News

Dear Colleagues

One only needs to think of the huge cases of lying and dishonesty within large industrial companies such as Volkswagen (car emissions fraud), Enron and Tyco (both accounting fraud), and the increasingly cynical commentary about these cases from a weary public to wonder whether this is a fast growing trend. I often wonder whether it is simply about people regarding it as a playful attempt at gaming the system rather than believing these cases are fraudulent.

However, there is no doubt that these cases above are simply representative of blatant dishonesty and lying. Ron Carucci has done extensive research on the issue and believes that there are a number of simple reasons why dishonesty and lying penetrates an organisation – no matter whether you are running a tiny plumbing company with three employees or a billion dollar industrial enterprise selling electrical switchgear throughout the world with tens of thousands of employees.

Ron’s research revealed that these reasons are easily within the control of the organisation and can save you from huge organisational value destruction. Even if an organisation isn’t actively pursued under the law for lying, thieving and corruption – there is no doubt that the resultant reputational damage is enough to destroy value. I saw this happen only this week; when a huge organisation was investigated for corruption and dishonesty in gaining governmental contracts – within weeks of the news being out – even though they were hugely profitable – they have been forced into liquidation as their banks being nervous about being tarred with the same brush – have withdrawn all banking facilities.

A few suggestions from the research (and my take on the issue):

A lack of Strategic Clarity. Where there is a mismatch between the organisation’s stated mission, vision and values and what happens on the shop floor, there is a high likelihood of dishonesty. When employees are required to do things which are in stark contradiction to what the overall positive vision requires - such as cutting quality corners and compromising safety in an attempt to lift production, things start going badly wrong.

Badly Designed Accountability Systems. Where employees are held to unfair targets which have no hope of ever being met. They then start to invent reasons why these targets are actually being met and being pushed to be dishonest. I think of the classical case with defective project management where an engineer is held to certain unreasonable time and cost targets where there is not a hope in hell of these being met – in an attempt to keep her job and her bosses happy, she will tweak the figures to show that she is still on target. Recently down the road from our offices, a huge business building power stations and mineral processing plants went belly-up because (too late) they discovered huge company-destroying losses in the construction costings as a result of dishonest (so-called ‘optimistic’) reporting.

Transparency in governance and management. Where open meetings are avoided and the truth forced underground about the real day-to-day operations of the company resulting in incorrect information spreading by rumour, the scene is set for the blocked artery syndrome of limited information flowing through the organisation and then being used to make poor decisions. Sure – giving bad news to management about problems on a project is hugely painful but the way the problems are dealt with is what predicates a successful company.

Development of Silos. I never cease to be amazed that even tiny companies rapidly develop a silo mentality where departments run their own race without working closely with their peers in other departments. This results in a dysfunctional company with dishonesty breeding as a result.

Conclusion

I can categorically assure you that there is no organisation on this planet which is 100% squeaky clean on these four measures above. However, working hard on an ongoing basis to address these points above will make a dramatic improvement to your operations, employee and customer satisfaction and indeed, your bottom line. And enable you to withstand the inevitable economic storms we all are buffeted with from time to time.

Warren Buffet says it all: "In looking for people to hire, you look for three qualities: integrity, intelligence, and energy. And, if they don't have the first, the other two will kill you."

Thanks to Ron Carucci and the Harvard Business Review for a fascinating take on dishonesty in organisations.

Yours in engineering learning

Steve

It seems engineering terms are becoming buzzwords within the industry.

For example, words like The Fourth Industrial Revolution, the Internet of Things, Artificial Intelligence, the Blockchain — and more — are all misused in quickly rattled off articles and political speeches.

In fact, it seems that the people peddling these terms are not actually aware of their meaning. It is easy to refer to the Fourth Industrial Revolution without giving credence to the technologies that are bringing the revolution about.

The risk is that engineers entering the industry might be unsure of which type of engineering to pursue when buzzwords are being thrown from all angles. When it comes to terms like the Internet of Things and Artificial Intelligence...it’s a delicate balance.

IoT vs. AI: Which way forward?

The Internet of Things refers to connecting machines together and harvesting the data that they generate, whereas Artificial Intelligence is about engineering an intelligence comparable to human intelligence.

The overarching difference is who interprets and essentially makes sense of the data. Thus, AI can be plugged in at the technological level that can make sense of the data generated by Internet of Things technologies. As a result, in some instances, some systems can be interconnected in an Internet of Things network and have an artificially intelligent software making sense of the data it is receiving.

However, a new report by EE Times has taken a look at the revenue expectations for the Worldwide Deep Learning Chipset industry. The report seems to indicate that ‘five-sixths of the growth in semiconductors' will be in AI technologies alone by the year 2025.

The Internet of Things, merely a technological shift where an interconnected network of things (or computers) talk to each other, may be on the back foot of the semiconductor industry because AI setups are usurping that sector.

Analyzing data with deep-learning algorithms seems more of a technical task than connecting things together and needs other AI technology altogether. CPUs, GPUs, and the like are unable to process the data networks generate as effectively as algorithms can, and so those technologies fitted with the correct semiconductors have reached the market and are ready to do the job.

So what kind of semiconductors can prospective engineers expect to see in the industry? Application-specific integrated circuits, application-specific standard products, systems on a chip, and accelerators for artificial intelligence. Each chip being algorithm specific in its own right.

Those algorithm-specific and application-specific semiconductors are tailor-made for, for example, autonomous vehicles, Wall Street, farming technology, weather forecasting, etcetera.

The Engineering Institute of Technology is delivering a Professional Certificate of Competency in Machine Learning and Artificial Intelligence. The course will begin on 13 May 2019. The course is presented by industry lecturers with more than 15 years of experience in the development and management of artificial intelligence. The course teaches students incredible problem-solving skills in the machine learning world and trains them in building algorithms to automate processes regardless of the industry.

Enquire about the course today and start clearing up the basics, and start your journey on focusing what the engineering industries that exist require right now.

Works Cited

Shuler, Kurt. “IoT Was Interesting, But Follow the Money to AI Chips.” EETimes, EE Times, 20 Feb. 2019, www.eetimes.com/author.asp?section_id=36&doc_id=1334342.

Sync, CRM. “The Future of IOT Is AI.” TechUK - Representing the Tech Industry in the UK, TechUK, www.techuk.org/insights/opinions/item/13827-the-future-of-iot-is-ai.

A decade of corruption, mismanagement, sabotage, poor power station designs, and a recent natural disaster has led to the implementation of more rolling blackouts in South Africa's energy sector.

At the end of 2018, Eskom admitted that they were unsure when the next break in transmission was going to be. Initially, they wanted to ensure that South Africans would not be in the dark during their Christmases.

During that time, an intensive investigation into the problems Eskom was experiencing was launched. They were looking for good, honest people with the right technical skills. They did not want Stage 2 load-shedding. However, three months later, the country would see an unprecedented Stage 4 load-shedding. For each customer, for an entire week, their electricity would be cut off twelve times, for two-and-a-half hours each time.

Eskom has 47,000 MW of installed capacity that is serving all South Africans. The current demand of South Africans at a theoretical peak during the summertime is 29,000MW. The demand Eskom is able to reach (with all of their problems considered) is about 26,000MW.

Eskom indicated that a contributing factor to their woes was the age of their plants was a massive problem, too. Monetary investment into the maintenance of the plants in the last few years, but they allege that the repairs were not done adequately.

Eskom is hoping to find the relevant skilled individuals who can quickly meet the requirements of the state-owned enterprise. They need the right people to take a look at their problems and suggest implementable solutions.

So, how can freshly qualified engineers or even students help solve the problem?

Managers, students, professionals

It is imperative that all professionals and future professionals in the electrical engineering industry in South Africa keep upskilling within the industry. They never know when a state-owned electricity utility could be knocking on their door and asking them to save the day.

Public Enterprises Minister Pravin Gordhan at a press conference on the 6th of December 2018 said:

“We are going to find independent experts, a few of them, so that they could take an arm lengths view of these plans and the nature of the problems, and the nature of the solutions we have prescribed.”

Gordhan said in December that Eskom was in crisis mode. He said they would look within the company to find capable individuals to become power station managers to ensure power stations ran at an optimal level with zero incompetence.

After looking inward, they began looking outward as well. At the beginning of 2019, Eskom began asking top engineers from Italian energy company Enel to assist with Eskom's maintenance issues.

Chairperson on the board of Eskom, Jabu Mabuza said:

“This cannot be solved by Eskom alone. These are problems that we have all caused as South Africans. Either through our people, or through our government, but these are problems that we have caused. So, there is a role that we all have to play - shareholders, providers of capital, staff, customers - this is a choice of pain we need to take going forward, to try and put us back into a sustainable way.”

The company has approached the Auditor-General and the National Treasury to secure a special procurement dispensation to pay professionals for their assistance with their services and expertise. They are hoping that these companies and the ultimately skilled individuals might help keep the lights on.

Gordhan also mentioned to media recently that they were head-hunting at universities for students who could take a look at the power stations and provide feedback and suggestions for how Eskom might better run them.

What is also clear is that the stage is set for more Independent Power Producers to flood into the energy industry in South Africa. There is also a US $310 million government fund ready to invest into small scale embedded generation (SSEG) projects which will also create new jobs for highly technically qualified engineering professionals and workers, but the fund has been held back because of regulatory constraints.

There are also regulations preventing individual municipalities in the country from generating their own electricity. The state-owned utility has taken that entire job on its own shoulders. Opening up the regulations allows for municipalities to hire professionals to build a brand new, unique grid and would lead to far more citizens getting access to electricity - perhaps some for the first time.

The result could see engineering professionals getting jobs in general and renewable energy projects the country desperately needs to keep the lights on and to circumnavigate load shedding on already aged infrastructure. It could take many homes, businesses, warehouses, factories, mines, and farms off of the national grid and reallocate the electricity for areas that are in desperate need of it.

As a result, South Africa’s electricity problems also present the country with opportunities. As the country draws closer to their next election, electricity (and the lack of it) will be something the voters might have at the back of their minds as they cast their vote.

Works Cited

6 Quick Fixes That Can Save South Africa from More Load Shedding, www.businessinsider.co.za/6-quick-fixes-that-can-save-south-africa-from-more-load-shedding-2019-3.

“Eskom, Gordhan Briefing on Operation Issues.” YouTube, 6 Dec. 2018, youtu.be/3KXg_o5Zth0.

It was close to being the first giant leap for womankind but is now a very public stumble for one of the world's leading space agencies.

NASA announced on Monday that the first all-female spacewalk in history would be cancelled due to a somewhat confounding mistake from the same agency that sent human beings to the moon; they didn’t have a spacesuit in the right size.

Anne McClain and Christina Koch were scheduled to walk together in space on Friday to change the batteries on some of the International Space Station’s (ISS) solar panels. What would have been a triumphant end to Women’s History Month came to an abrupt halt after realization that both astronauts would require medium-size torso components, in which the ISS only has one.

The mission will still go underway; however male astronaut Nick Hague will replace McClain.

"... after consulting with McClain and Hague following the first spacewalk, mission managers decided to adjust the assignments, due in part to spacesuit availability on the station," a NASA statement said.

"McClain learned during her first spacewalk that a medium-size hard upper torso -- essentially the shirt of the spacesuit -- fits her best. Because only one medium-size torso can be made ready by Friday, March 29, Koch will wear it.”

There has been a strong online reaction to the news, shifting a harsh spotlight onto the unsuspecting agency.

Immediate responses were seen on all social media networks with many seeing the change as another frustrating strike against progress for women participating in space missions. NASA sent their first female astronaut on a mission over three decades ago.

The agency even saw a response from politician Hillary Clinton, whose solution was to tweet “Make another suit” and whilst it might look good online, making another suit is no easy task and has been a sensitive issue with NASA before.

A 2017 inspector general report highlighted the need for new spacesuits as the ISS currently only houses eleven suits, all designed over forty years ago. The startling number was also followed up by the report further stating that NASA is still “years away” from having a new space suit ready for future deep-space missions. The 20 million dollar price tag on each suit doesn’t help the cause either.

Whilst it is disappointing that this major milestone for women in space won’t be reached this week, it’s more an important topic of safety rather than sexism.

"This decision was based on my recommendation," McClain tweeted yesterday (March 27). "Leaders must make tough calls, and I am fortunate to work with a team who trusts my judgement.”

We must never accept a risk that can instead be mitigated. Safety of the crew and execution of the mission come first."

Students at the Durban University of Technology (DUT) and at the Technical Vocational Educational and Training (TVET) institutions in South Africa are facing a horror situation at the beginning of their academic year.

At DUT some of the students are responsible. Their protests have been followed by vigorous retaliation from private security and have resulted in the shutting down of the institutions.

Students at the Durban University of Technology (DUT) have protested at the living conditions in their accommodation and also at the shortage of it. On the 5th of February, one of the twenty-year old students was killed by a private security guard; this forced the protests into overdrive.

The students have charged the National Student Financial Aid Scheme (NSFAS) with conspiring with DUT to defraud funds. They believe The NSFAS allocates thousands of rands to the university, for its student accommodation, but then squeezes eight or nine of them into apartments designed realistically for three.

The students say they could find much better accommodation if they were given access to the money themselves.

The accommodation troubles go further: DUT has accommodation available for 13,000 students, but has a student population numbering 30,000.

To alleviate this DUT is reportedly paying the landlords of apartments, in the surrounding town, to evict tenants. According to investigative journalism program, Carte Blanche, tenants who have lived in those apartments for decades are being given eviction notices to make way for the incoming students. The landlords reportedly agree to marginally renovate the apartments and then accommodate 8 students in a single apartment.

Sadly, apart from the student uprising, crime is also on the rise around the DUT campus. Women in particular say they do not feel safe.

Five of DUT’s campuses have suspended their academic programs due to a stalemate in conversation between the management and the student representative council headed up by the Economic Freedom Fighters (EFF).

To make matters worse for students in South Africa, in the more northern city of Pretoria, members of the National Education, Health and Allied Workers’ Union (Nehawu) have gone on strike citing ‘horrible working conditions’. They also made mention of low salaries and useless pension benefits. The strike meant that lecturers linked with the unions would effectively ‘down tools’ and not teach students in the TVET sector.

Workers from 50 TVET colleges were involved in the strike. Nehawu vowed to shut down all TVET and CET colleges around the country.

International standard

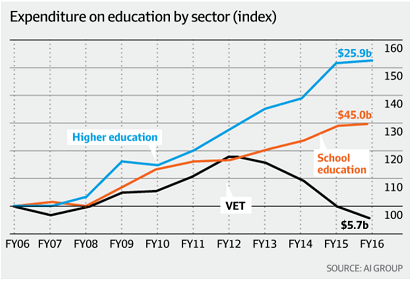

South Africa simply seems unable to sustain the TVET colleges they have. Constant shutdowns and general maladministration is stifling the academic progress of prospective technologists and future engineers.

Student leadership of the African National Congress believes that TVET college qualifications should be recognized as equal to university degrees. And yet at TVET colleges lecturers are striking and rebuffing professional development which does not bode well for the system.

Badly resourced and with a dwindling pool of skilled lecturers the TVET colleges are not only hindering their students, but also the country; South Africa and the South African economy desperately need able, vocationally trained graduates.

There are alternatives, of course, and one of them is the Engineering Institute of Technology (EIT). South African students can acquire Australian qualifications via a live and interactive platform of learning, from home.

EIT offers Bachelor of Science degrees (in 4 engineering fields), (and Master degrees) and a host of Advanced Diplomas. Away from the potentially disruptive elements of a campus and the scramble for accommodation students can attain a high quality qualification, accredited by the Australian Government, from the safety and comfort of their own homes.

EIT’s mission is to prepare students for work in the fields of engineering and technology. The technology used in the online learning platform enables learners to practice the theory they learn and they receive industry-driven content from an international team of engineering experts, who teach live online. There are also supported by dedicated Learning Support Officers throughout their studies.

The schools of engineering at EIT include:

- Data Communications and Industrial IT

- Industrial Automation, Instrumentation and Process Control

- Electrical Engineering

- Mechanical Engineering

- Civil Engineering

- Electronic Engineering

- Engineering Management

Visit the website and enquire today!

Works Cited

“Carte Blanche.” YouTube, YouTube, www.youtube.com/channel/UCW67mIQxNQ3G2AHffz8Bvvw/videos.

Ncobela, Stanley. “TVET Colleges Need Serious Attention from Government.” SowetanLIVE, Sunday World, www.sowetanlive.co.za/opinion/columnists/2019-02-14-tvet-colleges-need-serious-attention-from-government/.

Cameron Russell Bourne is an engineering and technical specialist with a background in Energy, Oil & Gas and Heavy Marine industries. He is currently employed at Synergy, a large energy supplier in Western Australia as a Mechanical Technician.

His day-to-day responsibilities at Synergy see him presiding over a plethora of systems. He says:

“I perform a wide range of tasks including inspection; fault diagnosis, investigations, condition monitoring, reliability testing, balancing, commissioning, and providing analytic reporting services for plants & systems used in large thermal power-generation processes. These systems include boiler, turbine, auxiliary plants, pumps, high-grade steam, pressure equipment, mobile plants, and fire, raw water and reverse osmosis systems.”

Cameron enrolled in and graduated through the Advanced Diploma of Mechanical Engineering Technologies with the Engineering Institute of Technology. He was a runner-up for the Graduate of the Year 2018, as announced at EIT’s Australian graduation.

Not only does he assist in the Oil & Gas industry, but he is also dedicated to the Emergency Response industry, and is a firefighting and emergency operations specialist too. How did Cameron manage to juggle all of these industries and manage to study at the same time? He chalks it up to EIT’s online delivery. He says:

“The online delivery of this course via the webinars and web page correspondence was the only way possible for me to achieve this qualification without having to give up my country lifestyle and regional location — this education model suited me very well.”

But, it wasn’t all smooth sailing. Cameron found that he had to break some old habits to get through the course successfully — going from never having studied online to studying entirely online was a new experience for him. However, something that motivated him throughout the course was the character and approachability of the lecturers.

“They have great background knowledge and in most cases are up to date with the latest technologies relating to the content of any particular module. They were always ready for further discussion post webinars and responded to any email queries within a reasonable time frame.”

Applying what’s been learned

Cameron has leveled up from engineering tradesman to a technician role in his workplace, since pursuing his qualifications with EIT. He has no doubts that the high level of success he was able to achieve in his workplace is because of his professional development. He said:

“In the role that I currently work in, I am fortunate enough to be able to use all of the skills that I have learned over the past 18 months and my development as a Mechanical Technician has gone from strength to strength.”

Now, he says, his time management skills are far better than they used to be. He says he is also more prepared for working with multidisciplinary teams in his workplace and feels more confident that he can get things done. He concludes:

“Having a deeper understanding of how and why things work, means I have developed a greater knowledge of how to manage their associated risks. I have found that my skill set as an emergency services officer has also been enhanced, which has been beneficial not only for my employer but also for the community in which I live.”

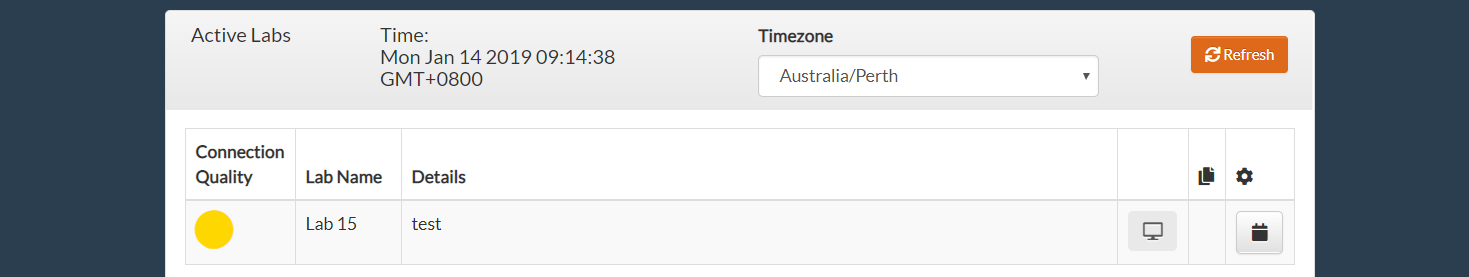

Remote invigilation - otherwise known as online proctoring - might just be the critical factor when measuring the success of online higher education. Online education without digital supervision would naturally be a sticking point for education accreditation boards across the globe. It is not surprising, therefore, that online proctoring solutions are growing.

The Engineering Institute of Technology (EIT) have been hard at work developing the IRIS Invigilation (IRIS). It is a cloud-based platform which utilizes machine learning to monitor students during online examination and tests.

This software program helps provide educators assurance of assessment integrity during online and remote assessment. IRIS records audio, video, and computer screen activity for the duration of a test/exam. It analyses this information using machine learning and automatically flags potential academic dishonesty displaying the data in an easy to use reporting dashboard.

Screenshots are taken at intervals and sent to the invigilating program, this is to double-check what students are seeing on their screens. If anything other than what should be there is detected, the program flags this as suspicious.

IRIS is cloud-based – this means that no heavy software is required on a student’s device; in fact it is so lightweight it can run on a web browser. Furthermore, because the machine learning is largely responsible for identifying potential cheaters, the requirement for staff involvement drops off significantly.

A big benefit to the system is the learning analytics that provide incredibly detailed insight into educational trends and patterns based on real student data. Curtin University told IT News that they hope to see the invention make its way to the ‘rest of Australia's 700 Vocational Education and Training providers’.

A new chapter in online education

Perfecting online proctoring is of utmost importance considering the global online education market is projected to reach a total market size of US$286.62 billion by 2023, as reported by Research and Markets. This means more and more students are opting for online study - but invigilating those students remotely, during examinations, is a tall order. An excerpt of the report reads:

“Platforms that facilitate learning through gaming are gaining popularity, improvements in IT security and implementation of cloud based solutions has increased the adoption rate of online education system as now, people can enjoy a smooth learning experience on safe online platforms. Advancements in the field of artificial intelligence are expected to further boost the growth rate of the online education market.”

Although critical in the virtual classroom, online invigilation is likely to become a useful tool in the physical classroom too – as part of an on-campus, hybrid learning invigilation system. The problems with on-campus invigilation are prompting the change; these include the need for a battalion of human invigilators and the greater margin for error (whereas an automated system can monitor students individually).

In South Africa for instance, even at the Further Education and Training phase (Grades 10 to 12), the Independent Examination Board has instructed schools to install invigilation cameras in any venue where examinations take place.

It is clear that invigilation technologies are becoming more vital to education institutions around the world, but especially to legitimize online education once and for all.

Works Cited

Johnston, Matt. “Benchmark Awards 2019 Finalists: Curtin Uni Remote Exam Invigilation.” ITnews, 4 Feb. 2019, www.itnews.com.au/news/benchmark-awards-2019-finalists-curtin-uni-remote-exam-invigilation-518736.

ltd, Research and Markets. “Global Online Education Market - Forecasts from 2018 to 2023.” Research and Markets - Market Research Reports - Welcome, www.researchandmarkets.com/research/nzxrnp/global_online?w=4.

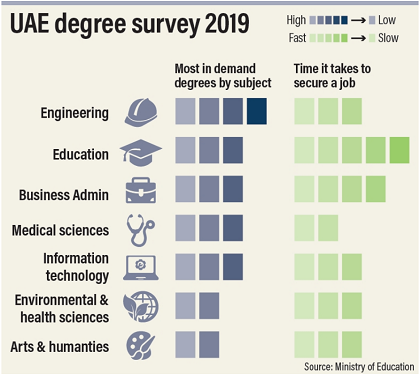

Twenty-five percent of engineering graduates are jobless in India, according to a study published by the All India Professionals Congress. Whereas a study published 1,618 miles away, in the United Arab Emirates, indicates that there are not enough graduates to go around. This is in a region where engineers are highly sought after.

The study in the UAE was named ‘Majors in Demand’ and was conducted by the Ministry of Education. The study took a look at over 13,000 graduates from government and higher education institutions who graduated in 2017.

They found that civil engineers were most in demand, but believe that their findings would be a useful guide to undergraduates generally.

The Minister of State for Higher Education and Advanced Skills in the UAE told state media:

“This study is an ideal forecasting tool for students”

The study in India paints a grimmer picture than that painted by the UAE. The country seems to have a glut of engineering graduates with not enough jobs available for them.

The report out of India comes from the All India Professionals Congress. They canvassed 2,600 engineering graduates, finding that 25 percent of the graduates were unable to find employment.

All India Professionals Congress secretary Sudheer M told media:

“It is the need of the hour that we consider education a serious factor in the country’s progress. This prompted me to conduct a study of engineering education to start with.”

The Times of India goes on to report on which graduates are having more luck: mechanical engineers are most likely to be employed, but that civil engineering graduates are also being hired.

Of the students canvassed, however, 80 percent indicated that they felt a lack of connection to the engineering industries in the country.

This connection to industry is something the Engineering Institute of Technology (EIT) feels is critical to a graduate’s success. And to this end the college works hard to contextualize all theory, add real practice into the engineering bachelor and master degrees and expose students to the relevant industries during their studies.

EIT also ensures that their industry-driven content is presented by experienced engineers from around the world. The online students interact with these experts in real time and the students on campus in Australia receive a combination of face-to-face teaching and globally-based lecturers streaming into their classrooms. EIT believes that graduates who are immersed in real engineering, throughout their studies, are more likely to find the jobs they dream of.

Works Cited

NewIndianXpress. “25 Per Cent Engineering Graduates Are Jobless, Says Study.” The New Indian Express, The New Indian Express, www.newindianexpress.com/states/kerala/2019/feb/03/25-per-cent-engineering-graduates-are-jobless-says-study-1933544.html.

Nowais, Shireena Al. “Engineering Graduates Most in Demand in UAE.” The National, The National, 9 Jan. 2019, www.thenational.ae/uae/education/engineering-graduates-most-in-demand-in-uae-1.811254.

TOI-Online. “Which Branches of Engineering Has the Highest Demand? - Times of India.” The Times of India, Business, 16 Jan. 2019, timesofindia.indiatimes.com/home/education/news/which-branches-of-engineering-has-the-highest-demand-bu/articleshow/67555535.cms.

Conflict and war are commonplace around the world and civilians are inevitably trapped in the midst of them. It is gratifying to report that engineering skill, in conjunction with technology, are working to alleviate some of the fall-out for the people caught up in these situations.

This doughty combination of technology and skill is making relief efforts more manageable: getting food, water, and medicine to those regions effected by war. It is also proving remarkably effective in remote areas.

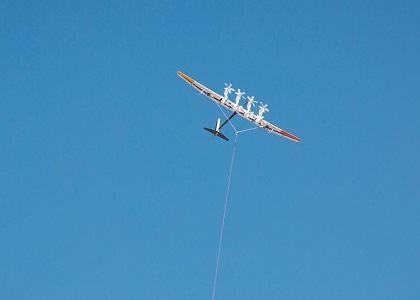

Australian company, Swoop Aero, is using drones specifically built for the betterment of healthcare. The company has been founded for the purpose of ‘redefining healthcare with airborne mobility’.

The company operates an on demand, high speed, autonomous airborne logistics network. And they have proven their usefulness on the Pacific island of Erromango, in Vanuatu.

ABC News was with the Australian company while they delivered vaccines to the island; an island notorious for low vaccination rates for children.

Separately the people of Erromango have been suffering with hepatitis and tuberculosis; vaccines for these maladies have also been successfully deployed by Swoop Aero.

UNICEF comments that Vanuatu’s ‘extreme remoteness’ makes delivery of vaccines, via traditional methods, very difficult. The nation is in fact an archipelago - made up of roughly 80 islands that stretch over 1,300 kilometers.

The United Nations International Children’s Emergency Fund (UNICEF) chartered the drone flights from Swoop Aero which are perfectly engineered for autonomous vaccine delivery.

On the company’s website Swoop Aero asserts that the drones can navigate the most hard-to-reach areas of the world. They write:

“Inhospitable terrain, unpredictable waterways, mountain ranges, poor infrastructure, traffic congestion, and long distances limit the capabilities of ground transport.”

The drones can travel at 100 kilometers per hour and are powered by batteries.

Unexpected variables

Nurses sometimes hike to reach the villages with the medicines they think the children and adults require. The villagers, however, often move from place to place, making it difficult to estimate the needs of each community. The drones proffer a solution because of their ease of mobility; they are more ably meeting the demands of the villages.

The price of drones has dropped considerably too, despite improvements to the technologies powering them. This drop in cost is making their use more viable in rural and remote villages.

Eric Peck, co-founder of Swoop Aero, told ABC News:

“It’s something that has been around for quite a while now, but we’re at this inflection point where for the first time we are seeing the cost of technology get down to a point where it’s economically efficient to use it.”

The Australian company is officially trialing the drones in Vanuatu and will measure the success of the project on completion. The system appears to be working with the backing of the Vanuatu government, UNICEF and the Australian government.

This is another example of how engineering can shape the world’s landscape for the betterment of humankind.

Works Cited

Dziedzic, Stephen. “A Two-Day Walk for Vaccines Is Now Just 20 Minutes Away with Drone Delivery in Remote Vanuatu.” ABC News, Australian Broadcasting Corporation, 18 Jan. 2019, www.abc.net.au/news/2019-01-19/using-drones-to-deliver-crucial-vaccines-to-remote-vanuatu/10728350.

Peck, Eric. “Vanuatu Uses Drones to Deliver Vaccines to Remote Island: BBC.com.” Swoop Aero, swoop.aero/swoop.aero/vanuatu-uses-drones-to-deliver-vaccines-to-remote-island-bbc-com/.

Ian Shivraj Doolun is originally from the Indian Ocean island of Mauritius. He completed his Bachelor of Engineering in Mechatronics with first class honors at Monash University. Upon obtaining his Bachelor of Engineering, he got offered a job at one of the best companies in automation and process control in Mauritius, where he worked for two and a half years as an Industrial Control Programmer.

Ian wanted to develop his career further and gain the cutting-edge automation knowledge needed as the Fourth Industrial Revolution continues to transform the engineering world. He decided to enroll in the Engineering Institute of Technology's Masters of Engineering (Industrial Automation). He reflected:

“I was surrounded by intelligent minds, and as a beginner I had to catch up quickly to integrate into the team and be able to provide efficient solutions. Doing the Masters course gave me a competitive advantage over my peers, both in terms of knowledge and chances of promotion.”

Ian then set his sights on Australia. Settling in Sydney, he is now working as an Automated Guided Vehicle (AGV) Project Engineer.

“The contents of the course aligned with my job. Some of the key modules that had a positive impact on my work were Programmable Logic Controllers; SCADA and Distributed Control Systems, and Industrial Process Control among others. I was also better at communicating my ideas, both technically and professionally. The course really stimulated my thinking process and enabled me to conduct my job more efficiently and effectively.”

Ian worked his way through the course so masterfully we are proud to recognize him as one of the finalists for EIT’s Graduate of the Year Award 2018. Ian did, however, learn the hard way in terms of simultaneously balancing work and his studies. But, eventually, a silver lining manifested. He said:

“The biggest challenge, at first, was the work-study balance in terms of time and dedication, but after the first couple of semesters, I got used to it. The assignments were also very challenging in some cases, but this allowed me to be more independent and enhance my research skills. The master’s thesis was also very strict in terms of schedule.”

Ian said through doing the course, he better understood industrial concepts and implementation strategies in the automation world. He concluded:

“I definitely applied what I learned to my work. My output at work improved tremendously.”

He is also about to take his Certified Associate in Project Management exam at the Project Management Institute, to further qualify him in his field. He said:

“I strongly believe that my strength resides in project management since I have very strong people and communication skills. However, I am always keen to enhance my knowledge of automation and other innovative topics.”

South Africa is a country with 27% of its population without work. Spirits have not been high for at least a decade; a struggling economy has been limping around entrenched and widespread governmental corruption. Thanks to a recent discovery, however, followed by an announcement by integrated oil and gas company Total, the country has perked up a little. Total said in a statement:

“We have made a significant gas condensate discovery on the Brulpadda prospects in the Outeniqua Basin, 175 kilometers off the southern coast of South Africa.”

The CEO of Total, Patrick Pouyanne, told journalists that there “could be around one billion barrels of global resources, gas and condensate light oil”. The site, in deep waters 175km off of the country’s southern coast, is in the proximity of a town named Mossel Bay.

Kevin McLachlan, senior vice-president of exploration at Total told the Financial Times:

“With this discovery, Total has opened a new world-class gas and oil play and is well positioned to test several follow-on prospects on the same block.”

South Africa benefits greatly as well. The country has been relying on oil imports for its national needs - now it is right on the doorstep. Experts say the find could lead to a growth of South Africa’s economy to the tune of more than USD $73 billion - or R1 trillion.

With a rig to be set up just off the coastline the South African Oil and Gas Alliance will be focusing on how to develop the skills of workers and ensuring engineering professionals are prepared for the forthcoming projects.

The announcement of the discovery came just at the right time for President Cyril Ramaphosa’s State of the Nation Address. Ramaphosa hoped the speech would encourage investor confidence in the country. In the speech about Total’s discovery, he said:

“Last night I received a call from Minister Gwede Mantashe {Mineral Resources Minister}. He told me that the oil giant Total would be making a big announcement today about a new ‘world-class’ oil and gas discovery off the coast of South Africa. We are extremely encouraged by the report….. which some have described as a catalytic find. This could well be a game-changer for our country and will have significant consequences for our country’s energy security and the development of this industry. We congratulate Total and its various partners and wish them well in all their endeavours. Government will continue to develop legislation for the sector so that it is properly regulated for the interests of all concerned.”

Eye Witness News reported that PetroSA is also very happy with the announcement. Their gas-to-liquid plant is allegedly running lower than 50% of its design capacity. This is heartening for the labor market too with the likely growth in jobs, from rig to refinery.

The next step for Total is utilizing 3D seismic data measuring equipment, after which drilling can begin. The drilling alone will reportedly be the largest scale hydrocarbon exploration project in the world.

Works Cited

Keohane, David. “Total Strikes South African Oil and Gas Find.” Financial Times, Financial Times, 7 Feb. 2019, www.ft.com/content/07b7798c-2abc-11e9-a5ab-ff8ef2b976c7.

Lauren Isaacs. “SA Offshore Gas Find Could Yield 1 Billion Barrels, Says Total.” Eyewitness News, 7 Feb. 2019, ewn.co.za/2019/02/07/sa-offshore-gas-find-could-yield-1-billion-barrels-says-total.

It is never pleasant to focus on engineering industry shortcomings. However, when new aircraft fall out of the sky, with multiple fatalities the result, the ugly business of discovering the faults commences.

On Sunday, 10 March 2019, a Boeing 737 MAX 8 (flight ET302) belonging to Ethiopian Airlines crashed just six minutes after takeoff from Addis Ababa. It went down on its way to Nairobi, Kenya, crashing into a town known as Bishoftu. Of the 157 people onboard, there were no survivors.

This crash was eerily similar to the Indonesian Lion Air Flight 610 which went down over the Java Sea in October 2018. It was the fact that they were both Boeing 737 MAX models which resulted in the inevitable comparisons. Both aircraft were iterations of a new series touted as ‘technologically advanced’ and more efficient than planes that had come before.

Worryingly, in both crashes the aircraft were only months old – essentially brand new. The US Federal Aviation Administration (FAA) reports that th

“The unmatched reliability of the MAX means more 737 flights depart on time with fewer delays. And technological advanced plus powerful LEAP-1B engines are helping to redefine the future of efficient and environmentally friendly air travel.”

Upon hearing the news of the Ethiopian Airlines crash, Chinese, Singaporean, Indonesian, Australian, Mexican and Argentinian airlines temporarily grounded their 737 MAX planes almost immediately – a ban which has now become a global one. Consultations with Boeing’s engineers and technical experts has begun, as has an investigation into what caused the Ethiopian plane to crash.

The United Kingdom took a hardline stance on the 12th of March 2019, the Civil Aviation Authority confirmed that they would ban all 737 MAX aircraft and would not allow any to enter UK airspace.

The regulator said in a statement:

“We have, as a precautionary measure, issued instructions to stop any commercial passenger flights from any operator arriving, departing or overflying UK airspace.”

This caused chaos for passengers - with some flights being diverted or turned back midair!

American President Donald Trump also weighed in on the conversation about modern day aircraft. Two days after the Ethiopian Airlines crash he tweeted:

“Airplanes are becoming far too complex to fly. Pilots are no longer needed, but rather computer scientists from MIT. I see it all the time in many products. Always seeking to go one unnecessary step further, when often old and simpler is far better. Split second decisions are needed, and the complexity creates danger. All of this for great cost yet very little gain. I don’t know about you, but I don’t want Albert Einstein to be my pilot. I want great flying professionals that are allowed to easily and quickly take control of a plane!”

Over complicating the aircraft?

Experts are treating both the Lion Air and Ethiopian Airlines crashes as suspicious. The Indonesian flight going down 13 minutes after take-off and the Ethiopian one going down after just 6 minutes is alarming aviation analysts.

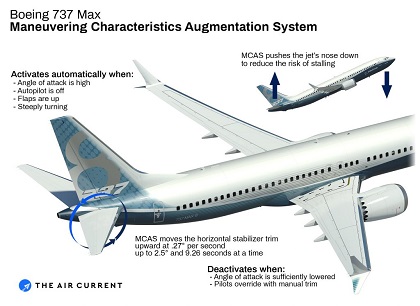

Boeing has announced that it will release software updates for the 737 Max jets by April. The work on the software tweaks started after the Lion Air disaster. This began after it was reported that the pilots in the Lion Air disaster had trouble with a new feature added to the Maneuvering Characteristics Augmentation System (MCAS). It is alleged that the pilots may have not had any control over the plane after the MCAS software kicked in.

The MCAS was implemented when they noted that the new engines Boeing had fitted to their 737 tended to push the aircrafts’ noses upwards. The MCAS sensors were designed to respond to the aircrafts’ upward nose tilt and trigger the software to push the plane into a semi-nosedive to prevent a stall. It is alleged that the software reacted when the planes were still climbing and pushed the two planes into nosedives which the pilots could not correct.

Boeing later said that the pilots in the Lion Air disaster should have taken the necessary steps to disable the software.

Boeing, after the Ethiopian Airlines crash, has had to defend their software, indicating that pilots do have the ability to override the software.

“It was put through flight testing as part of the certification process prior to the airplane entering service. MCAS does not control the airplane in normal flight; it improves the behavior of the airplane in a non-normal part of the operating envelope.”

Works Cited

Bazley, Tarek. “Control System under Scrutiny after Ethiopian Airlines Crash.” News | Al Jazeera, Al Jazeera, 11 Mar. 2019, www.aljazeera.com/news/2019/03/control-system-scrutiny-ethiopian-airlines-crash-190311094532350.html.

“Boeing.” Boeing: Philip M. Condit, 109380-Leslie Nichols, www.boeing.com/commercial/737max/.

Ostrower, Jon. “What Is the Boeing 737 Max Maneuvering Characteristics Augmentation System?” The Air Current, 23 Nov. 2018, theaircurrent.com/aviation-safety/what-is-the-boeing-737-max-maneuvering-characteristics-augmentation-system-mcas-jt610/.

Planet Labs has launched 146 satellites into space — officially it's the largest fleet of satellites in human history. The company began engineering the satellites with the intention of making each one roughly the size of a loaf of bread. They each weigh 12 pounds (5 kg).

The satellites are engineered by former NASA employees. Unlike when they were working for NASA, the turnaround time for the creation of these satellites is much shorter. They are as easy to design and build as a smartphone is.

The satellites orbit the globe every 90 minutes taking photographs of the earth below. Co-founder of Planet Labs Dr. Will Marshall spoke to the news program, Sixty Minutes, about what can be seen on the images these satellites take of the earth. He said:

“We see rivers move, we see trees go down, we see vehicles move, we see road surfaces change and it gives you a perspective of the planet as a dynamic and evolving things that we need to take care of.”

They call the satellites doves and release them in flocks. 28 small satellites have recently been launched by astronauts aboard the International Space Station. The flocks spend their time snapping away, generating many images of the ever-changing earth, providing insights for those viewing them. The satellites generate 1.2 million photographs every 24 hours.

Planet Labs now allows companies, academics, farmers, and governments to access their data sets and images for research and — in the government's case — spying on other nations. They currently have 200 customers that utilize their images of the globe.

Planet Labs is now giving the U.S. government a much clearer picture of parts of the earth that they have never been able to investigate before.

Historically, dozens of engineers would have to be working on one satellite, but the company has revolutionized the industry. Making the satellites and more manageable has led to one engineer working on a dozen satellites. They have turned the tables on the satellite industry. The company has engineered around 300 satellites over the years, refining and learning from the process as they go along.

And sometimes, those lessons have been hard ones. On one of their launches, 26 satellites were destroyed in a launch accident when one of their rockets sending satellites up to the space station fell to the ground and exploded. The engineers immediately snapped back into action and quickly began work on meeting the demand for those lost satellites.

The founders of Planet have seen technology develop in record time. In their careers at NASA, it would take 5 to 10 years to get a satellite to space - now, it takes only a couple of weeks.

Works Cited

“Private Company Launches ‘Largest Fleet of Satellites in Human History’ to Photograph Earth.” CBS News, CBS Interactive, www.cbsnews.com/news/private-company-launches-largest-fleet-of-satellites-in-human-history-to-photograph-earth-60-minutes/.

Surely civil engineers who get to work on the world's largest and most up-and-coming vacation spots are the envy of their profession!

South Korean (and Spanish) civil engineers will be hard at work on the world’s largest man-made surf park in Turtle Island, South Korea very soon. Spanish wave pool company Wavegarden made the announcement in November 2018, reporting that they had signed a contract with Daewon Plus Construction — who happen to be South Korea's largest real estate and theme park developers.

Turtle Island, a man-made island (literally in the shape of a turtle) is just an hour away from Seoul, the capital of South Korea. The image you are seeing above is the open land at Turtle Island where the hotels, Wavegarden park, and the marina will be constructed.

In their press statement, Wavegarden wrote:

“Constructed on land reclaimed from the ocean, Turtle Island is a new international waterfront destination, which will have different water and landside leisure facilities including hotels, convention centers, and marinas. The centerpiece of the 2.1 billion Euro (about $2.3 billion USD) avant-garde mixed-use development will be the Wavegarden Cove surfing lagoon.”

They intend to have the wave park open in 2020. The surf park will have a one-kilometer ‘beach front' that will provide lots of space for holiday goers. The Cove - an artificial wave generating pool - will reportedly create 1,000 waves per hour. Wavegarden says surfers of all ability levels are welcome. In their press release, they also talked about the novel engineering technologies that they work with:

“The state-of-the-art machinery can produce millions of waves per year and is designed to recover part of the energy used in the wave generation process to attain the lowest possible energy consumption. The innovative water treatment system, developed specifically for wave lagoons, will keep the water transparent and clean throughout the year. Its intelligent design uses the energy of the waves to acquire the highest level of energy efficiency available nowadays for large recreational water bodies."

Fernando Odriozola, Chief Commercial Officer at Wavegarden, told media:

“With consistent waves of different sizes and shapes, Turtle Island is going to be the new beach of Seoul and the place to surf for families, professional surfers, and everyone in between.”

And what better way to enjoy the world’s largest surf park than to surf the waves on the world’s most cutting edge carbon fiber surfboard? Alright, it’s a pretty regular surfboard with all things considered, but it is ‘engineered’ in collaboration with Tesla and Matt Biolos' Lost Surfboards. Elon Musk got the surfboard company to partner up with Tesla to create 200 boards and sell them for USD $1,500 each.

Wavegarden reports that they have signed a host of new contracts that will see Wavegarden technology making its way into five continents around the world. Two other wave pools are being built in Melbourne and Bristol.

To see what a Wavegarden experience looks like, see the video below:

Works Cited

SurferToday.com, Editor at. “Tesla Surfboard Accelerates down the Line.” SurferToday, SurferToday, www.surfertoday.com/surfing/tesla-surfboard-accelerates-down-the-line.

“Worlds Largest Surfing Lagoon: South Korea.” Carvemag.com, 7 Feb. 2019, www.carvemag.com/2019/02/worlds-largest-surfing-lagoon-south-korea/.

Toshiba Corp and General Electric have unveiled the robot that will again try to achieve what no robot has been able to accomplish before it; locating and removing the spent, melted nuclear fuel of the Fukushima Daiichi nuclear reactor number three.

The cleanup and decommissioning of the three nuclear reactors that fell victim to meltdowns after a powerful earthquake and subsequent tsunami in 2011 is ongoing. The cleanup will cost the equivalent of USD$190 billion.

The path to decommissioning began with locating the spent, melted nuclear fuel inside the reactors. No human can withstand the radiation levels present in the reactors. Consequently, radiation-resistant robots have been sent down to attempt to locate the fuel. But, all the robots that were entrusted to finish the job have all stopped short due to the large radioactivity present in the reactors.

However, a probe with a camera attached to it successfully managed to get images of the melted fuel in Unit 2’s reactor last year. The other two reactors’ melted fuel is still unseen, but engineers are confident they have detected it and can find it easily.

Back in 2017, the cleanup crew sent a Toshiba robot named the Scorpion Robot down to the No. 2 Reactor. The radioactivity caused the robot to stop midway and disabled one of the wheels. There is still no indication of where the spent fuel exactly is.

Engineers have tried four-legged robots, stair-climbing robots, robots with wheels, robots that could swim through water, and more. They all seemed to be unable to complete the mission.

In with the new

The new robot by Toshiba Energy Systems & Solutions Corp and GE is a device engineered to traverse into the hard to reach places in the nuclear reactors. The robot will go down an 11-meter long pipe and will be in reach of the melted nuclear fuel in Unit 2.

The robots are fitted with tongs that will attempt to grip the melted fuel and extract it. It also has lights and electronic measurement equipment at the tip of the pipe that will do the relevant tests the engineers need to determine if the extraction is done safely and efficiently.

Jun Suzuki, a Toshiba ESS group manager for the project said:

"Until now we have only seen those deposits, and we need to know whether they will break off and can be picked up and taken out. Touching the deposits is important so we can make plans to sample the deposits, which is a next key step."

The issue is that there might not be anything of value to pick up with the robot’s tongs when the robot goes down into the reactor in February of this year. However, the engineers at Toshiba say if the robot is unable to lift anything out of the reactor, that will also be a key finding. The Fukushima Meltdown aftermath is an engineering conundrum of epic proportions, and it's not over yet. Perhaps the engineers may have just figured out how to get closer to ending it with their novel tong-robot. Even if it's by taking baby steps.

Works Cited

“Toshiba Unveils Robot to Probe Melted Fukushima Nuclear Fuel.” Phys.org - News and Articles on Science and Technology, Phys.org, phys.org/news/2019-01-toshiba-unveils-robot-probe-fukushima.html#jCp.

“Toshiba Unveils Robot with Tongs to Probe Melted Fukushima Nuclear Fuel.” The Japan Times, www.japantimes.co.jp/news/2019/01/29/national/science-health/toshiba-unveils-robot-tongs-probe-melted-fukushima-nuclear-fuel/#.XFCmWVwzZPY.

South Africa's energy utility is in dire straits. On the 11th of February 2019, the utility's engineers implemented Stage 4 load shedding on South Africa's main energy grid. Stage 4 load shedding indicated that the country was short 4,000MW of the peak capacity requirement of 27,000 MW due to what the utility called ‘continued pressure’ on the national grid.

The utility has 45,000 MW of energy capacity installed, but cannot meet the peak demand of 27,000MW. Experts say the current situation reeks of gross incompetence at the very top levels of management at Eskom.

The country has never experienced Stage 4 load shedding in its history but is well acquainted with Stage 2 which the country saw intermittently in 2018. The new stage meant that South Africans would see their lights turned off twelve times in the space of four days.

Eskom pointed to the fact that there are six generators not functioning correctly in the country. Moreover, the utility's mega power stations —Medupi and Kusile — reportedly have major design and technical flaws that are causing the stations to underperform. What is clear is plant breakdowns, a lack of plant maintenance, a shortage of trustworthy engineers, and poor management of the energy grid, in general, has led to an energy crisis in South Africa.

The impact of the power cuts reportedly costs the country R2.5 billion (USD $181 million) in business revenue every day the lights are off.

South African President Cyril Ramaphosa recently delivered a State of the Nation address wherein he declared that Eskom would be unbundled. It would be broken up from one large organization and divided into three organizations.

This seems to have rung the alarm bells of the National Union of Mineworkers, the National Union of Metalworkers, the South African Communist Party and the Economic Freedom Fighters. They believe that the utility should continue to be state-owned, and assert that the unbundling of the organization points to the likelihood of privatization in the near future. If privatization follows, the previously mentioned groups may protest.

The financial problems Eskom has undergone in the last decade has led to incredible uncertainty for electrical engineers across the organization. The utility was R40 billion rand in debt in 2008. Ten years later, the debt has risen to over R400 billion.

Eskom has also been helping electrical engineering students complete their tertiary education with financial assistance in the form of bursaries. Upon graduation, the electrical engineers would have to work for Eskom to pay off the bursary. However, graduates who received bursaries from the parastatal in the last four years were informed at the beginning of 2019 that the salaried work they were to do was no longer available due to the financial trouble the organization is in.

Most worryingly, the utility has asked the prospective engineering staff that cannot work for the organization after graduation to sign an addendum to postpone the working obligation until they have recovered financially.

This means the graduates must either wait for the parastatal to turn a profit, or must go and find a job in the industry - but might face a disruption when the parastatal asks for them to return to work to repay their debt. Alternatively, the organization could write the employment contracts off. Nonetheless, the utility is disrupting the lives of electrical engineers in South Africa and stringing them along, leaving them in a state of limbo in their careers.

President Ramaphosa says that he is ‘shocked and angry’ at the events that have transpired in the Eskom debacle. He has also been quoted saying that the parastatal can no longer go about their business with all of their eggs in one basket. Diversifying the way Eskom does business seems to be in the country’s best interest.

However, privatization is not on the cards just yet. That, according to Public Enterprises Minister Pravin Gordhan who told media:

"In the Sona last week, the president did not talk anything about privatization. We are going to bring in external power stations engineers, get an independent audit on exactly what's going on so that we put Eskom back on track and give South Africans the assurance that we have an entity that is able to give us the energy security we require.”

Works Cited

“Load-Shedding Has Entered a Third Consecutive Day and Continues to Affect Most South Africans.” YouTube, YouTube, 12 Feb. 2019, youtu.be/k4vLv0f8b2U.

Dentlinger, Lindsay. “Pravin Gordhan Concedes Eskom Is Facing Massive Problems.” Eyewitness News, Eyewitness News | EWN, 12 Feb. 2019, ewn.co.za/2019/02/12/pravin-gordhan-concedes-eskom-is-facing-massive-problems.

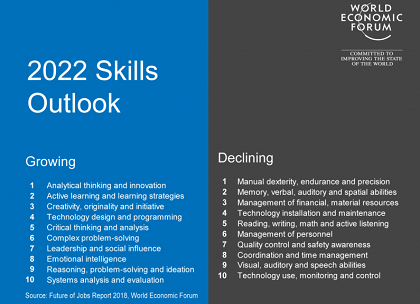

Today is International Women's Day. EIT is celebrating the women who are currently filling positions in the engineering industry across the globe. However, most experts are cognizant that more needs to be done to encourage women to enter the engineering industry.

The World Economic Forum reports that women account for just 11% of employees globally in architecture and engineering. The number is shockingly low, but the fight for women’s representation in engineering is beginning to gain traction.

Microsoft and KRC Research conducted a study on the STEM industry named Closing the STEM Gap: Why STEM classes and careers still lack girls and what we can do about it.

Dr. Shalini Kesar, Associate Professor at the Department of Computer Science & Information Systems at the Southern Utah University, writes:

“For years, girls and young women have been a critical missing part of Science, Technology, Engineering and Math (STEM) studies and careers. The stubborn gender disparity in STEM fields has sparked important debates on the underlying reasons. Some attribute the gender disparity to social and infrastructural factors, lack of mentors and role models, and lack of awareness about what these fields offer in terms of educational and career opportunities.”

She says the archaically held view that engineering is ‘boring' and ‘only for boys' dissuades females from joining the industry. The report says girls ‘have a hard time picturing themselves in STEM roles.'

So, what can be done to convince girls that STEM is cool, a great career choice, and an industry to stay in until retirement? Schools are saying it starts in the classroom at an early age — STEM subjects and after-school clubs are the perfect way to do that.

Clubs for girls

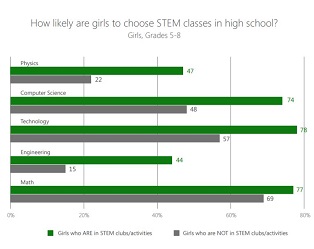

Microsoft and KRC Research report that 44 percent of middle-school girls who participated in STEM clubs or activities, said they would likely continue engineering studies after school. Only 15 percent of girls who were not in STEM clubs or activities said they would pursue engineering studies after school.

The numbers (seemingly) don't lie: educators should implement better mechanisms inside their schools to get girls interested in STEM.

Another way to encourage young women to get involved in STEM fields is through mentorship programs with successful female engineers. Essentially, attracting and retaining females in STEM industries should be prioritized in a world calling for equal representation.

Dr. Shalini Kesar would agree and chalks the confidence she has in herself as a woman in STEM to the spurring on her parents did when she was younger. She wrote:

“My parents used to tell me that, ‘even if you are one drop of water in an ocean, it is those drops combined that make the ocean.’ Across southern Utah, I see a domino effect: when one girl sees the power in STEM and computing, she becomes a role model for her friends and community.”

Works Cited

“Our Insight, Your Breakthrough.” KRC Research, www.krcresearch.com/.

“The Engineering Mystery: Where Are the Women?” The Globe and Mail, The Globe and Mail, 6 Mar. 2019, www.theglobeandmail.com/business/careers/article-the-engineering-mystery-where-are-the-women/.

In the United States, the Midwest and Northeast have shivered their way through a winter they won't forget. They are calling it the coldest temperatures in a generation. If boiling water was thrown into the air, it would instantly freeze. The deep freeze is reminiscent of the Sci-Fi film The Day After Tomorrow.

The North Polar Vortex has caused these freezing conditions — it pushed Chicago's temperatures down to -46 degrees Celsius. That is colder than Antarctica, Alaska and the North Pole.

The vortex was disrupted at the north pole, ejecting strong winds high up in the atmosphere, traveling southward. These offshoots of the vortex retained the cold from the Arctic region and carried these to parts of America.

A state of emergency has been declared in Wisconsin, Illinois, and Michigan.

The wholly adverse side effects of the cold snap were the fatalities caused by it. The vortex affected the lives of more than 89 million people.

Schools were shut down, flights canceled, and the post office had to abandon their operations as well.

The engineering challenges

One of the biggest concerns with a deep freeze this potent was the infrastructure. How would it cope with the freezing temperatures? The first to freeze was the water infrastructure — the water mains froze over, essentially cutting the water off.

With winds picking up in the Chicago area, many were at risk of being without electricity as branches fell onto power lines. The lower temperature can also cause overhead power wires to contract and cause breakages and result in power outages. Some areas in Chicago were without power as the cold air was dumped on the city.

Consequently, engineers had to be called out to restore electricity to customers.

Soon after the polar blast came down on Chicago, the train tracks became a concern in the cold temperatures too. Reports started flying in that they were beginning to ice over completely. Civil engineers sprung into action to prevent the tracks from contracting and cracking due to the cold.

The engineers utilized the gas-fed system already fitted on the tracks to keep the flames going. In Chicago, the system is used during normal winters anyway — but this time it was working to its fullest extent. With the contracting of the steel, the snapping of the railways where they are bolted is possible. The fire allows the rail to expand again, where they can then be re-bolted or welded to the other tracks.

Experts are saying with the United States seeing more bomb cyclones and polar vortexes, closer attention should be given to climate events. This is because of the engineering works required before and after an incident. Climate change is proving that aging infrastructure globally may not be ready to withstand these events.

Works Cited

Gstalter, Morgan. “Chicago Using Fire to Keep Rail Tracks from Freezing in Polar Vortex.” TheHill, The Hill, 30 Jan. 2019, thehill.com/homenews/state-watch/427654-chicago-using-fire-to-keep-rail-tracks-from-freezing-in-frigid.

Williams, Corey. “Polar Blast Envelops U.S. Midwest, Strains Aging Infrastructure.” CP24, 30 Jan. 2019, www.cp24.com/world/polar-blast-envelops-u-s-midwest-strains-aging-infrastructure-1.4274848.

Hassan Mwanjali is an Engineering Institute of Technology (EIT) graduate who acquired his Advanced Diploma of Applied Electrical Engineering. He is currently working at the Diplomatic Mission at the Embassy of Japan in Tanzania as a Maintenance Engineer.

“I oversee the satisfactory conduct of property services including but not limited to Embassy of Japan general maintenance, power systems, power generators installations, and maintenance, electrical installation works, air conditioning works, water pumps, and plumbing works.”

He found EIT advantageous because he could both retain his position at the Embassy and he could professionally develop his engineering skills.

He is trying to reach his goal of becoming a fully decorated electrical engineer. He reckons that the technological growth of power electronics in the industry is fascinatingly developing.

“The gained knowledge and skills from the Engineering Institute of Technology enhanced my workmanship to a great extent. They added to my practical experience and hence made me execute my duties with more simplicity, more confidence, more accuracy and more expeditiously.”

Hassan utilized his time after hours and on the weekend to study and train through EIT, working through the syllabus, continually being motivated to complete modules and get to the finish line. Next, he would like to pursue his Bachelor of Science of Electrical Engineering through EIT.

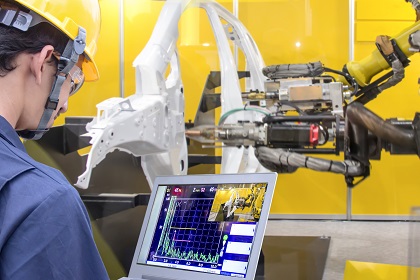

Industrial automation can transform the landscape of a country's workforce and economy.

Countries are transitioning from mining economies, into manufacturing economies with the sometimes unseen fourth industrial revolution's slow march.

Berg Insights reported that 4.6 million wireless devices were shipped globally in 2018 for the purpose of industrial automation. Industrial automation accounted for six percent of newly connected IoT nodes. It also meant that the number of devices connected for Industrial Automation reached 21.3 million in 2018.

Wireless devices are flowing into the industry replacing previous technologies that do not have the kinds of monitoring and data generating technology that modern-day sensors and communication devices do.

The Berg Insights report also points out that smart wireless devices monitoring the entire manufacturing process will lead to more ‘predictive maintenance.' The likelihood of manufacturing equipment lasting longer than its predecessor has increased with the new Industry 4.0 technology emerging in the industry. As a result, there will be less wasting of money for maintenance and more for the payment of employees.

Rockwell Automation's On the Move event for 2019 was held in India. It saw industry leaders encouraging the country to embrace automation to turn India into a manufacturing economy.

Rockwell Automation is so interested in growing the manufacturing output of India that they have recently branched into the country. Dilip Sawhney, Managing Director of Rockwell Automation India, said:

“We want to take the lead in building India’s first industry 4.0 ecosystem of partner companies that will create solutions for The Connected Enterprise that can analyze machine conditions in advance to avoid breakdown and enhance productivity but also improve on quality and compliance parameters.”

John Watts, Regional Marketing Director, for Asia Pacific at Rockwell Automation added:

“Globally, digital-induced disruption is inevitable. To maintain and improve global competitiveness, Indian manufacturers need to accelerate the adoption of Industry 4.0. While India has a lot of catching up to do in this respect, it can accelerate digital transformation by leveraging its strengths in the IT services sector and tapping the entrepreneurial spirit seen in the start-up sector.”

The experts at Rockwell believe that if India adopts more automation technologies, their combined factory output would make manufacturing a US$ 1 trillion business by 2025. Rockwell Automation has partnered with L&T, Cisco, Microsoft, Endress+Hauser, and Wipro Infrastructure Engineering to help develop smart manufacturing solutions in India.

Works Cited

“Industry 4.0 Tech Can Triple India's Factory Output, Says Rockwell Automation.” Tech Observer, 22 Jan. 2019, techobserver.in/2019/01/22/industry-4-0-tech-can-triple-indias-factory-output-says-rockwell-automation/.

IoT.Business.News. “The Installed Base of Wireless IoT Devices in Industrial Automation Reached 21.3 Million in 2018.” IoT Business News, IoT Business News, 21 Jan. 2019, iotbusinessnews.com/2019/01/21/62655-the-installed-base-of-wireless-iot-devices-in-industrial-automation-reached-21-3-million-in-2018/.

Petro Chisale is never in one place for too long -- he goes where his electrical and instrumentation expertise is required. He graduated from the Engineering Institute of Technology (EIT) with an Advanced Diploma of Electrical and Instrumentation (E&I) Engineering for Oil and Gas Facilities.

After high school, Petro attended Masvingo Polytechnic in Masvingo, Zimbabwe to do an electrical power engineering course. After he obtained his qualification, he became a class one journeyman electrician with an industrial attachment at the then Rio Tinto Renco Mine.

He later joined the National Oil Company as an electrician at the Beitbridge Oil Depot on the South Africa-Zimbabwe border. From there, he went into Harare to work as an assistant electrical technician before moving back to the border as a maintenance technician.

Currently, Petro is working at another oil terminal in Mutare on the border with Mozambique as a tank farm operator.

Every day he coordinates the receipts, storage, loading and transfer functions of quality cleared petroleum products. He produces all of the relevant reports for the management of the terminal. He also supervises assistant tank operators. The daily responsibilities of his roles include:

- Receiving products by road, rail and pipeline

- Plan for and clear petroleum products for loading in advance

- Monitor local and inter-depot transfers of petroleum products

- Accounting for all petroleum products

- Maintaining quality of the product in storage tanks

- Coordinating the suck back and spillage recovery programmes

- Tank farm security

- Supervision of subordinates

It sounds like quite a bit of work for one man to do, but Petro says the combination of interfacing with technology and field work is what he likes about the job. He said:

“I started my job at a remote oil terminal where there were no institutions to help improve myself through studying. I also found myself being transferred to different stations where I could not enroll or engage with conventional college setups. So, when I started online training, I discovered it was the best fit in my situation. As I moved from one oil terminal to the other, I would meet new technologies which coincidentally would be part of the program I studied.”

The fact that there is always something new to learn in the industry and to see new technologies getting implemented in it gives Petro the motivation he needs to keep going. He has already applied for the Bachelor of Science in Electrical Engineering with EIT.

We wish Petro all the very best in his challenging career and as he studies towards his Bachelor’s degree.

Universal access to clean drinking water is a challenge our world continues to face.

According to the World Health Organization (WHO), 2.1 billion people lack safe drinking water at home. That equates to 3 in 10 people worldwide. Moreover, twice as many people don't have access to basic sanitation.

The treatment of wastewater throughout the world is essential — that recycled water is used as drinking water in some cases.

Students and professors at the University of New South Wales and the Australian National University have for years been trying to develop what they believe is a new low-cost alternative to killing bacteria in wastewater.

Professor Ninham told The Australian:

“The work is the culmination of 40 years of pure undirected curiosity-driven research. In particular, the cost and destruction caused by viruses in water remains an unresolved challenge and poses a major limitation on the use of recycled water. Here, we develop an environmentally friendly technology for sterilising water.”

This particular methodology is being touted as a world first. The universities say their treatment methods have sterilized the water from bacteria, diseases, and drugs. These diseases include E-coli and potentially even Ebola.

The scientists engineered new technology that utilized carbon dioxide (C02) as a way of treating wastewater. They reached the conclusion that the C02 was instrumental in killing bacteria and eliminating the viruses present in the dirtiest kinds of water. The researchers noted that C02 was an essential factor in nature, in the way that it killed viruses and prevented infections.

These findings were published in the Nature journal. This treatment method had also proven useful for bringing the price of desalinating water down. Researchers found they were able to eliminate heavy metals like arsenic, lead, mercury, and radioactive waste through a novel bubbling process. Professor Ninham said:

“The technology bubbles heated unpressurised carbon dioxide or exhaust gases through wastewater in a bubble column, effectively destroying both bacteria and viruses. The process is extremely cost-effective, with no concerning by-products."

Similar work is being done all over the world, to develop new technologies for water treatment. Scientists and engineers are finding new ways to treat water that don't involve mechanical filters and membranes.

A system was also developed at Princeton University in 2017. The low-cost silicone rubber tube splits into two channels. Pressurized C02 goes through one of the channels, and the water goes through the other.

The carbon dioxide gas then mixes with the water, creating charged hydrogen and bicarbonate molecules. They separate the wastewater particles and let the filtered water pass through.

The Australian technology allows unpressurized C02 to be used in treating the water.

The Australian researchers say that their way of doing things will lead to less plastic bottle waste due to the treating of water straight from the source, and will also bring down the number of Ebola outbreaks in places like Africa.

Works Cited