News

The Sweetwater University City Pedestrian Bridge collapse at Florida International University is the latest civil engineering failure making headlines around the world.

Figg Bridge Engineers discussed a crack that had formed on the new bridge hours before its demise, but “concluded there were no safety concerns and the crack did not compromise the structural integrity of the bridge.”

Despite these assertions it did collapse and caused six fatalities and further injuries. Vehicles were pancaked underneath the rubble, as the photograph here depicts.

Lead engineer on the project W. Denney Pate had sent a voice mail to the Transportation Department; he reported the “cracking” that was observed on the “north end” of the bridge. The voice mail was sent two days before the bridge came crashing down.

Pate did say, in his professional opinion, the cracking “from a safety perspective” was not something they were concerned about. The cracking did not indicate that a collapse would follow. The engineering firm even did a stress test a few days before the collapse. All tests performed failed to raise any urgent red flags.

A civil lawsuit has been filed for gross negligence, in an attempt to hold the design-construction firm to account. The bridge was a US$14.2 million project. The National Transportation Safety Board is currently investigating the case, and also keeping a close eye on other new bridges across the country.

How was the bridge made?

The doomed bridge in Florida was being designed and constructed using a method known as Accelerated Bridge Construction (ABC). The process makes use of prefabricated materials that are brought on-site and then assembled - the end product here was a pedestrian bridge.

In fact Florida International University has an entire center dedicated to the rapid bridge building practice: the Accelerated Bridge Construction University Transportation Center.

The ABC method, used for quicker bridge builds, is also renowned for its cost effectiveness. And the bridges are usually robust - a Category 5 hurricane shouldn’t have the capacity to take one down apparently. An added benefit: roads can remain open during the building process. It was this that proved fatal!

The ABC method has been proving popular around the world, but is now, understandably, receiving greater scrutiny. The National Transportation Safety Board in the US is currently investigating the case (and keeping a close eye on other new bridges across the country). The investigation will drill down into the specific methods used during an ABC build in an effort to determine what the exact cause or causes were for this catastrophic failure.

America needs to monitor current civil engineering structures whilst also focusing on the ‘in-need-of-maintenance’ infrastructure that has been receiving stark criticism in the last few months.

Earlier this year aging infrastructure in the US took center stage when data generated from the Department of Transportation revealed that more than 54,000 bridges in America are currently structurally deficient. The information suggested that one in three bridges is in need of repair, including three interstate highway bridges.

This is essentially good news for structural and civil engineers interested and experienced in bridge design, construction and maintenance and based in the US.

Works Cited

Dearen, Jason. “Rapid Building Technique Gets Scrutiny After Bridge Collapse.” Popular Mechanics, Popular Mechanics, 18 Mar. 2018, www.popularmechanics.com/technology/infrastructure/a19472387/rapid-building-technique/.

Self, Zac, and Associated Press. “Engineer Reported Cracking before Miami Pedestrian Bridge Collapsed.” 10News, 17 Mar. 2018, www.10news.com/news/engineer-reported-cracking-before-miami-pedestrian-bridge-collapsed.

Palm Island

In 2001, there was nothing off the coast of Dubai except for shallow gulf water. However, the city was becoming overpopulated quickly. To solve this problem, local real estate conglomerate Nakheel Properties used GPS precision to shape 94 million cubic metres of sand into a 17-frond palm tree-shaped island. Sixteen quarries throughout the UAE were dredged for rock, which forms a breakwater around the island to protect it from wind and waves. It took a decade for Palm Jumeirah to be fully completed, although residents began moving to the island in 2008. The trunk is made up of luxury hotels and malls; the fronds are lined with mansions. A six-lane underwater tunnel allows people to travel to the island from the mainland and the Middle East’s first monorail travels the length of the island. Two other islands are currently under construction.

Burj Khalifa

Officially the tallest free standing building in the world, this skyscraper is 828 metre high and has 163 stories. The biggest challenge engineers faced were strong winds, so they conducted over 40 wind tunnel tests, not only to determine how the building would be affected, but to ensure the safety of the cranes used to construct it. Built in Dubai, UAE in 2010, the building changes width as it gets taller in a bid to “confuse the wind,” according to global engineering firm SOM, who created the structure. This means wind vortexes cannot form, as they encounter a new shape at each tier of the building. The building has been engineered to withstand earthquakes and other natural disasters.

Kansai Airport

Located in Osaka, Japan, this was the first airport to be built on an artificial island. The project was created as a solution to overcrowding, as the city was too small to fit an airport on the mainland. One of the biggest challenges engineers faced was the clay found in the seafloor they intended to build on – it retains too much water to be a reliable foundation. To combat this, engineers utilised 1.2 million sea drains, a new technique used for sea-based stabilisation. Tubes were driven deep within the clay, filled with millions of tons of sand, and then removed. The columns of sand still act as drains within the clay, to stop the foundation becoming saturated with moisture and moving. 48,000 concrete tetrahedrons were stacked upon the stabilised seabed, with each one weighing 181 tonnes. Nearby mountains were excavated and approximately 161 million cubic tonnes of earth were poured into the gaps. It took three years for the seawall and base to be completed, before construction could begin on the airport itself.

The airport is an architectural wonder, built to reduce environmental impact and save money – blade-like deflectors line the ceiling, channelling air through the building and acting as a passive air conditioning system. Completed in 1994, it took three years and saw over 10,000 workers contribute to its construction. The island is 4 kilometres by 2.5 kilometres and became the world’s most expensive civil engineering project, costing US $20 billion.

Tokyo Sky Tree

Engineers tasked with the construction of the 634 metre high-rise building faced many challenges while building Japan’s tallest building. They had to take into account not only the typhoons that strike Tokyo every summer, but also potential earthquakes as it is built on an active fault. Structurally, it features a reinforced concrete central column, which is separate from the outside steel frame – an adaptation of the design often seen in pagoda temples. Traditional Japanese building technique shinbashira was utilised, which sees the central column reduce sway by counterbalancing seismic waves.

Channel Tunnel

This 50.5 kilometre tunnel features the longest undersea portion in the world, coming in at 37.9 kilometres. Completed in 1994 after six years of construction, it cost approximately US $21 billion and required much problem solving from engineers. For example, they needed to ensure passenger safety, in case of a fire within the tunnel. So, engineers constructed a third, smaller tunnel in between the two full-sided tunnels, to act as an escape route during emergencies. There are also a number of passages that allow the trains to cross-over onto the other track. Eleven boring machines were used to dig the tunnel, collectively weighing over 12,000 tonnes – each one was as long as two football pitches.

Construction saw collaboration between British and French engineers, who had a competition to see who could reach the centre of the tunnel first: the British won. 13,000 workers were employed at the height of construction, and 10 people were killed while building the tunnel. The average depth of the tunnel is 50 metres below sea level, with the lowest point 75 metres down. The Channel Tunnel was included in the American Society of Civil Engineer’s “Seven Wonders of the Modern World” list.

Panama Canal

The French originally started this project back in 1880; however they failed because of poor design and high mortality from diseases such as yellow fever and malaria. So, the US took over and redesigned the endeavour in 1904, officially completing the project in 1914. Measuring 77 kilometres, this canal connects the Pacific and Atlantic oceans, allowing easier passage for ships. There were many challenges for engineers to overcome, such as the landmass being above mean sea level due to mountainous terrain, dense jungle, removing rocks and soil, and differences in tides. The Europeans believed canals should be built at sea level; however this would have involved much excavation and cost millions of dollars more. The Americans decided to utilise locks, which would raise and lower ships into the placid waters of the canal. Dams and spillways meant the water in this canal was better regulated than a strait in between two bodies of water, mitigating the issues brought on by the differences in tides.

Millau Viaduct

At 343 metres high, the Millau Viaduct is the world’s tallest bridge – it’s even taller than the Eiffel Tower. 18,000 tonnes of concrete were used to build its seven piers and the bridge cost a total of US $524 million to construct. The biggest marvel of this bridge is the short construction span of only three years from 2001-2004; builders were placed under enormous pressure to build it in less than four years; otherwise the French government would fine them US $30,000 per day. The bridge spans 2460 metres from France to Spain and carries between 10,000 and 25,000 cars per day.

Grand Canyon Skywalk

This glass bridge allows tourists to walk out onto thin air, 1219 metres above the Colorado River in the Grand Canyon. Its construction required over 453,000 kilograms of steel and 37,000 kilograms of glass to complete, with the total cost coming to US $40 million. Engineers had to undergo rigorous testing to ensure the structure could withstand the strong winds that come through the canyon; it has been designed to absorb vibrations. The foundation consists of eight support beams and the skywalk was assembled onsite, with the welding of the bridge taking four months to complete. A manipulator was designed to lift the 46 glass panels, each weighing 816 kilograms, into place. Three tuned mass dampers, which were specifically calibrated to meet the wind and weight requirements, were placed inside the horseshoe frame to make the bridge structurally sound.

Venice Tide Barrier

Despite construction beginning in 2003, this barrier is not yet complete. However the last of the giant floodgates designed to protect Venice from rising sea levels were built by a Croatian engineering firm earlier this year. In total there will be 78 gates forming four barriers at the three lagoon inlets of Lido, Malamocco and Chioggia. Each gate weighs 272 tonnes and measures 30 metres wide by 20 metres high, and five metres thick. The Electromechanical Experimental Module (abbreviated to MOSE in Italian) consists of over 18,000 tonnes of built-in steel, and is expected to have a 100 year lifespan.

Engineers have been faced with a number of challenges during this project’s construction, such as lowering the 23,000 tonne foundation into a lagoon. MOSE’s purpose is to only be deployed when it is necessary to do so; it will not stop tidal flow into the lagoon or cut Venice off from the ocean. The moveable barriers will sit beneath the lagoons surface during calm weather, allowing the gates to fill with water. However, when the tide rises, the water will be pumped out of the gates and replaced with air, so they rise to the surface and form a barrier capable of stopping water surges as high as 2.7 metres. This project will cost approximately US $6.5 billion in total.

Itaipu Dam

The world’s second-most powerful dam is located on the border of Brazil and Paraguay on the Paraná River. It was constructed in 1984, as a solution to projected energy crisis in Brazil due to its rapid population growth. The government decided to utilise the vast expanse of water surrounding Brazil and turn it into hydroelectricity. The dam took seven years to construct and provided jobs to 40,000 construction workers during this time. It generates enough energy to service 93% of Paraguay and 20% of Brazil.

The most challenging part of this project for engineers was changing the course of the Paraná River before construction could begin. It took three years for them to carve a 2 kilometre long, 91 metre deep channel for the river to divert through – fifty million tonnes of earth and rock had to be moved in the process. The dam wasn’t to be supported by any physical or natural features, so it had to weigh at least 61 million tonnes to withstand the water pressure, which was estimated to be the equivalent of 4000 bulldozers.

Trans-Siberian Railway

The world’s longest railroad took 25 years to construct. Completed in 1916, the Trans-Siberian Railway spans Russia from east to west for 9,198 kilometres; even today it’s the only way to cross the country, aside from flying. The idea was conceived by Tsar Alexander III; however the majority of its construction took place during Tsar Nicholas II’s reign, and stemmed from the fear of losing trade prospects. 90,000 labourers were contracted and the railroad was constructed simultaneously from both the west (Moscow) and the east (Vladivostok), working towards the centre. Challenges faced were the extreme weather conditions and the use of primitive hand tools, such as shovels, wheelbarrows, saws and axes to complete the labour. Budget constraints meant engineers avoided commercial centres, narrowed foundations and put down a reduced number of sleepers per kilometre. 12 million railroad sleepers were placed during construction and 100 million cubic metres of rock was moved. Line electrification began in 1929, but wasn’t completed until 2002.

Today, 30 per cent of Russia’s exports are transported via the railroad and trains carry an average of 250,000 containers to Europe each year. Not only does it link Moscow to Vladivostok, but has branching lines to China, North Korea and Mongolia. The 8 day journey spans 87 cities, 16 rivers and 8 time zones.

Bailong Elevator

The tallest elevator in the world is located in the side of a cliff in China’s Wulingyuan scenic area. Constructed between 1999 and 2002, the Bailong Elevator’s shafts and tunnels were carved from a quartz sandstone column in the heritage-listed area, despite protests from environmentalists. Made of glass, it offers dizzying views to passengers, as it carries them 326 metres up the sandstone column to the top of a mountain range. 154 metres of the lift are embedded into the column, and the remaining 172 metres are set into exposed steel and other components. The journey takes just under two minutes, with lift cars running at three metres per second, taking up to 50 passengers at one time. Earthquake detectors are fitted into each car, to allow for a quick evacuation in case of an emergency.

Sources:

https://interestingengineering.com/5-of-the-worlds-greatest-feats-of-engineering

https://edition.cnn.com/travel/article/engineering-feats/index.html?gallery=10

http://www.topengineer.com/news-detail/the-world-s-top-10-most-amazing-engineering-feats//

https://10mosttoday.com/10-most-amazing-engineering-achievements/

https://www.iveyengineering.com/modern-engineering-marvels/

https://list25.com/25-most-monumental-feats-of-construction-in-history/

https://www.cntraveler.com/stories/2015-11-23/the-real-story-behind-dubai-palm-islands

https://www.theguardian.com/travel/2008/apr/26/travelnews

https://www.som.com/projects/burj_khalifa__structural_engineering

https://interestingengineering.com/kansai-airport-the-worlds-longest-airport

http://global.ctbuh.org/resources/papers/download/2624-structural-design-and-construction-of-the-foundation-of-tokyo-sky-tree.pdf

https://www.engineering.com/Library/ArticlesPage/tabid/85/ArticleID/79/The-Channel-Tunnel.aspx

https://www.telegraph.co.uk/travel/destinations/europe/france/articles/The-Channel-Tunnel-20-fascinating-facts/

https://www.eurotunnel.com/uk/build/

https://hardyservices.co.uk/blog/seven-wonders-civil-engineering-world-itaipu-dam/

http://www.armyengineer.com/history/panama/engineers/How_Canal_Works/How%20the%20Canal%20Works.html

https://www.motiondrivesandcontrols.co.uk/impressive-feats-engineering-3-panama-canal/

https://www.istructe.org/blog/2016/millau-viaduct-a-triumph-of-engineering

http://allthatsinteresting.com/millau-viaduct

http://www.grandcanyonskywalk.com/wp-content/uploads/2012/02/Skywalk-Facts-2012.pdf

http://abcnews.go.com/WNT/Travel/story?id=2957548&page=1

https://e360.yale.edu/features/rising-waters-can-a-massive-sea-barrier-save-venice-from-drowning

https://science.howstuffworks.com/engineering/civil/how-the-venice-tide-barrier-project-works.htm

https://www.mosevenezia.eu/mose/?lang=en

https://www.newcivilengineer.com/world-view/the-gallery-the-62m-giant-flood-gates-designed-to-save-venice/10028977.article

http://www.cannon-cannon.com/amazing-engineering/amazing-engineering-itaipu-dam/

https://www.nesgt.com/blog/2017/03/top-engineering-achievements-trans-siberian-railway

http://factsanddetails.com/russia/Education_Health_Transportation_Energy/sub9_6d/entry-5156.html

https://www.britannica.com/topic/Trans-Siberian-Railroad

https://interestingengineering.com/bailong-elevator-dare-ride-insanely-tall-outdoor-lift

Engineers wait with bated breath for a call they may never get. Earlier this year, the United Kingdom’s Foreign Secretary, Boris Johnson, proposed a 22-mile bridge to span the English Channel.

Eleven tunnel boring machines and engineering expertise created the 50.45 kilometer (31.35 mile) Channel Tunnel link between England and France.The tunnel took five years to build with a total of 13,000 workers from both England and France. If the building of a bridge is announced it would mean a sizeable payday for engineers attached to the project.

Some have dismissed Johnson’s intention to build the bridge - calling it a fantasy that will never come to fruition. However, Channel Tunnel operators Eurotunnel have expressed interest in the project.

Speaking in the House of Commons, Johnson said:

“It is a curiosity that two of the most powerful economies in the world, separated by barely 21 miles of water, are connected by only one railway line. And I think it is a matter for legitimate reflection by our two countries on the way forward.”

The bridge would be an impressive feat, not just considering the engineering prowess it would involve, but because it would be a post-Brexit achievement for the country which is due to leave the European Union, but still retain its business connections with France.

What they’ll need

If the plan to build the bridge goes forward, engineering professionals will either be tasked with creating a cable stayed bridge or a suspension bridge. There is just one glaring problem that is already causing speculators some consternation: boats.

Wanda Lewis, Emeritus Professor in Civil Engineering at the University of Warwick took to The Conversation, to explain. She writes:

“The channel is between 40m and 60m deep and some passenger ships are more than 70m tall. So to let ships pass underneath, the pylons supporting the bridge would have to be around 150m tall. To support the cables you would have to add pylons above the deck, which would mean a total pylon height well above 500m. Again, nothing this tall has ever been built.”

If the bridge does get built, it will be the world’s tallest bridge, and may just get recognition as a marvel of the modern world. However, with height comes wind and this strengthens with greater height. The bridge could be poised to deal with a number of wind-related engineering challenges.

With the longest bridge in the world as a case study, the Danyang-Kunshan Grand Bridge in China, the Daily Mail estimates that the bridge would cost approximately £824 million (USD 1.150 billion).

The Boris Bridge - as it has now been humorously dubbed - has received a great deal of backlash. The UK Government may indeed scrap the idea, but they are not ruling out the possibility of another tunnel.

Eurotunnel maintain that building a second link to England is not a matter of ‘if’ but a matter of ‘when’. Chief Executive of Eurotunnel Jacques Gounon wrote in a letter:

“The idea of a second fixed link is something that we regularly consider in our long term plans, and we would be delighted to engage with your officials to explore the possibility further.”

Works Cited

Lewis, Wanda. “Boris Johnson's English Channel Bridge: an Engineering Expert's View.” The Conversation, 12 Mar. 2018, theconversation.com/boris-johnsons-english-channel-bridge-an-engineering-experts-view-90409.

Ravenscroft, Tom. “Eurotunnel ‘Very Interested’ in Boris Bridge between England and France.” Dezeen, Dezeen, 14 Feb. 2018, www.dezeen.com/2018/02/14/eurotunnel-channel-tunnel-interested-boris-bridge-england-france/.

The speed at which a lithium-ion battery charges, remains a unique scientific and engineering challenge. Historically, slow charging has been responsible for limiting the development of vehicles and technologies that need to constantly recharge. This is, however, changing as technology advances.

The safety of lithium-ion batteries has also been a sore point in the history of battery technology. But with new sensor technology these batteries are becoming less risky.

Ensuring no thermal runaway occurs in Li-ion batteries is important for the future of vehicles and other technologies dependent on them. In fact temperature control, the speed of charging and general battery safety is paramount.

Interestingly University of Warwick researchers claim that Li-ion batteries already sold in commercial settings can be charged faster than previously thought. They also assert that this could improve their safety. With new sensor technology embedded into the battery a speedier charge and reduction in risk will result, they believe.

The researchers have published their findings in a journal named Electrochimica Acta under the title: “Understanding the limits of rapid charging using instrumented commercial 18650 high energy Li-ion cells.”

18650 high energy Li-ion cells are the ones found in our electronics, future electric vehicles and our energy storage units. Now, with new sensor technology, the inner-workings of the Li-ion battery can be monitored and will open a new pathway to battery flexibility.

Lead researcher Dr Tazdin Amietszajew says:

“This could bring huge benefits to areas such as motor racing, which would gain obvious benefits from being able to push the performance limits, but it also creates massive opportunities for consumers and energy storage providers.

The Warwick University researchers say the new sensor technology will allow for flexible charging functionality, but has revealed that we have been charging the batteries more slowly than necessary. Amietszajew said:

“Faster charging as always comes at the expense of overall battery life, but many consumers would welcome the ability to charge a vehicle battery quickly when short journey times are required and then to switch to standard charge periods at other times. This technology is ready to apply now to commercial batteries, but we would need to ensure that battery management systems on vehicles, and that the infrastructure being put in for electric vehicles, are able to accommodate variable charging rates that would include these new precisely tuned profiles/limits.”

It may even ensure that the Li-ion batteries do not overcharge. There are already measures in place to prevent electronics’ Li-ion batteries from overcharging, although it still occurs in certain Li-ion applications.

The Battery University explains:

“Prolonged charging above 4.30 volts on a Li-ion designed for a 4.20V/cell will plate metallic lithium on the anode. The cathode material becomes an oxidizing agent, loses stability and produces carbon dioxide (CO2). The cell pressure rises and if the charge is allowed to continue, the current interrupt device (CID) responsible for cell safety disconnects at 1000-1,380kPa (145-200psi). Should the pressure rise further, a safety membrane on some Li-ion bursts open at about 3,450kPa (500psi) and the cell might eventually vent with flame.”

The research into how to get Li-ion batteries performing more efficiently, being charged up more quickly and living longer, is important research. This glimpse into the future, thanks to Li-ion batteries, has already signaled a new ‘gold rush’ - with lithium being the gold. The future of clean, renewable energy applications may indeed depend on Li-ion batteries performing better than they already do.

Works Cited

“Charging Lithium-Ion Batteries.” Charging Lithium-Ion Batteries – Battery University, batteryuniversity.com/learn/article/charging_lithium_ion_batteries.

Posted March 11, 2018 by Travis Horesh & filed under Newswire, The Tech. “New Li-Ion Battery Sensor Tech Promises 5x Faster Charging.” Charged EVs, chargedevs.com/newswire/new-li-ion-battery-sensor-tech-promises-5x-faster-charging/.

The scientific world has lost one of its modern day pioneers. Stephen Hawking, a modern cosmologist, passed away at age 76, on the 14th of March 2018. Hawking’s most notable work, “A Brief History of Time”, sold over ten million copies and he is remembered for his work on general relativity and black hole theories.

His impact on engineering is not lost either; Hawking popularized communication devices that aid those who are unable to speak. Hawking developed Amyotrophic Lateral Sclerosis (ALS) at the age of 21 - a motor-neuron disease. After a bout of pneumonia, and due to the effects of ALS, doctors had to perform a tracheotomy on Hawking; he lost the ability to speak. The engineered technologies that gave him his voice back became wonders of biomedical engineering.

Hawking started out with a speech synthesizer called CallText 5010. It was run by an AMD processor.

He was eventually persuaded to utilize Intel’s technology after the CEO asked him if he wanted to use a ‘real computer’. Since then, Intel has mobilized the ‘Intel User Experience Engineers’ to regularly update Hawking’s communication system. It was Intel who provided Hawking with his distinct voice.

Engineer, David Mason helped fit Equalizer and Speech Plus software to Hawking’s wheelchair. The software was developed by a company known as Words Plus. The software needed a clicker pressed to articulate speech, but Hawking eventually lost the use of his hand. Thereafter an infrared sensor on his glasses was able to detect when he twitched his cheek muscle.

As Hawking’s condition deteriorated he found it increasingly difficult to type words efficiently; this limited his ability to communicate ideas and write books. In response Intel’s engineers tested a number of new methods, but seemed stumped.

Eventually predictive text entered our lexicon of terms and has become a feature on our smartphones. It involved a great deal of trial and error, but allowed Hawking’s communication to speed up. He used word predictors by popular keyboard app maker SwiftKey.

The technology was fleshed out and dubbed the Assistive Contextually Aware Toolkit. Hawking began to use shortcuts and menus that had some pre-predicted tools; it can cut down typing time by half.

Lama Nachman is an Intel Fellow and the Director of the Anticipatory Computing Lab at Intel Corporation. After his death she summed up the challenging biomedical engineering endeavors that were pioneered with and for him:

“Working with Stephen was the most meaningful and challenging endeavor of my life. It fed my soul and really hit home how technology can profoundly improve people’s lives. We will continue developing and refining this technology in the open source community in his honor, to reach all people in need. This is something he cared about deeply.”

Hawking had the option to change the sound emitted from his communication device, but he chose to keep his iconic, robotic voice. It became synonymous with the man; a man with an incredible brain, enormous courage and boundless determination.

Works Cited

Farrell, Nick. “Intel Remembers Giving Stephen Hawking His Voice.” Fudzilla, www.fudzilla.com/news/processors/45820-intel-remembers-giving-stephen-hawking-his-voice.

Cruise ship holidays are growing in popularity. What’s not to like? Breakfast buffets. All-you-can-eat pizza and burgers around the clock. Restaurant dinners. Drinks. Great sea views. As the appetite for cruise holidays intensifies, the cruise companies are lengthening their pre-existing liners.

Instead of building new ships they are slicing the existing ones in half and inserting new middle sections. This feat of engineering has become standard practice for profit-turning cruise ship companies. MSC Cruises lengthened four of their fleet back in 2014-2015 in one of the biggest operations of its kind.

And Silversea has just performed its first cruise ship stretching operation this year. The Silver Spirit has been split in half in readiness for a 15-metre addition. The operation will be completed by May 5th 2018 – taking a total of 450,000 hours to complete – and 12% growth. Once the ship has been completed it will embark on a 7-day journey between Rome and Barcelona.

New builds cost many hundreds of millions whereas MSC Cruises’ latest lengthening operation only cost the company US$227 million. It is far cheaper to lengthen ships than build new ones.

One of the challenges for engineers is to meticulously fit and maneuver the new section into the designated space; to ensure it aligns perfectly with the other halves. Once the new section is welded into place it is painted to blend in with the older sections. The Silver Spirit’s renovation includes a complete overhaul of the interior (the old furniture is being donated to charity). The new additions, in essence, become indistinguishable and the ships are sent back out to sea.

The companies rely on this added capacity to facilitate an increase in the number of passengers, and thus create more profit.

The lengthening of ships for profit is a modern exercise, but it is an old practice. In the past ships were lengthened to allow for more engine room; the first such operation occurred as early as 1871.

Works Cited

“Cruise Industry: Why Do Cruise Lines Cut Their Ships in Half? -.” - The First Online Cruise Magazine for the Middle East and South Africa., 29 Nov. 2017, cruisearabiaonline.com/2014/09/22/cruise-industry-why-do-cruise-lines-cut-their-ships-in-half/.

Mclaughlin, Kylie. “Silversea Cruise Ship Silver Spirit Cut in Half in Lengthening Project.” Stuff, www.stuff.co.nz/travel/cruising/102243159/silversea-cruise-ship-silver-spirit-cut-in-half-in-lengthening-project.

It is difficult to train for outdoor sports indoors. We can try to replicate naturally occurring factors such as hills, valleys, wind and rain; but nothing can adequately imitate what the outdoors is capable of producing (even when training outdoors). Cycling is no exception. Training is regularly conducted indoors, to control things such as resistance and drag when slopes are sparse. Or, when practise riding into a headwind is required and there’s not a breath of wind outside.

Previously, an ergo (stationary bike) was the option, where gears were simply changed to add resistance to the ride, slowing a cyclist down and causing him/her to push harder to achieve the same speed. A relatively new product has emerged, however; it is completely changing the training game.

AIRhub is a revolutionary cycling training device produced by Terrain Dynamics. It is an electromagnetic braking system which adds watts to your ride without adding mass. The AIRhub connects to your smartphone via Bluetooth, with the AIRhub app controlling your output in real time. “AIR” stands for automated integrated resistance, and hub of course being the 1.5kg physical attachment to the front wheel of the bike.

The aptly named Terrain Dynamics is the brainchild of Perth man Michael Freiberg, a gold and silver Commonwealth Games medallist himself and 2011 Omnium World Champion. Freiberg developed this remarkable feat of engineering after years of training for both track and road cycling. He was finding he couldn’t control and manipulate his training schedule exactly to his needs with the technology that was previously available; his routine was often dictated by his location or the weather on the day. As this inventor and managing director Freiberg says:

"With the AIRhub, we've created that. A smart, one-of-a-kind electromagnetic braking system that works with you and can be customised to suit your program and your terrain.”

AIRhub has a series of different modes to select from, each regulating the system in a different way.

- Manual mode: it can add up to 100 watts while riding. This mode is ideal when riding with slower cyclists; it allows for a slower speed, but with the use of more power.

- Heart rate mode: it monitors the heart rate and automatically adjusts resistance to keep the training in a specific zone. This mode is ideal if riding in a large group – it increases resistance when positioned in the middle/back of the pack and decreases it if at the front; it is designed to maintain a consistent heart rate.

- CDA mode: it increases coefficient of drag to simulate headwinds.

This product is versatile. It can be utilised by leisurely weekend riders - wanting to increase average speed by a couple of km/h, all the way up to elite athletes – wanting to hone in on specific heart rate targets, oxygen intake and output wattage. Sitting at a current price point of $1950 per unit, the AIRhub is a fairly significant financial investment, but one that when used correctly, can dramatically improve results in very broad or very specific areas.

“I hope everyone who's ever struggled to take their performance to the next level, whether it be because they live in a flat area, don't have safe roads to train on or have to train solo just to get in those hard sessions, can find their answer in the AIRhub.” M. Freiberg

The results speak for themselves, with riders demonstrating a 10-15% improvement in riding power with no additional effort.

References:

En.wikipedia.org. (2018). Michael Freiberg. [online] Available at: https://en.wikipedia.org/wiki/Michael_Freiberg [Accessed 12 Mar. 2018].

Rainmaker, D. (2017). Hands-on: The AIRhub on-road cycling resistance unit. [online] DC Rainmaker. Available at: https://www.dcrainmaker.com/2017/01/airhub-cycling-resistance.html [Accessed 12 Mar. 2018].

Terrain Dynamics. (2018). AIRhub. [online] Available at: http://terraindynamics.com.au/airhub [Accessed 10 Mar. 2018].

Electricity, seemingly abundant in our world today, is something that we take for granted. The reality, however, is very different in the world.

It is estimated that 1.3 billion people still do not have access to electricity.

Electricity can mean many things for communities. Once electricity is established within a community, the access to power can lead to better health care, education, and self-determination. And prosperity soon follows.

Powering rural areas is an engineering work in progress. The remoteness of some communities means that relying on the grid is impossible.

The technologies that have been used to bring power to remote villages have historically been those which impact negatively on the environment; diesel generators have been a common source of power.

Powering the remotest villages on earth

Ladakh is inside the Indian state of Jammu and Kashmir in the Kunlun mountain range within the Great Himalayas. A small number of inhabitants brave the cold in the area; Ladakh is 12,400 feet above sea level. Until a few years ago they had never used electricity.

A team known as the Global Himalayan Expedition trekked to the remotest village in Ladakh: the village of Shadé.

These wonderful and courageous volunteer engineers installed a Solar Nano-Grid to provide the inhabitants with electricity in 2017. This complimented one previously placed in the village. The first installation had never been robust enough to power the entire village.

It took the team four days to travel the 56 miles before reaching Shadé Village. The Kashmir Monitor wrote:

“The village has never received any grid based electricity. The villagers have been using Solar Home Lighting Systems and old kerosene oil lamps. In winters, the village remains cut-off from the outside world for about six to seven months. There is one satellite phone in the village, which was installed in 2013 and remains the only medium of communication between the village and the outside world.”

The team intends to provide nanogrids to surrounding villages as well. They have been working to electrify a dozen other villages in the Himalayas in an expedition that started in 2013. The citizens of the villages are understandably delighted.

The government has, however, signed a Memorandum of Understanding with the Centre of Development in India to get two mega solar parks built in the region of Ladakh. This will be enormously valuable to the inhabitants in the region; securing them with a sustainable supply of electricity.

To see more of the work being done in the Himalayas, here is a documentary on the projects from NDTV:

Works Cited

“Remotest Village in Ladakh Gets Electricity for the First Time.” Kashmir Monitor, 14 May 2015, kashmirmonitor.in/Details/129269/remotest-village-in-ladakh-gets-electricity-for-the-first-time.

If you don’t have steel you don’t have a country - so says the President of the United States Donald Trump. And, based on an investigation conducted by the American government, their country had drawn the short straw when it came to steel imports and exports. To ensure it did not impact the elusive ‘American Dream’l import tariffs were back on the table.

President Donald Trump has announced a 25 percent tariff on steel articles exported to the United States. In an official proclamation, he said:

“This relief will help our domestic steel industry to revive idled facilities, open closed mills, preserve necessary skills by hiring new steel workers, and maintain or increase production, which will reduce our Nation’s need to rely on foreign producers for steel and ensure that domestic producers can continue to supply all the steel necessary for critical industries and national defense.”

And yet American steelworkers have been wondering where they fit in into the future of the metalworking industries - the increasing automation of steel factories will inevitably hollow out traditional roles. Barack Obama, before the end of his presidency, was quizzed on the return of jobs to the steel sector. He was less optimistic than his successor.

President Donald Trump is making a concerted effort to refocus attention on metalworking factories; the new tariffs will add 25% to steel imports and 10% to aluminum. Tariffs on foreign washing machines and solar panels were also recently imposed by his government.

Trump, on March 7th, tweeted:

“From Bush 1 to present, our Country has lost more than 55,000 factories, 6,000, manufacturing jobs and accumulated Trade Deficits of more than 12 Trillion Dollars. Last year we had a Trade Deficit of almost 800 Billion Dollars. Bad Policies & Leadership. Must WIN again! #MAGA”

Car manufacturing and beyond

Whilst most people would decry the tweets as Trump’s notorious ‘alternative facts’, a CEO of multiple engineering companies on the cutting edge of modern day engineering agrees that American business has not been getting a fair deal.

CEO of Tesla Motors, Elon Musk, also took a seemingly pro-tariffs stance. Responding to Trump on Twitter, Musk tweeted:

“Do you think the US & China should have equal & fair rules for cars? Meaning, same import duties, ownership constraints & other factors. For example, an American car going to China pays 25% import duty, but a Chinese car coming to the US only pays 2.5%, a tenfold difference. We raised this with the prior administration and nothing happened. Just want a fair outcome, ideally where tariffs/rules are equally moderate. Nothing more. Hope this does not seem unreasonable.”

Trump read Musk’s tweets from a printed piece of paper as he announced the Presidential Proclamation on Adjusting Imports of Steel into the United States.

Chief Equity Strategist for Goldman Sachs David Kostin said

“Steel is the primary material used by Automobile manufacturers Ford and General Motors. Based on 2017 production mix, if the proposed tariff of 25% on imported steel translates into a similar magnitude of increase in steel prices, it would impact each firm by roughly US$1 billion, representing 12% and 7% of their 2017 adjusted operating income, respectively.”

Furthermore, there are of course fears that the suggested tariffs could start a trade war with other superpowers, something China has all but confirmed. BHP Billiton CEO Andrew Mackenzie too is disheartened by the talk of tariffs. At a business summit on Tuesday, the 6th of March 2018, the CEO hit out against Trump’s attacks on free trade, calling the announcements a ‘black day for the world’. He said:

“I am worried about this sentiment shift that people all around the world might suddenly say that free trade isn’t good for the world and that would be particularly bad for a trading company like BHP. We have to speak up loudly against these measures as being bad for America and bad for the world.”

Works Cited

Cheng, Evelyn. “Goldman: GM and Ford Could Take $1 Billion Hit Each from the Steel Tariffs.” CNBC, CNBC, 5 Mar. 2018, www.cnbc.com/2018/03/05/goldman-tariffs-to-knock-gm-terex.html.

Williams, Perry. “Trump Tariffs Are a Black Day for the World, Says BHP CEO.” Bloomberg.com, Bloomberg, 5 Mar. 2018, www.bloomberg.com/news/articles/2018-03-06/trump-tariffs-are-black-day-for-world-business-bhp-ceo-says.

The 3D printing industry is a special one. A 3D printer has several necessary components: heat beds, bed surfaces, the printing materials (resins or filaments), extruders, hobbed gear, and more. Depending on the kind of printing materials engineers use, different printers are necessary. These several technological parts that make up a 3D printer can be sourced from around the globe from several manufacturers.

Thus, it takes quite a lot of engineered parts to make up an SLA workshop. What is a SLA workshop, you might ask?

It is a 3D printing facility that utilizes the printing method known as stereolithography (SLA) - less commonly known as additive manufacturing. Companies are building 3D printing factories, turning the advent of newer, improved 3D printing into businesses.

A SLA workshop utilizes the kinds of 3D printers that convert liquid materials into solid parts by printing them layer by layer using lasers or light sources. Using light sources to turn liquid materials into solids is done through a process known as photopolymerization.

It is known to be the most accurate method of 3D printing.

YouTube channel ‘Strange Parts’ went to investigate how Chinese 3D printing company Lexcent prints its parts.

Lexcent uses resins provided by a company in Europe named DSM Resins & Functional Materials. They are the leading global supplier of high-quality resins for 3D printing and other liquid material based applications. The lasers at Lexcent are manufactured in Germany.

The company offers a printing service. All you do is place an order, and their facility works around the clock to print a design that is sent to them for a nominal price.

It is important for companies doing high-profile additive manufacturing to have high-quality resins and precise printers. If any cutting of corners occurs in the additive manufacturing industry, printed solids can come out with rough exteriors or have uneven edges.

Thus, Lexcent has to regulate temperatures within its facility to ensure the printers do not overheat - if the resins are exposed to temperatures of 104 Fahrenheit or over, the items will not print properly. The company also has to utilize different colored lighting so that no white light interferes with the SLA printing method which utilizes its own laser-focused light.

Nonetheless, once a print has been completed, parts are sent into a workshop for polishing. This ensures that any rough edges are eliminated. Then, the parts are shipped off to the paying customers.

Each SLA 3D printer at Lexcent’s headquarters costs around US$55,200 - the company has eight of them. They also have 13 CNC machines for heavier duty additive manufacturing; they make titanium alloys, aluminium alloys and harder plastics.

Fused Deposition Modeling

Another company making their bread and butter off 3D printing is Voodoo Manufacturing. They have introduced something called the ‘Large Format 3D Printing’ service. Customers who require large scale, industrial-sized prints can send it to Voodoo Manufacturing - their printer, considered the biggest in the world, prints a customer’s file. They have added 10 Raise3D N2 Plus Printers which uses a form of printing called Fused Deposition Modeling.

The Fused Deposition Modeling 3D printing method uses fused filament fabrication. Instead of solidifying liquids, a continuous filament is melted and pushed out of a nozzle. The filament eventually becomes the solid it was instructed to print.

In many universities there are now 3D printing facilities which allow students to become familiar with these printing technologies, they often print t their own CAD files. And the emergence of 3D printing businesses allow customers to have rapid prototyping and additive manufacturing work done at reasonable prices.

Works Cited

“Voodoo Manufacturing Introduces Large Format 3D Printing Service.” Advanced Manufacturing, 21 Feb. 2018, advancedmanufacturing.org/voodoo-manufacturing-introduces-large-format-3d-printing-service/.

There is a toy revolution occurring. A renewed, concerted effort is underway to make toys for children and young adults, to condition their minds in preparation for the world of STEM (Science, Technology, Engineering and Mathematics).

Schools are implementing STEM programs which involve classroom renovations that are stimulating, but fun. For some time now too many students have been losing interest in science and maths, even before they reach high school, making it very difficult for them to rediscover a love for these later on. This not only limits their employment prospects, but leaves them without the excitement that STEM disciplines promise throughout their lives.

Primary schools are making a concerted effort to mitigate this slide. Robotics and innovative problem solving technologies, designed to cognitively challenge students, are creeping into classrooms. To ensure that this occurs around the world (even in the most rural areas), the technologies and learning equipment employed need to be as affordable as possible.

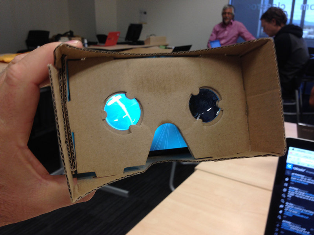

Nintendo has been showcasing what the future of STEM-inspired fun can encompass. Their new innovation utilizes one of the most cost-effective, most abundant materials known to man: cardboard.

Nintendo’s latest console, the Nintendo Switch, is a favorite amongst youths who are pressuring their parents to buy it. And it just got cooler. Nintendo has launched ‘Labo’; - it includes foldable cardboard sheets that interconnect with the gaming console.

The user folds the cardboard (DIY fashion) and connects it to the console controllers so that it can be used to play the games on the 6.2 inch screen.

Nintendo’s console has motion-sensing technology built in, making the cardboard interfacing even more fun. For instance users can fold together (in an almost origami fashion) a cardboard steering column and play a racing game on it.

The company has also introduced a robot suit, RC car, piano and fishing rod – all made out of cardboard and rubber bands.

Nintendo is hoping its new cardboard range will become tools that will spur kids to pursue STEM subjects later on in their academic lives.

Cardboard simulation technologies seem to be a marker for where the education and training industry is heading. Just a few years ago, companies were releasing cardboard virtual reality goggles with cheap lenses. It was a glimpse into the future of virtual reality. Since then, virtual and augmented reality headsets have taken off in a big way.

The only problem with Nintendo’s Labo? The price. Their Variety Kit costs US$69.99, and the Robot Kit costs US$79.99. Some parents will find this prohibitive. Nonetheless, if foldable cardboard toys that interface with technology become a focus for stimulating children in the fields of STEM, lower prices for similar technologies must follow.

Works Cited

Horaczek, Stan. “Nintendo's Labo Cardboard STEM Toys Are a Recycling Bin Full of Fun.” Popular Science, 2 Feb. 2018, www.popsci.com/nintendo-labo-stem-toy-impressions#page-3.

Are you interested in expanding your professional network globally and speaking to outstanding engineering students and graduates about your incredible engineering career?

By joining our Distinguished Industry Guest Speaker Program you will have the unique opportunity to share your technical insights and engineering experiences with our engineering bachelor and master students located at our East Perth campus. Your presentation can also be streamed to EIT’s 500,000+ followers around the world. It is an opportunity to raise your professional profile and keep your finger on the industry pulse nationally and internationally.

We are determined to expose our wonderful engineering students to engineering professionals such as yourselves so that they get a practical and useful engineering education.

Interacting with our enthusiastic students will give you and your company the chance to connect with the next generation of engineers and technicians and learn more about their practical projects and possible areas of collaboration.

An honorarium will be paid for your valuable contribution and you can also gain full access to our digital library of technical resources. We are particularly interested in professionals with industry experience in any of the following engineering areas: Industrial Automation, Electrical, Mechanical, Civil and Structural. To find out more, please contact Carolina Asenjo (

I have seen it; the future of engineering education and training. I have seen how it will equip engineering professionals globally and enable them to continue contributing to the turning of our world.

I have seen it; the future of engineering education and training. I have seen how it will equip engineering professionals globally and enable them to continue contributing to the turning of our world.

Acquiring professional development in engineering is changing; this process can be tracked by looking at the adaptations and growth of the Engineering Institute of Technology (EIT).

Over 25 years ago EIT was providing short classroom courses and onsite workshops. With the emergence of the internet the college began to keep an eager eye on the opportunities this would present to the world of engineering education.

Half a million students have since flown through our programs.

About ten years ago a live, online learning platform was devised for a range of accredited vocational qualifications. This enabling technology was one thing, but was never going to supersede a great teacher: the expertise of engineering professionals from around the world, with real industry experience, was the key. Their years in the trenches have been used for content development and for teaching. They also contribute to the creation of remote laboratories and simulation software.

The Internet-of-Things (IoT) has meant that our students can ably complete their practical learning via these remote labs; the reality is that most engineering tools are linked to the internet. I oversee the setting up of our virtual labs; they are connected to real engineering machinery that our students log into from across the globe.

Three years ago the college’s scope broadened with the accreditation of a range of Bachelor and Master Degrees, also delivered online. The reach of this learning platform has meant that EIT’s alumni hail from 146 countries.

One of the overarching benefits of connecting with students remotely, of removing a campus from the mix, is that they can attain their professional development and accumulated qualifications alongside full-time work.

I recently attended a schools’ career expo in South Africa and witnessed the hunger and passion of young students wanting to pursue engineering as a career. Despite the connectivity of young people we realised that school leavers do indeed benefit from face-to-face education, from engaging with their peers and lecturers on campus.

The institution’s latest achievement is the opening of a higher education campus in Perth, Western Australian. The traditional classroom has been blended with the ever-improving technologies surrounding online learning. This ensures that our international, engineering experts are still streaming into the classroom for the on-campus students.

It is an incredible privilege to be the Deputy Dean of Engineering at the college and I am certain that EIT will continue to explore innovative and meaningful education for engineers today and into the future.

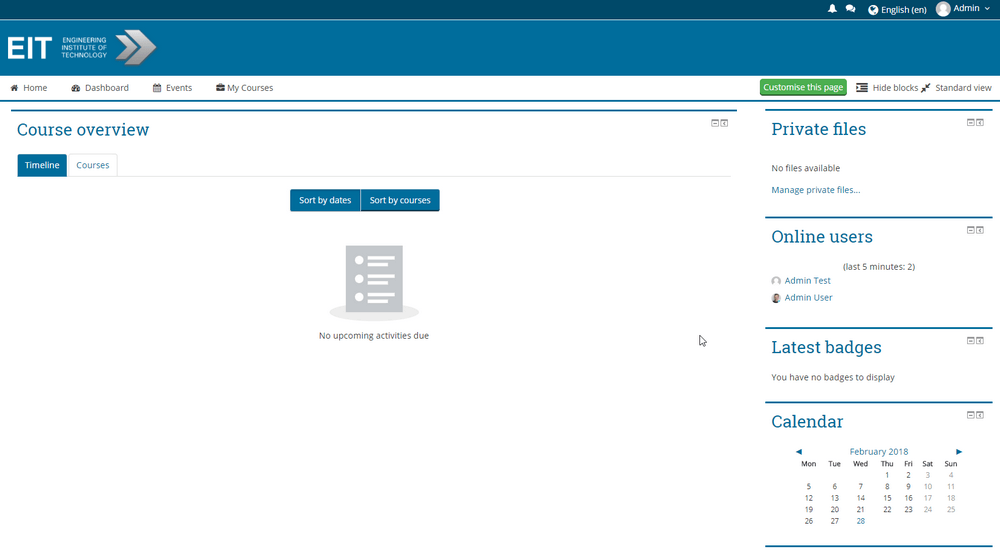

A Moodle Upgrade is Inbound...

The Engineering Institute of Technology has been in the works of implementing a new and improved Moodle LMS.

Here at EIT, we work diligently to ensure that we comply with the latest web standards available on the market. We’re dedicated to providing anonymity for all our students’ data, and ensuring that everyone has a comfortable experience when interacting with Moodle.

We are in the works of upgrading our current LMS, which will yield numerous benefits for all our students once implemented.

How Does this Impact Me?

As we endeavour to perform the upgrade, we’ll be forced to take Moodle offline for the weekend. This is a requirement of the upgrade, as the server will be under significant stress throughout this time. It also ensures that we mitigate any potential data corruption that could occur.

We highly recommend students download all the relevant materials they intended to use throughout the course of the weekend, as they won’t be accessible from Friday the 2nd of March at lunch time.

When we have completed the upgrade, we will then send an email out informing them of the status. We then urge all students to check that everything is in working order, as that will assist staff with cracking down on any potential errors or gaps.

2018 March Timeline:

- 2nd Friday: Moodle will go down at lunch time.

- 3rd Saturday - 4th Sunday: Upgrade in progress.

- 5th Monday Moodle will be live and useable again.

We’re undertaking this upgrade to enhance the experience of our students; therefore we thoroughly appreciate everyone's patience with this endeavour.

What is the Purpose of the Upgrade?

Theme

We have implemented an overhaul of the current platform, ensuring that our Moodle complies with the modern UI standards. The aesthetics of the platform attempt to focus the content relevant to you, highlighting any important updates or links that are presented by the LSO’s.

Functionally, the new look endeavours to reduce overall load speeds, and reacts well when accessing the platform on a mobile device.

Don’t panic though, as the primary navigation around the site platform has not changed all that much.

Security

We’ve noticed some minor security issues starting to appear on the platform; which has prompted us to move forward with the system. The new Moodle upgrade will facilitate the most up to date security features, ensuring that the data and course work of our students is protected.

Security of our students is our top priority at EIT. We will stop at nothing to ensure total anonymity of sensitive data, and protection against malicious attacks external to the platform.

The United Kingdom is between a rock and a hard place in the lead up to exiting the European Union. One of the concerns is that with a hard Brexit, EU students may not form part of the makeup of engineering professionals in the country’s future. Thus, more British-born students are being encouraged to pursue STEM (Science, Technology, Engineering, Mathematics) qualifications.

The Prime Minister of the UK, Theresa May, has used reverse-psychology to encourage more students to invest in STEM qualifications rather than in the humanities. The plan includes making arts studies cheaper than more STEM-focused qualifications. Essentially, she wants to devalue the arts.

The government will suggest that majoring in the arts may lead to ‘lower earning potential’ for students, whereas STEM degrees offer higher monthly salaried jobs. These suggested revisions are part of May’s current university ‘overhaul’ plan - a plan she is hoping may provide England’s students with improved education.

Nicky Morgan, a former education secretary, talking to the Evening Standard doesn’t believe devaluing BA degrees is a good one. She said:

“We want everybody to feel that all careers are open to them. If those who are struggling to afford university in the first place feel they cannot do a STEM degree because it is too expensive, ultimately it is the country that will suffer.”

Alongside this students in the United Kingdom are demanding that the government provides free education - a call that has been echoing in many universities around the world. Fees for courses in the UK can reach a maximum of £9,250 per year (US$ 12,866), with interest rates of 6.1% on any student loans. UK universities are among the most expensive in the world, next to the United States.

Putting arts into engineering

Qualification costs aside – there is an interesting push to embed the arts into engineering education. Among other benefits, such as improved communication skills, there is the belief that the arts may well enhance engineering designs.

Océane Boulais was the Hispanic Professional Engineering’s Extreme Engineer of the Year in 2014. Giving a TEDx Talk in 2015, she used Leonardo Da Vinci, Albert Einstein and Steve Jobs as examples of minds who expertly crafted artistic elements into engineering and scientific elements.

She is an advocate of putting the A in STEM: Science, Technology, Engineering, Arts, Mathematics.

She too highlights the fact that liberal arts qualifications get little funding compared to STEM qualifications. Yet, if STEAM-focused creators such as Da Vinci, Einstein, and Jobs created some of the most renowned products, then liberal arts should be more respected in STEM qualifications, Boulais argues.

Works Cited

“Integrating Art with STEM Education | Océane Boulais | TEDxBocaRaton.” YouTube, 5 May 2015, youtu.be/DjpWQkmopgY.

“Theresa May Warned Cheap Fees for Arts Courses 'Risk Driving Poor Students Away from Science and Tech'.” Evening Standard, 19 Feb. 2018, www.standard.co.uk/news/politics/theresa-may-warned-cheap-fees-for-arts-courses-risk-driving-poor-students-away-from-science-and-tech-a3770291.html.

One of the islands in the Japanese archipelago is Hokkaido. Sapporo, a city on the island, is burdened by snow; it costs 20.4 billion yen (US$190 million) on snow removal every winter.

Local government removes snow on state owned properties and streets, but private property owners are on their own. Alarmingly, it is not uncommon for a meter of snow to fall overnight in Sapporo.

From time to time the air force is required to perform rescue operations on houses that have been snowed in to the point of catastrophe. After all 1 cubic meter of snow weighs 500kg. This weight has resulted in many roof collapses in the suburbs of Sapporo.

A collection of technologies is both publicly and privately utilized to eradicate snow from the houses and streets of Sapporo and in Japan as a whole. Airport runways have to be cleared of snow and airplanes sprayed with anti-ice chemicals, for example. Impressively, Japan never cancels flights due to the cold.

Historically, Japanese cities have used warm groundwater and sprinkler systems to spray the roads and dissolve the ice. And back on the streets of Sapporo, snow plow trains are used to clear them of snow.

3,355 miles (5,400 km) of snow is cleared from Sapporo overnight. The work is done from midnight onward so that traffic is not impacted during the morning rush hours. Snow gutters have been added to the infrastructure of Japanese towns and cities, including Sapporo. These gutters dump snow into rivers.

The city has 47 weather stations that monitor temperatures and generate data on weather conditions. These help prepare the government snow removal teams. Data is checked hourly to get a real-time picture of weather patterns - sometimes lives depend on it.

After a heavy snowfall rotary snow removers flatten and transfer snow into dump trucks. Snow removal trucks are used to dump 20 million cubic meters of snow; this creates 10 to 20 meter high mountains at snow dump sites every winter.

For the safety of human beings, faced with iced up roads, there are gravel stations in Sapporo. 1,200 boxes filled with gravel bags are peppered across the city. The gravel is used to spread across the icy ground; it makes walking in the city less hazardous.

Further afield, near the city of Toyoma is Mount Tateyama, one of Japan’s holy mountains. The road leading up to the mountain is known as Snow Canyon. Extensive snow plowing is required to keep it clear for traffic; it creates mighty snow walls as seen in the picture.

The Japanese Society of Mechanical Engineers has indicated that an automated snow clearing robot is to be developed; it would work constantly to clean construction areas. This is technology that may indeed be used more widely eventually. Presently 3,000 people are employed though the night in Sapporo, to eradicate snow from the city. An automated roof snow-clearing robot has also been proposed, to assist the elderly who sometimes injure themselves trying to remove snow from their roofs.

Clearing snow in Japan is one of the most interesting engineering challenges in the world, and every year the Japanese improve the way they tackle it.

Works Cited

“Japanology.” YouTube, YouTube, www.youtube.com/channel/UCd4V3I7nYybm4nKwONcOSdA/videos.

Nobel, Justin. “How to Clear a Path Through 60 Feet of Snow, Japanese Style.” Atlas Obscura, Atlas Obscura, 10 Mar. 2017, www.atlasobscura.com/articles/snow-canyon-japan.

Victorien Erussard, an offshore racer and Merchant Navy officer has taken to the seas aboard the latest marvel of engineering. He has set aside six years of his life to travel around the world in a boat that will not generate any carbon.

50 engineers, designers and naval architects worked on the interdisciplinary, multifaceted ‘Energy Observer’ boat. The racing boat is powered by an assortment of renewable sources such as: a hydrogen fuel cell system, solar panels, and wind turbines.

The boat will visit 50 countries. 101 stopovers will be observed during the trip. It will be the first ‘hydrogen ship around the world’ the engineers behind the boat professed. At every stop, the team will investigate renewable energy projects and meet with leaders. So far they have met with Prince Albert of Monaco and the President of France Emmanuel Macron.

Documentary-maker Jerome Delafosse, is following the Energy Observer in its six year journey and keeping audiences entertained by releasing constant YouTube updates of its progress. In the intro video to their expedition, he said:

“The only way to combat global warming is to reduce greenhouse gas emissions. Today, we know that renewable energies and hydrogen is THE path forward. Energy Observer has taken up the challenge of becoming the symbol of energy transition to prove that a cleaner world is possible.”

The boat is 100 feet long and quite aesthetically pleasing. It is also a symbol of engineering change - a signal to other marine engineers that the times are a-changin’. The boat represents a hope that one day marine vessels may be powered only by renewable sources. The boat cost $5.25 million - and it’s easy to see why; there are 1,400 square feet of solar panels fitted on the surface of the boat.

Launched from Paris in May 2017, the boat is nearing its first full year at sea. The technology on board propelling the boat forward was developed by French research center CEA-LITEN. When the sun is shining and the wind is blowing it uses the solar panels and wind turbines. When the moon is in the night sky, it utilizes its hydrogen tanks to propel it.

The hydrogen fuel it uses is “three times” more efficient than regular fuel. The fuel is created through sea water electrolysis. Delafosse believes the technology powering the boat can be used in many more applications. He said:

“We can use this technology in hotels, houses, in cars...the idea is to be less dependent on the network. It shows how fast things can happen: as it did in London at the turn of the last century when moving from horses to cars, it will happen with renewable energy.”

Works Cited

Energy Observer, www.energy-observer.org/en/.

Dockrill, Peter. “This Self-Fuelling Boat Just Set Off on an Epic 6-Year Global Voyage.” ScienceAlert, www.sciencealert.com/this-self-fuelling-boat-just-embarked-on-an-epic-6-year-global-voyage.

More engineering industry jobs are coming to South Africa. That is, if the country’s brand new president, Cyril Ramaphosa, is to be believed. Much like in the United States, the new sitting president is promising the renewed strengthening of manufacturing and mining jobs - whilst promising that the Fourth Industrial Revolution will be a focus as well.

President Cyril Ramaphosa has given his State of the Nation Address a day after being sworn in as president. This, after the country’s previous president, Jacob Zuma, resigned from his position. Zuma’s presidency had produced a legacy of corruption that had sent the country’s economy into freefall.

Ramaphosa was the founder of the Union of Mineworkers in South Africa. He is also a successful businessman, and was a key negotiator for the African National Congress, credited for being one of those who helped facilitate the end of Apartheid. He was Nelson Mandela’s choice for the future president of South Africa.

Now his time has come. Plaguing the country is a high unemployment rate. Nonetheless, Ramaphosa is promising a revival of South Africa. He has said a new dawn is here for the country. In his State of the Nation address, he spoke of the mechanisms that might make South Africa great again:

“We are going to address the decline over many years of our manufacturing capacity, which has deeply affected employment and exports. We will seek to re-industrialise on a scale and at a pace that draws millions of job seekers into the economy. We are going to promote greater investment in key manufacturing sectors through the strategic use of incentives and other measures.”

Mining is one of the largest and more archaic industries in South Africa. A gold rush in the late 1800s began turning South Africa into a resources haven. The rest is, as they say, history. However, mining has struggled in the last few years. Ramaphosa said:

“Mining is another area that has massive unrealised potential for growth and job creation. We need to see mining as a sunrise industry.”

With a soon-to-be revitalized economy, the best thing school leavers and wannabe students can do is find education and training that will prepare them for this new South Africa.

The level of technological expansion in the country may, however, impede growth in the economy and education. South African institutions are struggling to produce highly qualified, globally relevant engineering professionals, for example. Ramaphosa is proposing change here too. He said:

“We will soon establish a Digital Industrial Revolution Commission, which will include the private sector and civil society, to ensure that our country is in a position to seize the opportunities and manage the challenges of rapid advances in information and communication technology. The drive towards the digital industrial revolution will be underpinned by the availability of efficient networks.”

Works Cited

Eyewitness News. “[MUST READ] President Ramaphosa's State of the Nation Address.” Eyewitness News, 17 Feb. 2018, ewn.co.za/2018/02/16/must-read-president-ramaphosa-s-state-of-the-nation-address.

Students and professors in research and development teams in the United States are setting the standard for nature-inspired engineering designs. Using nature as an influence for design, and using engineering design to better understand nature, may produce fruitful outcomes for engineering and nature alike.

A mechanical engineering team at the University of Illinois is using butterflies and snake scales as a blueprint for creating a new surface that will be used for ‘fluid and light manipulation’.

The team says the surface could service the scientific and engineering communities. In their paper, entitled ‘Magnetically Responsive Elastomer-Silicon Hybrid Surfaces for Fluid Light Manipulation’, they write:

“Stimuli-responsive surfaces with tunable fluidic and optical properties utilizing switchable surface topography are of significant interest for both scientific and engineering research.”

The engineers say that with their surface as a base, materials can be laid atop it. They are nanostructures that copy, to some extent, the subtlety of butterfly and snake scales. The engineers designed what are called ‘ferromagnetic micropillars’ above a flexible bottom later.

Thereby, the surface can be used for a plethora of applications including: ‘tunable wetting, droplet manipulation, tunable optical transmissions, and structural correlation’.

It all sounds very complex, but with tunable optical transmissions, virtual blinds could be designed, for example. Imagine booking into a hotel room and darkening the room without physically having to pull down the blinds. The window itself would be fitted with the light manipulating technology utilizing the scale-like nanostructured surface.

Other applications include biomedical engineering applications, implantation into photovoltaic arrays and more. Seok Kim, the assistant professor of mechanical engineering, said that he wanted to ‘emulate’ designs found in nature.

Helping nature out

At the University of Colorado Boulder an aerospace engineering team has put their energy into figuring out how to study animals more closely. Their senior design project saw them designing technology for the preservation of nature.

They have designed a drone that can get the closest to sperm whales than any other apparatus before.

Previously, marine biologists have reportedly been limited to binoculars and hydrophones. What the biologists want to do is voyeuristically listen in on sperm whale communications to decipher the ‘language’ sperm whales are using. The project’s name is - whimsically - SHAMU (Search and Help Aquatic Mammals UAS), which was also the name of a killer whale that was held at SeaWorld in San Diego in the United States.

The team is hoping the unmanned aerial vehicle will contribute to lessening the number of sperm whale deaths per year. The university’s online publication asserts that pollution and ‘collisions with ships’ lead to 1,000 sperm whale deaths annually. With more data generated, the engineers are hoping it could give marine biologists something to work with.

Lauren McIntire, the head of safety on the project said:

“One of the main reasons most of us joined the project is the desire to use engineering to better the world. In aerospace there’s a focus on defense or commercial projects, but SHAMU is about conversation and helping all life on earth.”

Works Cited

“Pushing Boundaries: To Save the Whales, Engineering Students Take to the Skies.” CU Boulder Today, 14 Feb. 2018, www.colorado.edu/today/2018/02/14/pushing-boundaries-save-whales-engineering-students-take-skies.

Yang, Zining, et al. “Magnetically Responsive Elastomer–Silicon Hybrid Surfaces for Fluid and Light Manipulation.” Small, 24 Nov. 2017, onlinelibrary.wiley.com/doi/10.1002/smll.201702839/full.

“Help me Obi Wan Kenobi, you’re my only hope”. - Princess Leia

In 1977, science fiction fans were treated to the very first Star Wars film. Years later, the series has branched off into comics, novels, more films, animation shows, and more. But back in ‘77 when Princess Leia spoke her very first words in the series, R2-D2, the robot relaying Leia’s three-dimensional recorded message, showed the world what the future of holograms could be.

A team of engineers at Brigham Young University, in Utah in the United States, have been working to make science fiction, science fact. Using the scene from Star Wars as an influence, the team started their ‘Princess Leia project’.

Using a phenomenon known as photopheresis, the engineers have manipulated unseen airborne particles with lasers to produce images in midair. The team has said the 3-D images are even more realistic than holograms.

They released a video to demonstrate their findings, and to give a sneak peak into the future of volumetric displays:

Historically holograms have been produced by using rotating or specially positioned glass displays with images projected onto them. Other methods have included using fog, mist, or dust on which to project 2D images - Disney has used these kinds of projection methods at their theme parks. But the Birgham University scholars have figured out a way to project 3D images onto thin air, making it significantly different to previous holography attempts.

Daniel Smalley, lead author of the photopheresis research, and an electrical and computer engineering professor, said that the new technique is tantamount to “printing something in space,” and then, “erasing it quickly.” The unseen specks are focused together by laser technology guided by mirrors.

The authors are ditching the ‘hologram’ name, due to its departure from holographic ideology and instead calling their invention the Optical Trap Display. They essentially trap particles and create a volumetric image in three-dimensional space.

100 years of research into these methods have been categorized as ‘volumetric display’ research. They have published their research in the Nature journal. The researchers fully intend getting this technology to market. In the report, they write:

“The reported prototypes use commercial hardware and have low cost relative to other free-space volumetric displays. We anticipate that the device can readily be scaled using parallelism and consider this platform to be a viable method for creating 3D images that share the same space as the user, as physical objects would.”

This means that the world is also closer to telepresence: much like the scene from Star Wars with Princess Leia, and a plethora of other science fiction novels and movies. We could soon see engineers perfect a ‘holographic’ Skype call – a bit like being in two places at one time. A Star Wars future might, therefore, not be far off.

Works Cited

Matt WarrenJan. 24, 2018 , 1:00 PM, et al. “'Princess Leia' Holograms One Step Closer to Reality.” Science | AAAS, 24 Jan. 2018, www.sciencemag.org/news/2018/01/princess-leia-holograms-one-step-closer-reality.

Smalley, D. E., et al. “A Photophoretic-Trap Volumetric Display.” Nature News, Nature Publishing Group, 24 Jan. 2018, www.nature.com/articles/nature25176.

The world is still looking for the most effective way of educating and training people. Privately owned universities and institutions are keeping their eyes on initiatives in the business sector.

Universities are looking towards the most efficiently built organizations of the last decade, noticing how they have construed to scale up. With the arrival of the internet and lower cost technologies, institutions have had to formulate new strategies. They have created online platforms for their students, saved money by reducing their dependency on infrastructure and extended their reach to students who are based around the world.

Tim Dodd, the Higher Education Editor for the Australian newspaper, says universities are following the Uber-model when it comes to transformation. He writes:

“Does this business model remind you of anything? To me it smacks of Uber or Airbnb, companies with no physical assets but enticing enough to consumers to dominate their sectors. So here’s the question. Are we entering the age of the Uber-university?”

Even investment companies are conceding that Uber, as a case study, has made them rethink how they provide their services to customers. Uber’s business model has led them to be the most profitable taxi service in the world. (They originally did not own the cars, but now have engineers designing automated vehicles that are self-driving.)

Many universities and institutions are hoping to follow suit; they are realigning their businesses to resemble a zero-cost operation like Uber without the cost of cars.

Business...what is it good for?