services industry. He is a highly credentialed professional in the inspection engineering field in South Africa.

While maintaining his employment, Jan recently completed EIT’s 52810WA - Advanced Diploma of Mechanical Engineering to formalize his 17 years of practical experience. He advocates for the importance of supplementing applied learning with theoretical knowledge in carving out a long term career in industry. He says he chose the course because it was most in line with the industry he is working in.

“This course gave me in-depth theoretical knowledge to my already in-depth practical knowledge — so it rounded me off nicely. The fact that it was online means you can work and still study no matter where you are. I literally studied in three different countries and did not struggle with any of my classes. The help and support you receive from the Learning Support Officers is life-saving.”

Jan has a wealth of practical experience in the industry. Still, he has been seeking opportunities to equip himself with the necessary knowledge to meet the challenges and demands of inspection engineering as the fourth industrial revolution continues to transform the profession.

“In this industry, sometimes certification outweighs qualification. Of course, you need to have some type of qualification to gain certification, but mainly, it is all to do with years of experience. I’m certified by the American Petroleum Institute, the International Institute of Welding, and the South African Institute of Welding,” Jan explains.

Jan remains passionate about the industry, even after 17 years of hard work. During that time, he has worked in the asset integrity field, performing inspections on pressure vessels, piping, storage tanks, and lifting equipment on refineries and chemical process plants. In almost two decades, he has learned the tools of the trade through a balanced approach of education and practical experience.

“There is always a problem to solve or damaged equipment to fix, and only engineering gives the solutions to these problems,” he says.

His daily responsibilities include evaluating NDT findings and identifying NDT methods. He also issues recommendations on items that need to be repaired and follows repair jobs from start to finish. He finds damaged mechanisms on equipment and evaluates the effect the damage has on the entire system. Moreover, depending on where he is in the world, he has to apply different kinds of inspection standards.

“A typical day will consist of verifying NDT reports, inspect equipment for damages, and following up repairs on pressurized equipment. I also work closely with engineering staff regarding the manufacturing and design parameters of pressurized equipment.

“Depending on the country you work in, you have to follow that country’s regulations on pressurized equipment. Most of the time, this gives you, the certified inspector, the right to keep equipment in service or remove it from service — if you feel it might put the public or employees’ lives in danger. It is an exciting job with a lot of responsibility that can cause you to be arrested if you miss something, and someone is injured due to your negligence.”

“The most fascinating developments in the industry are the remote inspection techniques that are now prevalent.”

He explains that new welding techniques have also arrived. Therefore, ongoing professional development is necessary to stay abreast of the changes that technology brings to the industry. His advanced diploma has served him well in that respect.

Jan explains he now finds himself at a crossroads and is pondering on what he should do next educationally. He is considering pursuing his Bachelor of Science in Mechanical Engineering. In the near future, he says he sees himself filling a technical manager or inspection manager role. Whatever he does end up doing, he wants to pass the torch on to the next generation, and influence them to take a step towards their engineering goals.