Industry

- Details

- Written by: Quintus Potgieter

In September of 2016, a fire broke out at the Central Aguirre Power Plant rendering electricity transmission lines useless. 1.5 million people were plunged into darkness. The blackout forced the government to declare a state of emergency. The Puerto Rican government was embroiled in a $9 billion debt crisis in 2016. New figures suggest the debt had totaled $70 billion.

Governor Alejandro Garcia Padilla was quoted saying: “This is a very serious event. The system is not designed to withstand a failure of this magnitude.”

A year later, Puerto Rico has become a victim of the tumultuous hurricane season. The territory was hit by Hurricane Maria – crippling the nation and knocking out critical infrastructure. 3.4 million citizens were left without drinkable water and no access to electricity after the hurricane swept over the land.

Once again, the territory’s fragile power grid failed to remain functional in the wake of the devastating hurricane. At least 16 people had died as a result of the storm as well.

According to CNBC, economists within the country are reporting that, thanks to the hurricane, Puerto Rico’s economic recovery has been set back by 10 years.

But how could the philanthropy of engineers assist the people of Puerto Rico? Well, with an electricity grid mostly useless, the engineering invention of lithium-ion batteries could have been of much help.

Power

Elon Musk took to Twitter to respond to a question pertaining to how useful his Tesla PowerWall house-powering - and more infrastructural PowerPack - batteries would have been, in response to Puerto Rico’s need for electricity after the hurricane. He said:

“The Tesla Team has done this for many smaller islands around the world, but there is no scalability limit, so it can be for Puerto Rico too. Such a decision would be in the hands of the PR govt, PUC, any commercial stakeholders, and most importantly, the people of PR.”

The latest governor of Puerto Rico, Governor Ricardo Rossello responded to Musk with a, “let’s talk.” Whether the two men have spoken is still not clear, however, Musk has intrigued many with his assertions that Puerto Rico could be powered by 100% renewable energy.

Nonetheless, the US Army Corps of Engineers jumped in to help Puerto Rico rebuild their infrastructure. They are trying to restore the power grid, using up to 270 generators. These would be used to power “life-sustaining facilities” first.

Internet and cellular

Alphabet, the company that owns Google, announced that they were to “help provide emergency cellular service in Puerto Rico”. They would do this by releasing and hovering an internet hotspot over areas that are without cellular service in Puerto Rico.

The hotspot is placed within a balloon and hovered over the area in need. The balloons used by Alphabet were conceptualized back in 2013 in a project named Project Loon.

Having access to a LTE network will ensure that vital communication needed to continue the rebuilding of Puerto Rico commences. Alphabet had to get a special license from the FCC to conduct the emergency cellular network. Once fully licensed and cleared with both the FCC and local providers, Alphabet intend to float 30 balloons over the territory to supply much needed coverage to those in need.

To see how Alphabet does this, look at their video below:

Works Cited

Imbert, Fred. “Puerto Rico's Economic Recovery May Now Take More than a Decade.” CNBC, CNBC, Sept. 2017, www.cnbc.com/2017/10/09/puerto-rico-economic-recovery-may-now-take-more-than-10-years.html.

Jon Brodkin. Oct 9, 2017 4:03 pm UTC. “Alphabet’s Internet Balloons Will Try to Restore Cell Service in Puerto Rico.” Ars Technica, Sept. 2017, arstechnica.com/information-technology/2017/10/alphabets-internet-balloons-will-try-to-restore-cell-service-in-puerto-rico/.

- Details

- Written by: Quintus Potgieter

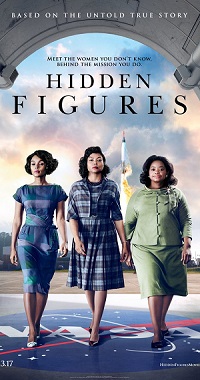

Marc Edwards is a Professor of Civil and Environmental Engineering at the College of Engineering at Virginia Tech. He is not only an engineer he is also a whistleblower. Along with citizen scientists, and concerned residents, Edwards exposed the Flint Water Crisis which began in 2014 and persists today.

Edwards blew the whistle on the ill practices of entities working to intentionally cut corners in the water infrastructure of Flint, Michigan, and the United States as a whole.

Source: Wikipedia

A keen studier of America’s aging infrastructure, Edwards pulled the veil back on ‘scientific misconduct’ of the Environmental Protection Agency and the Centers for Disease Control and Prevention dating as far back as 2001. He put together a report named: ‘A Public Health Tragedy: How Flawed C.D.C Data and Faulty Assumptions Endangered Children’s Health in the Nation’s Capital.”

In Flint, he found that the city had changed from a system where they initially got treated water from Detroit’s Water & Sewerage Department, to a system where they started consuming water from their own polluted river.

The situation was made more harmful due to the fact that the water was being distributed through old lead pipes. The water had purportedly transgressed the Safe Drinking Water Act four times. Flint’s treatment plant purportedly failed to use vital chemical treatments to prevent the corrosion of pipes - pipes that when corroded released lead into the water supply.

Edwards testified to the American Congress, accusing the Environmental Protection Agency of willful blindness to the pleas of inhabitants involved in the man made disaster. He accused them of being unrepentant, and unable to learn from their mistakes. Through his studies, he showed that the EPA’s malfeasance stemmed from 2001 all the way through to 2016.

“I guess being a government agency means you never have to say sorry,” Edwards said in his testimony. He believed that the Flint Water Crisis showed that there could be a dark side to science, engineering and academia.

Edwards explains that the installation of lead pipes into U.S. water infrastructure was a disaster and a tragedy. From 2000 to 2004 miscarriage and fetal death rates spiked due to mothers drinking water fed from lead pipes.

Even the Roman engineers as far back as the 1st Century BC knew not to use lead and water in the same system.

In February of 2016, in Flint, Michigan, it was revealed that the lead levels were 900 times higher than limits set by the Environmental Protection Agency.

Moral authority

Engineers should strive to operate in an ethical manner, thereby becoming the moral authority in their particular field of practice. Moral authority is defined as the quality or characteristic of a person, institution, or written work that is respected for having good character or knowledge, especially as a source of guidance or an exemplar of proper conduct.

In a bid to eliminate the chance of ethical or moral mistakes in the field of engineering societies were established in the 19th Century. The intention was to establish professional standards and ethical principles for engineers and their profession.

The American Society of Civil Engineers, for example, sets out the following ethical rule-of-thumb:

“Engineers shall hold paramount the safety, health and welfare of the public and shall strive to comply with the principles of sustainable development in the performance of their professional duties. “

The Institution of Civil Engineers’ creed reads:

“Members of the ICE should always be aware of their overriding responsibility to the public good. A member’s obligation to the client can never override this, and members of the ICE should not enter undertakings which compromise this responsibility. The ‘public good’ encompasses care and respect for the environment, and for humanity’s cultural, historical and archaeological heritage, as well as the primary responsibility members have to protect the health and wellbeing of present and future generations.”

Despite these strictures, around the world, from the governmental to the training levels of engineering, unethical practices persist and often snowball into tragic events.

When an engineer notices abuses within the profession, those that transgress the ethical and moral principles that engineers should adhere to, blowing the whistle may be the answer. It does, however, take an enormous amount of courage and a considerable depth of knowledge. Marc Edwards had both and is to be commended.

Works Cited

“Marc Edwards | The Flint and Washington D.C. Drinking Water Lead Crises.” YouTube, Apr. 2016, youtu.be/dEgZpM6j6cc.

VirginiaTech. “Virginia Tech's Marc Edwards Testifies about the EPA's Role in Flint, Michigan.” YouTube, YouTube, 2016, www.youtube.com/watch?v=3VG57IWQfZ4&t=196s.

- Details

- Written by: Quintus Potgieter

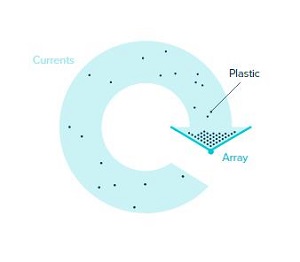

Over the last five years renewable energy technologies have seen more investment than ever before. Many governments have made plans to phase out energy generating technologies that harm the planet, hoping to achieve a world powered by fully renewable energy generating technologies by 2030. Solar and wind are two industries that have particularly skyrocketed - in both research and implementation. An idea that hasn’t seen an equal amount of attention is the harnessing of one of Mother Nature’s most powerful forces; the ocean. Harvesting the energy of waves and ocean currents is, however, not a new concept; engineers have been hypothesizing its feasibility for quite some time.

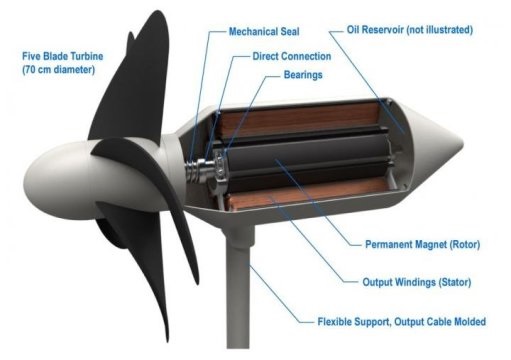

Research into the ocean’s energy is being conducted by Okinawa Institute of Science and Technology (OIST). Their graduate engineers and scientists have developed wave energy power turbines.

Research into the ocean’s energy is being conducted by Okinawa Institute of Science and Technology (OIST). Their graduate engineers and scientists have developed wave energy power turbines.

A project appropriately titled ‘Sea Horse’ is aiming to embed turbines in the seabed with mooring cables. The turbines will be aligned to capture wave energy and the ocean current that flows between Taiwan and southern Japan. The group’s first test of the turbines was purportedly successful - they are now seeking an industrial partner to turn the experiment into an electricity-generating commercial reality.

Professor Tsumoru Shintake at OIST and the Quantum Wave Microscopy Unit says that the turbines could even work alongside or in front of the current tetrapods on Japanese coastlines. Tetrapods are concrete structures engineered to weaken the strength of oncoming waves; common in coastal engineering. Shintake believes new ‘intelligent’ tetrapods fitted with wave energy turbines could generate renewable energy. He says:

“Particularly in Japan, if you go around the beach you’ll find many tetrapods. Surprisingly, 30% of the seashore in mainland Japan is covered with tetrapods and wave breakers.”

Shintake claims that the turbines, if installed in only 1% of seashores in mainland Japan would generate up to 10 gigawatts of energy. For context, the collective solar and wind power output in the United States at the end of 2015 was 100 gigawatts. A single nuclear power plant produces 1.21 gigawatts of power - meaning wave power could produce 10 times the amount of power a nuclear power plant could.

The turbines are designed with flexibility in mind. A turbine’s fins and its support stem are able to bend when a wave crashes into it and is able to handle tough conditions (rough seas, including extreme weather conditions).

According to the Bureau of Ocean Energy Management, the areas where ocean wave energy technology would be most effectively utilized include coasts of ‘Scotland, northern Canada, southern Africa, Australia, and the northwestern coast of the United States, particularly Alaska.’

Source: Professor Tsumoru Shintake

Works Cited

“Ocean Wave Energy.” Bureau of Ocean Energy Management, www.boem.gov/Ocean-Wave-Energy/.

“A Sustainable Future Powered by Sea.” Okinawa Institute of Science and Technology Graduate University OIST, 2017, www.oist.jp/news-center/news/2017/9/20/sustainable-future-powered-sea.

- Details

- Written by: Quintus Potgieter

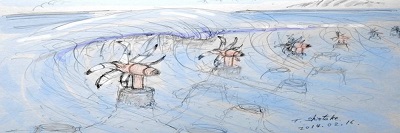

360 to 500 buildings and homes are in danger of collapsing days after a magnitude 7.1 earthquake rocked Mexico City. The earthquake rattled the city on Tuesday, the 19th of September 2017. As many as 38 structures suffered catastrophic failure when the earthquake hit, but the concern for civil engineers is that other structures may yet suffer a delayed collapse. The earthquake has already caused up to 355 fatalities.

Engineers on popular social media site Reddit have been mulling over this shocking video of a building simply crumbling after the earthquake had hit the city. The overarching question was why there was “no resistance” to collapse.

The consensus among the engineers - the building appeared to have old masonry. Some pointed out that the sides of the building could have been brick; brick generally performs poorly (if not reinforced) during events such as earthquakes.

Engineering teams are now descending on Mexico City to generate data on the brittle buildings and to deliver reports to the Earthquake Engineering Research Institute (EERI).

A Matter of Geography and Geology

To make matters worse Mexico’s capital is built on an ancient lake and therefore on damp sand and clay. Its situation results in the prolonging of the earthquakes and increasing the damage to buildings, particularly to those which are five stories or more.

Virtual representation of the 19 September 2017 earthquake. Source: New York Times

When an earthquake strikes, the sediments the city is built upon slow the shock waves, leading to them strengthening and becoming more violent. To make matters worse the area is prone to earthquakes as it is near to the meeting of renowned tectonic plates.

This geological knowledge is not new so the question remains: why are Mexico’s buildings not better prepared for earthquakes?

According to the New York Times, building inspectors and private engineers have said that the strict building codes are not being enforced. A 2016 study revealed that many buildings failed to meet city standards - a staggering 71 percent of the 150 buildings studied, failed to meet standards.

A school that collapsed during the 19 September earthquake was marked safe by city inspectors after the earthquake 12 days earlier, on the 7th of September.

The Vice President of the Mexican Society of Civil Engineers, Sergio Alcocer said:

“We are concerned if we have a huge earthquake like the one in 1985 we may have problems in buildings. It’s a wake up call.”

Even the most recently constructed blocks of apartments in Mexico City tumbled down during the earthquake.

Buildings using concrete are said to be lacking vital reinforcing bars with concrete columns facing catastrophic failure during an earthquake if not properly reinforced. This apparently was the case in the collapsed Enrique Rebsamen school. 26 children lost their lives.

There is an urgent need for the review of civil engineering practices and standards in Mexico. More importantly, however, is the determination to enforce them.

Works Cited

White, Derek Watkins And Jeremy. “Mexico City Was Built on an Ancient Lake Bed. That Makes Earthquakes Much Worse.” The New York Times, The New York Times, 2017, www.nytimes.com/interactive/2017/09/22/world/americas/mexico-city-earthquake-lake-bed-geology.html?mcubz=1.

“A Building Suddenly Collapsing after a 7.1 Earthquake Strikes Mexico City. - Can Someone Explain Why There Is No Resistance as It Came down. • r/Engineering.” Reddit, www.reddit.com/r/engineering/comments/72armp/a_building_suddenly_collapsing_after_a_71/.

- Details

- Written by: Quintus Potgieter

War. What is it good for? Competition.

Smartphone companies have released their latest devices, all vying for a space in your pocket.

Smartphones bring together a plethora of engineering and design disciplines to create incredibly multifaceted devices that have no doubt changed the way humans interact with technology. And there seems to be no stopping the effect they have on consumers. We all want a new one, every year or two. And the competition usually sends engineers into all-out design frenzy to create new functionality they think will excite and buy-over the consumer.

Apple

Apple has released the specs of their latest smartphone, introducing a host of new engineered additions to the flagship device, the iPhone X. The phone has been released to coincide with the release of the first iPhone, exactly 10 years ago. The company also released an iPhone 7 successor, the iPhone 8, which has impressive augmented reality features.

Apple has released the specs of their latest smartphone, introducing a host of new engineered additions to the flagship device, the iPhone X. The phone has been released to coincide with the release of the first iPhone, exactly 10 years ago. The company also released an iPhone 7 successor, the iPhone 8, which has impressive augmented reality features.

Head of Apple, Tim Cook, said that the release of the $999 iPhone X would ‘set the path for technology for the next decade’. The phone boasts an extended battery life when compared to the iPhone 7. More interestingly, the phone utilizes a new phone unlocking method called ‘FaceID’. Meaning, its users can gain access to their phone, and confirm purchases using the smartphone’s facial recognition capabilities.

The company does this through specialized hardware built for a set of machine learning algorithms - it also works with their Truedepth camera system that can even see a face in the dark thanks to an infrared camera and dot projection technologies.

The Apple engineering teams worked tirelessly to protect FaceID from imposters, utilizing mathematical models that map the face of the phone owner. The company says that the odds of another human being unlocking your phone are 1 to 1,000,000.

One ‘feature’ that Apple announced had already been a feature of Samsung devices, but they are carrying it further – the new iPhone X is basically ‘all-screen’ from edge to edge, and from top to bottom.

Samsung

Samsung, with their exploding Galaxy Note 7s in mind, came back swinging by bravely announcing a new line of Galaxy devices that were equipped with ‘Infinity Displays’. In retrospect, Samsung beat Apple to the punch with a larger screen surface.

The screens almost run the entire length of the phone, and they comb around the sides of the device - this was a main feature of their new Galaxy S8 and S8+ range.

But Samsung are venturing into even cooler territory. Reports suggest that, if all goes well, Samsung will launch a bendable smartphone in 2018. Bendable and wearable devices are the new in-thing for electronic and electrical engineering industries. Engineers have to adapt accordingly.

Samsung had already been alluding to eventual bendable devices in concept advertisements dating back to 2014. Other companies like Lenovo have also showed off concepts relating the future of the bendable device:

If the engineering limitations of bendable devices can be figured out in time they may be with us as soon as 2018, so says Koh Ding-jin, president of Samsung’s mobile business:

“As the head of the business, I can say our current goal is next year. When we can overcome some problems for sure, we will launch the product.”

The bendable smartphone may set an even greater precedent in the smartphone engineering industry and would be an even greater leap for technology than Apple’s iPhone X.

Further Chinese dominance and AI

Don’t discount the other Chinese heavyweights that have entered and set precedents in the game. Huawei has slowly risen to the top to become countries like Africa’s first choice when it comes to purchasing smartphones. They are the second largest smartphone manufacturer in the world, as of September 2017.

Don’t discount the other Chinese heavyweights that have entered and set precedents in the game. Huawei has slowly risen to the top to become countries like Africa’s first choice when it comes to purchasing smartphones. They are the second largest smartphone manufacturer in the world, as of September 2017.

And they’re heavily investing into a Mobile AI that will allegedly dethrone Apple’s Siri. Apple’s machine-learning rhetoric with their iPhone X is paving the way for a much larger AI announcement, if recent reports are to be believed. Whoever engineers a functioning artificial intelligence, and port it into a smartphone, will win the smartphone game, predict analysts.

Google recently announced a partnership between them and Chinese company Xioami. They will enter 40 countries and then, along with Google, they will bring out an Android device that they hope will see consumer uptake.

The smartphone manufacturing game seems to bring together many engineering industries and pit them against each other to see who can design and develop the most desirable features for consumers. It is an exciting time for engineers with imagination and design capability.

Works Cited

“Design - 6.3’ Infinity Display | Samsung Galaxy Note8 – The Official Samsung Galaxy Site.” The Official Samsung Galaxy Site, www.samsung.com/global/galaxy/galaxy-note8/design/.

Lechman, Ashley. “Huawei Aiming for the Top Spot.” IOL Business Report, 2017, www.iol.co.za/business-report/huawei-aiming-for-the-top-spot-11017393.

McGoogan, Cara. “Apple Unveils IPhone 8 and £1,000 IPhone X with All-Screen Display and Wireless Charging .” The Telegraph, Telegraph Media Group, Dec. 2017, www.telegraph.co.uk/technology/2017/09/12/apple-iphone-8-iphone-x-launch-event-live-updates/.

- Details

- Written by: Quintus Potgieter

Cars are becoming more like smartphones every day. But is that necessarily a good thing? And what does it mean for the engineers who want to make a career out of automotive engineering? The days of the combustion engine seem to be coming to an end. The desire of tech companies and vehicle manufacturers is now to create fully autonomous, environment-friendly vehicles that takes individuals from point A to point B.

Elon Musk’s Tesla Motors is a good example of where the electric/smart vehicle market is going - customers seem to respond well to what is seemingly the future of mobility. However, it has been a rocky road for Tesla and its software-driven vehicles.

In 2016, a man lost his life in a Tesla car, after the Autopilot hardware and software inside the Tesla vehicle failed to recognize a trailer in the middle of the freeway.

A year before that, Fiat Chrysler had to recall 7,810 Jeep Renegades with automated systems that could be exploited by hackers; a danger that they could be ‘remotely manipulated’. In response the company released USB sticks that would remedy the vulnerabilities and uploaded a safety update to the vehicles - it turned out that 1.4 million needed the update.

It follows then that as vehicles become more and more like computers they will need constant security upgrades.

Green-lighting OTA

On-the-fly software updates to the firmware inside vehicles are increasing rapidly. General Motors is the latest company to join the fray of vehicle manufacturers that are securing over-the-air (OTA) upgrades to their cars via a remote network. They can upgrade their network of vehicles with a click of a button, delivering specifically engineered code to their fleet of vehicles simultaneously

Software updates to a vehicle are becoming as easy as installing an app on a smartphone. According to ABI Research, 180 million new vehicles shipping between 2016 and 2022 will see the adoption of automotive over-the-air software updates.

“Three factors changed the course of the automotive industry and paved the way for the future of OTA: recall cost, Tesla’s success as the foundation of autonomous driving, and security risks based on software complexities,” said senior research analyst at ABI Research, Susan Beardslee. “It is a welcome transformation, as OTA is the only way to accomplish secure management of all connected car’s software in a seamless, comprehensive, and fully integrated manner.”

However, cybersecurity is a common concern among those critical of OTA updates. But with faster communication to the entire fleet of vehicles with OTA, the chances of blocking hackers’ attempts on vehicles could be more efficient than having to prevent hacking on individual vehicles as the need arises.

It is clear that the need for cybersecurity engineers in automotive engineering will grow and will need agile higher education institutions to step up.

Engineers interested in cars today can either work with the tech companies (like Apple, who are designing a fully autonomous car) or stick with the tried-and-tested vehicle manufacturers. The market is becoming more multi-faceted and interesting; a broader range of skills are required in the automotive engineering space than ever before.

Battery similarities

Automotive engineering companies are investing in the smartphone-vehicle-likeness by making vehicles battery powered. Lithium-ion batteries are found in our phones and will power your next car, but obviously on a grander scale.

After an emissions scandal, Volkswagen have pledged that they will invest up to $24 billion into zero-emissions vehicles by 2030 to try and challenge the already blossoming Tesla Motors. Volkswagen said that they will be manufacturing 80 new vehicles across its group by 2025. The company also wants to offer its other 300 group models in electric versions by 2030, Reuters confirms.

It seems there is no turning back for the unprecedented change the automotive engineering market is undergoing with the combustion engine heading into retirement? China has just announced that they will ban combustion engines within vehicles by 2040. Future engineers will become increasingly involved in e-mobility era in automotive engineering.

Works Cited

"ABI Research Anticipates Accelerated Adoption of Automotive Software Over-the-Air Updates with Nearly 180 Million New SOTA-Enabled Cars Shipping Between 2016 and 2022." ABI Research. Web. 11 Sept. 2017.

"As Your Car Becomes More like an IPhone, Get Ready to Update Its Software Regularly." Phys.org - News and Articles on Science and Technology. Web. 11 Sept. 2017.

Cremer, Andreas. "Volkswagen Spends Billions More on Electric Cars in Search for Mass Market." Reuters. Thomson Reuters, 11 Sept. 2017. Web. 11 Sept. 2017.

- Details

- Written by: Quintus Potgieter

Mazda has reinvented the wheel. Or rather, they claim they have reinvented the engine which drives that wheel.

They have engineered a ‘SkyActiv-X’ series of engines which purportedly use game-changing technologies which they believe will save the combustion engine from its seemingly inevitable demise.

The new engines use ‘Homogenous Charge Compression Ignition (HCCI)’. It is thought to be the ‘holy grail’ of combustible engines in a world which demands lower emissions.

SkyActiv-X shuffles between diesel engine compression and common spark ignition combustion engines in a best-of-both-worlds approach. They have assigned a name to this process; Spark Controlled Compression Ignition.

Mazda explains that this process of jumping between two kinds of compression can ensure that the engine works 20 to 30 percent more efficiently than its predecessors. HCCI engines are superior to that of standard gasoline and diesel engines because they remain cooler, resulting in a reduction of nitrogen oxide emissions.

The Mazda Motor Corporation has developed this next-generation engine to fit into their new long-term strategy aptly named ‘Sustainable Zoom Zoom 2030’. In terms of the details, however, Mazda is playing its cards close to its chest. As the cars near their release dates in late 2018, early 2019 more should emerge.

The question that persists with HCCI development is whether or not governments will trust further iterations of combustible engines as the world’s environmentalists call for the advancement of electrification.

Is it all for naught?

Britain has joined the list of countries determined to move to electric vehicles. They plan to ban the sales of petrol and diesel cars (and vans) from 2040 in an effort to curb nitrogen oxide levels in the country.

“Poor air quality is the biggest environmental risk to public health in the UK and this government is determined to take strong action in the shortest time possible. That is why we are providing councils with new funding to accelerate development of local plans, as part of an ambitious £3 billion program to clean up dirty air around our roads,” a government spokesperson said.

Governments have traditionally veered away from nuclear energy due to high profile incidents. Similarly, due to an increasing deluge of bad press, there is an increasing tendency to reject technologies that use ‘combustion’ and ‘engine’ in the same sentence. Furthermore, claiming to commit to a future of safer, electric-powered vehicles is a politically savvy decision at present.

The war against combustion engines could make Mazda’s last ditch effort for the ideal internal combustion engine an engineering non-starter. Mazda’s Research and Development head Kiyoshi Fujiwara says: “Electrification is necessary but...the internal combustion engine should come first.”

Germany’s Angela Merkel, despite the pressure of world-renowned German automotive engineering companies, has also issued statements pointing to the retiring of internal combustion engine technologies. In a recent speech she said:

“Large sections of the auto industry have gambled away unbelievable amounts of trust. This is trust that only the auto industry can restore. And when I say ‘the industry’ that is the company leaders.”

Critics, however, say that the move to electrification in Germany may cause 900,000 job losses in the country. What remains clear is that the pressure on phasing out the internal combustion engine vehicle for the next big thing in vehicle engineering technology is going to be a bumpy road.

Works Cited

Asthana, Anushka, and Matthew Taylor. "Britain to Ban Sale of All Diesel and Petrol Cars and Vans from 2040." The Guardian. Guardian News and Media, 25 July 2017. Web. 16 Aug. 2017.

Jamieson, Craig. "Here's How Mazda Plans to save the Internal Combustion Engine." Top Gear. Top Gear, 08 Aug. 2017. Web. 16 Aug. 2017.

- Details

- Written by: Quintus Potgieter

Friday night (the 25th of August) a tropical storm hit Texas in the United States of America. 60cm of rain fell overnight (23 inches) with a total of 50 inches expected before the week was out. Whether or not Texas’ drainage system is able to deal with the volume of water that climate change is bringing will be a pertinent question once relief efforts have been fulfilled. Questions surrounding Houston’s water infrastructure are already being asked.

Friday night (the 25th of August) a tropical storm hit Texas in the United States of America. 60cm of rain fell overnight (23 inches) with a total of 50 inches expected before the week was out. Whether or not Texas’ drainage system is able to deal with the volume of water that climate change is bringing will be a pertinent question once relief efforts have been fulfilled. Questions surrounding Houston’s water infrastructure are already being asked.

A New York Times opinionista has pointed to climate change as the leading cause for Hurricane Harvey’s wrath whilst accusations of America’s hand in contributing to global warming persist. Simultaneously many face practical considerations - what to do in the aftermath of an infrastructure-crippling hurricane.

The devastation caused by Hurricane Harvey will encourage engineers to lend their minds to climate science studies and funnel this knowledge into solutions for a world facing an increase in natural disasters, many of which involve flooding. The lack of engineering foresight, thus far, has been highlighted in neighboring state Louisiana.

No lessons learned

In New Orleans, Lousiana, critical water infrastructure (pumps and canals) were not prepared for heavy rainfall this hurricane season. This is despite the New Orleans’ levee failures in 2005, during Hurricane Katrina. Those levee shortfalls can be found in case studies comparing them to some of the largest engineering failures of all time - including Chernobyl. Furthermore, the studies pertaining to Katrina clearly highlighted the inadequacies of the civil engineering practices within the United States Army Corps of Engineers.

New Orleans experienced a spate of floods on August 5th of this year, with Louisiana’s governor declaring a state of emergency as a result of the flooding. According to the New Orleans Advocate, repairs and maintenance on pumping stations reduced their efficiency by a third!

To give a little clarity to the problem: the drainage system in New Orleans is designed to deal with one inch of rain in an hour, and a half an inch each hour after the first. With this in mind, and according to the Economist, four out of five turbines were not working at one of the state’s pump stations during the floods, and other pumps, in harder hit areas, were down for maintenance. Elsewhere, staff shortages led to inefficiencies so pumps were not switched on in a timely manner.

The citizens in flood-hit areas of New Orleans have accused the sewerage and water board, (amidst other allegations of incompetence) of uncleaned/cleared catch basins which prevented water from moving to the drainage systems. This latest event has led to a political crisis in New Orleans. Officials, however, have said that old and poorly maintained infrastructure is an America-wide problem.

Thankfully New Orleans seems to have escaped the worst of Hurricane Harvey, avoiding the full brunt of the catastrophe 12 years after Hurricane Katrina.

Texas

The rising waters in Houston have resulted in a double-explosion at a chemical plant and, at the time of publishing, the hurricane has led to the deaths of 50 people.

The chemical plant belonged to Arkema Group, one of the world’s largest chemical companies. The coolant systems and power generators were rendered useless due to the floodwaters, and as a result the Arkema Group warned that an explosion was soon to follow. The plant exploded sending a large black plume of smoke into the air and forced police to evacuate an area of up to 1.5 miles. The Environmental Protection Agency (EPA) said that no toxic materials were reported to have been released but will continue to monitor the situation as more explosions are possible.

In Beaumont, Texas, flooding has caused the city’s water pumps to fail, causing 118,000 people to be without any running water. Hospitals have had to evacuate their patients and transfer them elsewhere due to the lack of water.

The Atlantic reports that the Association of State Floodplain Managers in Houston has tried to get funding for flood control, but in vain. Without engineering expertise in storm water management technologies it is unsurprising that an event such as Hurricane Harvey has wreaked such havoc.

City planning has also copped some criticism. An excerpt from the Atlantic’s article points to the fact that Houston and New Orleans’ cities are in flood-prone areas:

“The hardest part of managing urban flooding is reconciling it with Americans’ insistence that they can and should be able to live, work, and play anywhere. Waterborne transit was a key driver of urban development, and it’s inevitable that cities have grown where flooding is prevalent.”

And it seems that Houston’s everyday citizens knew that a hurricane would inevitably cause a flood.

People outside of HOUSTON believe this is a ONETIME thing but this HAPPENS every 2 MONTHS or SO .. BAD ENGINEERING & FLOOD CONTROL pic.twitter.com/oRaX8x7IWg

— Aristotle Onassis (@OnassisHa36) August 28, 2017

This is gonna be fun... But we have to appreciate the City of #Houston Public Works and Engineering team. Or else this would be much worse. pic.twitter.com/YKow0yrKxy

— TheGreatNike (@XboxNike) August 27, 2017

Works Cited

Bogost, Ian. "Houston's Flood Is a Design Problem." The Atlantic. Atlantic Media Company, 28 Aug. 2017. Web. 31 Aug. 2017.

Leonhardt, David. "Harvey, the Storm That Humans Helped Cause." The New York Times. The New York Times, 29 Aug. 2017. Web. 31 Aug. 2017.

- Details

- Written by: Quintus Potgieter

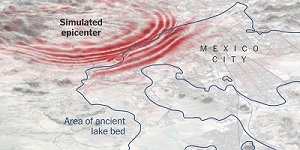

The United States has just witnessed the first total solar eclipse in 38 years. For some US states people would have observed a partial eclipse, but for 14 other states, the moon would have blotted out the sun completely. 2 minutes and 38 seconds of darkness was experienced in Madras, Oregon.

The next total eclipse will appear in American skies on April 8, 2024.

The power grid effect

An obvious impact of a solar eclipse is on photovoltaic cells that rely on the sun’s rays to generate power.

Steven Greenlee from CAISO - one of the largest independent grid operators in the world –commented, “Our solar plants are going to lose over half of their ability to generate electricity during the two to two and a half hours that the eclipse will be impacting our area,”

It is unlike a cloudy day because with an eclipse the loss causes a rapid decline and rebound of solar power that grid operators have to carefully manage.

The U.S. Energy Information Administration (EIA) explained that 70 percent or more of the sunlight for utility-scale solar power plants would be obscured during the solar eclipse.

Source: EIA

It has taken grid managers a year to prepare for the three hours of obscured sunlight. A startling fact when one considers that solar power only makes up 1 percent of the overall US power supply.

Another interesting fact: wind power cannot take up the slack during an eclipse and the drop in solar power because wind drops off too wind slackens during a solar eclipse as well.

Scientists and engineers have used the solar eclipse as a tool for research - keeping an eye on how technology reacts to an event that disrupts both space weather and weather itself.

Chasing an eclipse with engineering

Teachers and students in STEM-related classrooms in schools and universities across the United States ensured that they were ready for the solar eclipse; for example pinhole projectors were built to allow for the safe viewing of the event.

NASA took the eclipse very seriously, ensuring it was scrupulously tracked.

Utilizing specially engineered telescopes mounted to the front of two retrofitted WB-57F aircraft, NASA tracked the shadow of the moon as it shifted across the United States. The aircraft’s telescopes would also capture the Sun’s outer atmosphere (the Corona) during the solar eclipse and also took thermal images of Mercury. The sun’s atmosphere is usually harder to study without a solar eclipse, so it was a valuable moment in time.

The planes climbed to 50,000 feet, progressing through most of the Earth’s atmosphere to obtain the best images possible. Eleven other land-based investigations of the Sun’s atmosphere took place during the solar eclipse too.

Dan Seaton, a co-investigator of the project and researcher at the University of Colorado in Boulder, Colorado, believes the high altitude observations will be more advantageous than those from the ground. He spoke to NASA saying:

“These could well turn out to be the best ever observations of high frequency in the corona. Extending the observing time and going to very high altitude might allow us to see a few events or track waves that would be essentially invisible in just two minutes of observation from the ground.”

This quote that follows is anonymous, but reflects on most all of us during the light of day. Throughout the eclipse, however - just as with the night – most were perfectly still:

“Every morning in Africa, a Gazelle wakes up. It knows it must run faster than the fastest lion or it will be killed. Every morning a Lion wakes up. It knows it must outrun the slowest Gazelle or it will starve to death. It doesn't matter whether you are a Lion or a Gazelle; when the sun comes up, you'd better be running.”

Works Cited

DiChristopher, Tom. "The Total Solar Eclipse Is Going to Knock out a Lot of Solar Power." CNBC. CNBC, 21 Aug. 2017. Web. 21 Aug. 2017.

Garner, Rob. "Chasing the Total Solar Eclipse from NASA's WB-57F Jets." NASA. NASA, 25 July 2017. Web. 21 Aug. 2017.

Choi, Annette. “Solar eclipse 2017: how the solar power industry is prepping for a huge blip” VOX, 20 Aug 2017.Web 24 Aug 2017.

- Details

- Written by: Quintus Potgieter

A pedestrian bridge on the N3 road in Bedfordview, in Johannesburg collapsed in the early hours of the morning on Tuesday the 8th of August 2017. The bridge collapsed onto four vehicles, resulting in five injuries with zero fatalities.

The highway has been re-opened since the collapse. Transport Minister Joe Maswanganyi finds the collapse odd, saying the bridge was deemed safe in 2016. He said: “Sanral did an inspection of the bridge and we were told that the bridge was in a good condition and we have a certificate in that regard. What happened on Wednesday was shocking.”

The bridge was built in 1978. It was recently decommissioned and thus regarded as an abandoned bridge but still thought to be rigid enough to stay standing.

The transport minister has tasked forensic experts and officials from the Council for Geoscience and Sanral (South African National Roads Agency) with investigating what caused the bridge’s collapse.

Rubble removal teams spent the public holiday on Wednesday removing the collapsed bridge to allow traffic to flow.

Speculation

Whilst the investigation progresses armchair critics are offering possible causes for the bridge’s demise. Some of these assessments point to another disaster which occurred at a similar time: an earth tremor apparently triggered by the collapse of an illegal mine. The reports of this illegal mine caving in are unverified, but could certainly account for the accident if proved true.

Dr Eldridge Kgaswane, scientist for the Council for Geoscience was, however, skeptical. He pointed out that there had indeed been a tremor, but because it only measured 2.0 on the Richter scale was an unlikely cause. He suggested that a tremor measuring around 6.0 would have been a more likely catalyst for the bridge’s collapse.

Talking to IOL (a South African news website), a ward councilor Gill Humphreys says that vandalism could have been the cause. She pointed out the bridge had been tampered with for years, “Over this time, it has been stripped of nuts and bolts and all steel reinforcing. We are questioning why Sanral did nothing to ensure the safety of the bridge, as this almost certainly caused the collapse.”

Questions have also been asked about a truck bumping into it at some point and whether this had compromised the structural quality of the bridge.

Another more outlandish online allegation is that a bomb caused the pedestrian bridge to fall. At the time of publishing, however, none of these rumors have been confirmed.

The validity of infrastructure inspections has been questioned following the collapse. Engineers now tirelessly work to end the speculation. SANRAL delivered a statement reading:

“We are relieved that we managed to clear the debris and open the road in less than 48 hours. We wish to thank the teams involved in the collaborative effort to clear the site. At the same time, we have not forgotten those who were injured during the bridge collapse. We wish them a speedy recovery and are keeping them in our prayers.”

Avoiding future collapses

Twitter users are warning that more bridge collapses could occur in South Africa. They believe their age is one of the factors compromising their structural integrity. This photograph of a pedestrian bridge at the R61 next to Angus Station in Ekurhuleni clearly shows signs of structural disintegration.

They are asking for their photos to be retweeted in an effort to motivate their municipal governments to do something about these aging bridges.

A probe into what caused a bridge scaffolding collapse back in 2015 on Grayston Drive in Johannesburg is still ongoing. The bridge collapse caused the death of two and injured 19. What remains apparent is that South African civil and structural engineering entities need to take bridge construction, assessment and maintenance more seriously in years to come to avoid potential catastrophic failures.

Works Cited

Cox, Anna. "Industry News." Vandalism May Have Led to Bridge Fail | IOL Motoring. 10 Aug. 2017. Web. 10 Aug. 2017.

"Johannesburg N3 Bridge Collapse: Traffic Flow Restored, but Questions Remain over Inspections." Daily Maverick. Web. 11 Aug. 2017.

- Details

- Written by: Quintus Potgieter

What can house 1,000 passengers, a boatload of cargo, and 850 vehicles? You guessed it. A ferry.

The UK Government’s Department of Transport in their 2016 Provisional Sea Transport Report stated that the number of international short sea passengers was estimated at 20.0 million people in that year. Norway also utilizes ferries in a big way. Until the completion of the first underwater tube-shaped floating tunnel, the only way to navigate Norway’s fjords is via ferries.

With that many people utilizing the form of transport, it is in the best interest of the engineering companies that run them to regularly perform maintenance on the ships. Extending the lifetime of a ferry is a three week slog, that guarantees the ferry another ten years of operation.

A little South of Norway, a battalion of ferries operate in the North Sea, enabling transport between a number of countries including the United Kingdom, France, Germany and Belgium. One of the ferries that should be up for its next maintenance operation in 2022 is the Pride of Bruges. The ferry consists of 32,000 tonnes of steel, 7 football field sized decks, with 4 engines which burn two and a half thousand litres of fuel an hour. It was renovated in 2012.

Exterior

The operation involving exterior and interior maintenance takes an army to complete. The Newcastle engineering team consists of 120 engineers who work on the boat, examining over 1,000 separate parts.

The most critical parts of the ferries which require attention are underwater; if it is not docked, the boat cannot be repaired, maintained or renovated.

Thus, the first challenge is getting a mammoth ferry into the ferry lock. The lock is flooded with 133 million litres of water that allows the ferry to be pushed into the lock. After that, the water is emptied out so that the ferry can be accessed and assessed on dry land. Most of the engineering works are below the water line.

Once the hull of the ferry is accessible to the engineers, one of the first things investigated are the ballast tanks. Ballast tanks are compartments within a floating structure which take water in, in order to ensure stable buoyancy. The tanks are emptied and cleaned so that the overhauling of them can begin. Corrosion proofing ensues within the inner steelworks.

When the ferry is functional, water is pumped in and out of the ballast tanks, based on the buoyancy required. Engineers explain that saltwater and freshwater have different buoyancies. There is a measurement ruler on the side of the boat that suggests water levels for the different buoyancies.

Another crucial element of the ferry that must be checked, over and above everything else, are the retractable fins, known as stabilizers. They keep the boat from rocking back and forth and giving the crew sea sickness. Actuators ensure that they are perfectly synchronized on either side of the ship.

The most common of all ferry maintenance is performed on the steel boat itself. Seawater corrodes the steel, thus it needs to be constantly weather proofed to avoid rust and wear. To avoid seawater from eroding to the point of catastrophic failure sacrificial anodes are fitted to the hull - they take the brunt of the seawater damage so that the steel beneath it doesn’t corrode as quickly.

The ship’s two propellers are also polished. They are closely studied to detect cracks and other surface imperfections; fractures must be fixed. Propellers suffer from what is known as cavitation erosion. This occurs because of the implosion of water bubbles around the propellers during the ship’s operation. It has the ability to render propellers useless. Thus, polishing them ensures a longer lifetime.

Finally, rudders are checked to ensure that the boat can be maneuverered back into the sea. Controlled by hydraulic actuators, the rudders are controlled by the captain housed inside the bridge.

Interior

Aside from maintenance to the exterior, the complex technological systems responsible for, among other critical jobs, steering the ship, require trouble shooting and checking. These computers are vital to the smooth running of a ferry.

Global positioning systems are also being installed in ferries to make sure that captains are aware of exactly where they are going and to monitor other boats that are filling up shipping lanes.

Further inside the ship, the replacing of steel floors occur where the car deck is positioned. Wear and tear of the steel flooring occurs due to the tonnes of cars that weigh the steel down during its lifetime. A new layer of steel is placed atop the old one.

Image of the boat traffic between the English Channel.

In the engine room, refurbished barrel-sized pistons are positioned to fire away once the ferry is ready for action again. The pistons cost £15,000 per piston. 30 pistons are required for a ferry the size of the Pride of Bruges.

These are just some of the engineering challenges involved when maintaining ferries. On completion they are carefully moved from their locks back into the ocean. After their three weeks in dry dock they should remain in good shape for another decade. These maintenance visits keeps the teams of repairers on their toes; delays are extraordinarily costly.

Works Cited

"Engineering Giants - 3. Ferry Strip-Down." BBC IPlayer. BBC. Web. 10 July 2017

- Details

- Written by: Brad Lohoar

It is often difficult for engineers to position themselves into the search engines result pages (SERP's) because of the very competitive nature of the industry. It is dominated by the worlds major companies and the smaller more regional firms often find themselves on the back pages.

It is often difficult for engineers to position themselves into the search engines result pages (SERP's) because of the very competitive nature of the industry. It is dominated by the worlds major companies and the smaller more regional firms often find themselves on the back pages.

It is therefore vitally important that you do a SWOT analysis, that is, an internal study of your strengths and weaknesses as well as your opportunities and threats.

Once you understand yourself, have a look at your direct competitors, not just in your area of expertise but also similar firms in different regions. Look for where they rank, how the pages are laid out and what type of content they use.

Content is critical.

Do not try to impress with language that only a 10 year industry expert can understand. Remember, those looking to engage you are not necessarily the decision makers, it may be an executive assistant, secretary or office junior.

Have photos and a brief profile description of the owners and principles of your company, I would not put up all your employees as your competitors will probably try to poach them (you may have a couple of under-performers, so it may be a good thing).

The same goes for successful projects that you have completed, a few photos and a brief description of what you have done, once again, keep the language simple, and don't give away your key contacts/clients, your competitors are always looking for work.

Don’t be afraid to place your “job opportunities” on your website with an application lodgement form. If you don’t currently have any open positions, you will be amazed at who "appears" in your inbox. Economically it makes sense, I know of one firm who saved over $200K in recruitment fees in 6 months.

Make sure that you are not "too" broad in your descriptions of what you do, try to create a "point of difference". Have you ever noticed how well a "spelling mistake" ranks?

- Use bullet points - Bullet points help with the readability of your content and allow for a fast intake of content.

- Use relevant headings - This helps with the readability and allows readers to skim to the specific areas that interest them.

- Use relevant images - Stay away from stock images, some projects will not allow photos without permission.

Once you have got your content sorted, the rest is relatively simple.

- Page load speed - Ensure your site loads quickly on all devises and in all regions.

- Mobile friendly - The uptake of mobile visitors is well over 60% of web traffic, have a look at your site on your phone.

- Phone number - Top right hand corner of the page with a hyperlink to phone.

- Contact form - Name, Phone, Email, you do not need to know what they had for breakfast.

On completion of the above, the readability and usability of your site will be far better than average.

Having original relevant articles, written consistently, and posted on your site, maintains a freshness that the search engines want to see. (These articles can be used in your newsletters.)

Good, honest, fresh, relevant content with a site that loads quickly on multiple devices in multiple regions will ensure that you will improve your rankings. Why? because your competitors don't do it.

More in a couple of weeks

- Details

- Written by: Edwina Ross

The Rio-Antirrio Bridge is a modern engineering marvel that, at its heart, relies on engineering expertise and lessons from the past. Opened in August 2004, the bridge wowed engineers because it reflects and marks the progress of bridge building through history. The bridge is one of the longest multi-span, cable-stayed, suspension bridges in the world.

Credit: By Eusebius, CC BY-SA 3.0, https://en.wikipedia.org/w/index.php?curid=39009078

The bridge links the Peloponnese peninsula to mainland Greece. These landmasses have moved further and further away from each other over hundreds of years, subsequently creating what is known as the Gulf of Corinth. The 2 mile gap was not the only unique challenge the Gulf of Corinth presented to engineers. The other challenges were the strong winds in the middle of the channel, and the fact that the bridge was going to cross one of the largest seismic zones in Europe.

Too much ground to cover

A 2 mile stretch is too wide for a single span bridge; engineers realised they had to develop a multi-span bridge. In the planning stages the depth of the water posed the initial setbacks; the Gulf of Corinth is sixty meters deep.

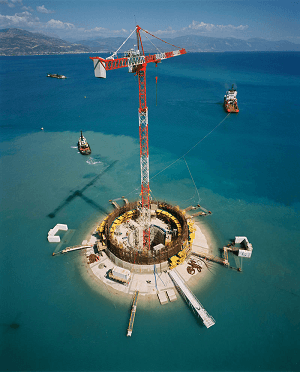

The answer was to use hollow, concrete, floating barges. This engineering concept was the brainchild of engineer Guy Maunsell, who invented floating forts for the purposes of battle during World War 2. Offshore wind turbine operations use these floating barges and they are commonly employed in modern day bridge building. Between 1998 and 2001, the four hollow pier foundations, needed to construct the Rio-Antirion Bridge, were floated into place.

Avoiding Natural disasters

Instead of burying the foundations in the ground, they were set atop the seabed, which had been reinforced by steel bars and ten feet of gravel. This was to ensure that the bridge could move with the ground during earthquake activity, to reduce the risk of the bridge being damaged by an earthquake. This is now known as seafloor stabilization, but it was a first in engineering bridge building history.

To further avoid the seismic activity’s effect on the bridge’s structure, the engineers implemented jacks and dampers that absorb any earthquake activity. Basically, the bridge has enormous shock absorbers.

Credit: "GEFYRA - Nikos Daniilidis"

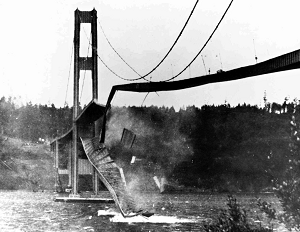

Furthermore, the bridge is completely suspended to ensure that earthquakes do not make the bridge sway. It is held in place by 348 cables. The cables are made of single strands of steel grouped together to form one large cable. The steel strands are more flexible and collectively stronger than iron. Previously iron had been used on bridges that had experienced catastrophic failure.

The Tacoma Narrows Bridge. Credit: Seattle Times

To guard against damage from the wind the bridge uses the same aerodynamic wind diffusing fairings and spoilers that you would expect to see on a car, but on a grander scale. The cables are also wrapped with spiral Scruton strakes that allow wind to flow around the cables instead of straight into them.

These civil engineering nuances of bridge building may have saved the Tacoma Narrows Bridge in 1940. It was given the nickname ‘Galloping Gertie’ due to the effects of the winds; its vertical sway caused catastrophic failure. The Tacoma Narrows Bridge disaster serves as a case study and explains why the Rio-Antirrio Bridge used a system of cable-stays and suspension bridge construction technologies instead.

The Rio-Antirrio Bridge is considered a modern masterpiece. The engineers are applauded for their considerations of past bridge failures, and for their ability to come up with solutions to problems that had never before been addressed in the industry. And that is why this bridge is considered a modern engineering marvel.

Works Cited

RION-ANTIRION BRIDGE - An Engineering Marvel - Dr. Carolyn Pararas-Carayannis. Web. 20 June 2017.

Panajotisx. "Rio Antirrio Bridge - Challenging Earthquakes." YouTube. YouTube, 19 Jan. 2014. Web. 20 June 2017.

- Details

- Written by: Quintus Potgieter

IBM has come a long way since they introduced their first personal computer in 1981. The advent of the device transformed the world. In the 36 years since then engineers have continued to innovate with computer technology, some might say that the effect computers have had on society is beyond measure.

Photo credit: THE Holy Hand Grenade! via Foter.com / CC BY-ND

The history of computers reaches to a period long before 1981, but IBM’s maiden voyage into unfamiliar territory undoubtedly changed the game, and influenced countless numbers of engineers. It was, after all, the International Business Machine.

Now personal computers are everywhere; in our pockets, in our televisions, and even in our watches. And, unfortunately for the technophobic, almost everything in our world is becoming a computer, thanks to the Internet of Things.

The World Economic Forum is closely monitoring the development of computers, tracking their role in creating a better world. As we know computers have had an immense impact on the industrial, commercial and domestic environments in the 21st century; this has encouraged the World Economic Forum to put them on their agenda. They plan to influence the changes that revolutionize the technologies involved and to measure the effect of the internet. Justine Cassell, the Associate Vice-Provost for Technology Strategy and Impact at Carnegie Mellon University, wrote a report for the WEF,

“In the same way we have a tendency to think of computers as rectangular boxes, we have a tendency to think of the internet as being some kind of ether that floats around us. But quite recently researchers have made enormous breakthroughs in creating a way for all objects to communicate; so your phone might communicate to your refrigerator, which might communicate to the light bulb. In fact, in a near future, the light bulb will itself become a computer, projecting information instead of light.”

Designing the future

IBM is continuing the trend of engineering the future with computational technologies (software and hardware), enabling engineers to work more efficiently and build a more interconnected, smarter future. They do this with what they call ‘Continuous Engineering’. They write:

“IBM IoT Continuous Engineering helps teams keep on top of the complexity of developing smart, connected products. Running in the cloud, it helps systems engineers and software developers to deliver against requirements, respond efficiently to change and create high-quality designs faster-- while controlling development costs and meeting compliance needs.”

In truth, many tech companies are tirelessly working at equipping computers with the ability to interconnect almost everything; from our clothes, to our cars, to our houses. They’re trying to make machines more intelligent, so they can do the repetitive tasks that humans find frivolous. In essence they want computers to think for us.

The first evidence of this is perhaps no better exemplified than in the recent boom of in-home artificial intelligence assistants. These devices use hardware and software and an internet connection which is connected to an artificial intelligence. This intelligence learns your preferences, understands what you need when you need it, and can talk to you as well.

Artificial intelligence

IBM has their very own ‘Watson’, Amazon has ‘Alexa’ and Google has their ‘Home’ device. The future of computers seems to involve engineers attempting to build seemingly omniscient machines. But are they getting it right?

Jeff Hawkins, founder of Palm Computing Inc, the company behind the Palm Pilot, has moved on to neuroscience technology. His new company, Numenta, utilizes the current technology within the neuroscience and engineering industry, in the hopes that it will enable computers to mimic the human mind. He writes:

“The solution is finally coming within reach. It will emerge from the intersection of two major pursuits: the reverse engineering of the brain and the burgeoning field of artificial intelligence. Over the next 20 years, these two pursuits will combine to usher in a new epoch of intelligent machines.”

Numenta discovered that for machines to think like humans, they need what is called sensorimotor integration. To see and ‘feel’ the world in the same way humans do. Hawkins calls it the “principle of combining movement with changing sensations”. Hawkins believes computers need to mimic the absorption of information which is traditionally the responsibility of a human neocortex. Unless they are programmed with this capability the ‘intelligent machine’ will remain elusive,

“Intelligent systems need to learn multidimensional models of the world. Sensorimotor integration doesn’t occur in a few places in the brain; it is a core principle of brain function, part of the intelligence algorithm. Intelligent machines also must work this way.”

The video below from IEEE sums it up:

Hawkins’ aim is to reverse engineer the neocortex and understand it from back to front so that he can somehow transfer that understanding into a computer. He says he does not think that those working in machine learning and artificial intelligence are aiming high enough. He concludes:

“While it is exciting for today’s computers to classify images and recognize spoken queries, we are not close to building truly intelligent machines. I believe it is vitally important that we do so.”

Works Cited

IBM IoT Continuous Engineering. 27 June 2017. Web. 27 June 2017.

Hawkins, Jeff. "What Intelligent Machines Need to Learn From the Neocortex." IEEE Spectrum: Technology, Engineering, and Science News. IEEE Spectrum, 02 June 2017. Web. 28 June 2017.

Written by Justine Cassell, Associate Vice-Provost for Technology Strategy and Impact, Carnegie Mellon University. "By 2030, This Is What Computers Will Be Able to Do." World Economic Forum. Web. 27 June 2017.

- Details

- Written by: Quintus Potgieter

Is it okay to fail? Engineering failure can be and has been a good thing; it is after all how we learn and how engineering designs improve. But it can be catastrophic; the tragic failure of a bridge, for example. There is another sort of failure in engineering: companies which have released products to the masses without adequate take-up have experienced market failure.

Failure for these companies usually means sending product engineers back to the drawing board; it is often very difficult to gauge whether or not there is a demand for a product. Nurturing skills in business and entrepreneurship, however, will hold engineers in good stead by giving them the edge when it comes to assessing the market and its demand for engineering merchandise.

Failure for these companies usually means sending product engineers back to the drawing board; it is often very difficult to gauge whether or not there is a demand for a product. Nurturing skills in business and entrepreneurship, however, will hold engineers in good stead by giving them the edge when it comes to assessing the market and its demand for engineering merchandise.

To show that companies are prone to designing, engineering, and manufacturing products that fail a Swedish town has opened a new museum. It is completely devoted to displaying the failed products that the world has seen throughout the ages. A clinical psychologist named Samuel West was behind the idea and his motivation for opening the Museum of Failure Innovation? He reckons that failure is a good thing.

“Even the biggest, most competent companies fail. The trick is to create an organizational culture that accepts failure so that you can fail small...rather than fail big,” West says. West displays some of the most recognizable failures that were seen on a global scale.

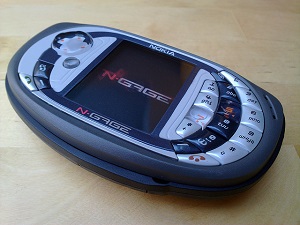

The Nokia N-Gage was poised to be the mobile phone of the future. Half-phone, half-handheld-gaming system, this was the must-have device of the naughties.

The Nokia N-Gage was poised to be the mobile phone of the future. Half-phone, half-handheld-gaming system, this was the must-have device of the naughties.

Initially the demand for it was quite high, but it had some design quirks: one of these entailed holding the phone vertically on its thick edge, whilst putting the thinnest edge to your ear to hear your caller. The buttons were also oddly laid out. It just wasn’t practical.

On top of this the device lacked good gaming titles. Ultimately the phone lost its value to customers.

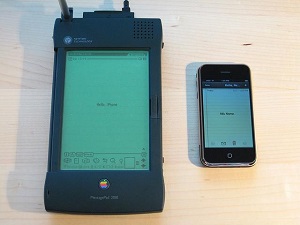

Long before the iPod, iPad, and Siri, was Apple’s failed digital assistant Newton. It was a very basic Palm Pilot, built three years before the Personal Digital Assistant was a thing.

Long before the iPod, iPad, and Siri, was Apple’s failed digital assistant Newton. It was a very basic Palm Pilot, built three years before the Personal Digital Assistant was a thing.

Steve Jobs, upon his return to Apple in 1997, allocated engineers positions in the designing and manufacturing of what would go on to be the iPod. Jobs, in Walter Isaacson's official biography, lamented:

“My gut was that there was some really good technology but it was [screwed up] by mismanagement. By shutting it down, I freed up some good engineers who could work on new mobile devices. And eventually we got it right when we moved on to iPhones and the iPad.”

But it’s not all doom and gloom with Apple’s Newton. It is a perfect example of how a device, with no real customer interest, set the stage for the rise of an engineering design that changed the world. That design being the eventual iPhone.

West has even put the two-wheeled engineering marvel, the Segway, into his museum of failure. Segway Inc spent $100 million developing their product. They went on to sell each one at an unrealistically high price of $3,000 for the entry-level version and $7,000 for the premium vehicle.

West has even put the two-wheeled engineering marvel, the Segway, into his museum of failure. Segway Inc spent $100 million developing their product. They went on to sell each one at an unrealistically high price of $3,000 for the entry-level version and $7,000 for the premium vehicle.

According to TIME, the company only sold 30,000 units between 2001 and 2007. The world wasn’t convinced that it was the ‘next big thing’ for getting from A to B.

“The Segway was supposed to revolutionize the way we transport people. And we all know that Segway today is used by tourists before they go get drunk,” West said sardonically.

Google also thought it could revolutionize our worlds and put our smartphone and smartwatches directly on our faces. They released a product named Google Glass - a head-mounted augmented reality wearable computer. The engineering of wearables is now commonplace within engineering disciplines and this will inevitably drive the cost down. But Google, in 2013, seemed to have put the cart before the horse.

Google Glass was released at an expensive price point of $1,500. The market felt it wasn’t adequately function-filled to justify that, in other words, $1,500 seemed a bit steep for a pair of cool shades. The product never really left beta testing;

Google Glass was released at an expensive price point of $1,500. The market felt it wasn’t adequately function-filled to justify that, in other words, $1,500 seemed a bit steep for a pair of cool shades. The product never really left beta testing;

Nonetheless, the future of head-mounted augmented reality wearables is bright, as shown with the Microsoft Hololens. It is clear therefore, that engineering failures bring about more innovation in the long run. However, for those products that miscarried, they now have a new home, in the Museum of Failures.

The world is now left wondering what fascinating engineering design will rise and fall next. Perhaps the latest craze, the fidget spinner will suffer the same fate, and find itself in West’s historical failures museum?

Works Cited

St., 24/7 Wall. "The 10 Biggest Tech Failures of the Last Decade." Time. Time Inc., 14 May 2009. Web. 26 June 2017.

Weller, Chris. "13 of the Biggest Product Flops Featured in Sweden's New 'Museum of Failure'" Business Insider. Business Insider, 14 June 2017. Web. 26 June 2017.

- Details

- Written by: Quintus Potgieter

To be cyber secure is becoming increasingly difficult because our interconnected world poses greater risks. The battle continues nonetheless; cybersecurity professionals are emerging in larger numbers and installed cybersecurity software and hardware is now essential across all industries.

To be cyber secure is becoming increasingly difficult because our interconnected world poses greater risks. The battle continues nonetheless; cybersecurity professionals are emerging in larger numbers and installed cybersecurity software and hardware is now essential across all industries.

Minter Ellison, one of Australia’s largest corporate law firms, warns universities of the potential data theft that they face due to underinvestment in cybersecurity. The firm’s research showed that ransomware attacks in Australia rose by 300% from 2015 to 2016.

The law firm’s Paul Kallenbach and Leah Mooney recently carried out their second annual Cyber Security Survey. The survey was created to “assess changes in Australian organisations’ cyber resilience over the past 12 months”, and covered many different industries. The following summarises their findings:

“Minter Ellison found that, while some progress has been made over the last 12 months among the entities surveyed, many Australian organizations have a long way to go to achieve an appropriate level of cyber resilience.”

The firm reported that 42% of the organizations they had surveyed did not have a data breach response plan, and 92% of them don’t “conduct regular staff training on IT security issues”.

The firm says that one industry that really needs to increase their cybersecurity infrastructure is the higher education industry. Universities hold the financial, personal and confidential information of many of their students - information that shouldn’t fall into the hands of cyber attackers. Data breaches could be very damaging to the reputations of universities across the globe. Another area of concern with data breaches within universities from Minter Ellison’s viewpoint is the fact that critical research is performed within the walls of universities. The impact of stolen data could have incredibly damaging effects on those who spend their careers in research and development.

Are blackouts to come?

Moreover, the vulnerabilities of critical infrastructure have been highlighted in the last few years due to some high profile cyber attacks. The most recent being the ransomware attack on the National Health System across Great Britain.

With remote control of key industrial operations increasing, hacking in the form of denial of service attacks could run rampant, and, for example, cause entire city electricity grids to shut down. Cybersecurity experts ESET and Dragos Inc have published warnings with key industries and infrastructure in mind; they report that a malware known as Industroyer or Crash Override could close down their operations.

Talking to Reuters, ESET’s malware researcher Robert Lipovsky, said:

“The malware is really easy to re-purpose and use against other targets. That is definitely alarming. This could cause wide-scale damage to infrastructure systems that are vital. The tactics, techniques and procedures described as part of the Crash Override malware could be modified to target U.S. critical information networks and systems.”

According to experts, the Industroyer malware is a sophisticated beast; experts say the hackers do not need to control it manually; it automatically overrides the systems of critical infrastructure. It is believed to be related to the malware that took down the Ukraine’s power grid in December 2016.

The official word from experts is for engineers to be alert and cognizant of their industrial control systems and ensure that all the steps to prevent a cyber attack are in place.

The fight against cyber attacks will be a long and tedious one. An ever larger numbers of devices are being connected to interconnected networks that can be remotely accessed. These devices and networks are becoming more vulnerable as a result.

With the demand for cybersecurity on the rise education opportunities for networking and IT gurus have risen too. After all it is up to these specialists to match the hackers’ agility in an attempt to keep ahead. Personnel able to design and implement key software and hardware with built-in reinforcements to prevent catastrophic cyber attacks, now and into the future, are essential.

In this spirit, the Engineering Institute of Technology (EIT) has designed an intensive 6-week online course that covers how to secure automation, control and SCADA systems used across industry: http://www.eit.edu.au/cybersecurity-automation-control-and-scada-systems

Works Cited

Finkle, Jim. "Cyber Firms Warn of Malware That Could Cause Power Outages." Reuters. Thomson Reuters, 12 June 2017. Web. 21 June 2017.

Minter Ellison - Paul Kallenbach and Leah Mooney. "Perspectives on Cyber Risk: Implications for Higher Education." Lexology. Web. 21 June 2017.

- Details

- Written by: Quintus Potgieter

Telecommunication technologies have grown in leaps and bounds in the last few years. Gone are the days of outdated wired technologies that supply us with our link to the internet, it’s all about the wireless connection in the modern day telecommunications industry.

It was just the other day that 4G LTE technology was being introduced, but now there is a new entrant in the game, due to the large number of devices that are making their way to the cloud.

Credit: Inform.tmforum.org

The research group Gartner, estimates that the world will see 20.8 billion connected devices by 2020. Investment into the Internet of Things is growing at a steady rate. The current level of the telecommunications industry is unable to facilitate that many connections worldwide.

A whole new spectrum is necessary to house the billions of connected devices the world is about to see. That is where 5G comes in. 5G will be interconnecting the myriad devices in the advancing fourth industrial revolution.

Engineers are looking to improve signal quality with 5G, amongst other things. Companies in the United States and China, however, are all trying to outdo each other and be the first to bring the elusive technologies into cities.

The 5G Race

T-Mobile is racing to be the first carrier to provide 5G in the United States, placing a sizeable $8 billion bid in to buy spectrum from the Federal Communications Commission (5G). They hope to have the 5G network fully operational by 2020.

China’s spending on 5G infrastructure will amount to $180 billion, making it the biggest investment into telecommunications technology in the world. According to the South China Morning Post, the country will spend 50% more, with the current estimate, than they did with 4G LTE technologies.

The Chinese mainland is expected to have 588.3 million users by 2020. That will be just less than half of the nation’s mobile users in 2020.

It is reported that the major Chinese internet companies, such as Baidu, Alibaba Group and Tencent Holdings, are all leading the way to a future 5G internet connection that would grapple with 8K video streaming, as well as augmented and virtual reality technologies.

It will also pave the way for an efficiently run smart city that generates data and analytics about key infrastructure such as water and electricity metering.

Korea and Japan are reportedly also encouraging their engineers to get 5G networks up and running for the 2018 Winter Olympics and the 2020 Summer Olympics. However, for now, the pronouncements of would could be outweigh the showcasing of technologies.

The Need for Standardization