Industry

- Details

- Written by: Quintus Potgieter

The digital world is a scary place. It is a place of automation, it is a place of digitization, it is a place of disruption. And it can’t be ignored. If you don’t have the skills for work as dictated by the fourth industrial revolution...you may be in trouble.

People may find themselves in jobs that will be automated out of existence in the near future. Thankfully, however, education and training is also undergoing a revolution and is ready to meet the challenge of bridging the digital skills gap.

To quell the anxiety, the Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, presented to a room full of graduated and budding engineers in South Africa. The presentation was entitled: ‘Taking control of your Engineering Career & Learning in the new Digital World’. Mackay said:

“You may be doing something today, but tomorrow, you will be doing something completely different. The most important message is that you should commit to continuously learning.”

Mackay advises that a good rule of thumb, when deciding what discipline of engineering to pursue, is to consider what engineering skills your country desperately needs. That way, pursuing and getting a job in industry is more likely. He said:

“Look for the job demands of the country you are based in and be open to always learning and upskilling. Every country needs a certain kind of engineer - in fact; every town has its own particular demands and needs its own kind of engineers.”

Once students start to pursue their discipline, Mackay says, they will acquire qualifications. But they must not underestimate the value of learning informally, through practical tinkering with technology and learning the ropes of engineering, at work, through others.

Joining Mackay at the seminar was engineer and EIT lecturer, Deon Reynders. He currently teaches the Advanced Diploma of Industrial Automation, the Advanced Diploma of Electrical and Instrumentation (E&I) Engineering in Mining, and the Advanced Diploma of Mechanical Engineering.

He is also one of two instructors who is teaching the module known as Fundamentals of Project Engineering. Reynders suggested that engineering professionals should be constantly upskilling because of the rapid progress made in technology every decade.

“I graduated in 1972. One of our professors gave us a little farewell speech and he said: ‘Gentleman, I want to tell you something. The technology that you will use in your career does not exist yet’. I was taught using the slide rule and printed logarithm tables - there were no computers, no laptop, no mobile phone, there was no internet and no wireless.”

45 years later and Reynders is still a student of ongoing technological development. As a senior engineer, he has to be on top of all of the new developments in industry. He says:

“In 20 to 30 years from now you’ll laugh at this outdated junk; mobile phones, laptops. They will be archaic museum pieces. Things are changing rapidly, you can see it, it’s changing rapidly. You see technology merging. For example, for a couple of bucks you can buy a drone now which is a combination of mechanical and electronic engineering; it’s got camera, WiFi, incredibly complex control algorithms, and it will fly and land in your hand. It’s made by a team of multi-skilled engineers.”

Online learning

In 2007, he began lecturing online for EIT. The institution advertised a course in cyber security, and one student enrolled. After that, they created a course in data communications. Reynders has penned two books entitled: ‘Practical Industrial Data Communications: Best Practice Techniques’ and ‘Practical TCP/IP and Ethernet Networking for Industry’.

Reynders officially went rogue from his university past (he was once head of a department at the Walter Sisulu University) and decided to become a full-time, online lecturer, able to teach from any place he could find an internet connection. He lectures from his home office and plans to lecture from his yacht - which he is still building.

“We have to keep upskilling, multi-skilling, and learning. Otherwise, you’re gone...you’re dead. Thankfully, the methods of learning are also changing. The days of going to a university and sitting in the class and resigning from your job are numbered. In ten to fifteen years from now you will see the lecturer in virtual reality - but let’s take it one step at a time. But, meeting people online, and teaching and learning online, and accessing laboratories online, it is becoming the new paradigm. It’s the new way we do things.”

At the conclusion to the seminar it was clear that - when considering how to upskill oneself - the mindset should be: digital first, traditional second.

And finally Mackay commented on the future of engineering degrees. He believes they will become more niched with the focus on ‘micro-degrees’. These will be acquired throughout a career to keep workers industry-ready. They will equip those in the workforce with the necessary theory, but with the essential and relevant practical, hands-on skills needed in the engineering industries of today and into the future

- Details

- Written by: Quintus Potgieter

Real-time Big Data and Analytics - Mobility - the Internet of Things - Social Media - 3D Printing - Drones - Self-driving Vehicles.

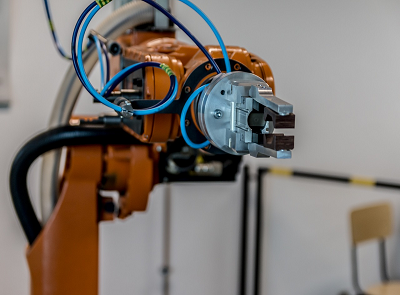

What do all of these things have in common? They are all associated with the digital disruption of the supply chain. They are technologies that are contributing to the Industrial Automation of today and will have an impact into the future.

They are also terms we should all be acquainted with. If we can keep an eye on the technologies responsible for replacing repetitive jobs in the supply chain we will be better prepared to be part of the revolution rather than part of the fall-out. Autoware is an example of a company which is automating and increasing the efficiency of processes in the supply chain.

The company has helped other companies produce 800,000 desserts, 14 million vials, 8 million bottles of beer, 5 million packets of pasta, 900,000 packets of mouthwash, and much more. Smart manufacturing is enabling it. When a company requires a product to be mass produced, Autoware employs their Manufacturing Execution System (MES) and facilitates it.

Whilst technology plays an integral role in improving the efficiency of the supply chain, digital implementation has disrupted the industry from end-to-end.

Luigi De Bernardini the CEO of Autoware is dedicated to developing ‘Wireless, autonomous production operation architecture for cognitive manufacturing’. He says the supply chain from four decades ago does not exist anymore. Now, supply chains are logistics, manufacturing, and the autonomous delivery of the product - all in one. He writes:

“Delocalization of production and globalization have created new challenges in managing supply chains, introducing new complexity in logistics and quality control. The main challenge has become finding the right combination of low production cost, necessary quality of products or semi-finished goods and reasonable transportation costs, guaranteeing at the same time the availability of the products when needed.”

No replacing work - just jobs

A law firm named Littler Mendelson P.C. has tackled the tough topic of whether automation in the supply chain is a good thing. They put together a report named: “The Future is Now: Workforce Opportunities And The Coming TIDE. A Call to Action”.

‘TIDE’ refers to the ‘technology-induced displacement of employees’. Top law and engineering firms agree - automation is and will continue to replace jobs. But, it won’t replace ‘work’ altogether. That is, if companies can meet workers halfway. The report states:

“The accelerating pace of automation will likely lead to productivity increases on a scale not seen since the Industrial Revolution, while displacing tens of millions of American workers from their current occupations. Too often, news reports dramatically focus on AI and robots as job killers. Unfortunately, the debate over whether jobs eliminated will outnumber jobs created ignores two related and no less important questions: 1) With the fast-paced arrival of innovative and transformative technologies, will workers whose jobs are most likely to be disrupted have the skills and training required for the new jobs being created? 2) Will employers be able to fill existing vacancies as this unstoppable transformation occurs?”

Bernardini agrees that smart manufacturers that utilize an automated supply chain must change to accommodate the digital future. He concludes:

“The hard work done in the past to optimize the supply chain in a delocalized environment is almost useless in the new world enabled by the usage of the technologies that have become available and affordable. A new approach -- and especially a cultural shift -- is needed in considering the end user as an active and driving part of the supply chain itself.”

Works Cited

“Digitalization Is Disrupting the Supply Chain.” Is Writing an Essential Skill for Engineers? | Automation World, www.automationworld.com/digitalization-disrupting-supply-chain.

Selko, Adrienne. “Automation Eliminates Jobs Not Work: New Report.” IndustryWeek, 22 June 2018, www.industryweek.com/talent/automation-eliminates-jobs-not-work-new-report.

- Details

- Written by: Quintus Potgieter

The UK government has dubbed 2018 the ‘Year of Engineering’. And as the year gallops into its final five months, innovation in Africa is a hot topic too. South Africa and Zimbabwe have both seen new presidents thrust into power, which may have also stimulated changes.

There also seems to be a renewed appetite for innovation in education and training - part of the blossoming global economy.

The UK government attended the Royal Academy of Engineering Workshop - hosted at Zimbabwe’s NUST University. They were represented by Catarina Laing from the University of Strathclyde in Scotland.

In 2015, the UK government set up the Global Challenges Research Fund. The £1.5 billion fund has been working to support cutting-edge research that addresses the challenges faced by developing countries.

They're particularly concerned about the number of people studying engineering in the UK - more specifically the fact that fewer girls are interested in studying engineering. Laing said:

“Engineering success is absolutely vital to the future of the UK, Zimbabwe and indeed all countries. We’ve seen how in the UK what a massive contribution engineering and engineering research makes to the UK economy and to the lives of UK citizens. Back in 2015 it was reported that engineering-related sectors have contributed around 280 billion pounds to the UK’s Gross Value Added in 2011 - about 20 percent of the total.”

Zimbabwe’s engineers and the engineering industry are well placed to help revitalize their economy and bring them out of the historical hyperinflation they have seen in the last few decades. However, with political tensions still present in the country, uncertainty reigns.

LEGO lends a helping hand

Another hot topic is the renewed push to prevent attrition rates in science and mathematics in schools. The United Kingdom, for example, continues to push for overhauling education and training in engineering. In this environment LEGO is reminding the world that the development of affection for STEM (Science, Technology, Engineering and Mathematics) starts with LEGO.

LEGO are now supporting the ‘Year of Engineering’ national campaign and will be travelling around the UK, visiting primary schools and inspiring the UK’s future engineers. The UK government said they see a shortage of 20,000 engineering professionals per year. On top of that, only 12% of engineers in the UK are female.

Therefore, LEGO will be running the ‘The Engineers of the Future’ roadshow. They will be giving children hands-on experience with new technologies and the opportunity to hear already prominent engineers speak about their careers.

Minister for the Year of Engineering, Nusrat Ghani said:

“Engineers are at the forefront of technology and infrastructure advances which are shaping all of our lives, from how we communicate and travel to tackling major challenges in healthcare and the environment. But the opportunities of this creative, innovative and hugely important profession are all too often misunderstood and overlooked by young people and their parents.”

The students will take part in challenge called the FIRST LEGO League. The challenge will see students trying to make sense of and solve some complex engineering problems.

Camilla Bottke, Head of LEGO Education After School and Competition said:

“For more than 35 years it has been our mission to inspire and develop all children, equipping them with the right skills to empower them to succeed, whatever their background and whatever the ambition. Our experience shows us the importance of supporting development of STEM skills in children from an early age. We are delighted to be part of the UK government’s ‘Year of Engineering’ initiative to further our commitment to developing these important STEM skills in children across the country and leveraging technology to give children the opportunity to become aspiring engineers.”

Works Cited

Commonwealth Office. “Engineering Success Vital to Zimbabwe's Future: UK Ambassador.” GOV.UK, GOV.UK, 18 June 2018, www.gov.uk/government/speeches/engineering-success-vital-to-zimbabwes-future-uk-ambassador.

“LEGO® Teams up with Year of Engineering Campaign to Inspire and Develop the Engineers of the Future.” GOV.UK, GOV.UK, www.gov.uk/government/news/lego-teams-up-with-year-of-engineering-campaign-to-inspire-and-develop-the-engineers-of-the-future.

- Details

- Written by: Quintus Potgieter

Grease (lubricant). Engineering industries’ little talked about best friend. Lubricants are present in many engineering industries: Power Generation, Water & Wastewater, Food & Beverage, Oil & Gas, Transportation & Fleet industries, and more. Lubricants simply help machines run at optimum efficiency - and have given rise to the term ‘a well-oiled machine’.

Industrial lubricants also ensure that machines stay healthier for longer. Reducing the amount of friction a machine undergoes during its operation is lubrication engineers’ bread and butter. For fleet owners, for example, having trucks work around the clock is an important outcome for their business models. Trucks still play a vital role in our modern day world - countless industries depend on trucks to get product from ‘A’ to ‘B’. Engine oils, transmission fluids and fuel supplements are important to the truck’s efficiency and lifecycle.

But how much innovation is occurring in the lubrication industry? It turns out that it is quite a bit.

Oil quality is a big focus of the grease world where innovation is welcomed. New blends of greases are being designed that can withstand far more heat and can lead to far less wear and tear - it is all done with synthetic-blend compositions.

A technical services manager for CHS Transportation, talking to Fleet Owner, says:

“Grease isn’t just grease. It’s changed. The quality of the base oil is incredibly important. It’s the majority of what goes into the grease. Synthetics tend to have better life expectancy. You want grease to stay in place so it can do its job where it’s supposed to do its job.”

Country specific recipes

Modern day synthetic greases are 70 to 90% base oil and the remainder is thickener. As newer technologies were introduced into the lubricant industries the thickener has vastly improved; now holding oil better than most greases in the past. Historically, greases would see much oil run-off and wastage.

Even modern day conventional oils sometimes fall short in countries where temperatures drastically drop during winter. Thus, there are specific standards developed per region, catering for what oils are needed. However, there are universal lubricants for specific industries.

Using synthetic oils that are specifically designed to work in those lower temperatures is advisable. But lubricants are not only utilized to keep those truck engines running in winter, they are also used to stop excessive metal-on-metal contact, Ball bearings are in the direct line of experiencing wear and tear. Woetzel says:

“You’ve got to avoid metal-to-metal contact at all cost. Any kind of direct contact leads to wear and tear, which eventually causes problems down the road.”

Future Markets Insights believe that the global industrial lubricants market will be seeing a high growth rate in the next few years due to the growing automotive industry. Power companies and plant operators also utilize oils for their turbines. Where there is machinery, there is always a need for some grease.

Another issue confronting lubricant makers is the need to create them with the environment in mind. Synthetic and renewable, non-hydrocarbon oils is where the industry has been moving to, and engineers have to adapt.

Online sensors have also made their way into the industry. The sensors scan the lubricants and analyze the lubricants in real time to ensure they are effectively offsetting the wear and tear occurring inside a machine. The need for efficiencies and preserving technologies over time has given rise to lubricant innovation, and more can be done despite synthetics being in existence for many decades now.

Mobil recently celebrated 150 years of lubricant innovations. To see how they built their entire company around lubricants - which propelled the industrial revolution forward - is shown in this video:

Lubricants simply keep the world moving. And they will be with us for many years to come to improve efficiencies, circumnavigate the wear and tear of machines, and keep things going along smoothly.

Works Cited

12, Jun. “Grease: The New Frontier in Fleet Technology.” Fleet Owner, 13 June 2018, www.fleetowner.com/lubricants/grease-new-frontier-fleet-technology.

Budholiya, Abhishek, and Himesh Khatri. “In-Depth Forecast & Analysis on Industrial Lubricants Market for 2015 – 2025.” SatPRnews, www.satprnews.com/2018/06/11/in-depth-forecast-analysis-on-industrial-lubricants-market-for-2015-2025/.

- Details

- Written by: Quintus Potgieter

110,000 Australian homes are to be powered by renewable energy sources before the end of 2018. Much of this is thanks to Partners Group - the global private market investment manager. They will be investing a total of AUD$700 million in a renewable energy platform named the Grassroots Renewable Energy Platform.

The investment will, over four years, help add 1.3GW of new wind power, solar power, and battery storage projects in Australia. It is not the first time Partners Group has thrown their weight behind the Australian renewables sector. In 2015, they pledged AUD$450 million for the building of the Ararat Wind Farm in Victoria. The local developer utilizing the funds and building the farms is CWP Renewables. They are in the business of delivering energy, and powering communities.

Then in 2016, the investment firm pumped a further AUD$250 million to complete the 270MW Sapphire Wind Farm in New South Wales. This particular wind farm is going to be the most important player in the new Grassroots Renewable Energy Platform the company plans to perfect in Australia. It is thought that the wind farm would be paired up with an upcoming solar and battery storage project.

This cash injection is changing the face of power generation in Australia. The Head of Private Infrastructure Asia-Pacific at Partners Group Benjamin Haan said:

“When we invested in Sapphire Wind Farm, one of the key attractions for us was the project’s potential to anchor an Australian renewable energy platform. Partners Group and CWP have a project in the pipeline of 1.3GW in generation capacity across wind and solar power, offering the scope to be selective and develop Grassroots into a quality renewables platform of significant scale. We look forward to working with the CWP team to further support the generation of clean energy in Australia.”

CWP boss, Alex Hewitt, believes that the platform will undeniably help Australia transition from a fossil-fueled electricity industry to one powered by renewables at ‘very affordable prices’. An added benefit of bringing the wind farms online will be a marked decrease in carbon emissions.

Not stopping there

An extra 55,000 homes will be getting clean power in 2019 when the second project, the Crudine Ridge Wind Farm, is completed. That farm will produce 135MW in Mudgee, New South Wales. And of course power isn’t the only thing being generated – jobs are too. By September of next year the General Electric wind turbines will be erected, producing 75 full time jobs.

Partners Group adds that over its lifetime, the Crudine Ridge Wind Farm, will offset eight million tonnes of carbon emissions.

And if all goes well, with continued innovation in renewables, the Grassroots platform could indeed become an Australian clean energy superpower. Talking to Clean Technica, Haan concluded:

“In Australia’s energy market, a significant transition away from fossil-fuel power is now underway. The compelling economics of renewables and the age of older coal plants is driving that change, the speed of which is ramping up. While it is true that political instability has delayed the transition in the past and the sector is still somewhat fragmented, the Grassroots platform is aimed at this transition and its business plan is robust enough to deal with any likely outcomes from the current political debate. We believe Grassroots has the scale and competitive edge to succeed and become a significant renewable IPP in Australia.”

Works Cited

“Partners Group to Invest AUD 700 Million in Australian Renewable Energy Platform; Announces Imminent Construction of Crudine Ridge Wind Farm.” Private Investors, www.partnersgroup.com/en/news-views/investment-news/current/detail/article/partners-group-to-invest-aud-700-million-in-australian-renewable-energy-platform-announces-imminent-construction-of-crudine-ridge-wind-farm/.

“Swiss Equity Firm Commits To 1.3 Gigawatt Australian Renewable Energy Platform.” CleanTechnica, 29 May 2018, cleantechnica.com/2018/05/29/swiss-equity-firm-commits-to-1-3-gigawatt-australian-renewable-energy-platform/.

- Details

- Written by: Quintus Potgieter

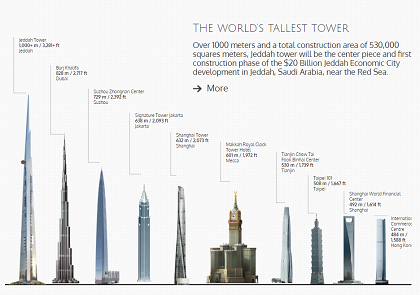

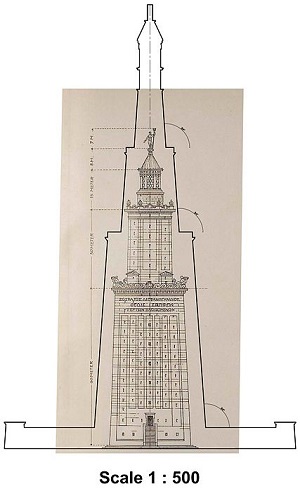

The world’s tallest building, the Burj Khalifa in Dubai, is about to be dethroned. 1,200 miles away, a new tower is nearing its completion in Saudi Arabia. In 2020, the tallest building in the world, the Jeddah Tower measuring in at one kilometer, will open. That is if engineers can complete the audacious towering skyscraper on the desert sand.

The tower’s construction is estimated to cost the Kingdom Holding Company around US$1.5 billion. Jeddah Economic Company website initially reported that the tower would stretch “over 1000 meters” but Engineering360 says those plans have changed. Nonetheless, the tower will also have the world’s highest observatory deck ever built.

The tower will also be the centerpiece of an almost Singaporean city, a center for business and commerce. This city will be called the Jeddah Economic City. The entire district is to cost US$20 billion. It will include a new airport and cutting-edge infrastructure, replacing the dated and aging infrastructure Saudi Arabia has become synonymous for.

Building on sand

Whilst building a kilometer high building is obviously an engineering challenge, another engineering conundrum is how to build on the fine sand in Saudi Arabia. Civil engineers have had to closely study the 5 subsurface layers of the sand in Jeddah.

Geographically the tower is near the Red Sea.

Roger Pink from IEEE Global Spec’s Engineering360 explains:

“The first layer, varying from half a meter to 2 meters thick consists of silty sand. The next 40 to 50 meters is coralline limestone, followed by a 2 to 10-meter thick mudstone/gravel layer. Next comes a poorly constituted sandstone layer about 35 to 50 meters thick, followed by another 3 to 9-meter gravel layer. Finally, below all of this is a sandstone layer as far as 200 meters.”

The unique challenges have been figuring out how to utilize the architecture blueprints and build sturdily according to those designs. The architect for the project is American born Adrian D. Smith - coincidentally the architect behind the Burj Khalifa in Dubai. He is also responsible for the Trump International Hotel & Tower in Chicago, the Jin Mao Tower in Shanghai and the Zifeng Tower in Nanjing.

The engineers have created a three-winged load-bearing design. This design also has to account for wind and the pressures that it brings. The project began construction in 2013, but a series of delays has led to the most recent end-goal which is 2020.

One of the delays arose because of the height of the Jeddah Tower. Civil engineering experts advised the architects that the higher up they go, the more unstable the concrete becomes. That high up, the wind load would cause the concrete to shrink under the pressure. (This has also meant the construction has had to be as aerodynamic as possible.)

Specialized concrete pumping equipment with thin, pressurized pipes is being utilized to counteract the forces of gravity on the concrete. Pumping wet concrete a mile in the sky is allegedly the most challenging element of the construction.

The engineers have had to work later in the evenings at lower temperatures. This allows the concrete - being pushed out a single tube - to set. However, concrete is not the only thing that needs particular attention - transporting humans to the top of the tower will be a challenge too.

Bart Leclercq, head of structures for WSP Middle East, explains:

“You have to make sure a tower is not too flexible and people aren’t getting nauseous in high winds. You have to put enough stiffening elements in your building. For example, sheer walls in combination with concrete cores in the case of a concrete building.”

A novel approach to an elevator system is being drawn up to ensure the elevators do not suffer under the wind loads and the building sway. The tower is expected to have a wholly different elevator system - the first of its kind in the world.

The engineering challenges and the feasibility of a mile-high tower have meant that the architect’s original plans have, in some instances, changed to accommodate the actual construction of the tower.

Hisham Jomah, chief development officer at JEC, told the Times of Oman:

“Between theory and application: what has been designed and what is actually on site is quite another world.”

This year, over 50 percent of the construction is reportedly completed. Here is a video of the progress made on the tower in the first half of 2018:

To see how six cranes will contribute to the construction of the Kingdom Tower Jeddah, take a look at this construction simulation:

The entire project is a marvel of engineering from construction phase to completion. And as far as tall buildings go, in 2020 this tower will have reset the bar. It does, however, make one wonder at the significance of it all?

Works Cited

“Home Page.” Times of Oman, NEWSPAPER_NAME, timesofoman.com/.

Pink, Roger. “Jeddah Tower - Building a Skyscraper on Sand.” A Water Treatment Alternative to Chlorine? | Engineering360, insights.globalspec.com/article/8791/jeddah-tower-building-a-skyscraper-on-sand.

_TWIITERID. “Jeddah Economic Company | Home.” Http://Www.jec.sa//, www.jec.sa/.

Ephgrave, Oliver. “Tall Order.” ConsrtuctionWeekOnline.com, www.constructionweekonline.com/article-13533-tall-order/.

- Details

- Written by: Quintus Potgieter

A startup in Melbourne, Australia, has introduced the world’s biggest 3D printer. The company in question is

They boast that they also have the industry’s fastest metal 3D printing production line.

They specialize in titanium, of course. They print for an assortment of industries. They produce and manufacture metals for space ships, automobiles, skyscrapers, bicycles, military marine vessels, yachts, wheelchairs, mining equipment, and offshore oil and gas drilling stations.

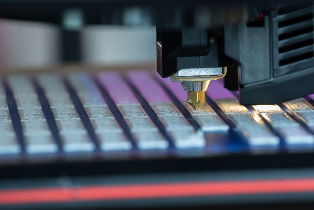

Their 3D printer stands at 1.5 meters high, has an area of 9 meters and is 3 meters wide. The 3D printer can produce 45kg (99lb) of printed material per hour. Smaller machines, CEO Jeff Lang says, can only do 1kg (2.2lb) per 24 hours. The size and efficiency of Titomic’s machine

CEO of

The printer has a printing function the company has dubbed

In short, the process uses kinetic fusion instead of melting metals to build.

The company has begun utilizing their new fusion methods to create seamless titanium bicycle frames. They produce a new bike every 30 minutes with a smaller machine utilizing the same fusion methods the larger 3D printer employs.

The process was created in collaboration with the Australian federal scientific research agency CSIRO. Business Insider reports that the previous title owner of ‘biggest 3D printer’ was GE’s machine - which could print metal objects of up to one cubic meter.

Here is a timelapse of Titomic’s machine printing a sign in four minutes:

Why titanium?

The benefit for bikers is immediately apparent. Titanium bike frames are more durable than those made from carbon fibre. The golf club company, Callaway, is also very interested in this very capable printer.

However, titanium isn’t the only metal the company is looking to use.

CEO of

“When we look at carbon fibre parts they generally make a hollow part called a monocoque construction. We’re sort of at the stage now where we can achieve that with metal,

Lang believes that their printer signals the birth of a new industry for metal manufacturing. He says now, with

The printer, Lang says, is creating titanium at a level that is “very close” to the strength of titanium when created using traditional methods - but concedes that more can be done to improve its printing methods. The printer has shown how efficient the process of additive manufacturing

Works Cited

Farquhar, Peter. “A Melbourne Manufacturer Just Fired up the World's Largest 3D Metal Printer.” Business Insider Australia, Business Insider Australia, 16 May 2018, www.businessinsider.com.au/a-melbourne-manufacturer-just-fired-up-the-worlds-largest-3d-metal-printer-2018-5.

Quick, Darren. “World's Largest Metal 3D-Printer Scales up Additive Manufacturing.” New Atlas - New Technology & Science News, New Atlas, 18 May 2018, newatlas.com/titomic-worlds-largest-metal-3d-printer/54667/.

- Details

- Written by: Quintus Potgieter

If you aren’t utilizing a service that delivers your groceries to your door now, you most likely will use one in the future. Thanks to automation, you won’t have to cast your mind to the nonexistent workers that are packaging all of your groceries up for you - because all of the workers will be robots.

If it sounds like a persuasive brochure from a futuristic sci-fi novel, it isn’t. It’s already happening. Ocado warehouse in Hampshire, England, utilizes hundreds of robots on a metal grid, speedily transferring groceries from holding cell to packet to your front door. And we have engineers to thank for that.

The warehouse where the robots perform their gymnastics is completely unmanned. Pick-and-place robots are abundant, carefully lifting and then putting down items that will be shipped to the demanding customer.

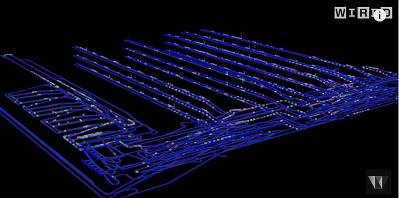

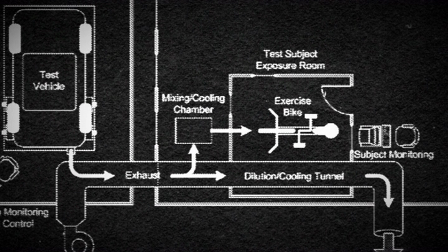

It is all made possible through an automated solution named the Ocado Smart Platform Automated Fulfilment Solution. The graphical representation of what is going on in the computers’ brains as it fulfills an order looks like this:

The whole robotic ‘ecosystem’ is orchestrated through a 4G-based wireless protocol system that is running the whole system in real-time and can optimize the operation on-the-fly. The company says the system is the most advanced system for logistics in the world.

Thousands of little specks on a digitized warehouse blueprint map show what the robots see - items ready to be fetched and delivered. It is called a resource map.

440 other specks (the robots) then need to travel into the interior of the warehouse and pick the items up. The 4G network makes the magic happen - it communicates at 10 interactions per second with each robot.

The robots need to know where to be at the appropriate time. The system can handle 3 million routing calculations per second. Something that quantum computing, upon its arrival, will more than quadruple. It is an ecosystem of robotic automation, working in complete harmony - something human workforces are hard pressed to perfect.

source:wired

Talking about efficiency, the grid that Ocado has designed ensures that all possible warehouse floor space is utilized so that there is no wasting of resources whatsoever. The company says that the grid can be retrofitted into existing warehouses.

The robots themselves can carry tens of kilograms and can move at several meters per second - there is no doubt that the robots are efficient. They are so efficient they have dubbed their robot battalion a ‘swarm’ of robots. Traversing a grid the size of several football fields, the robots communicate via a cloud-based solution and continually generate data that gets plugged into an analytics program named BigQuery.

It is a data and communications tour de force. Experts say the data communications network the company is running is the first of its kind and is the ‘first deployment of unlicensed 4G spectrum for warehouse automation’. The warehouse can handle up to 1,100 robots.

Thus, it is a glimpse of the not too distant future for all warehouses.

However, Ocado isn’t the only company utilizing robots in warehouses. Amazon has a staggering 45,000 robots currently whizzing around in 20 fulfillment centers - grabbing the relevant items customers have ordered, and transporting it to the delivery departments. From 2016 to 2017, they doubled the number of robots that was working for them. Amazon purchased the robot company Kiva Systems in 2012, and has been using warehouse robots ever since.

It is no secret, automation is replacing the pick-and-place workers in warehouses. What has been kept secret are the incredible data communications systems in place to ensure the most efficiency for a warehouse. Companies are looking to automate more efficiently than the next company, and it seems Ocado - with their own novel software and systems - is pulling ahead.

Works Cited

“Ocado's Robot Swarm.” New Electronics, 23 May 2018, www.newelectronics.co.uk/electronics-news/ocados-robot-swarm/174218/.

Shead, Sam. “Amazon Now Has 45,000 Robots in Its Warehouses.” Business Insider, Business Insider, 3 Jan. 2017, uk.businessinsider.com/amazons-robot-army-has-grown-by-50-2017-1?IR=T.

- Details

- Written by: Quintus Potgieter

Food and beverage processing has been achieved by

With the rise of

Fast food giant,

Four MIT engineering graduates have gone into the restaurant business and shown the world the future with their automated kitchen. It is the brainchild of Michael Farid, who during his Masters in Mechanical Engineering, found that he had almost no time to cook himself meals.

He recruited Braden Knight, Luke Schlueter and Kale Rogers to acquire the technology they would need for the project of creating an automated kitchen. They, too, agreed that they couldn’t find a decent meal at an affordable price point as students. They subsequently began their work on the restaurant of the future. ‘’

In 2015, they took their idea to MIT’s Global Founders’ Skills Accelerator program. They had officially become a startup. They gave the restaurant they would open a name: Spyce.

When they had all the robotics figured out, they had to get a menu going. Therefore, they brought in a gentleman named Daniel Boulud, a Culinary Director and Michelin-Star Chef. Michael Farid guessed Boulud’s email address and asked if he wouldn’t mind creating a menu for their automated kitchen. Boulund says the robotic kitchen brings ‘precision’ and ‘consistency’ to the kitchen - something which humans struggle with.

They eventually opened the restaurant in downtown Boston on May 3rd, 2018. What’s on the menu? An assortment of stir-frys. So how does the restaurant work?

Customers are ushered in by a host. Food is ordered via an automated kiosk. The automated kitchen then gets to work after which the

Every bowl costs US$7.50. Patrons can opt to add proteins for an extra cost.

The

To see how it all came together, check this video out:

The replacement of human workers in the food industry is already causing some consternation in the industry. Members of Las Vegas’ Culinary Workers Union recently went on strike to force employers to amend their contracts to protect their jobs from being replaced by automated technologies.

But Luke Schlueter, the head mechanical engineer on the project, has made assurances that only one or two processes have been automated in their kitchen and that humans are still as vital as ever. He said:

“Our robotic kitchen was designed to be a tool. At our restaurant, our robotic kitchen allows our managers to focus on making our bowls look beautiful, applying the finishing touches, and being creative. We also have a commissary team that preps our ingredients for the robotic kitchen. We’ve designed the robotic kitchen to work in harmony with

Works Cited

Coxworth, Ben. “Restaurant Keeps Its Prices down – with a Robotic Kitchen.” New Atlas - New Technology & Science News, New Atlas, 29 May 2018, newatlas.com/spyce-restaurant-robotic-kitchen/54818/.

“Las Vegas Food Service Workers Are Going on Strike so They Don't Lose Their Jobs to Robots.” Futurism, Futurism, 29 May 2018, futurism.com/las-vegas-food-service-workers-strike-automation/.

“Spyce Restaurant Opens with Robotic Kitchen Ready to Serve.” Should the Federal Government Raise the Minimum Wage to $15? - MIT Sloan School of Management, mitsloan.mit.edu/newsroom/articles/spyce-restaurant-opens-with-robotic-kitchen-ready-to-serve/.

- Details

- Written by: Quintus Potgieter

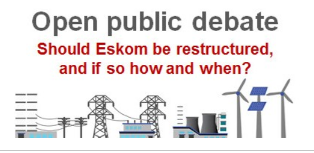

A vast number of jobs are potentially on the chopping block in South Africa: engineering professionals, senior project managers, energy storage specialists, coal truck drivers, technicians, asset managers, operations officers, and others. They are seriously threatened if the state-owned power utility, Eskom, restructures its operations.

Presently it powers 95 percent of South Africa, but it is not looking good. It is struggling to weather historical maladministration, a failed nuclear deal with Russia, crippling debt and a change of presidents. Electricity distribution is once again under the microscope.

The situation is looking particularly dire as the country moves into their winter months. Three managers at the company were recently suspended, deemed responsible for coal shortages, and the utility is also without a CEO at the moment.

Up for debate?

To ensure an ongoing electricity supply in the country an open public debate was held in Johannesburg earlier this month. It was tasked with asking the pertinent question: ‘Should Eskom be restructured and if so how and when?’

Frans Baleni, the Deputy Chairman of the Development Bank of Southern Africa and former Secretary-General at the National Union of Mineworkers (NUM) argued that the utility has served South Africa well; he believes it is impossible to turn back from the network footprint it has.

He says that Eskom has a solid fleet of generation plants, but concedes that they are now aging and need to be upgraded.

He says that Eskom has a solid fleet of generation plants, but concedes that they are now aging and need to be upgraded.

He warns that a complete restructuring of the utility would put 40,000 jobs at stake. He proposes that the utility deals with governance issues, focuses on building investor confidence and deals with corruption decisively, so that business performance can be prioritized.

Miss Nelisiwe Magubane was also one of the speakers at the debate. She is a Non-Executive Director of Eskom and Former Director-General at the Department of Energy. She is an electrical engineer with 25 years of experience. She is a key player in energy policy in the energy sector. She has also been named as one of the top 50 most influential people in the energy sector in South Africa.

She commented that those countries with a more privatized energy sector had superior systems, when compared to the vertically integrated state-owned utility business model. However, she thinks the terms and conditions surrounding the privatization of the energy sector in South Africa should depend on whether a private system would lead to the lessening of inequality and poverty.

She said:

“What kind of industry structure is going to meet our objectives? You need skills, you need drive, you need financial astuteness. We need to have a proper governance of the energy sector. It needs to be beneficial for all South Africans.”

Dr Grovè Steyn, a graduate from the University of Cape Town and the University of Sussex, was the last speaker at the event.

Steyn started his career as an Industrial Engineer at Eskom. He went on to become a leading infrastructure and regulatory economist in South Africa. He is currently the Managing Director at Meridian Economics. He says undoing the 95 year institutional model of Eskom is going to be a tough process, but it has to be done. He explained:

“This institutional model has long since outlived its usefulness. It has now become critical for South Africa to embrace the technological disruption and address the environmental imperatives in the power sector.”

Steyn says Eskom’s ‘abuse of dominance’ in South Africa has led to ‘managerial moral hazards’. Citing numerous studies, Steyn highlighted the ‘human cost’ of coal power stations - explaining that coal power reportedly kills 2,000 people in South Africa per year.

Steyn advocates for clean, renewable energy sources. He notes that the reduction of costs in technologies such as solar and energy storage means governments have little choice but to use the cleaner alternatives in new energy project builds.

He also wants the energy sector to open the industry up to new players, to move away from the state-owned monopoly. More choice, more competition and a democratized energy industry can’t be a bad thing.

“It is now globally recognized that electricity generation is best organized as a competitive sector. And our own experiences with our IPP program supports this very strongly.”

Where are the jobs being created?

Power sector talks, which are now a national conversation, are pressing for the sector to be overhauled. South Africans need to ensure they are skilled-up to deal with the newer power generation technologies, and the jobs that are created through them.

Some of the traditional jobs will begin to dwindle; coal truck drivers are particularly concerned that they will be made redundant. Already Eskom has said it wants to shut down four coal power stations by 2020. In their stead the country is asking renewable energy providers to apply for tenders to create renewable plants in South Africa.

The renewable energy industry is responsible for the creation of a large number of jobs around the world. According to the International Renewable Energy Agency, there were 3.4 million renewable energy jobs available in the photovoltaic industry in 2017 alone. The entire energy industry accounted for 10 million jobs last year - with China supplying 43 percent of the industry.

A group providing renewable energy, Abengoa, has just completed the construction of a concentrated power plant in the Northern Cape. They believe South Africa’s best bet for a secure renewable energy supply is to go with blended energy plants: with both solar photovoltaic (PV) technology and concentrated solar power (CSP) technologies.

Works Cited

Bloomberg. “Renewable Energy Jobs Are Becoming More Available.” IOL Business Report, 11 May 2018, www.iol.co.za/business-report/energy/renewable-energy-jobs-are-becoming-more-available-14881893.

Creamer, Terence. “South Africa Urged to Consider CSP-PV Blend to Lower Cost of Dispatchable Solar Generation.” Engineering News, www.engineeringnews.co.za/article/south-africa-urged-to-consider-csp-pv-blend-to-lower-cost-of-dispatchable-solar-generation-2018-05-07.

Watson, Amanda. “Which Way for Eskom?” The Citizen, citizen.co.za/news/south-africa/1925176/which-way-for-eskom/.

- Details

- Written by: Elyse Simich

The Vasa

This Swedish ship was constructed between 1626 and 1628 and intended to be part of the Royal Swedish Navy. However, it only got 1300 metres into its maiden voyage before it capsized and sank. King Gustavus Adolphus oversaw the project and put tight time constraints on the engineers to get the ship finished. He also requested design changes mid-project, despite the constructers advising against them. Once the construction was finished, engineers conducted stability tests on the ship and concluded it was not sea worthy. The King ignored this and ordered it to be launched anyway. Light breeze caused the ship to capsize as soon as it left the harbour, and the ship sank as water flooded into the gun portals. 53 sailors lost their lives.

St Francis Dam

The St Francis Dam in California had been operational for two years, when in 1928 it exploded and killed over 450 people. Constructed out of concrete, it started showing signs of cracking shortly after being filled. This is because the dam was built from plans that were originally meant for another site, with no location-specific modifications. During construction, the height of the dam was increased twice, but the base remained the same – this reduced the safety margin for structural stability significantly. For a considerable amount of time leading up to the explosion, muddy water was observed entering the dam from within the foundation. The dam failed less than 12 hours after the last inspection by its engineer.

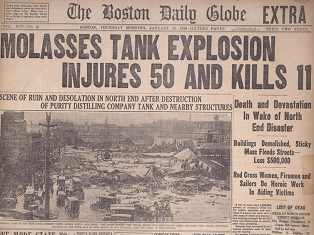

Purity Distilling Company Tank

On 5 January 1919, a giant molasses tank blew up and coated a Boston neighbourhood in sticky syrup, killing 21 people and injuring 150. Molasses wasn’t only used to make rum; during World War 1 it was used to make munitions. This tank was built hastily because of the war and as a result, it was never filled to capacity to test for leaks. As soon as it was filled with molasses it began leaking, so the owners painted it brown to camouflage the stains. Investigations into why the tank exploded were inconclusive; however some possible causes were a too-brittle tank or a reaction caused by a mix of hot and cold molasses brought on by extreme changes in temperature. When the tank exploded, 8.7 million litres of the syrup peaked at 27 metres and rushed into the streets at 56 kilometres per hour.

R101 Airship

In 1930, British Airship R101 crashed killing 48 people. Originally this airship was conceived by the British Government as an experimental platform. However, after completion, the government decided they’d like the airship to fly commercially in order to compete with a German plane which had just successfully flown around the world. Engineers weren’t given time to fix any of the structural and mechanical issues in the design, nor were they able to run flight trials. As a result, the plane was heavier than intended and the engines were half as powerful, yet twice as heavy as planned. The plane was dispatched on a flight to India, despite being unfit to make the journey and with no regard to the bad weather. The load of fuel and unnecessary cargo exceeded the ship’s abilities and compounded the other design flaws.

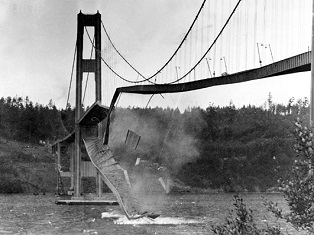

Tacoma Narrows Bridge Collapse

In November 1940, the third longest suspension bridge in the world collapsed, killing one dog. The Tacoma Narrows Bridge was designed to be the most flexible bridge ever constructed and despite exceeding standard ratios for length, width and depth, it was considered completely safe. It was later found that the engineers responsible for the project hadn’t taken into account all the aerodynamic forces brought about by strong winds. The sustained wind that passed over the structure that day caused vortices to occur, which started rocking the extremities of the bridge out-of-time with its middle. This caused one of the suspension cables to snap and the motion intensified, causing the entire structure to collapse.

Cleveland Gas Explosion

In 1944, two liquid gas tanks exploded in Cleveland, Ohio, killing 130 people. There were four above-ground tanks used as storage for the gas and one began leaking, sending white vapours into the air. The wind pushed the vapours towards the sewage system, which created the explosion. This storage tank caught fire and began destroying houses and factories in the area. As firefighters worked on it, a second tank also caught fire. 600 people were left homeless as a result of the damage. It took the all the firefighters in that town to put the fires out.

The de Havilland Comet

The world’s first commercial aeroplane featured turbojet engines rather than propellers, a bullet-shaped body, a pressurised cabin and square windows. These engines allowed it to fly higher than its competitors, avoid bad weather and increase its speed by up to 50 per cent. Built in 1949, it was commissioned by airlines such as Pan Am, South African Airways, Japan Airlines and Air India. In its first year it flew 30,000 passengers including Queen Elizabeth, taking customers from London to places such as Tokyo, Colombo and Johannesburg. By 1953 Comets were leaving London each week. However, there was a major structural design flaw which became evident after two crashes occurred in 1954.

On flight 781 from Rome, the plane exploded 20 minutes after take-off killing everyone on board. Crash investigators found the recovered bodies all had fractured skulls and ruptured lungs. When a South African airways plane crashed a few months later, the recovered bodies had all suffered similar injuries. Investigators found both accidents were caused by inflight metal fatigue failure, which led to explosive mid-air compression. The square windows were to blame for this – the sharp corners of the windows put the surrounding metal under stress at high altitude. Since the stress was localised to just the corners of each window, it resulted in metal fatigue. This is why round windows are always used in aeroplanes now; the stress is able to flow evenly around the window.

Firestone 500 Tires

There were over 60 deaths and a hundred serious injuries caused by Firestone 500s across the US, culminating in a recall of millions of tires in 1978. Firestone was a popular tire brand in US prior to the 1970s, however, when radials became available in the American market their sales began to fall behind. In response, they engineered a radial tire but cut corners in order to release it in the shortest amount of time possible. One of the biggest issues in the manufacturing process was the use of incorrect machinery, as the radial-specific equipment was yet to be installed. Over a period of four months the tires passed high speed tests, high mileage tests and overload tests at maximum weight. A couple of years after the tires had been put on the roads, major accidents occurred, caused by tread rubber separating from the brass-plated steel belt at high speeds. While the cause of this separation was never proven, it’s believed the tread wasn’t adhered to the steel belt correctly and water got in, causing the belt to corrode.

Kansas City Hyatt Regency Walkway Collapse

In July 1981, two walkways collapsed at the Hyatt Regency Kansas City hotel killing 114 people and leaving over 200 injured. During its construction the 40-storey building experienced some setbacks, including the collapse of the atrium roof. The lobby was one of the hotel’s defining features, with steel, glass and concrete walkways connecting the second, third and fourth floors from north to south. The walkways had been designed with support beams and tie rods to carry the weight of the people standing on them. However, the design of the fourth-storey walkway had been modified slightly, and the change critically undermined the safety of the structure. On the night of the tragedy, 1600 people were in the lobby for a Tea Dance event. There were approximately 40 people on the second-storey walkway and 16 on the fourth-storey walkway. The connections supporting the ceiling rods holding up the second and fourth-storey walkways failed, causing them to collapse onto the crowded first floor.

Therac-25 Medical Accelerator

Between 1985 and 1987 six cancer patients were exposed to overdoses of radiation, killing four of them and permanently injuring two. This was caused by a “cancer zapping” machine, which used X-rays to kill cancerous tissues in patients. One of the issues with this machine was that healthy tissue around the tumour was always damaged too, however, it was always hoped the patient would be healed more than they would be harmed. It turned out the machine was only controlled by a computer and there were no hardware interlocks or supervisory circuits to ensure safety. Engineers had also failed to conduct time-analysis and unit testing of the machine. The software developed a bug, which lead to catastrophic events as the wrong dosage was delivered to patients.

Originally the manufacturers denied that such an error was possible, however a technician familiar with the machine ran experiments in his own time to find out what was causing it to malfunction. It was found the same error could happen in the previous model; however the hardware interlocking system would act as an emergency stop. Since this system had been removed in the current model, there was nothing to stop the machine from administering an overdose. The computer had been programmed to have real-time control over the machine. However when the software was placed under scrutiny, it was revealed the source code had been written by only one person who had little experience with coding for real-time systems. The Therac-25’s code had just been based off the code for the two previous models. Both the software engineers and system engineers were at fault for not properly testing the machine and ensuring tight safety measures were in place.

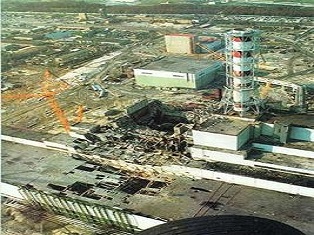

Chernobyl Disaster

In 1986, workers at the Nuclear Plant were preparing for a one-time shutdown, when they violated safety regulations by disabling the automatic shutdown system and removing most of the control rods, while allowing the reactor to continue running at seven per cent. This caused two large reactions to occur , sending radioactive material into the air. In the four months that followed 28 workers died – some knowingly exposed themselves to the deadly levels of radiation in order to prevent the plant from leaking further. Since the radioactive material affected such a large geographical area, many people were displaced from their homes. Thousands of people died prematurely from cancer because they were exposed to such high levels of the poison.

McDonnell Douglas DC-10

These commercial planes were manufactured from 1970-1989 and designed to compete with the Boeing 747 by operating medium to long haul flights. Over 1000 people were killed in a series of incidents brought about by various engineering errors. Two of these incidents involved faulty locking mechanisms on the cargo door, causing it to be ripped off mid-flight and depressurise the cabin. In another incident, the left pylon and engine separated from the wing just after take-off, which cut several hydraulic lines at the same time. 275 people died in the resulting crash.

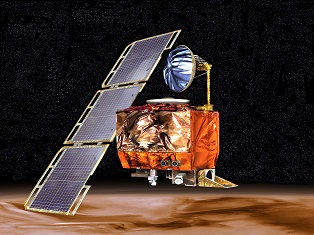

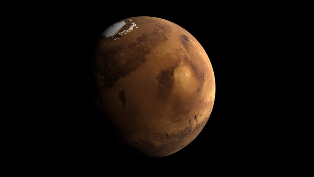

Mars Climate Orbiter

This US $125 million satellite was designed to be the first weather observer on another planet. However, in September 1999, it vanished as it approached Mars, burning up in the atmosphere. NASA reviewed their calculations and realised a conversion error caused the spacecraft to go too close into the Martian atmosphere. The software controlling the satellite’s thrusters calculated the necessary force it needed to exert in pounds. Another piece of software took this calculation and assumed it was in newtons. Unfortunately, the engineers didn’t pick this error up despite the spacecraft making 10 times the amount of adjustments than they expected. It got within 60 kilometres of the Martian surface despite simulations showing anything closer than 85 kilometres would exert enough atmospheric friction to destroy the satellite.

The Millennium Footbridge

This footbridge was opened in June 2000 to celebrate the new millennium and connected St Paul’s Cathedral with the Tate Modern Gallery. Two days later, it was closed indefinitely as engineers re-worked the structure’s design. The US $26 million bridge showcased a futuristic design with an aluminium deck supported by two Y-shaped frames, rather than overhanging arches. Unfortunately, the bridge was wobbly and even a light breeze made it swing. As pedestrians crossed the bridge, they attempted to keep their balance by walking in time with the swaying to counter the motion. This increased the force of the lateral swinging and the rocking increased. New York engineers stepped in and installed 87 dampers underneath the bridge to act as shock absorbers and decrease the motion, costing a further US $7 million. The bridge was reopened 18 months later.

Tokyo Disneyland Big Thunder Mountain Derailment

One person was killed and 10 injured when the rollercoaster derailed in 2003. The gap between the axel and the bearing on the back wheel exceeded design specifications, causing more vibration than it should have and placed extra pressure on the screw holding the axel in place. As a result, the axel broke and the carriage crashed. The reason for the large gap was a miscalculation in measurements when converting them from imperial to metric – the axel should have been 44.14 millimetres rather than 45 millimetres.

French Trains Too Wide For Platforms

In 2014, French train operator SNCF discovered the brand new trains they had ordered at a cost of €15 billion were too wide for many of their regional platform. The trains had been purchased to fit the measurements of platforms built approximately 30 years ago, without taking into consideration the skinnier platforms built 50 years ago. To solve this problem, the rail operator had to spend upwards of €50 million to reconfigure over 1000 platforms across the country.

Sources:

https://accendoreliability.com/vasa-engineering-disaster/

https://www.wired.com/2009/01/jan-15-1919-morass-of-molasses-mucks-up-boston-2/

http://damfailures.org/case-study/st-francis-dam-california-1928/

http://www.airships.net/blog/british-airship-r101-crashes-killing-48-day-1930/

https://www.forbes.com/sites/startswithabang/2017/05/24/science-busts-the-biggest-myth-ever-about-why-bridges-collapse/#58a74fac1f4c

https://www.history.com/this-day-in-history/tacoma-narrows-bridge-collapses

https://www.engineeringclicks.com/cleveland-east-ohio-gas-explosion-1944/

http://www.news.com.au/travel/travel-advice/flights/the-tragedies-that-changed-the-shape-of-plane-windows-forever/news-story/bc723a15ce58a97d839483bfd0e7ce4a

http://www.wheresmychampagne.com/mcdonnelldouglasdc-10/

http://www.rubbernews.com/article/19960812/ISSUE/308129970/the-14-million-firestone-500-radials-still-on-the-road-the-radial-was-prone-to-belt-separation-and-blowouts-and-contributed-to-61-fatal-auto-accidents-according-to-the-national-highway-traffic-safety-administration-500-tragedy-crushes-firestone

https://www.engineering.com/DesignerEdge/DesignerEdgeArticles/ArticleID/175/Hyatt-Regency-Walkway-Collapse.aspx

https://interestingengineering.com/understanding-hyatt-regency-walkway-collapse

https://hackaday.com/2015/10/26/killed-by-a-machine-the-therac-25/

https://www.livescience.com/39961-chernobyl.html

https://www.britannica.com/event/Chernobyl-disaster

https://www.wired.com/2010/11/1110mars-climate-observer-report/

http://mentalfloss.com/article/18407/embarrassing-moments-engineering-and-what-they-taught-us

http://www.mouseinfo.com/forums/tokyo-disney-resort/13134-olc-space-mountain-accident-report-released.html

https://www.nytimes.com/2003/09/06/us/man-is-killed-in-ride-accident-at-disneyland.html

http://www.bbc.com/news/world-europe-27497727

- Details

- Written by: Elyse Simich

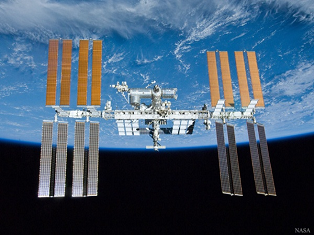

International Space Station

First launched into space in 1998, NASA’s International Space Station (ISS) is an engineering marvel. Costing close to US $100 billion, its construction required over 100 rocket and shuttle launches, plus 160 space walks, and the components were not all in place until 2011. Russia, the US, Canada, the European Space Agency and Japan all contributed, in what became a new collaborative approach to space exploration. The ISS is larger than a six-bedroom house and its systems are controlled by 52 computers – 3.3 million lines of software code on the ground support the 1.8 million lines of flight software code. Covering the area of a football field, the spacecraft is made up of living quarters, laboratories and robotic arms, and each module is connected by nodes. It is so large it can be seen with the naked eye from earth.

The main purpose of the station is to conduct research that cannot be explored anywhere else, such as the effects of microgravity on the human body and investigating the universe surrounding us. The robotic arms assisted in building the spacecraft module by module, after it had been launched, and they help astronauts go on spacewalks. The station gets its power from solar arrays attached to the edges of the craft. The spacecraft was first boarded by three astronauts in 2000. The ISS is now home to six permanent astronauts who live in orbit for four-six months each year.

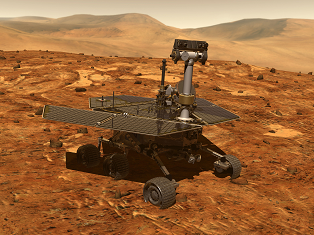

The Mars Opportunity Rover

NASA’s Opportunity Rover has been exploring Mars since 2004, despite originally being launched with the purpose of fulfilling a 90-day mission. This project was originally green-lit in 2000, so the rover was designed with seven instruments, including cameras, a miniature thermal emission spectrometer, magnets, a rock abrasion tool, a microscopic imager and an alpha particle X-ray spectrometer. These tools are designed to allow the rover to investigate the terrain and air compositions, and send this data back to scientists. The fact that Opportunity is now in its 15th year of exploring Mars is amazing in itself – given it’s now the longest living robot on another planet. Opportunity and its twin Spirit were originally sent to opposite sides of Mars to explore the terrain and search for signs of past water and potential habitats, in case Mars was once like Earth. Since then, Opportunity has roved for 45 kilometres and sent more than 250,000 images back to earth. This mission has helped scientists collect evidence of ancient, habitable environments on Mars, to give them a better understanding of the planet.

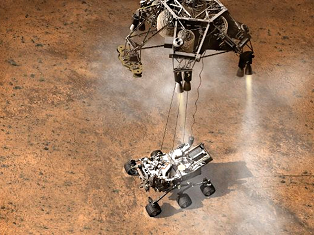

The Mars Curiosity Rover and Sky Crane

In 2012, Curiosity successfully landed on Mars with the intention of exploring the planet’s habitability on a long-term mission. This was the most sophisticated interplanetary probe ever created, with more than 7,000 scientists and engineers involved in its construction. One of the most challenging aspects of its launch was finding a place to have it land – the other rovers were secured inside a bag, which was inflated upon launch to protect the machines upon landing. Curiosity is five times the size of Opportunity, and a bag that big would have been torn apart during descent. In a marathon brainstorming session, scientists and engineers settled on the idea of creating Sky Crane to hover above Mars and lower curiosity down via a cable.

Fitted with the most advanced suite of scientific tools ever sent to Mars, Curiosity is using its built-in laboratory to analyse the composition of rocks and soil in the hopes of detecting chemical evidence of life, such as carbon. In a sample collected from its first drill, it found elements of sulphur, nitrogen, hydrogen, oxygen, phosphorus and carbon, which could potentially support life. Curiosity is also exploring Mars’ environment, including its weather and radiation emissions.

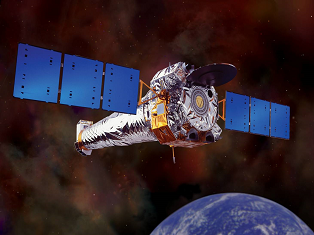

Chandra X-Ray Observatory

One of NASA’s “Great Observatories,” the Chandra X-Ray Observatory was first launched in 1999. Its purpose is to produce full-colour images of objects which are emitting X-ray light, so scientists can develop a better understanding of our universe. In 2007, the telescope monitored a galaxy 240 million light years away and helped astronomers realise the galaxy contained a type of exploding star which they had never seen before. The Chandra X-Ray Observatory circles the earth every two-and-a-half days; its elliptical orbit allows it to travel up to 140,000 kilometres away. It primarily focuses on collecting data about black holes, supernovae, starburst galaxies and exotic objects far from earth. It also has the capability to study foreign objects that cross its path spontaneously.

It has four pairs of mirrors which run perpendicular to the path of incoming light. As the light hits the top mirror in each pair, it filters down to the secondary mirrors, because two bounces are required before an X-Ray comes into focus. The X-Ray the travels down an eight-metre-long tube towards the telescopes scientific instruments, where the information is then sent back to earth to be analysed by scientists. The Chandra X-ray Observatory also contains devices called gratings, which can be used to filter the light and determine an object’s density, temperature, as well as its motion towards or away from the telescope.

Large Hadron Collider

The world’s largest and most powerful particle accelerator was first used in 2008, despite scientists at CERN developing the concept for over two decades. It consists of a 27 kilometre circumference made of superconducting magnets, designed to accelerate the energy of particles as they pass through. It reuses the underground tunnel built for CERN’s previous large accelerator, Large Electron-Positron Collider, which was dismantled in 2000. This is for environmental reasons, such as minimal disruption to the landscape and using the earth’s crust as protection from radiation, as well as economic reasons; it’s more cost-effective than finding enough above-ground space to accommodate the machine.

This machine’s purpose is to help scientists discover more about the universe by smashing subatomic particles together at almost the speed of light. This will allow them to confirm the existence of particles they’ve predicted, discover new ones, and possibly create microscopic black holes. For example, the Large Hadron Collider led to the discovery of the Higgs boson, the final missing piece of Standard Model physics. Scientists are hoping this machine will help them discover how many dimensions there actually are.

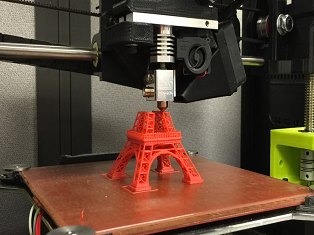

3D Printing

This technology was first developed in the mid-1980s; however, since then it has seen much advancement. At a very basic level, the process begins with the designing of an object via computer software to the correct dimensions. Spools of filament are fed into the 3D printer and turned into plastic; the object is then built layer-by-layer in a process known as additive manufacturing. However, many industrial-grade printers can use materials other than plastic – such as ceramic, brass and steel.

There are endless opportunities as this technology continues to develop, and its availability becomes more widespread. When the concept of 3D printing first came about, it was known as rapid prototyping because it was just used to make creating models easier for engineers. Now we have the ability to construct buildings, machines and furniture with one of these printers. Scientists are now looking into ways to engineer intricate food delicacies. There’s also the opportunity to generate biomaterials for the creation of organs and other body parts, something that would revolutionise the medical world. There are a few limitations to the technology, however. For example, the printer’s size determines the object’s size: you cannot manufacture a house using a regular sized printer. Additive manufacturing is also an incredibly slow process, which means mass production is not yet viable. The cost of these printers and the materials is incredibly high, and it’s currently impossible to achieve the same finish as an industrial machine would.

CT Scanners

Computed Tomography is traditionally the process of using X-Rays to examine a specific part of the human body. Invented in 1972, this machine works by pin-pointing the area to be examined with a narrow X-ray beam, which is quickly rotated around the body to generate a cross-sectional image of the human body. These images, known as “slices,” are far more detailed than that of an X-ray. Once a number of successive images have been taken, the slices can be put together to form a 3D image of the human body. When the machine was first invented, taking these images was a slow process, one slice at a time. The newest machines can record up to 640 slices at a time; however it’s more common for machines to record between four and 320.

However, technological advancements have allowed this machine to be used for much more than the medical field. Industrial Computed Tomography allows engineers to capture the precise dimensions of external and internal structures, without destroying them. This opens the door for reverse engineering in a manufacturing setting: this process determines the measurements of an existing object to allow for mass production. It also allows for easier management of quality control, determining material posterity and ensuring internal contact points are made during assembly. There are still limitations, such as the cost and size of these machines, however this technology has the potential to change the engineering world.

LightStrike Germ-Zapping Robot

In 2010, the LightStrike was launched commercially to combat the spread of hospital acquired infections, as studies showed this was a leading cause of death in the US and throughout the world. This robot uses pulsed xenon lamps to produce flashes of germicidal UV light which destroys bugs in hard to clean places. The high-intensity UV light penetrates the cell walls of micro-organisms and fuses their DNA to kill them without making physical contact. Different pathogens die at different wavelengths, so this machine can be programmed to combat specific diseases: such as, the pathogens most commonly associated with hospital acquired infections, Ebola, Anthrax, HIV, and other communicable diseases. The disinfection cycle runs for approximately five minutes and the robot can clean 64 rooms per day without overheating. The UV-C light it emitted is highly dangerous for humans; however the light cannot travel through walls and glass, so it’s only harmful to humans who are in the room while it’s operating. As a safety measure, the robot is fitted with heat and movement sensors to automatically turn off if a human enters the room.

Bladeless Wind Turbines

Wind is a major contributor to the generation of renewable energy, and reliance on it will only increase as fossil fuels continue to deplete. The most common way to harvest this resource is via wind turbines, which convert wind energy into electrical energy, as the movement of the blades fuel an electricity generator. The top-heavy nature of these machines means high-quality components are required for the blades to decrease the risk of structural damage. Therefore, the cost of producing traditional wind turbines is high.

A Spanish engineering start-up has developed bladeless turbines, which harness the vorticity of air. When wind passes through the cylindrical wind turbines, it becomes a spinning vortex which exerts force onto the cylinder and causes it to vibrate. The kinetic energy created by this cylinder is then converted into electricity via a linear generator. The lightweight design doesn’t have any gears or bearings, and it can produce electricity for approximately 40 per cent less than traditional wind turbines. It’s also less of a danger to birds flying near it. Currently, bladeless turbines are not as effective at generating electricity as traditional turbines; however, with time these machines will be adapted to increase their efficiency.

Sources:

http://www.washingtonpost.com/wp-srv/special/national/nasa-iss/

https://www.nasa.gov/feature/facts-and-figures

http://www.spacesafetymagazine.com/space-exploration/international-space-station/international-space-station-15-years-groundbreaking-achievements/

https://www.nasa.gov/audience/forstudents/5-8/features/nasa-knows/what-is-the-iss-58.html

https://www.nasa.gov/mission_pages/mer/overview/index.html

http://www.planetary.org/explore/space-topics/space-missions/mer-updates/2018/01-mer-update-opportunity-completes-14-years-of-exploring.html

https://www.space.com/17963-mars-curiosity.html

https://www.theguardian.com/science/2013/jul/28/curiosity-rover-descent-mars-nasa

http://www.wired.co.uk/article/large-hadron-collider-explained

http://cds.cern.ch/record/2255762/files/CERN-Brochure-2017-002-Eng.pdf

https://home.cern/topics/large-hadron-collider

https://www.space.com/26612-nasa-chandra-xray-observatory-15-years.html

https://www.airspacemag.com/how-things-work/how-things-work-chandra-x-ray-23580481/?all

https://www.britannica.com/topic/Chandra-X-Ray-Observatory

https://www.independent.co.uk/life-style/gadgets-and-tech/features/3d-printing-for-dummies-how-do-3d-printers-work-8668937.html

http://theconversation.com/explainer-what-is-3d-printing-and-whats-it-for-9456

https://www.nibib.nih.gov/science-education/science-topics/computed-tomography-ct

http://www.digitaleng.news/de/ct-scanning-a-new-way-to-look-at-parts/

https://www.allaboutcircuits.com/news/germ-zapping-robot-aims-to-make-hospitals-cleaner-and-safer/

http://sweetcrudereports.com/2018/01/08/wind-energy-innovations-bladeless-wind-turbines/

http://www.offshorewindindustry.com/news/vertical-bladeless-wind-turbines-future-wind

- Details

- Written by: Elyse Simich

Palm Island

In 2001, there was nothing off the coast of Dubai except for shallow gulf water. However, the city was becoming overpopulated quickly. To solve this problem, local real estate conglomerate Nakheel Properties used GPS precision to shape 94 million cubic metres of sand into a 17-frond palm tree-shaped island. Sixteen quarries throughout the UAE were dredged for rock, which forms a breakwater around the island to protect it from wind and waves. It took a decade for Palm Jumeirah to be fully completed, although residents began moving to the island in 2008. The trunk is made up of luxury hotels and malls; the fronds are lined with mansions. A six-lane underwater tunnel allows people to travel to the island from the mainland and the Middle East’s first monorail travels the length of the island. Two other islands are currently under construction.

Burj Khalifa

Officially the tallest free standing building in the world, this skyscraper is 828 metre high and has 163 stories. The biggest challenge engineers faced were strong winds, so they conducted over 40 wind tunnel tests, not only to determine how the building would be affected, but to ensure the safety of the cranes used to construct it. Built in Dubai, UAE in 2010, the building changes width as it gets taller in a bid to “confuse the wind,” according to global engineering firm SOM, who created the structure. This means wind vortexes cannot form, as they encounter a new shape at each tier of the building. The building has been engineered to withstand earthquakes and other natural disasters.

Kansai Airport

Located in Osaka, Japan, this was the first airport to be built on an artificial island. The project was created as a solution to overcrowding, as the city was too small to fit an airport on the mainland. One of the biggest challenges engineers faced was the clay found in the seafloor they intended to build on – it retains too much water to be a reliable foundation. To combat this, engineers utilised 1.2 million sea drains, a new technique used for sea-based stabilisation. Tubes were driven deep within the clay, filled with millions of tons of sand, and then removed. The columns of sand still act as drains within the clay, to stop the foundation becoming saturated with moisture and moving. 48,000 concrete tetrahedrons were stacked upon the stabilised seabed, with each one weighing 181 tonnes. Nearby mountains were excavated and approximately 161 million cubic tonnes of earth were poured into the gaps. It took three years for the seawall and base to be completed, before construction could begin on the airport itself.

The airport is an architectural wonder, built to reduce environmental impact and save money – blade-like deflectors line the ceiling, channelling air through the building and acting as a passive air conditioning system. Completed in 1994, it took three years and saw over 10,000 workers contribute to its construction. The island is 4 kilometres by 2.5 kilometres and became the world’s most expensive civil engineering project, costing US $20 billion.

Tokyo Sky Tree

Engineers tasked with the construction of the 634 metre high-rise building faced many challenges while building Japan’s tallest building. They had to take into account not only the typhoons that strike Tokyo every summer, but also potential earthquakes as it is built on an active fault. Structurally, it features a reinforced concrete central column, which is separate from the outside steel frame – an adaptation of the design often seen in pagoda temples. Traditional Japanese building technique shinbashira was utilised, which sees the central column reduce sway by counterbalancing seismic waves.

Channel Tunnel