News

Space travel is heating up again. The tongue-in-cheek way people are choosing to treat this new boom in space pioneering, is by calling it the second space race. Except this time it’s billionaire versus billionaire. Business giants like Virgin’s Richard Branson and Amazon and Blue Origin’s CEO, Jeff Bezos, are looking to the skies, and hoping to define the future of space travel. Another one of the esteemed gentleman at the helm of the new age of space travel is South African born Elon Musk.

Musk famously said: “If one can figure out how to effectively reuse rockets just like airplanes, the cost of access to space will be reduced by as much as a factor of a hundred. A fully reusable vehicle has never been done before. That really is the fundamental breakthrough needed to revolutionize access to space.”

SpaceX recently achieved the breakthrough and have made aerospace engineering history by reusing a previously launched, refurbished rocket. The company sent the rocket into orbit and brought it back down to land, on a drone barge in the ocean. The rocket in question was SpaceX’s Falcon 9. It retained its original engines and components and delivered a satellite for company SES at a fraction of the price.

Reusing rockets will minimize the costs of future rocket launches, and save money on engineering rockets from scratch. SpaceX says the majority of the price of a rocket launch is the building of the rocket itself. Prices will be driven down if the reusability technology becomes commonplace in the aerospace industry.

After a USD$1 billion investment and fifteen years in the making, SpaceX was ready to launch a previously launched rocket into orbit, and bring it back down again. SpaceX’s President, Gwynne Shotwell, says that they are just getting started:

“Looking forward for reusability, we don’t believe it really, really counts unless you can turn it around rapidly, or almost as rapidly, as you turn around an aircraft. Our challenge right now is to refly a rocket within 24 hours. That’s when we’ll really feel like we’ve got reusability right.”

According to Popular Mechanics, the Russian government was initially undecided on reusable rocket technology unsure it would turn a profit for their aerospace giant, Roscosmos. However, after the success SpaceX achieved, they are now reconsidering.

The Chief of Roscosmos Igor Komarov said: “The innovations SpaceX is making are forcing us to work on lowering the cost and raising the product quality. We are running pilot projects in the sphere of retrievable components.”

The Russians risk being left behind in this Space Race 2.0, if they don’t start acquiring the engineering skills necessary to engineer reusable rockets. SpaceX and America’s space authority NASA are linking arms to take another giant leap for mankind and take crafts to Mars by 2020. SpaceX have also said that they would be flying two tourists to the moon in 2018.

The reusing of already engineered components is a philosophy that is seldom tried so remains largely untested. However, electric vehicle (EV) companies, like Musk’s Tesla Motors, are testing their already engineered hardware for reuse. And some headway has been made elsewhere.

Reusable batteries for cars and homes

For quite some time now, car companies working on the implementation of electric vehicles on our roads, purported that once a car-powering lithium-ion battery had served its purpose within an electric vehicle (in accordance with electric vehicle standards), it could be taken out of the car and used as a home-powering energy storage device afterward.

According to experts in the field, the lithium-ion batteries in electrical vehicles still retain 70% to 80% of their energy storage capacity after they reach the end of their legal life cycle inside the vehicles. The idea was that once the battery had been used in the vehicle and was ready for decommissioning, it could be added to a photovoltaic solar array and be used to store the energy produced for the electricity used to power a home during peak demand times.

General Motors realized in 2016 that a 2012 Chevrolet Volt that had driven 300,000 miles had no battery degradation issues – a clear sign that the battery could be reused outside of the vehicle.

“Even after the battery has reached the end of its useful life in a Chevrolet Volt, up to 80 percent of its storage capacity remains,” said Pablo Valencia, GM’s senior manager for Battery Life Cycle Management.

However, a new report by Lux Research, an independent research and advisory firm in the United States, claims that recycling the lithium-ion batteries, instead of reusing them, is the best way forward for the automotive industry. An excerpt from the report read:

“Reuse of batteries from electric vehicles will deliver questionable returns on account of reduced performance, limiting them to application with less frequent and shallower depth of discharge cycles.”

Christopher Robinson, Lux Research Associate and the author of the report named ‘Reuse or Recycle: The Billion-Dollar Battery Question’, said:

“With present technology, recycling old batteries for new materials is the more economical option for creating the most value from existing materials. That said, innovations in areas like packaging and testing could tip the balance in the future, so companies should have plans for both recycling and reuse.”

BMM and Nissan both recently announced that their respective electric vehicles would be able to reuse the batteries as home energy storage systems in the near future. However, Lux Research cautions that the companies need more efficient testing, sorting, and repackaging than that which has already been advertised. Robinson says that second-life systems or the EV battery to wall systems, offer only limited cost savings and not much else.

However, BMW’s Manager of Connected eMobility Cliff Fietzek asserted that people could power their homes for 24 hours with the decommissioned batteries from their i3 EV car models. He said:

“It doesn’t make sense to scrap the battery at the end of the useful life of the car because it’s still good for services like powering your home. The car battery may be over designed for a home storage system, but well suited.”

Works Cited

Grossman, David. "After SpaceX's Success, Russia Wants a Reusable Rocket Too." Popular Mechanics. 04 Apr. 2017. Web. 06 Apr. 2017.

"Recycling, Not Reuse, Is the Better Choice for Batteries from Retired Electric Vehicles." Recycling, Not Reuse, Is the Better Choice for Batteries from Retired Electric Vehicles | Lux Research. 22 Nov. 2016. Web. 06 Apr. 2017.

Shanklin, Emily. "Reusability." SpaceX. SpaceX, 23 Mar. 2013. Web. 06 Apr. 2017.

A grim reality the world has had to face in the modern age is the fact that the planet’s waterways are overwhelmingly polluted. Much of it is unfortunately thanks to the technologies and products engineered in the past.

A grim reality the world has had to face in the modern age is the fact that the planet’s waterways are overwhelmingly polluted. Much of it is unfortunately thanks to the technologies and products engineered in the past.

Humans need to put their waste somewhere; most of the time it is the ocean that gets the tough task of handling it all.

The National Ocean Service at the U.S. Department of Commerce reports that most ocean pollution begins on land. In fact, 80% of pollution that is prevalent in the marine environment comes from land, the group says. The biggest contributors are from nonpoint sources. The group writes:

“Nonpoint source pollution includes many small sources, like septic tanks, cars, trucks, and boats, plus larger sources, such as farms, ranches, and forest areas. Millions of motor vehicle engines drop small amounts of oil each day onto roads and parking lots. Much of this, too, makes its way to the sea.”

One of the places that effluence gathers and creates visible pollution ‘soups’ is The Great Pacific Garbage Patch. The Patch is a supposed Texas-sized, floating island of marine pollutants. It is also known as the Pacific Trash Vortex. Plastics and other pollutants apparently swirl around the ocean from the West Coast of North America all the way to Japan, according to National Geographic.

The Ocean Clean-up Project

Expertise has been garnered to eradicate pollution in the ocean, initiatives that have been realised in response to concerted pleadings from environmentalist communities. The technological solutions envisioned are challenges faced by those with a bent for engineering design and involve a range of organizations.

Conventional methods of ocean clean-up have involved trawling through the oceans with nets to catch plastics and other floating pollutants. One organization developing pollution-ending technologies, Ocean Cleanup, believes this method is slow, inefficient, and in some cases harmful.

In June of 2016, Ocean Cleanup - a non-profit foundation - unveiled a prototype of their large-scale plastic catcher.

The Ocean Cleanup Project’s Prototype - Credit: YouTube.com

Boyan Slat is a 21-year-old Dutch inventor and entrepreneur and also the founder and CEO of the Ocean Cleanup project. He is behind the novel ocean-cleaning design; a design which was named one of Time Magazine’s top 25 inventions of 2015.

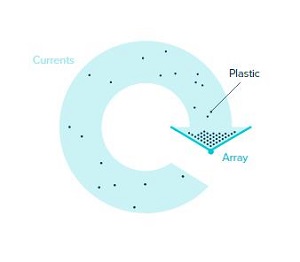

“Why move through the ocean, if the ocean can move through you? So, I came up with this passive system, which would allow the natural ocean currents to do the hard work for us,” Slat told an audience in a prototype unveiling.

The prototype funnels plastics and garbage into an area where it all collects in a V-shape formation barrier. The prototype prevents plastics from traversing physical barriers and targets floating plastic - on and near the surface. The organization installed the prototype in June of 2016. They are ready to peruse their findings and present arguments for the further utilization of the technology. The feasibility of the project will be calculated this year, and if successful the world will see the first placement of the plastic catcher by the end of 2017.

A spokesman for the Project commented, “Computer models showed that with a single one of those systems, deployed for ten years, we should be able to clean up about half of the Great Pacific Garbage Patch. Or more, if we were to deploy more systems.”

Prototype unveiling

Has it lived up to the hype?

Two oceanographers, Kim Martini and Miriam Goldstein, have had their reservations about the feasibility of the technology. In an email to the Guardian, Martini wrote that Ocean Cleanup was not well read on “oceanography, ecology, engineering and marine debris distribution.”

The oceanographers are not sure the designs Ocean Cleanup have presented will be useful in capturing the volume of plastic. They felt strongly enough to offer their own review of how unfeasible the project is.

Other experts point out that it is better to trap plastic at source, instead of waiting for it to disperse across a large area of ocean. It has been estimated that it can take 50 years for plastic that has just been introduced into the ocean, to reach the Great Pacific Garbage Patch.

The Guardian reports that 19 billion pounds of plastic will make it into our oceans this year alone. Further engineering innovation is needed to nip the problem in the bud.

Lapping up the oil

Cleaning up the mess resulting from engineering endeavours has also become a bone of contention, especially with offshore oil drilling operations. Oil spills are a nasty by-product of the oil industry and of great harm to the oceans’ ecosystems.

A group of science and engineering researchers at Argonne National Laboratory at the University of Chicago have presented a possible solution to minimizing the effects oil spills have on the ocean and its marine wildlife. They suggest that they could soak it up before it becomes a problem.

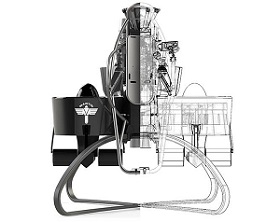

The researchers presented the Oleo Sponge to the internet this March; an invention which soaks up oil and petroleum products and removes them from the water.

The laboratory showed in a demonstration that the Oleo Sponge worked efficiently at minimizing prevalent oil within water, and fared better than “industry-standard” technologies. The sponge is also reusable. The researchers say they are still testing the product, but are looking for licensing partners to allow them to sell the sponge to private companies.

A prototype of a sponge that can be used to extract oil from water. Credit: The University of Chicago

“We already have a library of molecules that can grab oil, but the problem is how to get them

into a useful structure and bind them there permanently,” said Seth Darling, a student of the University of Chicago’s Institute for Molecular Engineering. He is one of the scientists contributing to the new sponge.

As Mary Shelley, author of Frankenstein, said, “Invention, it must be humbly admitted, does not consist in creating out of void, but out of chaos.” She may have lived before the world faced such unprecedented levels of pollution, but her words, aided by her fertile imagination, ring true.

Works Cited

"Argonne News Brief: Oleo Sponge Soaks up Oil Spills from Water." YouTube. 06 Mar. 2017. Web. 27 Mar. 2017.

"Boyan Slat Unveils The Ocean Cleanup Prototype." YouTube. 30 June 2016. Web. 27 Mar. 2017.

Kratochwill, Lindsey. "Too Good to Be True? The Ocean Cleanup Project Faces Feasibility Questions." The Guardian. Guardian News and Media, 26 Mar. 2016. Web. 27 Mar. 2017.

https://www.brainyquote.com/quotes/keywords/invention.html

The breakthroughs in the biomedical engineering industry are staggering. For instance, the world has moved closer to a system of wearable diagnostic tools that are designed to continually monitor human health – consider the Fitbit for instance. And ideas that had previously been designated to the realm of science fiction are becoming reality.

One such advanced study involves ingestible robots, used for retrieving swallowed button batteries and also for the treatment of the wounds they cause. In the US alone 3,500 batteries are reportedly swallowed annually. These robots are controlled by magnets on the outside of the body, but some robots may eventually be powered by stomach acid.

With biomedical engineering technologies becoming more apt at generating data about the human body and with more accuracy, the world is edging closer to more precise medical diagnoses.

Robert F. Graboyes, a senior researcher at the Mercatus Center at George Mason University, has said that wearable telemetry will redefine the future of doctors’ appointments. In his article, ‘Wearable Telemetry - Eating Health Care’, he writes:

“Wearable telemetry (Jawbone and Fitbit are familiar examples) is helping to overturn 2,500 years of medical tradition. For the first time, wearables offer convenient, passive, continuous monitoring of vast numbers of human bodies. Implications for the doctor-patient relationship are profound.”

Patients will be equipped with data that doctors might have to peruse and consider, before diagnosing a patient.

However, the affordability of wearables in a time when there is still a stark gap between rich and poor highlights the need for affordable novel applications for medical diagnosis in the biomedical engineering industry.

Smartphone apps

Credit: HearScreen.com

Audiologists in South Africa are making it as wallet-savvy as possible, by installing an app on your smartphone.

“Hearing loss is considered an invisible epidemic because people don’t see it or know that someone suffers from it,” said De Wet Swanepoel, a professor of audiology at the University of Pretoria, South Africa, in an interview with the BBC.

The project that Prof Swanepoel worked on has led to the development of an app called HearScreen. All you need is your smartphone and a pair of headphones. The app uses a series of beeps that tests the hearing of the person through the headphones. Based on what they can and cannot hear, the app determines the extent of medical assistance required.

The app is not only ensuring that poorer rural communities get the diagnoses they need, but it also addresses the shortage of audiologists in South Africa.

“Mobile apps can serve a very useful role in raising awareness about hearing and making hearing care more accessible. But if a mobile app for hearing assessment is not accurate this can give incorrect information to the user, which can be harmful,” Dr Shelly Chadha, technical officer for deafness and hearing at the World Health Organization, speaking to BBC News.

A report compiled by Research2Guidance revealed that there are 259,000 health apps available on the app stores available to smartphone users.

But wait...there’s more

In a surgery first, a robot stitched up a pig’s small intestine. Relying on its own tools and artificial vision and intelligence it carried out the procedure without assistance. Furthermore, the procedure performed by this Smart Tissue Autonomous Robot (STAR) was deemed to have been completed more ably than by human surgeons who were given the same task.

One would predict that real, mortal surgeons might consider this robot dexterity and prowess threatening. On the contrary; one of the researchers on the STAR project, a paediatric surgeon, was not in the least concerned, saying, “Even though we surgeons take pride in our craft at doing procedures, to have a machine that works with us to improve outcomes and safety would be a tremendous benefit.”

And the sky is the limit: robots that allow doctors to login from around the world through internet connections, and perform surgeries from hundreds of miles away, are no longer merely futuristic notions.

It is indeed an exciting time for would-be students interested in both engineering and medicine. Biomedical engineering offers a number of options, from software design to the design, building and maintenance of machinery and gadgets for medical facilities.

Dean of Engineering at the Engineering Institute of Technology (EIT), Dr Steve Mackay, presented at the annual Biomedical Engineering Conference in Canberra, in Australia last week. As an educator he spoke of the challenges faced by EIT’s course designers endeavouring to expose students to just the right mix of content in this dynamic and broad field of engineering. He also spoke of his delight in the technologies available today which enable the instructors to reach students all around the world on a live, interactive platform.

The Engineering Institute of Technology offers an Advanced Diploma in Biomedical Engineering. The course brings together applied science and engineering, interspersed with electrical and electronic engineering. Advanced Diploma of Biomedical Engineering.

Works Cited

Jackson, Tom. "The 'invisible Epidemic' Afflicting Millions Globally." BBC News. BBC, 14 Mar. 2017. Web. 22 Mar. 2017.

"Wearable Telemetry - Eating Health Care – InsideSources." InsideSources. 21 Mar. 2017. Web. 22 Mar. 2017.

HearScreen. "Main." Hearscreen. Web. 22 Mar. 2017.

Hardesty, Larry. “Ingestible Origami Robots.” 12 May 2016

Strickland, Eliza. “Autonomous Robot Surgeon Bests Humans in World First.” 4 May 2016

http://remotesurgery.wiki-site.com/index.php/Main_Page

It was the world’s worst nuclear disaster.

(The Chernobyl Disaster 2015).

The catastrophic Chernobyl disaster occurred on 26 April, 1986. Chernobyl, the nuclear power plant in Ukraine, is responsible for thousands of deaths, including large numbers of people suffering from premature cancers linked to exposure to the deadly radiation (The Chernobyl Disaster 2015).

The accident occurred during an experiment to test a way of cooling the core of the reactor in an emergency situation (The Chernobyl Gallery n.d). The reactor design was flawed and was operated with inadequately trained personnel. A chain reaction began after the reactor vessel broke during a power surge. The resulting fire carried the radioactive material into the atmosphere and spread across a vast area. The extent of the radiation can be seen below.

Radiation across Europe (Otro Mundo Es Posible 2015).

What went wrong?

Firstly, there was a deficit when it came to process control; partly explained by the fact that the plant was built for military purposes. It was designed to operate a constant loading in a plutonium production mode. Secondly, in the Soviet Union at the time the dominant philosophy invested faith in the worker - the operators in this instance (who unfortunately lacked adequate training). Automation was viewed with suspicion as it impacted on jobs (Chernobyl Did Not Need to Occur 2009).

The control room of reactor 3, not 4. (The Chernobyl Gallery n.d)

The experimental procedure was intended to run as follows:

- The reactor was to be running at a low power level, between 700 MW and 800 MW.

- The steam-turbine generator was to be run up to full speed.

- When these conditions were achieved, the steam supply for the turbine generator was to be closed off.

- Turbine generator performance was to be recorded to determine whether it could provide the bridging power for coolant pumps until the emergency diesel generators were sequenced to start and provide power to the cooling pumps automatically.

- After the emergency generators reached normal operating speed and voltage, the turbine generator would be allowed to freewheel down.

(The Chernobyl Gallery n.d.)

Prior to the accident the operators violated the plant’s technical specifications. The operators ran the plant at very low power, but without following the safety procedures (Nuclear Energy Institute 2015).

The reactors were unstable at low power, primarily owing to control rod design and ‘positive void coefficient’ factors. Without sufficient cooling for the reactors when the water levels dropped the nuclear chain reaction and power output accelerated.

Consequently, these factors all lead to an uncontrollable power surge, which destroyed Chernobyl reactor 4. This created an immediate increase in heat, which shattered a few of the pressure tubes containing fuel. The hot fuel reacted with water and caused a steam explosion lifting the 1,000-metric-ton cover off the reactor. The pressure tubes ruptured causing a second explosion which exposed the reactor’s core to the environment (Nuclear Energy Institute 2015).

The fire burned for 10 days. Deadly radioactive material escaped into the environment.

Could this disaster have been prevented?

In short, yes.

If the process controls had been properly designed, the Chernobyl disaster could have been averted. Additionally, with more able and appropriately trained operators the outcome may have been less catastrophic (Chernobyl Did Not Need to Occur 2009).

The International Atomic Energy Agency created a group known as the International Nuclear Safety Advisory Group. In its report in 1986 it supported the theory of operator error, “the catastrophic accident was caused by gross violations of operating rules and regulations” (INSAG safety report).

Overall, this detrimental accident proved that a process must be understood before it can be controlled. The most experienced control engineers would all tell you this (Chernobyl Did Not Need to Occur 2009).

Are you interested in learning more?

The Engineering Institute of Technology (EIT) have an array of engineering programs. The School of Industrial Automation, Instrumentation and Process Control is dedicated to this area of expertise, which would have been invaluable in this Chernobyl disaster. If this area is of interest, have a look at the programs offered: http://www.eit.edu.au/engineering-institute-technology-eit-school-industrial-automation-instrumentation-and-process-contro

Additionally, EIT’s Master of Engineering (Safety, Risk and Reliability) is an ideal gateway to boost your capacity to tackle these real world increasingly complex issues, specifically in; safety, risk and reliability. This carefully designed learning journey will develop factual understanding and also exercise participant’s creativity and design-thinking capabilities. Employers are hungry for these skills, and program graduates can expect a significant advantage when interacting with employers, clients, consultants and fellow engineering peers.

Gallery from the Chernobyl Disaster:

A sea of gas masks is left behind in an abandoned building (It Looks like our Planet after Humanity Disappears 2016).

An innocent child who was affected by this horrific engineering failure (Chernobyl Disaster 2013).

An abandoned park (World Remembers 30th Anniversary of Chernobyl Disaster 2016).

Looking into the reactor (The Chernobyl Gallery n.d.).

Inside Chernobyl: Rare Footage of the disaster zone. Have a watch of this YouTube video

We would love to hear from you. Please send us your comments and/or personal experiences relating to this infamous disaster.

References:

Arbor, A. 2016. World Remembers 30th Anniversary of Chernobyl Disaster. [ONLINE]. Available at: https://bhavanajagat.com/2016/04/26/world-remembers-30th-anniversary-of-chernobyl-disaster/

Alvarez, B. 2015. Otro Mundo Es Posible. Avaialble. [ONLINE] Available at: http://www.otromundoesposible.net/contaminacion-radiactiva-incidentes-en-la-industria-nuclear/. [Accessed 4 March 2017].

Bogdan. 2015. The Chernobyl Disaster. [ONLINE] Available at: http://historyconflicts.com/chernobyl-disaster/. [Accessed 1 March 2017].

Chernobyl Disaster 2013, ‘The affects to children after the Chernobyl disaster’, Twitter post, 16 October. Available at: https://twitter.com/chernobyl_facts

Grossman, P. 2014, Inside Chernobyl: Rare footage from ruins left by world's greatest nuclear disaster, YouTube video, 5 December. Available from: https://www.youtube.com/watch?v=VvH7BRubFIg

Liptak, B. 2009. Chernobyl Did Not Need to Occur. [ONLINE]. Available at: http://www.controlglobal.com/articles/2009/chernobyl0907/. [Accessed 20 March 2017].

Moore, C. 2016. It Looks like our Planet after Humanity Disappears. [ONLINE]. Available at: www.dailymail.co.uk/news/article-3556058/

Paul. n.d. The Chernobyl Gallery. [ONLINE]. Available at: http://chernobylgallery.com/chernobyl-disaster/cause/

Safety Series No. 75-INSAG-4, IAEA, Vienna, 1991. Available from: http://nuclearsafety.info/safety-culture/

2015. Nuclear Energy Institute. [ONLINE]. Available at: https://www.nei.org/Master-Document-Folder/Backgrounders/Fact-Sheets/Chernobyl-Accident-And-Its-Consequences

China’s National Energy Administration (NEA) has announced that all construction projects for new coal power plants will be cancelled, effective immediately. Instead, the NEA is investing $361 billion into expanding renewable energy technologies in an effort to reduce the crippling smog levels in many cities in China. The number of coal power stations that will be halted, according to Reuters, is “over 100”.

The Independent predicts that the move from coal to renewable power will reportedly generate 13 million jobs in the renewable energy sector in China.

Credit: Pixabay.com

The job losses in the coal industry will be extensive, but the plan is to retrain these workers for the oncoming renewables revolution. The reality, however, may not be quite as clear cut or as rosy as hoped.

Australia

Australian experts seemingly have a different story to tell when it comes to renewable energy employment. The Australian Bureau of Statistics (ABS) reported that there had been a 16% drop in employment in June of 2016.

According to ABS’ research, the employment in renewable energy activities was estimated as follows:

|

Year |

No. of employees |

|

2011/12 |

19,220 |

|

2014/15 |

13,300 |

|

2015/16 |

11,150 |

Olivia Kembler, the Head of Policy at the Climate Institute said, “A 16% decline since last year, following after several years of falling job numbers, is a direct result of the government’s failure to set a national strategy for clean, modern energy. That costs us in terms of higher prices, less reliable and more polluting power, but we should also recognize it costs us in terms of the thousands of new jobs that we could have but don’t.”

However, the Minister of Environment and Energy, Josh Frydenberg, said that the figures were not wholly correct. He said that the Australian Renewable Energy Agency was about to announce developments that would lead to 2300 new jobs in the renewable industry - just as the ‘record low’ numbers were reported.

The job situation in the renewable energy sector needs to be monitored – projections of huge growth in employment have not panned out. In Australia small-scale solar installations are on the rise, not the large-scale ones. And yet it is the latter that require labour, alongside their inevitable maintenance issues.

American optimism

Researchers at Greentech Media Research, a media company that publishes daily reports on the renewable energy sector, are optimistic about the future employment prospects for the global electricity market.

They report that they have seen an annual growth of 50% across the global solar market. They have also reported on “major mergers and acquisitions in energy storage companies, and utilities spending billions of dollars in renewable energy technologies”.

The Environmental Defense Fund (EDF) reported that from 2012 to 2015, renewable energy employment figures rose by 6%. Their bolder claim is outlined in the report: ‘Now Hiring: The Growth of America’s Clean Energy & Sustainability Jobs’:

“Solar and wind jobs have grown at rates of about 20% annually in recent years and are each creating jobs at a rate 12 times faster than that of the rest of the U.S. economy”.

The Solar Foundation performed a census of Americans working in the solar energy industry and found that there had been more than 260,000 working professionals actively working in the industry. The figure was three times it was in 2010.

The important question to ask is, ‘Will jobs in the renewable energy sector be retained?’ Some argue that the key to ensuring demand for jobs in this sector continue to rise is up to the government of the day, but automation technologies may yet replace some of those which are presently using manpower.

Automation

“Substation automation, decades ago, removed the need for workers at substations to carry out hour to hour adjustments in the control settings of the grid,” A GTM Researcher told social media site Reddit during a Q&A session.

Automation has been, and will be, a force that replaces the more rudimentary jobs in the energy generation industry.

He went on to say: “Distribution automation is increasingly reducing the number of truck rolls (and with it man-hours) required to manually isolate faults in the grid. Furthermore, new customer service technologies are reducing the need for call center employees - a primary driver of costs within utility retail operations.”

Another researcher at GSM offered a comment about automation as well:

“I’d add that while automation has an effect on the solar market, most jobs scale with demand. Automation is at play in the factory, where modules, inverters, and other solar equipment are manufactured. However, selling those components and installing systems requires real people talking to customers, designing projects, and getting out in the field to build them.”

Finding a job in the green collar sector - as it is being called - has also been a question amongst engineering professionals who want to get involved with what seems like the next big thing. Experts from GTM Research say the key to finding employment in the industry is a combination of networking and ‘developing passion projects’ and showcasing your interests and abilities to future employers.

Works Cited

"Home | Environmental Defense Fund." Home | Environmental Defense Fund. Web. 20 Mar. 2017.

"We Are GTM Research, a Market Analysis Firm Focused on the Transformation of the Global Electricity Industry. AMA • R/Futurology." Reddit. Web. 20 Mar. 2017. The Australian.

http://www.theaustralian.com.au/business/technology/renewable-energy-sector-employment-falls-abs-figures-say/news-story/0d06f72f928e427f0cd983cc1910e6ee"China Halts over 100 Coal-fired Power Projects: Caixin." Reuters. Thomson Reuters, 16 Jan. 2017. Web. 18 Jan. 2017.

“The future wars will be fought over water.”

Are we heading for a future where those who have the cleanest and most abundant water will be the most prosperous? As it stands, to discern which countries are first world and which are third the cleanliness of drinking water is a consideration.

To conserve clean water some have been thinking outside the box. California’s county of Los Angeles has been through a long drought so is ready to go ‘balls to the wall’ to try and save their water.

In 2015, 96 million apple-sized, black polyethylene (plastic) balls were floating in the Los Angeles Reservoir.

American news outlets ran with the story with the following headlines, from the New York Times: In California, Millions of ‘Shade Balls’ Combat A Nagging Drought. And the Washington Post reported: Plastic ‘shade balls’: The hypnotizing tool California is using to save water.

Except, the balls were never intended to be the answer to California’s drought problems. California was utilizing the balls before the drought had ever started ravaging the land. The media had failed to do its research.

Credit: XavierC

All about chemicals

The L.A. Department of Water and Power had been introducing the plastic balls into their reservoirs since 2008. The first few were dumped into the Ivanhoe water reservoir in Silver Lake, Los Angeles.

The county had begun to notice that the UV rays of the sun were turning naturally occurring bromide into bromate. Bromate is a concern for municipal reservoirs around the world - it is a cancer-causing chemical. Silver Lake’s reservoir is especially at risk because, being uncovered, it is directly exposed to sunlight.

The balls were commissioned by the Los Angeles Department of Water and Power to counteract the sun’s UV rays and keep the water safe. Incredibly they delivered a dual benefit: they did indeed keep the water safe from bromate, but they also conserved water by reducing evaporation.

They slowed the evaporation of water and prevented the degradation of its quality, but at a cost - the shade balls cost the state USD$34.5 million, with each ball costing 36 cents. Reducing evaporation would’ve only saved Los Angeles USD$2 million per year. (But the cost savings to individuals who may have contracted Bromate inducing cancers should also be factored in.)

LADWP General Manager Marcie Edwards told NPR:

“This is a blend of how engineering really meets common sense. We saved a lot of money ; we did all the right things.”

Many reservoirs do not need to take these kinds of measures due to being covered; the ones that remain open require preventive measures so that chemical contamination does not occur.

The company that designed and manufactured them is XavierC. They specialize in the manufacturing of the “ballasted plastic conservation balls” and were well aware of their ability to slow evaporation. The company says it is a “cost effective, low maintenance solution for Cities and Municipalities”. The company says the balls should last for 25 years.

The solution is unfortunately not so neat. Richard Harasick, the director of the L.A. Department of Water and Power said that the department knew the shade balls would not be a permanent solution for reservoirs that supply drinking water to Los Angeles. Drinking water reservoirs have to be covered - shade balls allegedly do not comply with the standards needed.

The shade balls are being removed from the reservoirs in L.A. and costly coverings are being built. The shade balls do, however, remain in L.A.’s Reservoir #2 as the reservoir does not hold any drinking water.

The market for creating a technology that conserves water and presents a solution for drought- stricken areas remains.

Works Cited

Maddaus, Gene. "Shade Balls Are a Really Stupid Way to Conserve Water." L.A. Weekly. 02 Apr. 2016. Web. 28 Mar. 2017.

Wagner, Laura. "LA Rolls Out Water-Saving 'Shade Balls'" NPR. NPR, 11 Aug. 2015. Web. 28 Mar. 2017.

Dear Colleagues

Great work! You have been offered a tremendous new engineering job and are poised to accept. Subject to a final negotiation session to finalise the details, of course.

When you are offered a job – this is normally a signal that you are near end of a long road of a job search, investigating the opportunities and then going on interminable interviews. This period of time when you are close to acceptance of the job is a critical one as you have a huge opportunity to shape the job and remuneration – more so than for many years after you have accepted this job offer.

When you are offered a job – this is normally a signal that you are near end of a long road of a job search, investigating the opportunities and then going on interminable interviews. This period of time when you are close to acceptance of the job is a critical one as you have a huge opportunity to shape the job and remuneration – more so than for many years after you have accepted this job offer.

A few suggestions follow below on considering the job. Remember in all your discussions with your would-be employer or HR recruiter that you must stay positive, enthusiastic and level-headed in the discussions. You should always remember that ultimately you may have to reject the job.

Suggestions on Assessing the Job Offer

The Bucks

While salary is a vital component of the job (and often a reason for changing jobs); bear in mind that this is only one component of a happy job. Look at the salary package holistically and trade-off other non-financial benefits such as sick leave / time off / study leave and the actual quality of the job and location. For example, you would be expecting huge compensation for working on a remote mine site for a company with a dubious safety record which is financially highly stressed and which has high turnover of employees. On the other hand; getting a dream job in a beautiful part of the world with fabulous professionals in a very creative industry may not pay as much. Thus do a careful and dispassionate assessment of salaries on the internet, through job sites and recruitment consultants. The latter often have a very good handle on remuneration levels in your area.

Requirements of the Job

What does the job require? What are the daily activities? How many off these tasks do you love and how many do you hate? Are the requirements for the job aligned with who you are and what you enjoy doing? How will you be measured for promotion and success in the job? What are the prospects for growth in the organisation or is it a tiny one-woman band?

People and Culture

What are the people and culture like? Is it a free wheeling flat organisation or frightfully bureaucratic and structured? Which culture do you fit in with? Talk to others who know the business and people and confirm that you will be happy.

Unspoken Benefit/Defects

Unspoken benefits or hidden defects are often a minefield. Investigate carefully the features of the job that no one has explicitly spent too much time talking about. What are the hidden benefits of the job? Lots of international travel to exotic fascinating places? Or perhaps, regular trips to ghastly polluted industrial sites staffed by unhappy people. Is the job flexible allowing you to work from home or to take time off ? Does the company pay for further study with good study leave? Do you work a four day week with longer hours?

Design a Strategic Plan

In going forward it is important to come up with a creative plan to negotiate some additional features or to change the structure in the job to something more aligned with who you are. Above all through the discussions stay positive and enthusiastic about the job. Ensure you don’t sound mercenary after the ‘buck’. You don’t want to poison the relationship with your future employer who may feel that you are avaricious and self-serving.

Do not Hesitate to Say NO

Sometimes, you simply have to say no if you have doubts or unresolved concerns about the job. As Robert De Niro says: When in doubt do without.

Katharine Whitehorn hits the nail on the head with her comment:

Find out what you like doing best, and get someone to pay you for doing it.

Thanks to Rebecca Knight of Harvard Business Review for some inspiration.

Yours in engineering learning

Steve

Mackay’s Musings – 4th April’17 #646

125, 273 readers – www.idc-online.com/blogs/stevemackay

The breakthroughs in the biomedical engineering industry were staggering in 2016. The world moved closer toward wearable systems that could continually monitor human health, and even produced studies for ingestible robots, designed to be powered by human stomach acid.

With biomedical engineering technologies becoming more apt at generating data about the human body and with more accuracy, the world is edging closer to more precise medical diagnoses.

Robert F. Graboyes, a senior researcher at the Mercatus Center at George Mason University, has said that wearable telemetry will redefine the future of doctors’ appointments. In his article, ‘Wearable Telemetry - Eating Health Care’, he writes:

“Wearable telemetry (Jawbone and Fitbit are familiar examples) is helping to overturn 2,500 years of medical tradition. For the first time, wearables offer convenient, passive, continuous monitoring of vast numbers of human bodies. Implications for the doctor-patient relationship are profound.”

Patients will be equipped with data that doctors might have to peruse, and consider, before diagnosing a patient.

However, the affordability of wearables in a time when there is still a stark gap between rich and poor highlights the need for affordable novel applications for medical diagnosis in the biomedical engineering industry.

Smartphone apps

Audiologists in South Africa are making it as wallet-savvy as possible, by installing an app on your smartphone.

“Hearing loss is considered an invisible epidemic because people don’t see it or know that someone suffers from it,” said De Wet Swanepoel, a professor of audiology at the University of Pretoria, South Africa, in an interview with the BBC.

The project that Prof Swanepoel worked on has led to the development of an app called HearScreen. All you need is your smartphone and a pair of headphones. The app uses a series of beeps that tests the hearing of the person through the headphones. Based on what they can and cannot hear, the app determines the extent of medical assistance required.

The app is not only ensuring that poorer rural communities get the diagnoses they need, but it also addresses the shortage of audiologists in South Africa.

“Mobile apps can serve a very useful role in raising awareness about hearing and making hearing care more accessible. But if a mobile app for hearing assessment is not accurate this can give incorrect information to the user, which can be harmful,” Dr Shelly Chadha, technical officer for deafness and hearing at the World Health Organization, speaking to BBC News.

A report compiled by Research2Guidance revealed that there are 259,000 health apps available on the app stores available to smartphone users.

But wait...there’s more

Wearables and smartphone apps aside, surgical robots, with ten times the dexterity of humans, already exist in the biomedical engineering industry and are becoming progressively more adept at what they do.

A new robot used at Mitchell’s Plain District Hospital in South Africa, has performed a knee surgery with more accuracy than ever before. The surgery has been called the 1st robotic knee replacement surgery in the world.

One of the doctors involved in the procedure, Dr Yusuf Hassan, spoke to News24 saying:

“This technology allows you as a surgeon, using the technology and patient’s own anatomy, to place the implants exactly where you want them. And then, not only does it allow you to put the implants where you feel necessary, but it also allows you to assess the soft tissue components.”

And the sky is the limit: robots that allow doctors to login from around the world through internet connections, and perform surgeries from hundreds of miles away, are no longer merely futuristic notions.

It is indeed an exciting time for would-be students interested in both engineering and medicine. A number of options are available to them in the area of biomedical engineering: software design and the design, building and maintenance of machinery and gadgets for medical facilities.

Dean of Engineering at the Engineering Institute of Technology (EIT), Dr Steve Mackay, presented at the annual Biomedical Engineering Conference in Canberra, Australia last week. As an educator he spoke of the challenges faced by EIT’s course designers endeavouring to expose students to just the right mix of content in this dynamic and broad field of engineering. He also spoke of his delight in the technologies available today which enable the instructors to reach students all around the world on a live, interactive platform.

The Engineering Institute of Technology offers an Advanced Diploma in Biomedical Engineering. The course brings together applied science and engineering, interspersed with electrical and electronic engineering. Inquire here today: Advanced Diploma of Biomedical Engineering.

Works Cited

Jackson, Tom. "The 'invisible Epidemic' Afflicting Millions Globally." BBC News. BBC, 14 Mar. 2017. Web. 22 Mar. 2017.

"Robotics Used in First Knee Op." News24. 22 Mar. 2017. Web. 22 Mar. 2017.

"Wearable Telemetry - Eating Health Care – InsideSources." InsideSources. 21 Mar. 2017. Web. 22 Mar. 2017.

HearScreen. "Main." Hearscreen. Web. 22 Mar. 2017.

What are they and can they provide the solution to the ‘skill gap’ conundrum?

One can earn a micro-credential in a specific, targeted skill or acquire a number of them – part of a broader, inclusive skill set.

Udacity, one of the Massive Open Online Course (MOOC) providers refer to those micro-credentials which form a skill set as nonodegrees and describe them as ‘curriculums designed to help you become job ready’.

Krista Moroder, a software engineer, states that micro-credentials are ‘empowering lifelong learners’.

She tells the story of her father, ‘I've watched him create both a successful photography business and construct a two-story cabin from blueprints. In many circles, my father is respected for the vast array of skills and content knowledge he has gained through years of research and deliberate practice. What he's missing, however, is the piece of paper that recognizes that knowledge - his highest level of educational attainment is a high school diploma.’

The Engineering Institute of Technology (EIT) is a convert; we believe that micro-credentials, gained singly or accumulated incrementally, are a vital means of further study for working adults requiring specific expertise, knowledge and the associated credential.

EIT’s online, but live and interactive platform of learning, presented by an international team of experts, also means that the credentials can be accessed from any corner of the globe.

Micro-credentials promise a more personalized, but professional learning. They can meet learners’ individual knowledge and skill gaps; plugging the holes and proving immediately useful within their careers and in the workplace.

Michael Netzer and Chris Reynolds, from the American Public University System believe in their wider application, ‘microcredentialing has the capacity to transform education at all levels and for all students, from non-traditional working professionals to traditional-age graduate and undergraduate students.’

At EIT, we call our micro-credentials Professional Certificates of Competency, which are three month short courses.

With changes happening across the world, thanks to globalization and the fourth industrial revolution, the future of employment will inevitably evolve as the internet of things and the internet of systems exponentially infiltrate workplaces. It is imperative that engineers and technicians who are working in the industry stay on top of these changes through continuous professional development.

We offer these non-accredited short courses to deliver specialist skills to engineers and technicians that can be immediately implemented into the workplace. These courses focus in on topics such as Machine Learning and Artificial Intelligence, IEC 61850 based Substation Automation, Programmable Logic Controllers (PLCs) & SCADA Systems, Power Distribution, Fundamental E&I Engineering for Oil and Gas Facilities, Gas Turbine Engineering, Heating, Ventilation and Air-Conditioning, Project Management for Engineers & Technicians, and many more.

Thanks to the following sites for a range of views on the topic and for the images:

https://www.youtube.com/watch?v=bMfsTyUEFbg

https://balancingacts.wordpress.com/2010/08/09/lifelong-learning-learning-for-life/

http://study.com/academy/popular/what-is-micro-credentialing.html

https://www.edutopia.org/blog/micro-credentials-empowering-lifelong-learners-krista-moroder

What has the Engineering world taught us in the past month? From brilliant developments to quirky new inventions, the good news and the not so good, the month of March has proven to be an interesting one...

Development announced of a new BLAST PROOF tower in Melbourne’s CBD

Image courtesy of Sourceable.net

Can any building really be engineered to be “blast-proof”? A new “blast-proof” and “ram raid-proof” 39-storey tower in Melbourne’s CBD will be built to house 2500 police.

Read more on this here.

3000-piece hand cranked wooden instrument is played by 2000 marbles

An incredibly complex music box that took a whopping 14 months to build has been created by Martin Molin from the band Wintergaten. It replicates the sound of a full band; containing around 3000 parts, 3000 screws, 500 Lego parts, five sheets of Baltic birch plywood and 2000 marbles.

You can read more on this intriguing new invention here.

Check out this short video to see how it runs:

The wearable robotic that will change the way we operate - literally.

A team of researchers at the University of the West of England (UWE Bristol) are developing a wearable robotic system to be used on keyhole surgeries. The wearable ‘”exoskeleton” will allow surgeons natural and agile movement as well as the ability to ‘sense’, ‘see’, control and safely navigate. Read more on this rebotic revolution here.

Watch the UWE Bristol professors give a valuable insight into this incredible new technology:

New foam developed that soaks up an oil spill

Introducing the Oleo Sponge: a reusable foam that can pull dispersed oil from water (the entire water column, not just the surface!). This exciting new innovation has been developed by scientists at the US Department of Energy’s (DOE) Argonne National Laboratory: an invention that could potentially lead to far more effiicient oil spill clean ups in the future.

Check out the video below for an interesting preview on how it works.

Click here to read more about the Oleo Sponge.

Teaching drones to land on moving targets via fuzzy logic

Landing drones on moving targets is scientifically quite difficult to achieve, according to Manish Kumar (associate professor of mechanical engineering, University of Cincinnati’s College of Engineering and Applied Science.). To address this problem, fuzzy logic can be adopted as it allows for more nuance, or degrees of truth.

Image courtesy of Eureka Magazine

For a deeper look into how this works, click here.

Ford first car manufacturer to use Stratasys’ Infinite Build 3D printer

Image courtesy of Eureka Magazine

At Stratasys’ Research and Innovation Centre in Dearborn, Ford has been exploring how large one-piece car parts can be 3D printed for prototyping and future production vehicles. Stratasys states that its new printer could revolutionise the way we manufacture vehicles in the future.

Trump immigration policy threatens India’s $75 billion revenue

It seems the Mexican border wall isn't the only barrier that President Donald Trump would like to build. Trump’s proposed immigration reform could build a so-called “wall” against Indian IT being able to enter the market on skilled H-1B visas (non-immigrant visas). As an unfortunate consequence, India may face a large period of unemployment.

To read more on this topic, click here

45 Aussies travel to Nepal to spread the word on Sustainable Engineering

Engineering students from throughout Australia embarked on a cultural two week program to teach Nepalese villages sustainable tactics to better their futures. Students looked at projects such as innovative ways of collecting rainfall and waste for water for irrigation.

Read more here.

Works Cited

Smith, Stephen. “Blast ‘Proof’ or Blast ‘Resistant’ Engineering”. Sourceable. 7 Mar. 2017.

Austin-Morgan, Tom. “3000-piece hand cranked wooden instrument is played by 2000 marbles”. Eureka! 16 Mar. 2017.

Austin-Morgan, Tom. “Wearable robotic tools being developed for surgery.” Eureka Magazine. 17 Mar. 2017.

Austin-Morgan, Tom. “Soaking up an oil spill.” Eureka Magazine. 13 Mar. 2017.

Austin-Morgan, Tom. “Using fuzzy logic to teach drones to land on moving targets”. Eureka Magazine. 28 Feb. 2017.

Austin-Morgan, Tom. “Ford and Stratasys test large scale one-piece 3D printing.” Eureka Magazine. 7 Mar. 2017.

Rao, Rajiv. New Tech for Old India. “Indian IT’s gargantuan re-engineering problem.” ZDNet.com. 17 Mar. 2017.

Pidgeon, Emily. “Poor given a leg up by Gladstone’s engineering future.” Ballina Shire Advocate. 6 Mar. 2017.

Dear Colleagues

You would often be confronted with the situation where you have to disagree with your boss or even worse – a client. Is it worth going through the pain of disagreement and the agony afterwards? My belief is that if you want to stay true to yourself as a credible engineering professional - you have to raise your objections.

It is perfectly natural to avoid conflict – it can be the source of pain and perhaps (in an extreme case – being fired for being obstructive). After all – you won’t get paid more for actively disagreeing with your senior manager or boss and you could poison your relationship forever.

However, if you handle this correctly – you can clearly mark yourself as someone who is going places and is adding real value to the organisation. By changing a bad decision of a superior manager, you can also avoid being placed into an invidious position in the company by executing something which could be a nightmare and ultimately damage the company and your job.

A few suggestions when considering the best strategy if you disagree with your boss are outlined below.

Assess the risks carefully

Is your boss someone who listens to other opinions or who is absolutely paranoid about any dissent? What would happen to the organisation and your job; if you don’t confront the issue and change the decision of your boss?

Often, it is a good idea to sit back, cool off and think carefully or consult with others before telling your boss that you disagree with her. It is also often a great idea to talk in private to your boss rather than ‘show them up’ in public.

Follow these Tactics if you are going to disagree

Initially, ask for permission to disagree. When your boss says ‘yes’; you are getting their tacit assent to listen to something contrary to their viewpoint. You are showing them respect.

Try and align your disagreement with a higher purpose of the organisation or something your boss feels deeply about. It could be the environment, regulatory changes or cash flow challenges.

Deal with the objections calmly and dispassionately. Almost with some disinterest. Focus on the problem and above all – do not attack your boss personally in any shape or form. Take deep breaths and speak slowly if you are stressed.

Clearly state the original statement from your boss in her terms and from her perspective so that everyone understands the context your objection is framed in. Avoid making subjective statements using emotional language.

Stay modest, humble and detached from your opinion. Appeal to the higher order purpose that everyone subscribes to in the organisation.

Finish by restating your boss’s authority and ability to accept or reject your disagreeing opinion.

Inject some mild humour into the discussion and emphasise that this is really your opinion.

As Sam Hunt remarks: I like disagreement because it forces both sides to question their own opinions and why they feel that way.

Thank you Amy Gallo of Harvard Business Review for a stimulating article on this topic.

Yours in engineering learning

Steve

Mackay’s Musings – 28th March’17 #645

125, 273 readers – www.idc-online.com/blogs/stevemackay

The Engineering Institute of Technology (EIT) is very proud to present a glimpse into the quite remarkable work being undertaken by our students completing the Master of Engineering in Industrial Automation.

These students, who are studying alongside their work in industry, are deep into the research for the thesis component of the degree. They have delivered the first of two progress presentations and it is clear that their projects will have academic applications, but more profoundly, will benefit and improve the engineering communities they serve.

Wherever the students are based in the world EIT’s innovative, live online education enables them to ‘meet’ and ‘interact’ with their globally-based lecturers and student cohort. They are all immersed in their workplaces, but also have access to EIT’s remote laboratories and simulation software; these practical applications underpin the theory in the degree.

The nature of the degree has inevitably focused the students’ thesis topics on the growing industrial automation industry. The relevance and significance of the research projects, however, can be attributed to the fact that they themselves are inspired and driven by the work they do in industry.

The following is a summary of the intentions behind the Master projects. It does not adequately illustrate the progress being made by these scholars, but it does hint at the pertinence of the research being undertaken for and with industry.

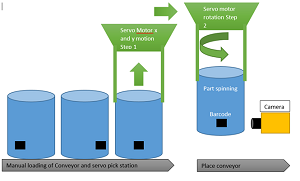

Bryan Crump is an Automation Engineer who is developing a strategy for the optimization of 2D matrix Barcode reading and part placement machinery. His thesis focuses on where the system places objects on a conveyor belt. He is aiming to create a strategy which optimises the placement of objects on the belt to allow the 2D barcode matrix to be scanned by a camera.

He hopes it will be implemented in the pharmaceutical and biological industries. He said: “The objective of this thesis is to define the optimum configuration of the equipment to ensure consistent part placement (within a pre-defined tolerance) whilst minimizing station cycle time and using readily available off the shelf products.”

Kannan Periyaiya is a senior engineer who has proposed an online monitoring platform suitable for machinery protection applications. The monitoring system will utilize the General Electric Bently Nevada 3500 monitoring system. According to General Electric, the system is the “industry’s most extensive selection of machinery measurement parameters combined with software configuration for virtually all monitor options.”

Periyaiya explains that all high-criticality equipment at gas plants is moving to completely online condition monitoring strategies in the future. Thus, the target of his project is to “scope the requirements of connecting these Bently Nevada racks to the existing System 1 Framework to enable continuous vibration monitoring and analysis of all Bently Nevada modules.”

System 1 is a software framework that connects all the vibration measurement hardware at a gas plant and allows the measuring and monitoring of those vibrations. Periyaiya will be implementing his expertise at his current employer, Santos GLNG.

Tom Davies, is an asset and sewerage manager. He is working on the implementation of a lower budget online monitoring system for a rural wastewater/sewerage scheme. He is focusing very specifically on the reliability of such a scheme, and how dynamic the system may be for highly regulated public utilities.

He explains, “At full potential, I see this type of work augmenting works of Professor Duncan Mara at Leeds University in the simplification, increased understanding and effectiveness of a limited budget sewerage scheme. The technology that I am looking at would sit on top of those schemes making effective and reliable wastewater management possible for all rural, and regional economic zones.”

The scheme Davies is proposing would be the first implementation of its kind in the industry. The Shire of Moora, Australia, is supporting the strides he is making and will benefit from the scheme he is proposing.

James Croft is a Control Systems Engineering Support practitioner for a large coal exporter in the Bowen Basin in Queensland, Australia. He has tested and documented state-of-the-art solutions for the Process Control Systems at the BMA Caval Ridge Mine Project. These systems increase the reliability of coal handling. He is also targeting methods which will increase the efficiency of the processing systems in order to attain higher production targets.

Mike Calvert is a metallurgical engineer. He will present his findings on a new control parameter for reflux classifiers on fine coal recovery. He explains that, “The final submission will include a literature review of previous laboratory studies which have progressed to pilot scale tests and then through to early models at full plant scale. The study involves conducting trials at full plant scale, varying the proposed new control parameter and collecting and analyzing samples. It will include a discussion on the new potential for use in a control system to maximize resource recovery.”

Muhammad Naveed-Ul-Hassan works in a nickel smelter providing engineering support in control systems. Many automated initiatives are designed to improve safety (among other benefits), and so it is with this project. The skimming cabins are located next to the converters, exposing the operator to radiating heat and light from molten metal. It is the operator’s job to assess the colour difference between Slag and Matt – a manual process. Muhammad aims to automate this skimming process utilizing state of the art thermal and high resolution IP cameras which will be monitored from a remote cabin. In fact his overall plan involves automating three converters all supervised from a central control room.

Dear Colleagues

We all yearn for that magic formula to success in life and perhaps in our engineering careers, as well. Although I doubt a simple formula exists. However, scientists at University College London have found what they believe are the five key life skills that will bring you health, career success, wealth and overall success.

Five Fantastic Life Skills

- Emotional Stability

- Determination and Grit

- Control of your environment

- Optimism

- And Conscientiousness

You will probably laugh and exclaim that this is all pretty obvious. True enough. But oddly enough - my favorite expression); many of us don’t practice this mantra. And I hasten to also add – what is the definition of ‘success’ and 'happiness' ? I have come across poverty stricken farmers in poor countries who seem to be very happy and seemingly conducting a successful life despite having very little.

This particular research was conducted in a scientific way and seems to make sense. It was conducted by following the lives of 8000 middle-aged Britons for the past eleven years.

Those who didn’t have these skills were seemingly condemned to loneliness, depression and to ill-health. This incidentally also means that even if you are hyper intelligent or from a wealthy background – you may not end up with a successful life if you don't have these skills - as you can see from the qualities listed, many rich people don't necessarily have these.

No single attribute counted – they all contributed towards success. Naturally, in the lottery of Life, many of us are unfortunately condemned to ill health or bad luck due to our genes, environment, war and upbringing.

Other Positive Spin offs

From a health point of view – people with these seemingly five attributes had lower levels of cholesterol, heart disease and inflammation and were fit and lean. Interestingly enough from a community point of view – these people were likely to volunteer more frequently and make a big contribution to society.

Build on them for a Successful Life and Career

In essence, it is important to build on these skills and nurture them throughout your life for ensure good health and happiness well into your dotage. And to use these skills to build your engineering career into something very successful.

Thanks to the Daily Telegraph for an interesting summary of this research.

As Sam Ewing remarks: Success has a simple formula: do your best, and people may like it.

Yours in engineering learning

Steve

Mackay’s Musings – 21st March’17 #644

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

Is the world finally ready to embrace the significance of technical and vocational skills and in doing so bump higher education qualifications off their pedestals and out of their ivory towers?

The government of the United Kingdom is certainly addressing this traditional imbalance.

They are introducing a new ‘T-levels’ system that will run alongside the customary ‘A-levels’, with a plan to implement it by 2019. ‘T-levels’ would prepare a student for further study in the vocational sector and a student attaining ‘A-levels’ would qualify to enter a higher education college or university.

Credit: Wisegeek.com

Experts are hoping that technical and vocational qualifications will gain the reputation they deserve and ultimately achieve an ‘equal-footing’ with degrees which are attained in the higher education sector. It is being called the (long-awaited) ‘technical skills revolution’.

To ensure the reputation is indeed deserved and in order to raise the bar, students pursuing technical and vocational education will be exposed to 50% more study. To gain their qualification they will need to have completed 900 hours of training.

The system that exists today in the UK sees 13,000 individual qualifications being awarded in the technical and vocational sector. Philip Hammond, the Chancellor of Exchequer, who outlined the new T-levels in his budget speech, said that 13,000 qualifications in the technical sector was confusing to students. The government proposes a dramatic cut, with a focus on just 15.

These 15 credentials will cover catering and hospitality, social care, construction and engineering and manufacturing. The new system is hoping to address a widening skills shortage that some fear could be exacerbated by Britain’s exit from the European Union; a move which has now been passed by the UK Parliament.

Richard Black from the Telegraph writes:

“UK universities receive an additional 15 per cent in funding from the EU and some believe the UK could lose this if Brexit happens. It could also mean academics will struggle to cooperate on research projects. A change in visa arrangements for other European countries may also deter high-caliber academics from joining British universities.”

The UK is also encouraging students to apply for apprenticeships in their chosen industries. The UK government has plans to overhaul and improve the quality of apprenticeships with an apprenticeship levy that will see £2.5 billion making its way into technical and vocational sectors.

In addition the country is poised to launch the Institute for Apprenticeships in April of 2017. This Institute will ensure that apprenticeships maintain a level of quality, and create pathways which will enable students to progress.

Is less more?

Ireland’s education system is also undergoing change; they are redefining how their higher education system operates. The Higher Education Authority (HEA) of Ireland is reassessing how effective their engineering education and training is to ensure they remain relevant within a global context. Part of this scrutiny also involves refining the number of engineering qualifications that exist.

Dr Graham Love, the new CEO of the HEA, said that it is a challenging time for higher education, but is looking forward to shaping the future of the system.

“The review will examine the current state of engineering education provision in Ireland to establish if it is fit for purpose, efficient and effective and will make recommendations to better meet national skills needs,” the HEA told the media.

The review, according to the HEA, will also suggest new amendments for “apprenticeship models, professional development for working engineers, and teaching methods.” In accordance with Great Britain there is a concerted effort to raise the reputation and appeal of technical and vocational qualifications.

The right way forward

Emma Bridgewater, a renowned ceramics manufacturer in the UK, has said that the United Kingdom at large is suffering a skills crisis because the engineering syllabi fail to consider the needs of local students and the manufacturing sector. In an interview with The Guardian, she suggested that courses were designed to appeal to international students.

“A lot of vocational courses around manufacturing are evaporating - we are not training to future captains of the industry. There’s a very significant lack of the right courses being devised. I think that education is responding to the appetite among foreign students to study here.”

The unnatural tug of the higher education sector combined with the tempting foreign student market may have both contributed to the burgeoning skills gap. It is not surprising therefore, that engineering experts are optimistic about the proposed T-levels. The Chief Executive of the Federation of Master Builders told the media:

“T-Levels could be the answer if they genuinely rival A-Levels in the eyes of parents, teachers and young people. UK society as a whole has been guilty of putting too much emphasis on the academic route - this has made it more difficult for vital sectors like construction and house building to attract the talented new people we need.”

Works Cited

Black, Richard. "How Will Brexit Affect British Universities and will EU Students Still Be Able to Study in the UK? ." The Telegraph. Telegraph Media Group, 03 Mar. 2017. Web. 13 Mar. 2017.

Hickey, Shane. "'T-levels' Aim to Improve Technical Education and Improve UK Productivity." The Guardian. Guardian News and Media, 09 Mar. 2017. Web. 13 Mar. 2017.

"T-Levels Must Match A-Levels." T-Levels Must Match A-Levels. Web. 13 Mar. 2017.

In 2013, Nicolene Murdoch, the executive director for teaching and quality at Monash South Africa - a higher education institution - said that historically only 15 to 20% of South African students at universities end up graduating.

More recently, in 2015, the Council of Higher Education calculated the dropout rate (or more formally, the attrition rate) of students that had been studying five year degrees countrywide. The research found that 18% of the country’s 18 to 24 year olds entered university in 2015, but of that number 50% - 60% dropped out in their first year of studies.

Andre Van Zyl, the Director of the Academic Development Centre at the University of Johannesburg, referring to the research, said:

Andre Van Zyl, the Director of the Academic Development Centre at the University of Johannesburg, referring to the research, said:

“Part of what we have to ask ourselves is whose fault is this. We try to give simple answers to complex problems. People blame a variety of things like schools and the universities. The reasons are as complex as the number of those who drop out.”

The Department of Higher Education’s latest report on the topic - Statistics on Post-School Education and Training in South Africa - indicated that only 185,375 people graduated from South Africa’s 26 universities in 2014. Out of that group, 5,680 of them were engineers. How many engineers failed to complete their studies is unknown.

A study conducted at the School of Chemical Engineering at the University of KwaZulu-Natal, published in the South African Journal of Science alluded to various reasons for students dropping out of university. The study’s author, Jonathan Peacock writes:

“The first is academic exclusion of students from a department or faculty as a result of slow academic progress. The second is ‘walking away’ - in other words, those students who leave universities before completing their degrees regardless of progression. The third is financial leavers (or financial exclusion) where students leave because of an inability to continue to fund their studies.”

The high drop-out and failure rate of engineering students in South Africa may also have something to do with a relatively new attitude to Mathematics in the schooling system. Sara Muller, a researcher at the University of Cape Town, wrote in an article published late last year,

“In the past 20 years there’s been a major shift internationally towards thinking of education in purely economic terms (as opposed to critical citizenry, creativity or self-actualization). This reduction of education to purely economic ends, coupled with the conflation between mathematical prowess and problem-solving skills for the “knowledge economy”, has resulted in mathematics being isolated as “essential knowledge”. Its proponents insist that maths is required for an education of value.”

The consequence of this change in attitude has been to push students into studying Maths whether or not they have an inclination to do so, let alone the aptitude for it. She explains,

“To fully appreciate this shift in thinking, South Africans need to suspend their collective amnesia: passing mathematics was not a requirement to move into Grade 10 a generation ago. And yet adults from this era are often economically productive, creative and academically accomplished. Many would publicly acknowledge their own struggles with numbers.”

She points out sagely that,

“The vast majority of jobs of many flavours and incomes do not require the type of maths taught even in Grade 9. This is forgotten when mathematics is positioned as supremely important for the job market, or for students’ personal development.”

The inherent danger of this drive for compulsory maths (and there is evidence of it already) is a drop in standards. And the consequence of this: students who are determined to complete tertiary qualifications in the STEM disciplines (science, technology, engineering and maths) will not cope.

This may indeed be partly responsible for the low numbers of engineering graduates, but it cannot be the only factor. Electrical Engineering students from the University of Pretoria were asked to give a rough guesstimate of what the dropout rate in their modules might be, based on their observations in class. The students reported that 40-60% of those who start out in the first year are not present in final year modules.

One of the students, who asked that his identity not be revealed, said:

“I don’t think the dropout rate is as high as the module failure rate. People fail enough to give up, or fail enough to be told to give up. I think a 60% attrition rate is an accurate amount if you only look at how many of us started and how many you don’t see at the end.”

It is abundantly clear that brick-and-mortar higher education institutions are struggling to retain students in courses across all faculties, but engineering student retention rates appear to be particularly low.

Is online education the answer?

The Deputy Dean of the Engineering Institute of Technology (EIT), Steve Steyn, cut his engineering teeth at the University of the North West in South Africa.

Steyn says that when he studied engineering in 2006, out of a class of 250 students, only 22 graduated. The attrition rates in South Africa have not improved. Engineering remains notorious for being a field of study with large student drop-off numbers 11 years later.

The Engineering Institute of Technology recently introduced prospective South African students to the future of higher education: interactive, online education and training.

Steyn, speaking to a crowd in Johannesburg in South Africa last week, said that EIT’s most recent performance measures revealed the attrition rate to be much lower than figures quoted above. The college is, however, aiming for a retention rate of 80% which it is not yet achieving, Steyn said.

Steve Mackay, the Dean of EIT has been involved in a good number of the publicly accessible Massive Open Online Courses (MOOCS), hosted by top-tier American universities. He has witnessed a 90% attrition rate.

He lamented that a free MOOC course, for the purposes of continued professional development, with 10,000 students initially registered, eventually fell to only 400 (not because of a lack of quality). He points to the absence of interaction between student and lecturer as one of the reasons for the high rate of attrition. He said: