Developments

- Details

- Written by: Quintus Potgieter

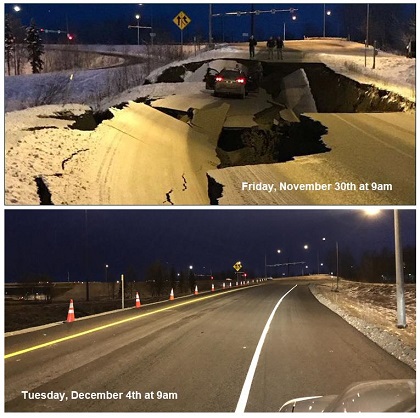

In the field of civil and structural engineering, urban stormwater management is a complex and challenging issue. As cities continue to grow, so does the number of impermeable surfaces — those that do not allow water to infiltrate the ground. From concrete sidewalks to parking lots, excess stormwater runoff from these structures can have serious adverse side effects on the surrounding ecosystem.

In more regional areas, rain can soak into the ground to be absorbed and released by plants. By contrast, when rain hits water-resistant surfaces in urban areas, it causes runoff, and water begins to collect sediment, bacteria, oils, metals, and other known pollutants. It has long been a civil engineers' tradition to direct stormwater into nearby systems to be treated at wastewater facilities or discharged directly into waterways.

However, as cities expand, significant precipitation events are having a higher chance of overwhelming stormwater systems. Scientists are warning that the effects of global warming may cause more rain to fall in one storm than an entire year prior. This means that countries with aging or poorly designed infrastructure are falling behind in their ability to manage runoff.

For example, Mumbai, India, has experienced its wettest monsoon season in more than 61 years. Torrential rains halted city life as many establishments, transport links and homes were submerged in waters waist deep. The coronavirus crisis impacted drain cleaning throughout the city, worsening the effects of devastating floods across the city.

An important legal consideration for most construction projects is to ensure that the final build won’t worsen downstream flooding for a particular area. On the stormwater front of a project, the engineers need to look out for that when runoff does occur, the interventions help:

- Reduce erosion

- Minimize pollution

- Prevent flooding

More water diverting infrastructure is necessary to achieve less flooding and mitigate the amount of water overwhelming a drainage system. One method of stormwater management would be to increase water infiltration through the inclusion of permeable surfaces. This approach would allow stormwater to still reach soil while reducing runoff from urban infrastructure.

Topmix Permeable is a fast draining concrete pavement solution that rapidly directs stormwater off streets, parking surfaces, driveways and walkways. This efficient approach to stormwater management would help reduce environment impacts, costs and maintenance efforts. Topmix Permeable’s video of their innovative pavement recently went viral online.

Topmix Permeable’s video, while impressive, saw them receiving critique. The concern among some of the online civil engineering community was that sediment buildup would occur rapidly if stormwater and other elements filtered in below the road surface at such speed. They caution that pavement as permeable as Topmix Permeable would require a lot of maintenance, and expert level drainage - making it tough to implement in roadways.

Nonetheless, all permeable pavements should have stone reservoirs below the surface. The stone reservoir is another fine art the engineer must perfect to create effective permeable pavements. The stone reservoir is generally made of uniformly sized stones that create enough gaps underneath the porous surface. It then temporarily stores water when precipitation is occurring and then slowly moves it off. Nevertheless, Topmix Permeable does look like an intriguing development in pavement that could lessen the chance of flash flooding for cities.

The company says their permeable pavement can provide relief to aging stormwater infrastructure inside the cities. Permeable pavement is still considered a new and developing avenue of the civil engineering world. It is to see much more attention as stormwater drainage continues to make headlines due to added precipitation. If some form of it is to be implemented on roadways in the future, it would require careful design features and construction techniques.

Civil engineers will be keeping an eye on the development of permeable pavement. It may appear at their next project build. Several configurations of how to implement permeable pavement are becoming known as engineers try an assortment of different styles. If these kinds of porous pavements can limit the number of floods worldwide, more and more civil engineers will be looking to lay them at their next project.

Prepare for the future of road construction with EIT’s Professional Certificate of Competency in Fundamentals of Road Construction.

Works Cited

Matchar, Emily. “This Concrete Can Absorb a Flood.” Smithsonian.com, Smithsonian Institution, 5 Oct. 2015, www.smithsonianmag.com/innovation/concrete-can-absorb-flood-180956830/.

“Mumbai Records Decade's Highest 24-Hour October Rain, 2nd Highest Monthly Rain in 10 Years.” Hindustan Times, 15 Oct. 2020, www.hindustantimes.com/mumbai-news/mumbai-records-decade-s-highest-24-hour-october-rain-2nd-highest-monthly-rain-in-10-years/story-5DGtX98zNszUW9jkdXMEWK.html.

- Details

- Written by: Quintus Potgieter

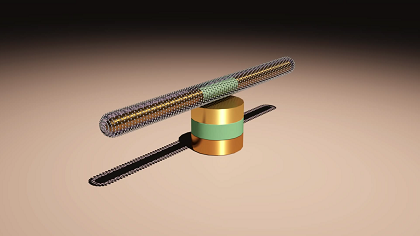

The industrial facility or smart-factory of the future is, in fact, here today. Automated processes ensure efficiency, and round-the-clock monitoring promises ongoing operations. However, not a lot of consideration is given to the crucial sensors in an industrial set up that makes this possible. Industrial sensors are the smaller but omnipresent element within those industrial facilities and factories, monitoring the entire ecosystem of an industrial operation and making sure those processes continue without a hitch. As sensor networks are brought online and form part of the Internet of Things (IoT) future, keeping them online is imperative. Industrial sensors typically run off of lithium-ion batteries and inevitably need replacing. A new startup is innovating in the space and taking the battery out of the equation altogether.

Smart factories and other industrial operations face replacement costs since sensor batteries eventually deplete. Some sensor batteries can last for up to a year before they need to be replaced.

However, a startup named Everactive says they have the answer to eliminating battery requirements that modern-day IoT sensors have. They are launching a self-powering sensor without a battery that can last up to 20 years.

How does the sensor work?

The sensors have come a long way since their inception. The initial concepts were bouncing around inside the minds of the two future co-founders of Everactive who were attending the Massachusetts Institute of Technology. David Wentzloff and Benton Calhoun focused their academic careers on low-power technologies. The former on low-power digital circuits and memory, while the latter focused on low power radios. Their combined skills have given birth to their new sensor — the Eversensor.

“It’s all enabled by the ultra-low-power chips that support continuous monitoring. Because our source of power is unlimited, we’re not making trade-offs like keeping radios off or doing something else [limiting] to save battery life,” Everactive Co-Chief Technology Officer David Wentzloff said.

Everactive says the ultra-low-power integrated circuits harvest energy from indoor light and vibrations. There is also an outdoor self-powered sensor available that can utilize small collar cells to power the sensors. The Eversensors can be fixed to key infrastructure in industrial operations and can sense when those machines stop functioning. The sensors do this by measuring temperature, acceleration, vibration, pressure, and more.

Everactive says the sensor meets all of the sensing, processing, and wireless capabilities that any battery-powered sensor does. Process optimization and reduced maintenance cost of both the sensors and industrial machinery are just some of the benefits of sensors working around the clock.

“Removing the need for batteries solves one of the key limitations of the IoT and represents a fundamental paradigm shift, allowing our customers to deploy wireless sensors at scale and gain access to new, high-value data-driven insights,” Bob Nunn, the CEO of Everactive, said.

The company is boasting the world’s lowest power radios and are deploying them for some of the biggest industrial companies in the world. With batteryless technologies generating much interest in the world of industrial engineering, more battery-intensive technologies could see new opportunities in a plethora of industries.

Works Cited

“Industrial IoT - Batteryless Sensors Data Analytics.” Everactive, 31 July 2020, everactive.com/.

Zach Winn | MIT News Office. “The Factory of the Future, Batteries Not Included.” MIT News, 20 Aug. 2020, news.mit.edu/2020/everactive-sensors-0820.

- Details

- Written by: Quintus Potgieter

An electricity startup company in New Zealand says they are working toward a launch of a world-first wireless energy transmission system they assert will be opening up the world's access to power. They reportedly will be using tele-energy technology to enable long-range wireless energy transmission that is safe, reliable, and cost-effective. Echoing the work of inventor Nikola Tesla, the company hopes to democratize access to electricity. If the company succeeds in rolling out the technology, it could usher in a new era of electrical engineering.

Nikola Tesla, who famously engineered the alternating current system toward the end of his life, was attempting to engineer a system where electricity could be transmitted to single antennas in consumers' homes. In turn, he hoped the wireless energy would power entire households and give everyone in the world access to electricity — the attempts at figuring out the technology led to the creation of the Tesla coil. Tesla, in the 1890s, managed to light a bulb across a distance of two miles using a Tesla coil.

Since then, wireless electrical transmission has been an elusive technology that no single company has been able to implement at a level that consumers could benefit from. However, a government-backed startup in New Zealand seems to have picked up where Tesla's work left off. Emrod, the startup in question, says they have developed a safe method for wirelessly transmitting electric power across long distances.

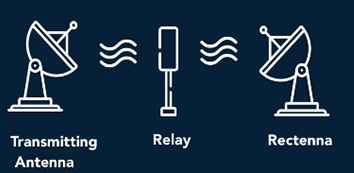

The technology utilizes electromagnetic waves to transmit energy wirelessly over vast distances. New Zealand's second-largest electricity distribution company, Powerco, will be first in line to test the new Emrod technology.

Tech entrepreneur Greg Kushnir spearheaded the technology. Surprised by how little development of wireless electricity technology was being worked on in the industry, he set out to recruit scientists and engineers from a company named Callaghan Innovation.

"We have an abundance of clean hydro, solar, and wind energy available around the world but there are costly challenges that come with delivering that energy using traditional methods, for example, offshore wind farms or the Cook Strait here in New Zealand requiring underwater cables which are expensive to install and maintain," said Kushnir.

"I wanted to come up with a solution to move all that clean energy around from where it's abundant to where it's needed in a cost-effective, eco-friendly way. Energy generation and storage methods have progressed tremendously over the last century, but energy transmission has remained virtually unchanged since Edison, Siemens, and Westinghouse first introduced electric networks based on copper wires 150 years ago."

How it all works

The company has patents pending for its technology, so the more proprietary technology the company is using is mostly under wraps for the time being. However, they do say they are working in frequency ranges in the ISM (Industrial, Scientific, and Medical) band - which are typically used in WiFi, Bluetooth, and RFID.

The prototype point-to-point transmission system Emrod engineered, along with Callaghan Innovation, impressed Kiwi government funders. To further demystify the tech the startup is working on, Kushnir spoke to New Atlas.

"Transferring energy with microwaves has been around for decades. In the 70s, NASA showed it could support a helicopter drone in the air, charging it with microwaves from the ground. It's been around for a while. What's changed in the last few years is mostly metamaterials technology. New materials that allowed us to convert the energy back into electricity very, very efficiently. That was what made it viable for commercial use. Before that, it's been around, but mostly used for military purposes," he said.

IT is the proprietary beam shaping, metamaterials, and rectenna technology that Emrod is keeping under wraps for now.

Kushnir goes on to say, "Electromagnetic metamaterials can absorb electromagnetic radiation and turn it into heat, or electricity, or make it go away. It's essentially stealth technology, that's what it's been used for in the military."

The startup assures critics that their system will produce no waves, no radiation, and no environmental impact. They have been testing their tech, sending 'a few watts' between two points spaced 130 feet from each other. The startup ultimately has faith that they are on the right track:

"The statistics are pretty compelling. We are talking about a potential 50 percent increase in sustainable energy uptake, up to 85 percent reduction in outages and up to 65 percent reduction in electricity infrastructure costs due to the Emrod solution," Kushnir concluded.

The startup wants people to imagine the possibilities when power can be accessed anywhere. The startup hopes this technology can finally power rural communities who don't have much access to electricity. If they get wireless electricity for consumers right, the startup might be hailed as one of those that managed to achieve what Nikola Tesla dreamt of over a hundred years ago.

Works Cited

"Press Release: NZ Start-up Launches World-First Long Range Wireless Power Transmission." Emrod Energy, 2 Aug. 2020, emrod.energy/press-release-nz-start-up-launches-world-first-long-range-wireless-power-transmission/.

silvae/Depositphotos, and Emrod. "New Zealand's Wireless Power Transmission: Your Questions Answered." New Atlas, 4 Aug. 2020, newatlas.com/energy/wireless-power-transmission-emrod-interview/.

- Details

- Written by: Quintus Potgieter

How do engineers move something as heavy as decommissioned offshore oil rigs? How about moving two at the same time? Oil and gas rigs can weigh up to 50,000 tons, far outweighing what tugboats are capable of moving. Transporting monumental cargo out at sea is complex work that requires complex vessels to do the heavy-lifting. The engineering solution lies in semi-submersible ships. A marvel of engineering, semi-submersible ships go about solving the conundrum of heavy cargo transportation amid battling the elements and the unpredictability of the ocean. Engineers can appreciate the incredible engineering that goes into these vital players in the marine engineering world.

A company formed in 2014 named GPO specializes in Semi-Submersible Heavy Lift Vessels. The vessels have been described as part-cargo ship and part-submarine. One of the four submersibles they have engineered is named the Amethyst. These kind of ships help with the transportation of:

- Jack-up drilling rigs

- Semi-submersible drilling rigs

- Dredging equipment

- Cranes

- Barges

- Other floating cargo

- Offshore & onshore modules

How a semi-submersible works

The Amethyst, and its twenty-six-man crew, when dispatched to load heavy cargo, have to first consult the meteorologists to determine if the weather will be conducive to heavy cargo lift. Once the crew is happy, they embark on their journey, battling winds out at sea on their way to pick up their target.

Once the ship reaches its destination, the semi-submersible performs the operation that gives it its name. The vessel is partially sunk into the ocean.

The Amethyst is one of the biggest of its kind in the world. The entire ship’s hull, at multiple levels, is lined with ballast tanks. The hull is split into 76 ballast tanks, distributed in three layers within the ship. These tanks take sea water in and weigh the ship down, submerging it in the water. 160,000 cubic yards (49 Olympic swimming pools) of water is pumped into the hull, in a very precisely engineered way to prevent the capsizing of the ship. At this point, the ship is at serious risk of sinking. Two towers at the stern of the ship, with empty ballast tanks, help keep the vessel afloat. Each tower holds ballast tanks that weigh 3,370 tons. Equally as important is the bow section that keeps the ship horizontal and not tipping.

Heavy lifting, heavy power

Loading the cargo onto the deck is the next part in the operation. The key to submersibles is the flatness of the deck that takes on the incredible weight of its cargo. The Amethyst's deck is six hundred feet long and one hundred eighty feet wide. The thickness of the steel, whilst some might think needs to be majorly thick to support immense weight, is actually the opposite. They are in fact super-strong, ultra-flat decks. The first deck is, in fact, only one inch thick. Underneath the first deck, however, lies a second deck with steel in the shape of I-beams. The force of the cargo the ship is lifting pushes down on the thinner top deck, with the second latticed I-beam deck absorbing the rest of the weight.

The cargo load needs to be balanced perfectly to ensure that the deck does not cripple underneath the immense weight of whatever is being transported. For something as big as an oil rig, three tugboats need to pull and position the rig over the sunken submersible ship. To lift the semi-submersible ship back up out of the water, with the cargo carefully balanced, the ship has to eject the water from its flooded ballast tanks back into the ocean. Pumps with high-speed impeller blades use centrifugal force to eject the water from the ballast tanks.The pumps can fully empty in 7 hours. Before that, however, engineers have to ensure the final position of the cargo they are transporting, and have to be millimeter accurate, otherwise the semi-submersible will be damaged. Once the semi-submersible is up out of the water, the ship can journey onwards.

The Amethyst has an incredibly powerful propulsion system. Diesel is the fuel source of choice. Each engine weighs 132 tonnes. Each of the four Diesel engines push out an impressive 9,600 horsepower. The ship can do one full round-world trip with full tanks.

The engines untypically reside under the bridge and in the bow - the only place where they could go in a vessel that partially sinks. The engines’ power feeds into electric generators that push electricity through cables to electric motors at the back of the ship and, in turn, powers the propellers. The 18-feet tall propellers are specifically designed to efficiently cut through water. The high-tech propellers can also reverse course immediately to bring the mammoth ship to a halt in only 500 yards of stopping distance.

Moving extremely heavy cargo out at sea was once an engineering challenge. The arrival of the semi-submersible to maneuver below heavy floating cargo and move it, was an engineering solution. The GPO Amethyst as seen above is capable of moving two decommissioned oil rigs each weighing north of 13,000 tons. What was once impossible, has now become possible, thanks to engineering. Encouragingly, instead of leaving decommissioned oil rigs out at sea, an engineering solution can ensure they are returned onshore and be disposed of in the right ways.

Works Cited

“Fleet.” GPO Heavylift, www.gpo-heavylift.com/fleet/.

“Watch Superstructures Engineering Marvels Season 1 Episode 2 on Disney Hotstar VIP.” Disney Hotstar, www.hotstar.com/in/tv/superstructures-engineering-marvels/s-2203/ultimate-cargo-ship/1000237821.,

- Details

- Written by: Quintus Potgieter

Australia is well-known for its beautiful beaches, with over one million tourists making their way to the beach each year. From national surf competitions to school swimming lessons, Australian beach culture is a huge part of the country’s national identity.

However, there is one significant challenge that comes with enjoying over 20,000 kilometers of coastline, and that is patrolling it. Due to not only its size but also the sheer amount of potential dangers lurking beneath the waters surface, keeping Australia’s majestic coastlines safe is a logistical nightmare.

But a world-first in drone technology may be the potential solution.

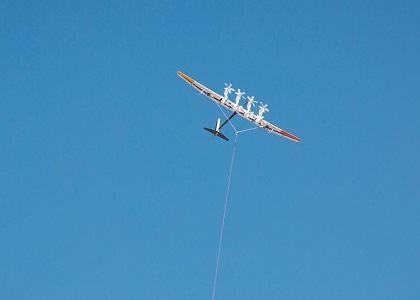

Founded in 2015, Australian company ‘The Ripper Group’ develops search and rescue drones that can monitor beaches and deploy emergency care packages to people in need. With features including being able to alert lifeguards to people who need saving to being able to spot incoming predators, their drones are already being used across the country to help keep Australian beaches safe.

Sponsored by Westpac, the ‘The Little Ripper Lifesaver’ project represents the future in shoreline safety, being able to identity and respond to incidents beyond the human eye. In January of 2018, the lifesaving drone rescued two teenage boys off the coast of Lennox Head in New South Wales. Controlled by lifesavers onshore, the drone was able to be sent to the boys with an inflatable rescue pod attached.

John Barilaro, the state's deputy premier, praised the rescue as historic. "Never before has a drone fitted with a flotation device been used to rescue swimmers like this," he said.

However, The Little Ripper Lifesaver doesn’t only save struggling swimmers. The groundbreaking drones are now equipped with an Artificial Intelligence based system that can detect a variety of marine threats such as sharks and crocodiles. With a proven accuracy of 90%, the drones can identify possible threats and relay this information to emergency services, beach lifeguards and endangered swimmers.

“This is a great example of how an AI application can help humans, as it has significantly higher rates of visual accuracy in shark detection than people. The drone will certainly help us to improve detection rates and to maintain safer conditions for those in the water,” says Dr Nabin Sharma from the UTS Centre for Artificial Intelligence.

Anyone who wishes to fly a surf lifesaving drone is simply required to do a two-day course, making it easy for surf lifesavers across the country to get involved in the program. This lifesaving combination of AI technology and mechanical engineering is a leading example of how technology can unlock opportunities in supposedly unrelated fields, enhancing the human experience as well as unlocking new job opportunities.

Currently, the drones are also being used in partnership with Chinese UAV giant DJI to help combat COVID-19. The drones can assist in two key areas, being aerial spray disinfection and crowd control.

“Through environmentally friendly active disinfectant agents we can neutralize the Coronavirus in public places on surfaces in places like playgrounds, malls, public gyms, public transport areas, sporting arenas, schools, universities, hospitals, child-care centers, aged-care facilities, shopping centers, supermarkets, factories and warehouses,” said CEO of The Ripper Group, Ben Trollope.

Mr. Trollope also explained how the drone could help authorities in dispersing crowds to further enforce social distancing conditions.

“Using drones protects the lifeguards and police by allowing safe social distancing and does the job quickly and efficiently. This will protect first responders and front-line personnel,” he said.

Works Cited

Ballantyne, Kreisha. “Drones Watch over Beaches.” Flight Safety Australia, 10 Feb. 2020, www.flightsafetyaustralia.com/2020/02/drones-watch-over-beaches/.

Spires, Josh, et al. “Drones to Fly above Australia's Beaches This Summer.” DroneDJ, 7 Feb. 2020, dronedj.com/2020/02/07/drones-fly-above-australia-beaches-summer/.

- Details

- Written by: Quintus Potgieter

The threat of the coronavirus pandemic has sent most of the world into lockdown. As a result, many of us are relying on the Internet to stay connected. As schools and workplaces continue to encourage working from home, an increasing amount of sensitive and personal data is making its way online, meaning now is the time to make sure both you and your computer are keeping safe.

Due to the high Internet usage across the globe, Internet hackers are increasingly able to exploit networks during this time of crisis. Ranging from spreading false information online to sending fake pandemic warnings directly to your inbox, scammers and hackers are embracing a whole new toolbox of possibilities.

Multinational cybersecurity and anti-virus provider Kaspersky, recently reported that on 12 March 2020, Australia saw 248,864 network attacks or data breaches. This is an increase of 284% when compared to just four days earlier on 8 March, where 64,690 attacks were reported.

With digital communications now more important than ever for the continuation of company operations across the globe, hackers are ready to see what network breaches they can exact on the unsuspecting digital public.

Key websites that inform the public have already become a focus. Worldometers.info — which many people use for updates on coronavirus statistics — was hit with what the owners of the site called a ‘malicious act.’

The US Department of Health and Human Services website was also a target of a denial of service attack. Thus, information the public depended on was momentarily disrupted. Social engineering cyber-attacks are occurring too. Email malware was recently being sent around disguised as important information on COVID-19 from official health agencies. Unsuspecting people opened what they thought was useful information regarding the coronavirus pandemic and instead had their personal data stolen.

Hackers are on the lookout to see how they can profit off of a crisis and swindle companies and people out of their data. And it is clear to see that they will try every avenue — no matter how big or how small — to try and garner some profits out of this crisis and sow societal discord.

How to fight back and how to help

The World Economic Forum has a good 3-step system to ensure you stay safe online during this time. Algirde Pipikaite, a Project Lead in Governance and Policy at the WEF, and Nicholas Davis, a Visiting Professor in Cybersecurity at the UCL Department of Science, Technology, Engineering and Public Policy write:

1. Step up your cyber hygiene standards: Check that you have a long, complex router password for your home wifi and that system firewalls are active on your router. Ensure you’re not reusing passwords across the web (a password manager is a great investment) and use a reliable VPN for internet access wherever possible.

2. Be extra vigilant on verification: Be far more careful than usual when installing software and giving out personal information. Don’t click on links from email. When signing up to new services, verify the source of every URL and ensure the programmes or apps you install are the original versions from a trusted source. Digital viruses spread much like physical ones; your potential mistakes online could very well contaminate others in your organization, an address book or the wider community.

Organizations are encouraging their workers to activate two-factor authentication on their work systems that they are logging into from home. This forces a user to put their password in, and give a second layer of authentication before being let in to their employers’ system. This gives a company peace of mind, knowing that no bad actors are logging into their systems and stealing any data - especially while many are working from home.

3. Just as you pay attention to trusted sources of data on the spread and impact of COVID-19, be sure to update your system software and applications regularly to patch any weaknesses that may be exploited. If at any stage you feel that the advice you’re being given sounds bizarre - whether the virus threat is offline or digital - search the Internet to see whether others have similar concerns and look for a well-known site that can help verify the legitimacy of the information.

Seemingly, the world’s preparedness for real viruses and digital viruses is being tested during this coronavirus pandemic. The lessons learned during this time will put the world of engineering in good stead in the future. The protection of key resources and infrastructure underpinned by developed cybersecurity strategy will now forever be of vital importance.

Works Cited

“Live Coronavirus Updates: US and Global News on COVID-19.” NBCNews.com, NBCUniversal News Group, 26 March. 2020, www.nbcnews.com/health/health-news/live-blog/coronavirus-updates-senate-white-house-reach-deal-2-trillion-stimulus-n1169196/ncrd1169696#liveBlogHeader.

Pipikaite, Algirde, et al. “Coronavirus Pandemic: Why Cybersecurity Matters.” World Economic Forum, www.weforum.org/agenda/2020/03/coronavirus-pandemic-cybersecurity/.

- Details

- Written by: Quintus Potgieter

Transformative technologies demand flexibility in the modern era. Consumers demand that technologies be smaller, thinner, wearable, fireproof, bendable, etcetera. On top of all that, the battery still needs to hold a charge.

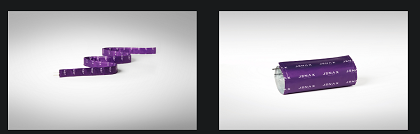

In Busan, South Korea, a company named Jenax has been hard at work at revolutionizing the lithium-ion battery. They are ensuring a battery can scrunch, bend, flex, and more. The battery is called the J-Flex. And it looks like this:

Jenax says they have batteries as small as 0.5 millimeters that could power sensors, with their biggest battery being a 200mm by 200mm battery. The company says after 1,000 charge-discharge cycles, the cells retain 90% of their capacity.

Creating ultra-flexible batteries that can twist and turn increases the chances of flammability. Lithium-ion batteries are prevalent in many of the technologies that we plug-in to charge every day. Most notably, our smartphones, smartwatches, and tablets.

Jenax has created a non-flammable liquid electrolyte solution for their batteries. Lithium-ion batteries are well known to suffer from a phenomenon known as thermal runaway once the battery gets too hot. The company has 100 patents related to its flexible battery technology. Jenax is keeping mum on how they achieve their level of flexibility, and rightly so, due to the market heating up.

Director of Jenax, EJ Shin, said in a statement, “Liquid is the best conductor for ionic movement, which means it delivers the best battery performance. But because liquid can also be a tremendous fire hazard, many manufacturers try to use solid state electrolyte instead. They sacrifice efficiency and in the case of wearables, comfort and usability, for safety. Jenax has always been focused on delivering the greatest combination of safety and performance. With this non-flammable electrolyte - we’re taking both to the next level - providing peace of mind manufacturers and consumers need with the high performance they deserve.”

Here is a safety test that demonstrates how other lithium-ion batteries fair when undergoing stress tests:

The company says their battery can be used to revolutionize the following battery-powered technologies:

IT wearables

- Smart Watch

- Smart Glasses

- Headset

Health

- Fitness Band

- Medical Device

Fashion

- Smart apparel

- Accessories

Military

- GPS Tracker

- Military Helmet

- Wearable Robot

The company recently showcased their flexible batteries at the Consumer Electronics Show which took place in Las Vegas from Tuesday the 7th of January to the 10th of January 2020.

Jenax showed their willingness to see their battery tech installed into other companies’ applications. They reportedly powered a sensor-lined football helmet developed by HP1 Technologies. Engineers are being called to see where they could implement the flexible batteries in their daily applications.

On the eve of their appearance at CES, EJ Shin explained, “Too many connected products fail to attract customers because they are awkward, uncomfortable, or difficult to use. Hardware designers often tell us that traditional battery limitations - including rigidity, thickness and lack of flexibility - are getting in the way. We created J-Flex specifically to help innovators overcome these challenges and meet consumers’ needs.”

Works Cited

“Jenax Announces Snack & Demo Sessions on Ultra-Flexible Batteries at CES 2020 | Markets Insider.” Business Insider, Business Insider, markets.businessinsider.com/news/stocks/jenax-announces-snack-demo-sessions-on-ultra-flexible-batteries-at-ces-2020-1028719460.

Zenopa. “Jenax Announces a Non-Flammable Liquid Electrolytes Solution.” Recruitment Within Pharmaceutical Jobs, Medical Jobs, Scientific Jobs, Tech PR Jobs, Zenopa, 3 Jan. 2020, www.zenopa.com/news/1976/jenax-announces-a-non-flammable-liquid-electrolytes-solution.

- Details

- Written by: Quintus Potgieter

Australia’s fire season has been the most damaging in living memory. The skies have been tinged red by the earth-scorching fires that have burned up about 12 million acres of land in Australia.

The bushfires, which are usually observed between October to March, have been raging since September 2019. They are the worst in the country’s history. Each state has been affected in a variety of ways, but it is New South Wales and Victoria that have been most severely hit by the fires.

As Australia picks up the pieces, while still blazing fires as temperatures soar, engineers are both assisting where they can and wondering how to prevent another disaster like this in the future. Each engineer in every engineering discipline could use their technical studies to the country’s benefit to mitigate future fire events.

Back in 2016, a Research Scientist at IBM, Anna Phan, asked the question: Can we outthink natural disasters? IBM’s artificially intelligent systems could be a potential solution to future flare-ups in the bushfire season in Australia.

On an article posted to LinkedIn, she wrote, “At IBM, our researchers are applying science and technology to tackle problems like predicting which areas and properties are most at risk of bushfires, investigating evacuation plans in hypothetical scenarios, or recommending the best evacuation route in a crisis.”

One of the elements of fire spreading that IBM had to account for as they began their research in 2016 was ember attack. Ember attack happens when burning foliage, twigs, and other flammable materials become airborne after gusts of wind. Larger fires create more embers. Therefore, Australia has seen runaway fires continue to develop.

The civil engineering implications in the aftermath of the fires could be significant. Updating building standards with future fires in mind will be imposed.

Ian Weir, Head of Landscape Architecture at the Queensland University of Technology, who is researching bushfire-affected architecture, spoke to NPR. He explained that in Australia, conventional homes that do not comply with the latest building standards are more flammable. A remedy for that has been cutting away vegetation to create buffer zones for properties. However, with embers spreading over the landscape, conventional homes catch fire in any case. Hence the need for future retrofitting and construction regulations to protect properties from fires in the future.

Newer automated technologies can play a part in prevention, mitigation, and disaster relief.

Anna Phan writes, “By using big data and analytics such as fire spread simulations and traffic modeling, IBM’s researchers have also developed an evacuation planner. This can provide answers to how long it will take to evacuate an area, the impact of road blockages and what shelters are available to help town councils and emergency services better prepare for bushfires.”

Electrical engineers will also be learning vital lessons for future disasters, as the bushfires have threatened electricity distribution. In New South Wales, the bushfires blazed through a link connecting the state’s electricity link with Victoria. Some transmission lines were reduced to rubble which led to pleas from the government to limit power consumption.

Two substations in the Snowy Mountains region were closed, causing 900MW to be lost from the grid - but impressively, electrical engineers managed to keep the lights on thanks to emergency backup sources of power. However, there were some regions, specifically from South Nowra to Moruya, Tumbarumba, and others where power was non-existent due to the ravaging fires.

The crisis is ongoing and will be remembered for years to come. However, the resiliency of the Australian firefighters during this crisis will be most remembered. The world will continue to celebrate them. Their job is not yet complete as they continue to battle fires, which are expected to continue burning. Moreover, the heroic stories of everyday Australians’ survival will number in the thousands after the dust has settled on these bushfires, and each deserves an equal measure of attention.

Works Cited

Hersher, Rebecca. “Australian Fires Prompt Questions About Protecting Houses From Embers.” NPR, NPR, 7 Jan. 2020, www.npr.org/2020/01/07/793991736/australian-fires-prompt-questions-about-protecting-houses-from-embers.

PhanFollowResearch, Anna, and Anna PhanResearch. “Can We Outthink Natural Disasters?” LinkedIn, www.linkedin.com/pulse/can-we-outthink-natural-disasters-anna-phan/.

- Details

- Written by: Quintus Potgieter

“With global developments characterized by higher demand for transportation, increasingly congested roads, and major environmental challenges, the industry needs to provide transport solutions that are safer, have a lower environmental impact, and are more efficient.”

Those were the words of the Volvo Group, the Swedish multinational manufacturing company, in their recent media statement. Volvo busies itself with the production and distribution of automobiles, trucks, buses, and construction equipment. Naturally, their equipment finds its way into the mining sector. This means that their aim of creating safer transport solutions trickles into mining as well.

They are manufacturing in a rapidly transforming world, effecting change in the mining industry and warping the traditional practices of the industry at large. To meet the demands of safety and efficiency in mining, Volvo has announced a new automated solutions business area - aptly named Volvo Autonomous Solutions - that will hit the ground running in 2020. The new business area will continue to develop automation solutions for their products. Volvo Group write:

“Autonomous transport solutions, based on self-driving and connectivity technologies, are well-suited for applications where there is a need to move large volumes of goods and material on predefined routes, in repetitive flows. In such situations, autonomous transport solutions can create value for customers by contributing to improved flexibility, delivery precision, and productivity.”

Australia (and China) - leading the charge on automation

Mining operations globally have not yet fully assimilated into automating many of their services, but in countries like Australia, automation in the mining sector is quickly becoming the norm. Australian owned Resolute Mining is one of those companies automating many of their operations, and exporting the methodologies to mines they own around the world. They are famously automating their Syama mine in Mali, West Africa. It is expected to hold the title of the world’s first fully automated gold mine.

In their published financial results, Resolute Mining reported that they were nearing commercial production rates after their rollout of a network of automated technologies within the Syama mine.

“This represents the initial delivery of one of the main benefits of automation, the ability to maintain production over periods when operations would normally cease in a typical manual mine. This network enables the automated haulage loop, automated rehandle level, mine digitization and production automation, all of which allows operators to monitor and control mine production in real-time.”

Resolute Mining says that the workforce that would have been spending their days inside the mine can now spend their time upskilling and training themselves for new roles within the company - they do not intend to chip away at the workforce in Africa, but rather empower it. The menial drillers' job may be a thing of the past in the future of the mining industry, but the remote controller jobs are now open season.

Rio Tinto, an Anglo-Australian mining giant, has also made a considerable investment into automated mining equipment. In four of their iron ore mines in Australia, 73 driverless trucks are working around the clock, 24 hours a day. The command center that gives those driverless trucks the instructions they require to function lies 750 miles away in Perth, where employees of Rio Tinto keep an eye on all of the operations from afar. These are the remote control engineers of the mines, and they are a shining example of what automation has achieved thus far.

For other mining operations, however, the remote controller engineer job is not an open position yet, because the mining company has not gotten out in front of the digital disruption occurring in the sector. ReportLinker.com’s report on the Automated Mining Equipment Market, China has been dominating in the mechanization of their mines trumping the world average, but still remaining sluggish when compared to their own standards.

It seems that the fourth industrial revolution’s moderately fast march may be keeping engineers in their traditional roles in some emerging markets for now, but the Internet of Things technologies are rapidly transforming the industry and is expected to creep into most countries in the future. Interconnected and autonomous mining equipment seems unavoidable at this point, and the message to mining companies is clear: adapt or die.

Works Cited

FR, ReportLinker. “The Automated Mining Equipment Market Is Expected to Grow at a CAGR of 7.21%.” GlobeNewswire News Room, "GlobeNewswire", 11 Oct. 2019, www.globenewswire.com/news-release/2019/10/11/1928488/0/en/The-Automated-Mining-Equipment-Market-is-expected-to-grow-at-a-CAGR-of-7-21.html.

“Resolute Mining Starting to Deliver Automation Benefits at Syama Underground.” International Mining, 30 July 2019, im-mining.com/2019/07/30/resolute-mining-starting-deliver-automation-benefits-syama-underground/.

“Volvo Builds out Automation Offering on Industry Demand.” International Mining, 21 Oct. 2019, im-mining.com/2019/10/21/volvo-builds-automation-offering-industry-demand/.

- Details

- Written by: Quintus Potgieter

Engineers are the driving force behind the digital revolution. In just the last decade, there has been a rise in automation technologies that have turned menial tasks at almost every level of society into an automated process.

Emerson, a global technology and engineering leader, is designing automation solutions for engineers that they believe could propel the industry forward and increase efficiency. Emerson serves up automation solutions for a broad spectrum of engineering disciplines, including Automotive, Chemical, Industrial Energy & Onsite Utilities, Oil & Gas, Mining, Power Generation and Water & Wastewater.

Their latest solution to engineering efficiency is a set of new digital, cloud-based tools that can help individual engineers stay on top of their projects. The MyEmerson engineering tools promise to save engineers time and allow them to work on the things that matter.

For instance, the online tool repository has on-demand CAD drawings and diagrams, plus configurators that can help engineers quickly create CAD drawings for the operations they need. Emerson says CAD drawings only take 15 minutes to be uploaded to their database, whereas it typically takes four hours to get CAD drawings to a user database in traditional engineering fields.

For engineers that work with gas, liquid, and steam, the MyEmerson application has a flow solutions technology advisor that can assist with measurements and provides configuration assistance for flow technologies specific to an engineer’s needs.

The online toolkit has various calculators, including:

- Power Module Life Estimator

- Appleton Lighting Retrofit Calculator

- Wireless Cost Savings Estimator

- ASCO Conversion Calculator (Metric/Imperial)

- Wireless Gateway Capacity Estimator

- ASCO Numacalc Pneumatic System Design Calculator

The application can assist with finding information on how to configure instrumentation found in the field — which purportedly helps engineers set instrumentation up at 93% faster than traditional methods. There is even a live chat that engineers can utilize to ask questions and get rapid answers from an online expert.

Emerson’s website states, “The process of specifying devices is often complex. From seasoned engineers to those new to the industry, it can be difficult to specify solutions for a range of applications.

“MyEmerson engineering tools allow you to confidently design solutions, regardless of your level of expertise. With these tools, you can quickly create a valid configuration, accurately select a device, generate required documentation, or calculate ROI. Use digital engineering tools to save time and augment your own expertise - to confidently engineer the best solution.”

The future of web apps for engineers

There are several web applications that engineers can utilize in their day-to-day operations to make their jobs easier. Doing back-of-the-envelope calculations and simulating engineering scenarios on the cloud before carrying them out in reality, is extremely popular with engineers.

One website that hosts loads of engineering calculations useful for civil and structural, and mechanical engineers is webappsforengineers.com.

For those wading into the machine learning and big data sectors of the engineering industry, MATLAB Online is a useful tool. MATLAB is used for analysing data, developing machine learning algorithms and creating models and applications. With no installation necessary, and just a standard browser required, engineers can access a lightweight online app that can help them efficiently develop algorithms of the future.

Another engineering website that lists the top fifty free web apps for engineers is EngineeringDegrees.org. They lay the categories out according to; CAD Software, Calculators, Odds and Ends, Productivity, and Engineering Tools Overload. This new way of seeking out digital tools that help engineers calculate and simulate is changing the way they do their jobs.

Cloud synchronization for engineers within companies, and general web apps and digital tools that can assist engineers in their work are rapidly being rolled out to produce more efficiency in all industries. We can expect to see more online resources and smartphone apps that make the action of remote and on-site engineering much more complex and efficient.

Works Cited

“Engineering Tools.” Emerson US, www.emerson.com/en-us/automation/digital/engineering-tools.

“MATLAB Online.” MATLAB & Simulink, uk.mathworks.com/products/matlab-online.html#no-downloads-or-installations.

- Details

- Written by: Quintus Potgieter

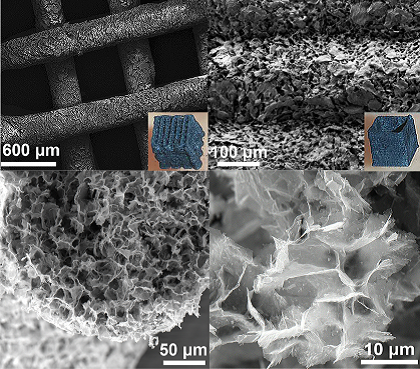

Engineers are collaborating on a project to strengthen energy storage technologies through the use of 3D printers. This project is also highlighting the importance of 3D printing in electrical engineering.

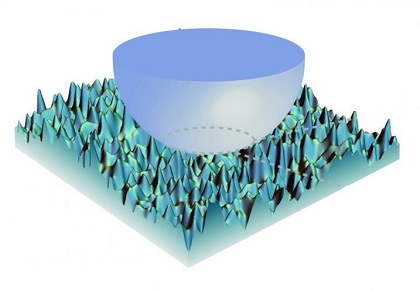

Researchers at the University of Manchester have developed a unique way to convert 2D materials into electrodes that can be stored in devices such as supercapacitors. This requires turning a clay-like substance known as MXene into an ink, which once dried, can conduct electricity.

In 2011, engineers from Drexel University in the United States created MXene. It consists of carbon atoms and transition metals. This substance has two properties which make it particularly useful; it is hydrophilic, which means it can be turned into an ink, and it is conducive for electricity. This means it is more suitable for energy storage than other 2D clays.

MXene has been derived from graphene, the world’s first 2D material which was a better conductor than copper, but one million times thinner than human hair, stronger than steel, transparent, and flexible. The discovery of graphene opened the door for scientists to experiment by creating other 2D inks, each with differing properties.

However, to make effective use of these properties, the inks need to be integrated into devices and structures.

Drexel College of Engineering Professor in the Department of Materials Science and Engineering, Dr Yury Gogotsisaid, “so far only limited success has been achieved with conductive inks in both fine-resolution printing and high charge storage devices.

“But our findings show that all-MXene printed micro-supercapacitors, made with an advanced inkjet printer, are an order of magnitude greater than existing energy storage devices made from other conductive inks.”

University of Manchester researchers have done just that. They put MXene through their 3D printer and showed how they could make the most of the compound.

Team leader Suelen Barg said, “We demonstrate that large MXene flakes, spanning a few atoms thick, and water can be independently used to formulate inks with very specific viscoelastic behavior for printing.

“These inks can be directly 3D printed into freestanding architectures over 20 layers tall.

“Due to the excellent electrical conductivity of MXene, we can employ our inks to directly 3-D print current collector-free supercapacitors.

“The unique rheological properties combined with the sustainability of the approach open many opportunities to explore, especially in energy storage and applications requiring the functional properties of 2-D MXene in customized 3-D architectures."

University of Manchester researchers said 3D printed MXene electrodes could have significant use in supercapacitors. The supercapacitors could store power and weigh less than what is already in energy storage devices today. In future, this could help electric vehicles, solar panel energy storage batteries, smartphones, and other electronic devices deal with electrical charges much more efficiently and expand the energy storage capabilities.

Ph.D. students from the University, Wenji and Jae, said, “additive manufacturing offers one possible method of building customized, multi-materials energy devices, demonstrating the capability to capture MXene’s potential for usage in energy applications.

“We hope this research will open avenues to fully unlock the potential of MXene for use in this field.”

EIT offers a range of electrical engineering courses - find out more!

Works Cited

Greenwood, Matthew. “Engineers Use 3D Printing to Turn 2D Materials into Electrodes.” Engineering.com, www.engineering.com/DesignerEdge/DesignerEdgeArticles/ArticleID/19430/Engineers-Use-3D-Printing-to-Turn-2D-Materials-into-Electrodes.aspx.

- Details

- Written by: Quintus Potgieter

Offshore wind turbines have continued to face a glaring problem ever since their conception: their maintenance being a dangerous endeavor any engineer involved.

A number of occupational health and safety measures must be put in place to protect these engineers, which ultimately means more money needs to be spent by the companies building the turbines.

When turbine blades require maintenance, engineers are tethered to the wind turbine by ropes, they then walk out on the turbine and access the blades. This is naturally a highly dangerous operation. For the energy company, the downtime of a turbine is also a costly exercise.

However, automation is beginning to creep into the industry to save both lives and save money. The world’s first autonomous robotic inspection and repair solution for offshore wind farms has been announced and the numbers are looking positive. The pilot project is to cost roughly $7 million dollars and is expected to help cut costs of the wind farm by nearly $50 million dollars throughout its lifetime.

It’s called the MIMRee (Multi-Platform Inspection, Maintenance and Repair in Extreme Environments) project. It employs cutting edge technology to analyze wind farms like no human crew would have been able to do before.

The solution includes utilizing drones, which are deployed to analyze and scan the turbine blades. These are deployed off an autonomous vessel that scans the wind turbines on approach. Based on the repairs needed, the drones carry robot repairers to the affected blades so they can begin the repair process.

There are also underwater robots that can be used to maintain and repair the submerged portions of the wind turbines. The robots that companies such as Innovate UK and their affiliates are considering using are named Autonomous Aquatic Inspection and Intervention (A2I2) robots.

The key objectives of the UK-funded automotive project were put together in 2018, and now engineers are working to meet them. The objectives were outlined in project notes, which were released to the public, and said the use of robots will:

- Remove the need to send humans offshore to carry out wind turbine blade IMR (Inspection, Maintenance & Repair) tasks

- Remove the need to shut wind turbines down to carry out blade inspections

- Reduce the risk of using autonomous vehicles offshore to carry out IMR tasks in real-world operating conditions.

- Establish the business case for using autonomous vehicles for blade IMR.

- Develop a roadmap for transferring the MIMRee system to other relevant industries.

Dr Sara Bernardini of Royal Holloway from the University of London told BIM+:

“We will be working closely with a group of offshore wind technicians to create personas for the robots and map the tasks that will turn a human-led mission into an autonomous operation. Testing and consultation with technicians will be crucial to designing the interface for remote monitoring and intervention and understanding how to deal with the unexpected in a mission.”

Works Cited

“Project to Develop World's First Robotic Wind Farm Repair and Inspection Solution.” BIM , www.bimplus.co.uk/news/project-aims-develop-worlds-first-robotic-wind-far/.

- Details

- Written by: Quintus Potgieter

It appears capitalism plus mechanical engineering equals food deliveries, with Uber set to deliver McDonald’s via drones in California later this year.

Uber Elevate is the department responsible for this — its focus is on developing aerial delivery and transport technologies.

According to their website, “The Uber Elevate team is working toward transforming the world through aerial ridesharing at scale. Imagine soaring above congested ground traffic. With Uber Air, this future is closer than you think. Uber is developing shared air transportation - planned for 2023 - between suburbs and cities, and ultimately within cities.”

However, the department has faced some setbacks. They predicted that they would have a ridesharing service ready to go by 2021, but at this stage, the commercial release won’t be until at least 2023.

Despite this, they have already begun implementing these technologies in collaboration with the Uber Eats side of the business. The company was cleared by the Federal Aviation Administration (FAA) in San Diego to deliver food via drone technologies.

They have since announced they will deliver meals from McDonald’s and two other local restaurants in San Diego via drones.

So, how will this work? Staff at the restaurant will load the order onto an Uber Eats drone. The drone will fly the food to a staging location, where it will be collected by a courier and driven the final kilometre to the customer.

Eventually, the company plans to have the drone land on top of Uber Eats delivery cars, using an identifying QR code.

The reason behind this new endeavour is to maintain fast delivery times in dense urban environments. Uber will still be utilizing couriers for the last leg of these deliveries to negate the problems associated with home deliveries in built-up areas. According to Uber Elevate’s head of flight operations Luke Fischer, 68% of the world’s population expected to live in such areas by 2050.

“We don’t need to get drones direct to our customer, we just have to get it close,” he said.

“There have been many attempts at drone delivery: landing on mailboxes and in backyards with parachutes attached.

“But we run into the same problems with those. It simply doesn’t work in dense urban environments where people don’t have backyards, don’t have drone capable mailboxes and don’t have backyards for parachutes.”

Uber has already tested some deliveries from McDonald’s to the San Diego State University campus, using an off-the-shelf AR200 drone.

The company has now built a custom drone specifically for food delivery to be debuted later this year.

“Our goal is to expand Uber Eats drone delivery so we can provide more options to more people at the tap of a button,” said Fischer.

“We believe that Uber is uniquely positioned to take on this challenge as we’re able to leverage the Uber Eats network of restaurant partners and delivery partners as well as the aviation experience and technology of Uber Elevate.”

Works Cited

Dickey, Megan Rose, and Megan Rose Dickey. “Uber Adds Another Air Taxi Vehicle Partner to the Mix.” TechCrunch, TechCrunch, 11 June 2019, techcrunch.com/2019/06/11/uber-adds-another-air-taxi-vehicle-partner-to-the-mix/.

Rapier, Graham. “Uber Says It Will Deliver McDonald's Meals via Drones in San Diego as Soon as This Year.” Business Insider, Business Insider, 12 June 2019, www.businessinsider.com/uber-eats-drones-will-deliver-mcdonalds-in-san-diego-2019-6?IR=T.

- Details

- Written by: Quintus Potgieter

Engineers are no strangers to technological advancement. The advent of the computer has rapidly transformed the world, and engineers are constantly driving the growth of technology. Development of computers has now reached levels once thought impossible; the automation of virtually every industry perceivable.

The breakaway success of computers was observed by the co-founder of Intel Gordon Moore. He made a prediction back in 1965 that from that year onwards, the number of transistors on integrated chips inside computers would double every year. As transistors were getting smaller, he envisioned more and more being added to the internal chip.

In 1975, he revised his initial prediction. The new prediction was that the transistors would continue to double and that their cost would halve every two years. This prediction became known as Moore’s Law because every two years his prediction rang true.

What Moore eventually learned was that the reality of development would far surpass what he had ever imagined. He observed incredible technological leaps from the 1960s and onwards that would make computers increasingly faster and more efficient.

Think about the smartphone — in Moore’s day that was merely a twinkle in engineer’s eyes. By the time the iPhone 6 was released to the world in 2014, the proprietary A8 chip inside the smartphone was made of up 2 billion transistors.

Fast forward to 2018, and the most premium of Apple’s iPhone X range has 10 billion transistors on its A12 chipset. As of 2017, the largest transistor count in a commercially available single-chip processor was 19.2 billion.

The issue that Intel faces in the short term is that at some point transistors might be too small to be scientifically useful. In 2019 Intel said the company could only keep shrinking the transistors for another 5 years from that year on before they would reach the dead-end. After some delays in the manufacturing process of their new chip, Intel is beginning to roll out their 10-nanometer transistor processors in the latter half of 2019.

And as the transistors get smaller, the creation of them is beginning to cost more. Intel says making the chips smaller and sticking to the two year time frame set by Moore is becoming too stringent of a deadline and is essentially causing Moore’s Law to come undone.

However, it seems that Moore’s Law is ending at a time when a quantum leap in computing is needed. With more automation being required in industries, computing is going to need a new dawn. Computers as we know them will need to change from being glorified calculators, into artificially intelligent, sentient machines.

Artificial intelligence

Engineers and scientists are hard at work putting together true artificial intelligence. Engineers are being tasked to build something that can learn, something that has its own human-like neural network.

The task is so big, novel approaches to the microprocessor are needed. Intel and others are investing over AU $18 million into startups that specialize in experimenting with the newer chip technologies that could lead to a new computing revolution. A startup named Untether AI is one of those companies. They reportedly have a new chip that can transfer data 1,000 times quicker than conventional chips that are being utilized for AI.

The opportunities that the future computers present, is becoming realized by industries in the fourth industrial revolution. And the benefit of new, novel processors will unlock a new computing future that will benefit business and humans in general. Untether AI’s focus is on their website - they write:

“Future devices will sense and make sense of the real world environment around them. They will do that by leveraging AI technology. To make that possible, processors have to handle the neural nets that make up AI with extreme efficiency. Devices that can react naturally to your spoken word and your slightest gesture are coming. To be able to accurately interpret the meaning, neural nets will run right on the device without draining your battery or overheating the device.”

Works Cited

Knight, Will. “Intel Buys into an AI Chip That Can Transfer Data 1,000 Times Faster.” MIT Technology Review, MIT Technology Review, 23 Apr. 2019,

www.technologyreview.com/f/613258/intel-buys-into-an-ai-chip-that-can-transfer-data-1000-times-faster/.

“Untether AI.” Untether AI, untether.ai/.

- Details

- Written by: Quintus Potgieter

Industrial automation technologies have been commonplace in the aerospace industry for some time. This innovation is now starting to be seen inside aircraft, and within the aircraft manufacturing industry, airports, and ground support equipment.

Aurrigo is a UK-based company developing the world’s first automated dolly. A dolly is used at most airports around the world to transport baggage and cargo. The company utilizes driverless technology and has been testing its innovations out in Britain.

It was the International Airlines Group (IAG) that asked Aurrigo to get their engineers working on automating ground equipment, in hopes that they could roll out the technology worldwide.

Utilizing their wealth of knowledge in LIDAR and GPS technology, Aurrigo went to work. After some developing and designing, the company has rolled out a prototype that is now wheeling around Terminal 5 at Heathrow Airport in London.

Director of Operations at Aurrigo Richard Fairchild in the official press announcement of the dolly innovation said, “Until you have seen it first-hand, it’s difficult to explain how big an operation it is moving bags around an airport.

“In Terminal 5 alone, BA operates around 900 dollies. The current method is to have one manually driven tug towing three dollies behind. It can’t move until they are all full, which means there are a lot of empty dollies waiting around.

“What IAG wanted to do was look at an alternative solution and that’s where we came in, using the knowledge gained from our hugely successful Pod Zero passenger-carrying vehicle to turn a standard dolly into a self-driving vehicle capable of moving bags from the baggage hall to the aircraft stand.”

In the Bristol area, Aurrigo is testing out the autonomous Pod Zero passenger carrier pod. The company showed what the very first implementations of driverless technologies could be — in this video they are transporting the elderly to and from.

David Keene, Chief Executive Officer of Aurrigo, about the dollies utilizing the driverless technology at Heathrow, said: “This is another fantastic example of British innovation and engineering and I’m delighted that our team has again delivered — this time for a new application.

“Our driverless pods are now in operation all around the world and the work with IAG and BA shows how similar technology can be used in a completely different industry to deliver significant results.”

In this case, industrial automation is making the entire process of transporting cargo and baggage at airports even more efficient than it was before.

For engineers, automating cargo-carrying shows that the things they design for one industry can be embedded into other industries and make a big impact. And that’s why industrial automation is a subject that all engineers should be upskilling themselves with.

Works Cited

“Aurrigo Delivers Autonomous 'Baggage' Solution for Heathrow.” Aurrigo, 25 June 2019, aurrigo.com/news/2019/06/aurrigo-delivers-autonomous-baggage-solution-for-heathrow/.

- Details

- Written by: Quintus Potgieter

The world’s first 360-degree infinity pool will be fitted into the roof of a London Skyscraper.

Those brave enough to swim will have death-defying views as they float 220 meters above the city. Designs show that the pool will feature four clear walls and a transparent floor, so visitors to the hotel below will be able to look up and see both the swimmers and the sky.

UK-based pool manufacturer Compass Pools is behind the Infinity London project. They have designed the pool to be made out of cast acrylic, rather than glass, as this material transmits light at a similar wavelength to water. The idea is that the pool will look crystal clear.

At night, it will be lit up with twinkling lights, to make the building look like a sparkling jewel-topped torch.

Those brave enough to swim atop the 55-storey building will have uninterrupted views over London. The question is; how will swimmers get in and out of the pool?

That is a feat of engineering itself, and it relies on a rotating James Bond-esque staircase beneath the pool.

“Normally a simple ladder would suffice, but we didn’t want stairs on the outside of the building or in the pool as it would spoil the view — and obviously you don’t want 600,000 litres of water draining through the building either,” said Compass Pools’ technical director Alex Kemsley.

“The solution is based on the door of a submarine, coupled with a rotating spiral staircase which rises from the pool floor when someone wants to get in or out — the absolute cutting edge of swimming pool and building design and a little bit James Bond to boot.”

This rising staircase isn’t depicted in designs, so it still remains to be seen exactly how this will work.

The company has also designed a sustainable heating system, to keep the pool at a comfortable temperature. This involves recycling waste energy from the skyscraper’s air conditioning system. The hot gas produced as a by-product of creating cold air to pump throughout the building will be run through a heat exchanger to keep the pool water warm.

The design features even more technological advancements. A Programmable Logic Controller will ensure the entire system and its sensors are working in harmony.

To assuage the fears of those who think a swimming pool atop a skyscraper is a scary idea, the company says they will fit the pool with an anemometer. This will measure wind speeds at the top of the skyscraper to ensure swimmers have a good idea of what the conditions for swimming are like.

The system will also monitor the water levels and use the wind speed data to ensure water does not get displaced and splash onto the street below.

But, if you are reading this and drafting an email to your boss in hopes that you may get an infinity pool built atop your own office block, slam on the brakes. A 360-degree infinity pool is something tougher to build on already existing constructions.

“Architects often come to us to design rooftop infinity pools, but rarely do we get a say in the building design because the pool is usually an afterthought,” said Kemsley.

“But on this project, we actually started with the pool design and essentially said, ‘how do we put a building underneath this?’

“When we designed the pool, we wanted an uninterrupted view, both above and below the water.”

The location of Infinity London is yet to be determined. However, construction is expected to begin in 2020 once partners and contractors are confirmed. A five-star international hotel will occupy the top floors of the skyscraper and the pool will be used by their guests.

- Details

- Written by: Quintus Potgieter

Temperatures in Nairobi, Kenya, reach 35 degrees centigrade in the summer months. Over five hundred kilometers away is the town of Malindi, where a brand new photovoltaic solar project is kicking off. If Kenyan engineers are looking to work in renewable energy, their chance has arrived.

The Malindi project will be the first utility-scale independent power project the country will see. Globeleq is a company hailing from the United Kingdom, and is heading up the project. They are also investing in renewable energy solutions in South Africa.

The company will be selling electricity to Kenya’s national electricity provider Kenya Power, recently agreeing to a 20-year deal.

Paul Hanrahan, Globeleq’s CEO, told media:

“The attractive investment climate combined with strong local community support sets the stage for this important project as well as future investments in Kenya. We are extremely pleased to be making this investment into the Kenyan energy sector.”

The construction will be complete and in operation by mid-2020, producing up to 40 megawatts of power. The rights to the land, the environmental impact assessment and the necessary permits needed for constructing have all been procured. The project’s construction has received nearly $100 million dollars AUD in funding from investors, who will all be enjoying a cut of the eventual profit. The engineering companies behind sourcing the necessary technology and constructing the actual plant are Sterling and Wilson Solar.

Kenya, unlike many of its other neighboring countries, is opening their energy market up to whatever entities may be able to provide electricity to its people. They intend to rely less on coal powered power stations and move to more renewable sources. It is all a part of the government’s National Electrification Strategy which aims to power Kenya by completely green energy by 2020.

A recent coal power plant construction reaching completion in Kenya is undergoing scrutiny for purportedly lying about the price of the electricity that will be produced at the power plant. The plant in Lamu, Kenya, is seeing a big level of pushback after the revelations were made public. Experts are saying the entire project should be scrapped.

The Kenyan government and the World Bank set up a $67 million dollar AUD facility under a project named Kenya-Off-Grid-Solar to further develop the private solar sector, in hopes that they can bring electricity to 14 communities that have been lacking energy solutions.

Principal Secretary of the Ministry of Energy, Joseph Njoroge, said:

“The country has made great strides in achieving connectivity with access to electricity standing at 75% though both grid and off-grid options. However, access to electricity is low in the 14 marginalized counties, which represent 72% of the country’s total land area and 20% of the population.

Works Cited

“Kenya in $47m Financing to Provide Solar Solutions.” Journal Du Cameroun, 11 June 2019, www.journalducameroun.com/en/kenya-in-47m-financing-to-provide-solar-solutions/.

“Kenya: First Utility-Scale IPP Solar Project Achieves Financial Close.” ESI, 3 June 2019, www.esi-africa.com/industry-sectors/renewable-energy/kenya-first-utility-scale-ipp-solar-project-achieves-financial-close/.

- Details

- Written by: Quintus Potgieter

Triton Submarines have taken man to where no man has gone before...to the bottom of the ocean.

Businessman and amateur pilot, Victor Vescovo, went down to what is believed to be the deepest point of the ocean a human being has ever travelled to. Its name is the Challenger Deep, located in the Pacific Ocean at the southern end of the Mariana Trench. From surface to seabed the underwater marvel is 10,928 meters deep and is the deepest point in the Earth’s hydrosphere. The vessel would have to sustain pressure equal to 50 buses pushing down on it. Descending nearly 11km in April 2019, Vescovo now holds the record for the deepest ocean dive made by a human. What he found on the ocean floor will shock you.

Triton has recently been working on creating prototypes of submersibles that are able to withstand incredible amounts of pressure atat significant ocean depths. And they have struck gold - or should we rather say titanium - with the Triton 36000/2 Hadal Exploration Systems. They explain how the submersible came to life on their website:

“Three years ago, an American client came to us with a dream. He had climbed the seven summits, the tallest peaks on each of the seven continents, and next he wanted to dive to the deepest point in each of the five oceans. The challenge was set. Only two manned submersibles have ever dived to full ocean depth, and each made only a single dive. Could Triton design and build a submersible capable of repeat dives to the most remote, hostile and unexplored region of our planet? The answer, a resounding “yes”.”

The company spent every weekday (and probably weekends) working on designing and engineering feasibility studies of the submersible. Then, in 2016, the last design was decided upon and a manufacturer was chosen. They were off to the races.

The submersible’s alloy would be made of titanium, and surrounding the vessel, glass-bead based ‘syntactic’ foam to allow for buoyancy. The two materials are able to withstand immense pressures - whilst making enough space for two passengers. But, what made this submersible novel was the lack of welding work required. One of these submersibles can be purchased for just US $48.7 million.

Triton eventually settled on a name: The DSV (Deep Submergence Vehicle) Limiting Factor. A fully commercially accredited full ocean depth (FOD) manned submersible. And the plan was to take it on a journey that would see it visit the bottom of all the five oceans - a mission entitled Five Deeps Expedition. He has since completed four out of five of the expeditions and is to complete his mission in the Arctic Ocean in September 2019. His entire journey has been filmed and will be made into a documentary to air on Discovery networks.

Filming the documentary also required some engineering. The team had to design cameras that could sustain the pressure down at 10,000m below sea level. Unmanned vehicles would also be sent out onto the seabed to scan the surface so it could be recreated in virtual reality - which too had to be built out of the robust materials the Triton 36000/2 was made up of.

Here is a video from Triton that shows some of the engineering work around the testing of the submersible before they took on the five oceans.

<iframe width="702" height="395" src="https://www.youtube.com/embed/bTuKBeG1bRE" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

At the bottom of the Challenger Deep, Vescovo made a chilling discovery on the seafloor… plastic waste. After spending four hours hovering above the seafloor, he said he observed a plastic bag and sweet wrappers. Manmade waste was at the deepest levels of the ocean.

Nonetheless, the expedition is an amazing feat of engineering. Upon returning from the Challenger Deep expedition, Vescovo (talking to the BBC) said:

“It is almost indescribable how excited all of us are about achieving what we just did. The submarine and its mother ship, along with its extraordinarily talented expedition team, took marine technology to a ridiculously higher new level by diving - rapidly and repeatedly - into the deepest, harshest, area of the ocean.”

Works Cited

“Hadal Exploration System.” Triton Submarines, tritonsubs.com/hadal/.

Morelle, Rebecca. “Mariana Trench: Deepest-Ever Sub Dive Finds Plastic Bag.” BBC News, BBC, 13 May 2019, www.bbc.com/news/science-environment-48230157.

- Details

- Written by: Quintus Potgieter

Engineering is transforming Kenya into an innovative hub of new technologies that are both helping the poorest of the poor and assisting the growth of the business sector.

A startup from the Penn State College of Engineering, Kijenzi, has been training Kenyans in the art of 3D printing. The startup also helps address several key issues encountered in the rural medical facilities in Kenya.

In Kenya, clinics are being faced with many issues like outdated machinery, unrefined supply chains, and limited access to equipment they need to ensure a healthy environment for patients. On Kijenzi’s website they explain how their 3D printers work: