Industry

- Details

- Written by: Quintus Potgieter

Want to go into a joint venture with Aston Martin? It's not only good-looking cars the company produces, they also design a host of other quality products. Now they are looking to consult and collaborate with companies again.

Aston Martin worked with Foster + Partners to work on the London bus of the future. According to Autocar, they also worked along with Quintessence Yachts to build the AM37 powerboat.

Now, Aston Martin wants further engineering and manufacturing collaboration. They have set up a consulting branch of the company that will operate under the name Aston Martin Consulting.

Aston Martin says it will give companies a platform to engage with their "expertise centered on design, engineering, and manufacturing."

CEO of Aston Martin, Dr. Andy Palmer said, "We are often asked to collaborate on projects with other companies. My belief is that we can expand the provision of our expertise and experience even further. The formation of Aston Martin Consulting means that we can offer a more structured approach to these projects."

The man at the helm of the consulting company will be Bradley Yorke-Biggs who works for Aston Martin as their director of strategy, information technology and governmental affairs. It was clear that he couldn't wait to get started. He said: "We are very excited to extend the reach of the business to include the provision of services across different sectors: both automotive and beyond. We have an incredibly talented and experienced team within Aston Martin and we look forward to expanding our horizons as we work with new clients on interesting new projects."

Contact

Good luck.

- Details

- Written by: Quintus Potgieter

Lithium – What is it?

Lithium batteries are commonly used in consumer electronics but the global interest in lithium batteries of late has generated state-of-the-art breakthroughs in lithium battery technology opening up new markets and applications. The trend seems to be moving away from traditional lead acid batteries in favour of lightweight lithium based batteries. The technology is developing so quickly that Standards Australia has recently announced it is forming working groups to update the current standards in relation to energy storage.

Lithium Battery “Megafactories” in China

Production capacities of lithium batteries are on the rise and China seems to be the place it’s all happening. It is anticipated that production will triple by 2020. Previously an expensive option for industry and home consumers, lithium batteries are now well within reach. Large-scale facilities are popping up all over China and this surge in production capability shows that the lithium batteries industry means business and is serious about reducing unit cost and becoming a market forerunner.

Lithium Mining in Australia

Obviously to make lithium batteries one requires the resources. Global technology companies are seeking a reliable supply of lithium for their battery suppliers, electric/hybrid vehicle manufacturing and even some military and aerospace applications. Australia is an emerging lithium market with the potential to be a world leader in lithium production. Australia currently has 14 ASX listed companies with lithium deposits and is already one of the world’s top producers.

Lithium Battery Production in China

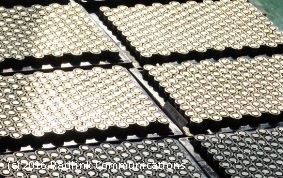

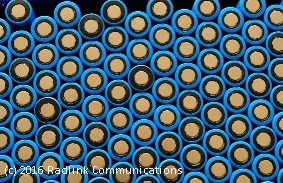

Radlink Communications, a Perth based Telecommunications Company, have been working on an innovative modular and scalable energy storage solution, initially for the mining industry. This has taken them to Melbourne, China and Hong Kong to work with leading edge lithium battery solutions providers and collaborate with them in the development of highly energy dense yet safe battery solutions for extreme industrial temperatures (up to 65 deg C) with extraordinary longevity (up to6000 charge-discharge cycles or about 16 years of daily usage). Radlink’s solution is specifically targeted at parties who require high temperature storage in a robust 19-inch form factor. Radlink have kindly provided some photos from their recent trip to China. In the photos below you can see the lithium battery cells in various stages of production.

Manufactured cells undergo rigorous testing in a controlled environment.

The below image displays 256 cells per cabinet of batteries being tested, and there are about 120 cabinets in the temperature controlled test chamber.

Cells after testing and grading.

Cells are then turned into battery packs by human operators.

Then the lithium batteries are dispatched all over the world for sale to users.

Other areas of interest relating to lithium batteries….

Lithium and Dangerous Goods Safety:

Lithium batteries contain more energy per unit of weight than traditional batteries which is great for energy storage but does create safety concerns as high-energy density can produce hazards if the energy is released at a fast, uncontrolled rate. This is a common concern in the aviation industry.

Lithium and the Electric Car:

In 2016, Tesla Motors plan to bring their new batteries to Australia, which will join Germany as the company's first two markets outside the US. Tesla have already installed electric car charging stations in Victoria and New South Wales called “Superchargers”.

Lithium & Solar:

The lithium & solar market is emerging in Australia. Local energy provider Ergon in QLD is currently running a trial with 33 Toowoomba homes having state-of-the-art rooftop solar and battery systems installed in their homes. It is expected their electricity bills will be significantly reduced as approximately 75 per cent of their power will be generated by the sun. It is predicted that these in-home batteries, such as the Tesla Powerwall could produce not only domestic power but also feed power back into the grid when the network is overextended in the summer months. The desirable combination of solar and lithium has unlimited potential and meets many of Australia’s energy needs. It could very likely be the future of off-the-grid energy, helping to reduce the cost and increase the supply of renewable energy in Australia.

If you want to learn more about the lithium battery industry in Australia then why not attend the upcoming Lithium Batteries Conference in Sydney on May 24th & 25th 2016. The aim of this conference is to explore industry issues and the future of lithium mining and technology advancement in Australia. Lithium industry experts will share their technical knowledge and discuss how the upsurge of lithium battery demand will affect the mining, technology, manufacturing, solar, recycling, electric vehicles and dangerous goods industries. The event will also cover recent research developments and how these can be applied in the real world to benefit industry and the Australian consumer.

Download the full event brochure HERE or register online HERE.

Topics include:

- Lithium Batteries - Past, Present and Future

- The Lithium Rechargeable Battery Supply Chain

- Lithium Ferro Phosphate (LFP) Batteries – The “Safe Lithium”

- Lithium Battery Management Systems (BMS) - Electric Vehicles vs Recreational Vehicles

- Lithium Technology: Overview and as a Replacement for Sealed Lead Acid

- Not all Lithium Batteries are the Same - Lithium Titanate Oxide (LTO) Batteries

- Battery Recycling - End of Life and End of First Use

- Advanced Materials for Lithium-ion Batteries

- Smart Energy Management Opportunities Utilising Li-ion Battery Technology

- Ultra High Power Lithium Opens the way to Increase Efficiency of Power Plants and Reduce Emissions

- Sources and Availability of Materials for Lithium Batteries

- Reconfigurable Utility-Scale Lithium Battery Energy Storage System

- Battery Storage for Recreational Vehicles - Why Lithium is the Next Big Thing

- Update on the Regulations Applicable to Air Transport of Lithium Batteries

- Unearthing Off-Grid and On-Grid Battery Energy Storage

- Making Global Lithium Supply Ubiquitous – New Paradigms in Lithium Exploration to Prevent Lithium Becoming the Next “Oil”

For conference or registration enquiries please contact the conference department at

- Details

- Written by: Quintus Potgieter

The Global Mobile Suppliers Association (GSA) has said LTE and LTE-Advanced connections skyrocketed by 156 million connections in the fourth quarter of 2015. In the last year, LTE connections went up by 552.2 million.

Alan Hadden, VP of research at GSA said, "A daily average of almost 1.7 million LTE subscriptions were being signed up during Q4 2015 and the rate of LTE subscriptions growth is accelerating. LTE technology is now being used by one in seven mobile subscriptions worldwide."

According to Telecoms.com, China is the "dominant market" globally, registering the largest number of LTE subscriptions. They went from 84 million to 386 million subscribers.

The GSA said the amount of global networks offering LTE - which would be 116 operators - will only grow from here on out and reported that 24% of the world's operators are currently facilitating LTE-A connections. According to ITWeb.co.za, 57 countries are using LTE-A, which the GSA says will change soon, they expect 100% global penetration.

There is no denying that LTE and LTE-A give users all over the world a faster connection to the internet but if the networks become over saturated with users, will it slow the networks down? For now, it is a viable technology that is allowing more than a billion people to access the internet and at good upload and download speeds.

- Details

- Written by: Quintus Potgieter

The construction industry is fluctuating globally according to multiple news sources this week. IOL reports that in South Africa, the construction industry has been in a decline since the concluding of the 2010 World Cup. Murray & Roberts and Wilson Bayly Holmes-Ovcon - companies that designed and established Cape Town Stadium - have allegedly retrenched staff and are blaming the lack of new projects that require their engineering teams and/or workers.

IOL also claim that the "four largest construction companies" have retrenched at least "20,000 permanent and contract jobs in South Africa over the last two years" in the current slump that the construction industry is trying to survive.

An industry that is still booming in South Africa, or, at least, appears to be, is the shopping centre industry. The Mall of Africa, in Waterfall City in Midrand, is eight weeks away from its launch in April. The mall that is still under construction will be Africa's largest shopping mall development to date and is valued at R4.5 billion. Multiple other malls in South Africa are also going through renovations which have no doubt produced more engineering construction jobs. But, companies are still reporting a slump in the construction industry as a whole.

However, in the United states, according to ConstructionEquipment.com 235,000 construction jobs were made available from December 2008 to February 2016. The site says this a 4% rise, from 2008 when 6,631,000 construction positions were being filled. This reveals the construction industry in the US is doing quite well. The analysis was done by the Associated General Contractors of America. The association's chief economist, Ken Simonson, said, “The overall picture for construction employment is very positive with robust job growth and very little unemployment."

Moreover, Germany is also reporting a growth in the construction sector. Markit Economics estimated that in February of 2016 a reading of the Purchasing Managers' Index showed a fast expansion rate of the industry that was cross-referenced to the last record expansion from March 2011. Their measurements read 55.5 in December 2015 and had grown to 57.9 when another measurement was taken in January 2016. They also revealed that commercial building and civil engineering output had also seen more orders than expected.

Oliver Kolodseike, an economist at Markit explained the growth and the subsequent growth to come for Germany by saying, "House building remained a particularly bright spot in the data, rising at the steepest rate in nine years. With large inflows of refugees and the government planning significant investments to support residential building projects, it is likely that construction activity will continue to expand in the coming months."

.

- Details

- Written by: Quintus Potgieter

TheEconomist.com estimates that more than a million people have lost their lives due to earthquakes in the last two decades alone. Most of these deaths are caused due to collapsing buildings, which has spurred a fascination amongst civil engineers with earthquake-proofing buildings to ensure less of them fall down during an earthquake.

Engineering students that form part of the Seismic Design Team at the University of California, Los Angeles, are to present their new project focusing on earthquake-proofing buildings at the Earthquake Engineering Research Institute in April. This would form part of a competition called the 2016 Undergraduate Seismic Design Competiton.

The team will construct a 5-foot tall wood model skyscraper that will have to be subjected to simulated ground motions. The judges of the competition will determine which models that are presented respond the best to simulated earthquake movements.

The judges will also estimate how much money a country would spend buying earthquake-proof buildings and the wooden structure should be built in a way that it would attract a potential tenant who would be looking for earthquake-proof buildings.

The teams could also give examples of how to earthquake-proof monuments and buildings that already exist. Kyle Williams, an architectural studies student assisting the civil engineering team said, “Since this year’s competition is in San Francisco, we want to include prominent structures like the Transamerica Pyramid and Golden Gate Bridge.”

The competition encourages civil engineering students to think about the real world they are theoretically designing buildings for. Jian Zhang, one of the civil engineers entering the competition with his team says that they are ultimately striving to "fit the reality" they are trying to "mimic".

Each team gets seven minutes to position rods in their wooden skyscraper clone that will be subjected to earthquake-like conditions atop a shaking table and see if they are able to create a full proof, earthquake-proof building.

For more information on how to get involved with the 2016 Undergraduate Seismic Design Competition, CLICK HERE

- Details

- Written by: Quintus Potgieter

It had to happen at some point...right?

Google's self-driving car technology has caused an accident. The company's self-driving Lexus SUV was the first out of the fleet of self-driving vehicles that has CAUSED a crash. The incident occurred on the 14th of February 2016, colliding with the side of a bus near Google's headquarters in Mountain View, California.

The company now has to appear before California's Department of Motor Vehicles, otherwise known as the DMV, to engage in conversation about the incident and investigate what exactly went wrong.

Head of Google's self-driving project Chris Urmson explained the collision to the Associated Press, saying, "We saw the bus, we tracked the bus, we thought the bus was going to slow down, we started to pull out, there was some momentum involved."

Google has released a statement that you can read in full: Click here. They admit to some responsibility but chalk the incident down to "a classic example of the negotiation that's a normal part of driving." They also concede that just like humans are trying to predict each other's movements on the road, that is what their self-driving technology is trying to do as well.

Luckily, there were no injuries reported. This begs the question of whether or not the technology is ready to release to consumers around the world. Earlier in February, it was reported that the artificial intelligence system invented by Google would be considered under the same laws that human drivers are. However, after this incident, there might be some delays in the process.

For more information on how self-driving technology was engineered, here is Chris Urmson's TED talk

- Details

- Written by: Quintus Potgieter

The battle continues between the FBI and tech industry giant, Apple. The FBI are wanting to access the contents of an iPhone belonging to a terrorist known as the San Bernadino shooter who shot 14 people in the United States. Apple CEO, Tim Cook, is warning against allowing such a bypass of security services because of the prescedent it might set and is also warning against the criminal hackers that could get their hands on the software that would need to be invented to make such a backdoor possible.

In a recent Apple release, they say, "The government says: “Just this once” and “Just this phone.” But the government knows those statements are not true; indeed the government has filed multiple other applications for similar orders, some of which are pending in other courts."

In more recent developments, other tech companies such as Google, Facebook, Amazon and Microsoft have vowed to file briefs to the courts to try and prevent a magistrate's order of forcing Apple's hand and strongarming them into developing the software to allow access to the contents of the phone. It is rumored that Twitter will join the fight as well.

Along with companies voicing their support for Apple, the situation could escalate to a future of hardware and software engineers who would have to build backdoors into devices so that security of state can be ensured in the future.

"Once created, the technique could be used over and over again, on any number of devices. In the physical world, it would be the equivalent of a master key, capable of opening hundreds of millions of locks—from restaurants and banks to stores and homes. No reasonable person would find that acceptable," Tim Cook said.

- Details

- Written by: Quintus Potgieter

Airplane engineers at Boeing might have a rocky week ahead. Boeing Co said that it is planning to retrench some of its airplane engineering staff, confirmed by an exclusive Reuters report.

Allegedly, a memo sent around within the company stated that they could be making voluntary layoffs. The memo quoted by Reuters stated, "We do not intend to backfill for people who retire from their executive or management roles unless the position is absolutely vital to carrying out our work statement." The department that is directly affected is the department that deals with the commercial airplanes.

Ray Conner, Airplanes chief at Boeing, said, “To win in the market, fund our growth and operate as a healthy business, we are taking thoughtful steps to reduce the cost of designing and building our airplanes, part of which involves evaluating our employment levels across all of commercial airplanes."

The retrenchment of airplane professionals is on the heels of a known slump in the airplane industry. There are some critics of Boeing for the retrenchment but are confident that this presents an opportunity for other companies to recruit aeronautical engineers from the company which is in constant competition with Airbus.