Industry

- Details

- Written by: Quintus Potgieter

In January 2019, the Consumer Electronics Show kicked off in Las Vegas, Nevada. And it seems mechanical engineering, propped up by artificial intelligence, is the talk of the town.

Mercedes-Benz rolled their latest marvel of mechanical engineering out on the floor, touting some impressive artificially intelligent add-ons. The car’s name is the 2020 Mercedes-Benz CLA 250 Coupe, and the AI software is called MBUX (Mercedes-Benz user experience).

The company’s presentation kicked off calling the CLA ‘The most bling-bling gadget’ at the expo. You can even talk to the car by calling out the words, “Hey Mercedes,” and follow it up with a command you want the car to perform - like rolling up the windows. It also has hand gesture recognition.

There are also semi-autonomous features that help the car drive; further propelling the car industry into a self-driving future. Moving to an artificially intelligent car, empowered by software, is a watershed moment for automobile engineering - it shows that car companies are becoming far more multifaceted.

It also signals an interdisciplinary move in the automobile industry, bringing many engineering industries into one. But, the Head of Group R&D at Mercedes-Benz, Ola Kallenius, says the company itself is also changing the way it operates as a company. Speaking at CES 2019, he said:

“Speaking of the future, we show very clearly where the technologies of our company are heading. Our vehicles are now platforms of digital progress and we operate as a software company with more flexibility and adaptiveness, with agility to do developments and customer requirements [faster]. Our goal is to build trailblazing mobile devices that enhance our customers’ lives.”

The car can also integrate with wearables. The smartwatch informs the car how its driver is feeling. Consequently, the car can then offer massages and hotter or cooler seats. Using the heart rate monitor will also fill the car in on how stressed the driver is. The MBUX system was designed in conjunction with Nvidia. This further highlights how engineering industries that may have previously existed independently, now regularly collaborate to create new products in the future.

Real Robots

Humanoid robots seemed to attract the most journalistic cynicism at the CES event this year. Purportedly the robots at the 2019 expo were a little disappointing; lacking the expected sophistication or improvement when compared with the 2018 expo. It seems that consumer robots are still a bit too clunky to be considered ready-for-market.

The online publication, The Verge, believes that the delivery robots were the most impressive and with the most future-proof uses - namely, delivering items or food to the consumer.

Pudutech had a robot rolling around the CES floor named the HOLABOT. It is equipped with AI speech and face recognition functionality and is specifically designed to deliver food to a customer inside a restaurant. Pudutech is the company looking to be the leader in delivery robots and self-driving low-speed robots. And their multi-robot deployment system will help - it enables one hundred HOLABOTs to work at the same time.

The robots that were highly regarded at CES 2019 may indicate which ones will see huge corporate and consumer uptake (the first cousins of robots like the Roomba vacuum cleaner).

Works Cited

Eisenstein, Paul A. “Mercedes' New CLA Coupe Loaded with High-Tech Extras in Clear Pitch to Millennial Luxury Buyers.” CNBC, CNBC, 9 Jan. 2019, www.cnbc.com/2019/01/09/mercedes-cla-coupe-loaded-with-high-tech-extras-to-lure-millennials.html.

Vincent, James. “The Five Types of Robots You Meet at CES.” The Verge, The Verge, 9 Jan. 2019, www.theverge.com/2019/1/9/18175168/ces-2019-robots-best-worst-delivery-butler-tablet.

- Details

- Written by: Quintus Potgieter

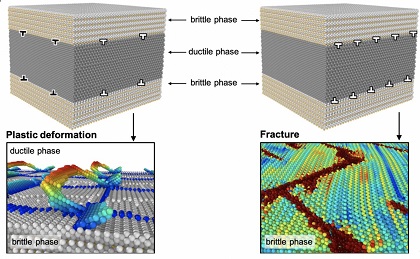

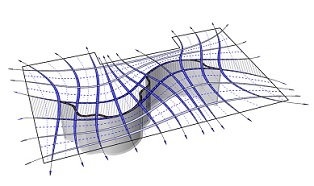

Pearlitic steel, or pearlite, is one of the most durable materials in the world. This microstructure occurs in steel and can be made into steel wire.

You might have seen these wires bundled together into ropes for suspension bridges or steel cords for tire reinforcement. They are also prevalent in piano wires.

Kanazawa University students in Japan have been studying its atomic structure and have made a few first-time discoveries. They hope the atomic properties present in pearlite could be applied to newer materials to ensure bridges and buildings sustain less damage during earthquakes.

In their published findings, titled ‘Proposed engineering method could help make buildings and bridges safer,' the researchers report that they were able to ascertain the distance between locations in nanolayer interfaces in pearlite. The university’s news website writes:

“Perlite is made of alternating nanolayers of cementite and ferrite. The cementite helps make it strong, while the ferrite helps make it ductile. However, until now researchers did not know exactly how the two worked together to give pearlite its special quality, or better yet, how to control their working together to engineer an even better material.”

The researchers discovered that the disruptions, or dislocations, in the arrangement of atoms along the interface between a cementite and ferrite layer protect the layers from fracturing or stretching or compression.

Pearlite is often used in the construction of suspension bridges — it helps the bridges withstand shaking, and also supports a lot of weight.

The researchers studied how the material performs under stress. They found that pearlite prevented cracks from forming and spreading at the atomic level. Therefore, its elasticity is guaranteed.

These findings are particularly pertinent to civil engineers in countries affected by seismic activity.

For example, Mexico City in Mexico is located atop an ancient lake. Once an earthquake occurs, the sand and clay sediments in the lake intensify the severity of the shaking.

This leads to immense damage.

With these new pearlite findings in Japan, building materials could be strengthened to withstand severe earthquakes.

Now engineers are equipped with the knowledge of the dislocations in the nanolayer interfaces of pearlite, they can begin experimenting with ways of transferring that atomic makeup into other materials.

Works Cited

“Proposed Engineering Method Could Help Make Buildings and Bridges Safer.” ScienceDaily, ScienceDaily, 17 Jan. 2019, www.sciencedaily.com/releases/2019/01/190117102359.htm.

“金沢大学.” 金沢大学へ移動, www.kanazawa-u.ac.jp/latest-research/64033.

- Details

- Written by: Quintus Potgieter

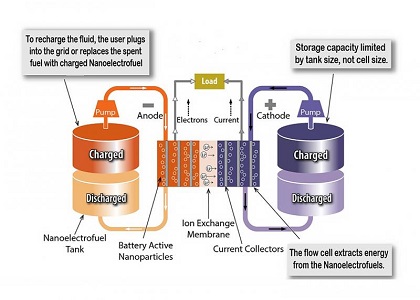

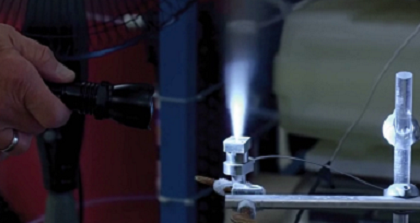

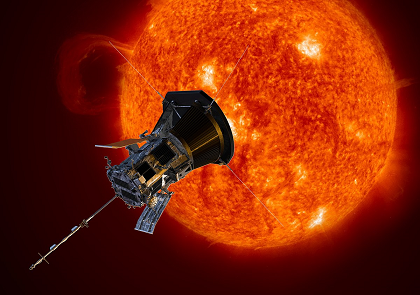

National Aeronautics and Space Administration (NASA) has been working on nano-electrofuel (NEF) flow batteries for electric aviation.

This means they could eventually power aircraft with non-explosive liquid rechargeable batteries.

The development of these flow batteries is being done by the Armstrong Flight Research Center's Aqueous Quick-Charging Battery Integration for Flight Research (Aquifer) within NASA. The aerospace company has always been innovative in the flow battery space — they invented a functioning flow battery back in the 1970s.

NASA says the flow batteries they are developing will have a higher energy density than solid lithium-ion batteries. However, there is a debate as to whether liquid batteries are better than solid-state batteries, particularly when it comes to electric vehicles.

Liquid vs. solid-state

Lithium-ion batteries are made up of liquid electrolyte solutions that utilize an anode and cathode system. A solid-state electrolyte results in a smaller battery with a higher energy density, using a lithium metal anode.

In the electric vehicle industry, liquid-based lithium-ion technology is being called into question. This is a result of fires that have occurred due to the bigger battery banks and the flammable liquid within the cell. Consequently, the industry is starting to pay a lot more attention to solid-state technology.

Solid-state batteries would be less prone to leaking or bursting into flames. They are also considerably smaller than liquid-based batteries. Researchers are indicating that solid-state batteries with a lithium metal anode might enable electric vehicles to travel longer distances than they already do with liquid-based batteries.

However, it seems the car manufacturers are struggling to find a solid-state solution that works for them.

But some companies are going ahead with developing Vanadium Redox Flow batteries — an energy storage technology that organizations like NASA are looking into. The other benefit of the redox battery is that it can be recharged faster than a lithium-ion battery.

The Vanadium Redox Flow batteries are liquid batteries, but unlike normal liquid cells, the electrolytes are housed in tanks outside the cell. These cells work by pumping the liquid into a stack of cells, where the electromechanical reaction takes place and electricity is produced. And word on the street is that they are less explosive than traditional liquid batteries.

NASA Electrical Engineer, Kurt Papathakis told media:

“We have demonstrated multiple recharge cycles and seen minimum to zero degradation. Also, unlike Li-ion batteries, NEF does not pay a penalty in cycle life for charging above 80-percent capacity or discharging below 20 percent.”

Cobalt, lithium, and vanadium are subsequently the most in-demand elements seeing a global demand in the energy storage industry.

Taking to the skies

It's not only NASA that are looking to power electric aircraft in the sky...Rolls-Royce is too. The company plans to launch an all-electric aircraft in 2020. They are also eyeing a world speed record for the plane — the engineers are looking to design an electric plane that can reach a top of speed of more than 300mph. They’re calling it the ACCEL.

The current title holder is the Siemens Extra Aircraft 330LE. It currently boasts the world's most powerful electric motor in an aircraft. It is powered by battery packs and is a joint engineering venture with Extra Aircraft, Siemens, MT-Propeller, and Pipistrel. The company reckons that passenger flights in small electric flights could happen as soon as 2025.

Rolls-Royce is working alongside a company named Electroflight and YASA on their project.

The most important benefit of battery-powered aircraft will be that they emit zero emissions.

Matheu Parr, the ACCEL Project Manager for Rolls-Royce said:

“This plane will be powered by a state-of-the-art electrical system and the most powerful battery ever built for flight. In the year ahead, we’re going to demonstrate its abilities in demanding test environments before going for gold in 2020 from a landing strip on the Welsh coastline.”

Works Cited

“Introducing ACCEL.” Rolls-Royce, www.rolls-royce.com/media/our-stories/innovation/2018/introducing-accel.aspx.

Robinson, Isabelle. “Using Liquid Batteries for Electric Aircraft.” AZoCleantech.com, AZoCleantech.com, 18 Jan. 2019, www.azocleantech.com/article.aspx?ArticleID=843.

- Details

- Written by: Quintus Potgieter

The World Economic Forum is inviting other industrial companies to study nine world-leading smart factories they have identified as having the latest in automation technology.

Not surprisingly, these ‘manufacturing lighthouses' as the WEF call them, utilize the Industrial Internet of Things, and in their opinion show the most promise in Fourth Industrial Revolution implementation.

WEF are helping build seven more to join the other nine already in existence.

Factories are becoming far more automated with communications and networking technologies that can integrate with modern day smartphones and remote technologies. The world has witnessed the advent of 4G in the last few years, which transformed the speed of access to the internet and created interconnected networks within factories.

But 4G's successor is here, and it is unsurprisingly called 5G. The technology is boasting more bandwidth and faster speeds.

However, rolling it out across the world is going to take the building of some new infrastructure.

Nonetheless, many novel applications for 5G have been touted in the media. These include connecting all vehicles on the road to an autonomous driving telecommunications server, hosting entire virtual reality worlds that users can log in into, speedy mobile internet infrastructure, and industrial automation.

Now, countries are racing to be the first to implement the new technology. Chinese companies Huawei and ZTE appear to be frontrunners in the testing of 5G technologies. Qualcomm is one of the American companies making progress designing modems and technology to process the signals broadcasted by 5G antennas.

Ericsson, a company also dedicated to shaping the future of mobile broadband internet communications, says that before 5G is used on products like smartphones and home-based internet, it will go to the factories. They write:

“In our market research we have identified the most crucial manufacturing use case categories that 5G will enable operators to address. These include industrial control and automation systems, planning and design systems, and field devices.”

Ericsson is confident that 5G technology will create the smart factory of the future, made more efficient by the Industrial Internet of Things, powered by 5G internet speeds. 3G and 4G technologies have been classified unable to meet the demands of the cyber-physical manufacturing systems (CMPS) that manufacturers are eager to employ in their factories.

Engineering a technology war

5G is also quickly becoming a bone of contention in geopolitics.

The United States Air Force Brigadier General Robert Spalding told Bloomberg that China's progress on 5G was something the US should be aware of. He said:

“The more connected we are, and 5G will make us the most connected by far, the more vulnerable we become.”

Soon after, the Chief Financial Officer of Huawei, Meng Wanzhou, who is also the daughter of the company's founder, was detained in Canada on request of the US.

Then came the announcements that Huawei would be banned from operating 5G technologies in the US, Australia, New Zealand, Japan, and most recently, Norway. The United Kingdom is currently debating whether to rip out Huawei infrastructure as well.

The US claims that Huawei was not cooperating with an investigation into Huawei's relationship with the Chinese government and the Chinese Communist Party.

Countries who are banning China's no-doubt impressive 5G technologies must figure out how to implement 5G networks by themselves, for now.

The US is particularly worried about what access the Chinese government will have to the data generated by running mobile internet infrastructure in other countries. They claim security vulnerabilities and the supposed connections Huawei has to the Chinese military is enough reason to discourage the use of their technology.

Huawei did, however, hit back after the arrest of their CFO, and said customers can make their own decisions in this technology war — and said they would push on with 5G technology implementation in countries who would work with them.

Consequently, we may have to wait a little longer for the 5G revolution. Until then, the World Economic Forum will be showing off what's possible in their ‘manufacturing lighthouses' and trying to push the fourth industrial revolution that much further.

Works Cited

“5G For Manufacturing and Industrial Automation Technology.” Ericsson.com, 5 June 2018, www.ericsson.com/en/networks/trending/insights-and-reports/5g-for-manufacturing.

Leurent, Helena, et al. “The Fourth Industrial Revolution and the Factories of the Future.” World Economic Forum, www.weforum.org/agenda/2018/08/3-lessons-from-the-lighthouses-beaming-the-way-for-the-4ir/.

Santo, Brian. “5G And Autonomous Vehicles Might Not Go Hand-in-Hand.” EDN, www.edn.com/electronics-blogs/5g-waves/4461460/5G-and-autonomous-vehicles-might-not-go-hand-in-hand.

- Details

- Written by: Quintus Potgieter

As 2019 begins another year of engineering innovation lies ahead.

This year’s engineering buzzword is: REVOLUTION. The cutting edge technologies that have begun to change the way engineers are educated and the way they perform their tasks in the workplace will only increase.

The Engineer, a UK based engineering magazine, has outlined what technologies will see ongoing development in 2019:

- Electric-powered mobility

- Additive manufacturing

- Virtual and augmented reality

- Artificial intelligence: smartphones, smart factories, etc

They suggest that the Fourth Industrial Revolution will impact all industries and all levels of society and reach mainstream status in 2019. This makes it critical for people across the board – but particularly in industries underpinned by these technologies – to become familiar with them, to ensure they can contribute ably in their places of work.

Most importantly, they warn that the engineering sector should address the skills shortages that may well become prevalent with the disruptive nature of these technologies.

The UK based magazine is inevitably reflecting on the lingering uncertainty of Brexit. If all goes smoothly it should be a done deal by the 29th of March 2019. They write:

“Despite this, the pace of technological change in the UK has continued largely unabated. And while most engineering and manufacturing businesses we’ve spoken to over the course of the past couple of years would happily turn the clock back to those uncomplicated pre-referendum days, there’s a growing sense that technology - in particular processes and techniques that can help boost manufacturing productivity - will play a key role in helping the UK adjust to the outcome of Brexit.”

The global shifts in government - prompted by elections – also impacts engineering. But aside from government policy changes and the impact of the Fourth Industrial Revolution, technical skills remain vital. They are needed for the maintenance of already existing technologies (and indeed those still emerging).

Training and education providers will need to ensure they are prepared to service this changing workforce. It is likely that micro-degrees and micro-credential will gain further attention and traction in 2019, as people seek to update skills and knowledge.

Computers, robots, coding

Luke Dormehl, a technology commentator and author, speaking to the team at the Engineering & Technology website said:

“AI and its related hardware-centric field of robotics will continue transforming the workplace in 2019. Whatever profession you work in, whether it’s medicine, law, driving a taxi or working in a warehouse, you can expect to see a growing level of disruption from the steely hand of automation.”

He comments on one of the World Economic Forum’s predictions: 75 million jobs will be replaced by automation in 2025; the good news is that 133 million jobs will be created. He says:

“Many new jobs will involve computer skills. For instance, machine learners and coders will be poised to reap the rewards. However, not every new type of job will involve being the next Mark Zuckerberg.”

Examples abound: if you are based in India, for instance, it may be worth viewing your career through an Uber-lens - an Uber-digital lens: Uber in India will be doubling its engineering workforce - from 500 technologists to 1,000. They will also be sourcing product designers, data scientists, user researchers, front-end and back-end engineers, plus machine learning and artificial intelligence professionals.

For prospective engineers this New Year: stay in the loop, constantly upskill and work hard! And one more thing: keep your eye on those companies which were established in the last decade and are on the cutting edge of engineering endeavor - they are hiring dozens of engineering personnel.

Works Cited

Pozniak, Helena. “Technologies to Watch in 2019: Predictions for the Engineering Year Ahead.” RSS, 7 Dec. 2018, eandt.theiet.org/content/articles/2018/12/technologies-to-watch-in-2019-predictions-for-the-engineering-year-ahead/.

“Tech Trends 2019 - the Engineering Year Ahead.” The Engineer, 5 Dec. 2018, www.theengineer.co.uk/tech-trends-2019/.

“Uber India to Double down on Hiring Engineers in 2019.” The Economic Times, Economic Times, 8 Dec. 2018, economictimes.indiatimes.com/jobs/uber-india-to-double-down-on-hiring-engineers-in-2019/articleshow/66998276.cms.

- Details

- Written by: Quintus Potgieter

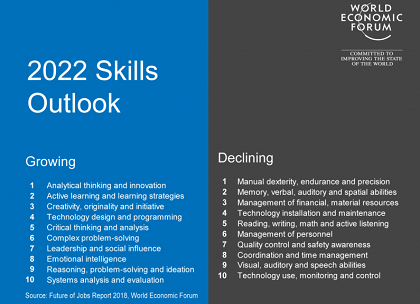

A substantive reduction in the global workforce - due to automation - is expected to occur in the next 3 years. However, according to a report by the World Economic Forum (WEF), some businesses are more excited than anxious.

The WEF report states that 38% of businesses are positive about the future of jobs; they ‘expect to extend their workforce to new productivity-enhancing roles’. Inevitably the new roles will entail new tasks, so to avoid skills shortages companies and educators need to make this a priority:

“By 2022, no less than 54% of all employees will require significant re- and upskilling. Of these, about 35% are expected to require additional training of up to six months, 9% will require reskilling lasting six to 12 months, while 10% will require additional skills training of more than a year.”

Upon that reskilling and upskilling, the WEF says that there will be a ‘net positive outlook for jobs’.

Understandably, though, many people are baffled: which skills should be nurtured and honed and which ones discarded? The following table created by the WEF goes some way to clarifying this, although I believe in many respects it’s a ‘wait and see’ situation.

How did we get here?

The future of work has been growing legs thanks to several drivers of change. The name we have given collectively to these drivers of change is: The Fourth Industrial Revolution. It was in the previous three industrial revolutions where work and domain expertise became more pronounced in society.

The Fourth Industrial Revolution is doing away with work as we know it and domain expertise as we know it. The drivers of change specifically referenced to in the WEF report are:

- High-speed mobile internet

- Artificial intelligence

- Big data analytics

- Cloud technology

These inventions are causing immense change and disruption in most, if not all industries. But disruption is not entirely bad experts are asserting. Disruption in the education space, for instance, is something that could democratize education with more people able to access it.

What can you do?

The WEF reckons that we need to be aware of the rapid development of technology, but particularly with regards to its impact on our jobs. The report suggests that upskilling to meet these shifting job requirements, throughout a career, is best practice for workers in the modern age.

The WEF says that workplaces are going to undergo accelerated technology adoption, but that there will be positive spin-offs: it will relieve workers from some dangerously physical work and will allow us to dodge the more repetitive and dull tasks. Furthermore, the report stated:

“Our findings indicate that by 2022, augmentation of existing jobs through technology may free up workers from the majority of data processing and information search tasks--and may also increasingly support them in high-value tasks such as reasoning and decision-making as augmentation becomes increasingly common over the coming years as a way to supplement and complement human labor.”

Works Cited

“The Future of Jobs Report 2018.” World Economic Forum, www.weforum.org/reports/the-future-of-jobs-report-2018.

- Details

- Written by: Quintus Potgieter

Engineers often borrow from the natural world and biological processes for their work. But there was one natural process engineers could not fathom, or rather failed to take the time to figure out. Why, or how it is that a wombat’s faecal matter is cube-shaped.

The process of copying some of nature’s principles and using them as inspiration for engineering design is called ‘biomimicry’. But how the study of wombat stools could contribute to the engineering industry has not, up until now, been asked.

Patricia Yang, a mechanical engineer, specializes in hydrodynamics in animal bodies at the Georgia Institute of Technology. She spoke to the Institution of Mechanical Engineers:

“The first thing that drove me to this is that I have never seen anything this weird in biology. That was a mystery. I didn’t even believe it was true at the beginning. I Googled it and saw a lot about the cube-shaped wombat poop, but I was skeptical.”

Yang and her team embarked on a process of studying wombat’s digestive tracts. What they found was that wombats’ intestinal walls caused the formation of cube-like faeces. They are, as far as humans know, the only animal to produce cube-structured faeces.

The thinking is that engineers could design something that mimics the digestive tract and intestinal makeup of the marsupial wombat to help mould cubic structures.

“We currently have only two methods to manufacture cubes: we mould it, or we cut it. Now we have this third method. It would be a cool method to apply to the manufacturing process - how to make a cube with soft tissue instead of just moulding it.”

Whilst Yang and her team are based in the United States, this discovery is quintessentially Australian. The wombat is found in the forest-covered area of southeastern Australia. Yang explained that the intestines are responsible. Apparently the wombat faeces are in a liquid state early on in the intestine, but become firm and cube-shaped in the final 8% of the intestinal tract. She said:

“Wombat intestines have periodic stiffness, meaning stiff-soft-stiff-soft, along the circumference to form cubical faeces.”

Biological Transformation

Europe’s largest application-oriented research organization, Fraunhofer-Gesellschaft is encouraging biomimicry with a new campaign entitled: Futuras In Res. They say that innovators should keep using nature as inspiration when they design new products. They make specific mention of salt shakers - modeled after poppies, robot gripper arms - reminiscent of elephant trunks or cameras - like insect eyes. President of the Fraunhofer-Gesellschaft, Professor Reimund Neugebauer says:

“We regard Biological Transformation as the systematic application and combination of processes, principles and materials found in nature to engineering. It will lead to entirely new and more sustainable processes in value creation and manufacturing. By focusing on nature as a driver of innovations, we can use in a new era.”

Biological Transformation and biomimicry is becoming a hallmark of the Industrie 4.0/fourth industrial revolution. The group brought many industries together in June of this year to collaborate and brainstorm on future technologies that could benefit the world.

The main topics discussed were Industrie 4.0, bio-manufacturing, artificial intelligence, biotechnology, bionics, the circular economy and sustainability.

Engineers should look out for opportunities in these cutting edge industries which are innovating and changing the world. But they should also remain alert - sometimes the breakthrough can be something quite surprising and no more sophisticated than the humble wombat poop!

Works Cited

Mechanical Engineering History Timeline - IMechE, www.imeche.org/news/news-article/engineer-solves-mystery-of-cubic-wombat-faeces-to-inform-manufacturing-processes.

“Biological Transformation: Nature as a Driver of Innovations in Engineering and Manufacturing.” Fraunhofer-Gesellschaft, www.fraunhofer.de/en/press/research-news/2018/june/Biological-Transformation-nature-as-a-driver-of-innovations-in-engineering-and-manufacturing.html.

- Details

- Written by: Quintus Potgieter

Another Black Friday and a Cyber Monday have come and gone, as has Christmas and Boxing Day.

According to VOX, it is estimated that the US Postal Service makes 850 million deliveries from Thanksgiving to New Year’s Day. That equates to a lot of parcel deliveries via a host of transportation technologies.

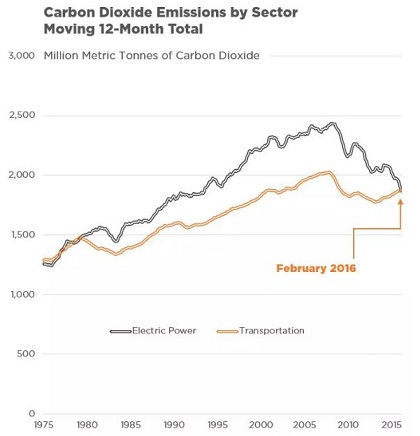

Executive Director at The Energy Policy Institute at the University of Chicago pointed out back in 2016 that US C02 emissions from transport eclipsed power stations for the first time since 1979.

Air quality is becoming a bone of contention for many people around the world, but do they know exactly which entities are the worst offenders for polluting the air?

Not until now – and it is thanks to engineering.

Sensor and satellite technologies are producing data which will help inform citizens and make private sector and government far more transparent.

An organization named Resources for the Future, use satellite data to measure air pollution. Their conclusions, as compared with previous studies, indicate that 24% more Americans live in areas that do not meet the federal air quality standards, as set out by the Environment Protection Agency.

The 24% spike is concerning, but the use of multiple sensors may account for the increase.

New technologies = more data

Engineered sensor technologies are becoming increasingly important to climate scientists and energy policy makers alike. Historically, air quality monitors have been overly expensive. This has led to single investments of air quality monitors in US states, and the statistics, therefore, are relevant only to focused pockets rather than to the length and breadth of each state. Some states literally have one stationary sensor measuring air quality.

The Environmental Defense Fund demonstrates the illogical nature of single monitors versus the clearly superior mobile sensors:

Google Earth Outreach has come to the rescue, piloting a project that will see low-cost sensors map air pollution at a ‘hyperlocal’ level. The EDF says these sensors can ‘be mounted on cars, trucks, and even bicycles - or in denser stationary networks than regulatory monitors’.

With the wider network of sensors capturing air quality data, a clearer picture of the degradation of air quality can be made. Furthermore, the mobile sensors will enable everyone to access the information via online maps with updated air quality readings.

Making the data freely available could have interesting consequences.In the near future, for example, before people make a property investment, the air quality of the area may be considered first and foremost.

Forbes is encouraging companies to equip themselves with the kind of processes which might spare them the public scorn of their carbon footprint. Especially the kinds of companies involved in the shipping and logistics industries. They suggest companies do the following to prevent future outrage when mobile sensors give the public a clearer picture of the air quality around their buildings:

- Do an energy audit, invest in energy efficiency, and electrify building heat sources.

- Invest in renewables or purchase energy from clean energy providers.

- Work with your supply chain to set science-based targets, adopt best practices, and measure and report progress.

- Partner with other companies, utilities, communities and governments to innovate, create infrastructure, and show demand for heavy-duty vehicle electrification

Works Cited

Fund, Environmental Defense. “New Technology, Transparency Will Soon Tie Air Pollution Back To Brands.” Forbes, Forbes Magazine, 20 Nov. 2018, www.forbes.com/sites/edfenergyexchange/2018/11/20/new-technology-transparency-will-soon-tie-air-pollution-back-to-brands/#276af29a10b6.

Ori, Sam. “Sam Ori (@samori8).” Twitter, Twitter, 26 Nov. 2018, twitter.com/samori8.

“A New Challenge for Sensors: 24 Million More Americans Breathing Unhealthy Air than Previously Thought.” Environmental Defense Fund, www.edf.org/blog/2018/09/20/new-challenge-sensors-24-million-more-americans-breathing-unhealthy-air-previously.

- Details

- Written by: Quintus Potgieter

The technological advancement in education has lagged behind other industries. Yet there are technologies available that would transform the classroom, the lecture hall, or even a person’s home, and ultimately transform learning.

The Future of Management Education Alliance wants to bring these technologies to the learners of the 21st century. The alliance is headed up by the Imperial College Business School who plan to introduce hologram technology to their MBA students.

The Imperial College Business School has an educational technology lab (Edtech Lab) that assists the school find the kinds of technologies that would better train the students at the institution.

David Lefevre, director of Imperial’s Edtech Lab said: “This gives our teaching staff a sense of presence when talking with students. Otherwise we might as well run a lecture on Zoom.”

Zoom is video conferencing software employed by some institutions to reach their students via the internet and conduct lectures virtually.

Emmanuel Métais, Edtech Labs’ dean told Financial Times:

“This initiative reflects our commitment to be at the forefront of innovation, not only to provide students with a better learning experience but to make them succeed in a fast-changing world. At Edhec, we believe that excellence and innovation are the two pillars on which our people build their own personalities and careers to make an impact on the world.”

Built by engineers, for engineers?

The hologram technology was developed by Canadian company AHRT Media.

Holographic technology can be leveraged to teach students while a lecturer is on the other side of the world. And the technology has come down in price.

It is not inconceivable to think that students may be taught by lecturers who would appear as holograms. And engineering scholars might need it most. Through simulation technology (virtual and augmented reality) engineers can be taught in virtual spaces.

Even though the technology has not been directly targeted at engineering education, it will be in the next few years. Lefevre concludes:

“Introducing hologram technology to the classroom will break down the limitations of traditional teaching by creating an interactive experience that benefits both students and academics. Rather than replacing or reducing real-life lectures, the hologram technology will provide greater flexibility for academics by enabling them to continue teaching whilst travelling, ensuring consistency and quality for students.”

Works Cited

Moules, Jonathan. “MBA Students to Be Offered Hologram Lectures.” Financial Times, Financial Times, 1 Nov. 2018, www.ft.com/content/01749584-dcf9-11e8-8f50-cbae5495d92b.

Singleton, Laura. “Imperial College Business School to Offer Live Lectures via Hologram | Imperial News | Imperial College London.” Imperial News, 2 Nov. 2018, www.imperial.ac.uk/news/188851/imperial-college-business-school-offer-live/.

- Details

- Written by: Quintus Potgieter

2018 marked 100 years since the end of World War I. On the eleventh day, of the eleventh month, of the eleventh hour in 1918, the Allies of World War I and Germany signed a treaty that ended the war.

World War I was a turning point in warfare. In its time, it was the most significant war with the most modern warfare equipment ever invented — Mortars, machine guns, rifles, poison gas and the surprising entrant of the flamethrower. But it wasn't just the handheld equipment and biological weapons that were new.

Even light railways were set up between the trenches upon which petrol-powered locomotives could ride and transport both soldiers and weaponry. But the British still needed something that would give them the upper hand on the Germans.

A stalemate on the Western Front, where endless trench warfare was taking place, had produced the need for a new land-based, cross-country vehicle that could breach enemy lines.

The British army then received a shipment of heavy artillery that they had never seen before.

Director of the Lord of the Rings trilogy Peter Jackson has captured some of the mysticism surrounding the arrival of the tanks in his latest documentary on World War I named ‘They Shall Not Grow Old.' Real soldiers whose stories were captured by the Imperial War Museums and sampled in the documentary relayed their stories:

"They were on the roadside covered with tarpaulin sheets. You could see nothing except a square outline."

"And then the officer said, ‘these are supposed to be hush-hush,'" another soldier recalled.

Another said, “When we asked what it was, the simple reply was: tanks. Knowing the shortage of water we had actually assumed water tanks and thought we were getting reserve supplies. It was one of the best kept secrets.”

The engineering of the tank ushered in a new era of mechanized warfare that has continued until today.

Fiction becomes fact

In 1903, H.G. Wells wrote a short story named ‘The Land Ironclads.' In the fictional story he writes about 100-foot-long armored fighting vehicles that would carry key army personnel across enemy lines. Thirteen years later, Wells’ prediction that ironclad machines impervious to machine gun fire would traverse the battlefield came true.

It was actually a young Winston Churchill - who at the time was the First Lord of the Admiralty - that had a hand in the commencement of the engineering of tanks. He set up a top-secret collective in February 1915 named the Landship Committee.

After a spot of trial and error — and a few prototypes went wrong — Sir William Ashbee Tritton (a British expert in agricultural machinery) and Major Walter Gordon Wilson (a mechanical engineer) were the designers behind the world’s first tank. It was named Little Willie, intentionally mocking German Imperial Prince Wilhelm.

The caterpillar tracks fitted on to the first iteration of the tank was good for traversing over land but got stuck when it tried to ride over any of the parapets (a protective wall or earth defense) in front of the German trenches.

The second iteration of Tritton and Wilson's invention was a more rhomboidal shape that had tracks going all the way around the hull. A mock battlefield with a trench even wider than those in the actual war was set up, and the tank was tested. It surpassed expectations. This was the prototype they sent off to the war.

David Lloyd George, who in 1916 became the secretary of state for war wrote: “At last, we have the answer to the German machine guns and wire.”

Another two prototypes were eventually released toward the end of 1917 and mid-1918 respectively. Nonetheless, the tank had woken up the militaries of the world, and in the wars to come, everyone would want one. The rest, as they say, is history.

It is estimated that nearly one million British and Empire servicemen were killed between 1914 and 1918. The total number of military and civilian deaths in the entire war was determined to be between 15 to 19 million people.

Works Cited

“How Britain Invented The Tank In The First World War.” Imperial War Museums, www.iwm.org.uk/history/how-britain-invented-the-tank-in-the-first-world-war.

“They Shall Not Grow Old.” IMDb, IMDb.com, 9 Nov. 2018, www.imdb.com/title/tt7905466/?ref_=nv_sr_1.

- Details

- Written by: Quintus Potgieter

Friday 30 November is Systems Engineer Day!

A systems engineer's job is to create and manage complex systems. They ensure that the system has a good life cycle and that all systems are running efficiently.

This celebration debuted in 2012, lauding the engineers who, through design and implementation of digital solutions, make a difference in the many workplaces globally. On the day, everyone is encouraged to high five their systems engineer and show their appreciation.

Systems engineers are becoming increasingly valuable to companies as the Fourth Industrial Revolution brings about complex networks to facilitate the Internet of Things. These system engineers are vital and essentially — at least in the interconnected technological industry— make the world go round.

Systems engineers have to work tirelessly to understand user experience. They need to tailor their systems to what they think other people will enjoy and consider efficient.

Dice Insights, an institution which provides advice for tech professionals, reports that systems engineers with an extensive understanding of Linux systems specifically, could be looking at a bigger salary per month.

How to become a systems engineer

According to Dice Insights, the best path to becoming a systems engineer starts with a degree in computer science, information systems, or engineering. They write:

“As systems engineers gain experience, they’ll learn the tools and techniques necessary to manage systems at scale--for example, a senior systems engineer (i.e., systems engineer III) will not only need experience in designing and implementing the overall architecture of a software system, but must have tactical knowledge of virtualization, containers, systems design tools and languages, and analytics.”

Systems engineers need to be fully aware of what networking technologies are available. They should also anticipate the release of new ones that they can implement.

System engineers can go by many names, according to SystemsEngineerDay.com. They can be called systems engineers, infrastructure engineers, system integrators, architects, system analysts, and more.

It’s therefore clear that systems engineer can be present across most of the disciplines of engineering. With engineering becoming more and more interdisciplinary, education institutions are creating new qualifications to formalize the domain expertise moniker of ‘systems engineer.' Boston University has a minor qualification, MEng, MS, and Ph.D. in Systems Engineering.

They say that their graduates can work in a plethora of industries that include but are not limited to:

- Developing computer simulation packages for software providers

- Building and evaluating models for communication, computer and sensor networks

- Developing effective air traffic management systems

- Analyzing the feasibility of relying on teams of autonomous vehicles for military and civilian applications

- Developing, enhancing and maintaining quantitative stock selection models that are used to pick high-performing stocks for clients

- Developing and supporting software that optimizes a company’s global supply chain operations and provides multiple-year production plans based on various supply, demand and capacity scenarios.

- Inventing new scheduling and production control algorithms for manufacturing enterprises.

- Developing a pairing optimizer and crew controller, to provide crew pairing and rostering for more than 30 airline companies all over the world.

- Designing innovative algorithms and software to direct user traffic across the internet, optimizing the end-user experience.

The Engineering Institute of Technology’s Dean of Engineering, Steve Mackay, says that adding systems engineering into the career mix is a wise decision. Systems engineering, in his opinion, represents the function of teaching the old engineering ‘dog’ new tricks. He writes:

“Systems engineering would appear to be mainly in the aerospace and military sphere but it is across all fields of engineering ranging from car manufacturing, building plants & infrastructure, oil and gas, mining and transport and in many newer areas. A great example of a growing field of systems engineering is the smart grid - dynamic, complex with many different disciplines involved in its creation coupled with a high degree of uncertainty and a great opportunity to optimize. Or smart self-driving cars - the number of different disciplines here are mind boggling.”

Consequently, if you know someone working towards becoming a systems engineer, who can grapple with all of the technological development that the convergence of engineering disciplines has produced, celebrate them this Systems Engineer Day.

Works Cited

KolakowskiNovember, Nick. “Systems Engineer Salary Rises Even Higher with Linux Experience.” Dice Insights, Dice, 16 Nov. 2018, insights.dice.com/2018/11/13/systems-engineer-salary-rises-even-higher-with-linux-experience/.

“What Is Systems Engineering?” Family and Medical Leave Act (FMLA) | Human Resources, www.bu.edu/eng/departments/se/prospective-students/what-is-systems-engineering/.

“What Is Systems Engineering?” Family and Medical Leave Act (FMLA) | Human Resources, www.bu.edu/eng/departments/se/prospective-students/what-is-systems-engineering/.

“Systemsengineerday.com.” Systemsengineerday.com, www.systemsengineerday.com/.

- Details

- Written by: Quintus Potgieter

Future generations will judge us for not taking the necessary precautions to offset the effects of climate change on our world. The blame will inevitably involve our reticence to cut down on fossil fuels. In reality, however, the task is massive and will rely on science, technology, engineering and government all committing to solving the problem.

Mark Lynas, a British journalist and environmentalist, has been issuing warnings since 2007. He explains what will happen to the world if the earth continues to warm, Six Degrees: Our Future on a Hotter Planet.

In one chapter he writes about the Palmer Drought Severity Index — a computerized forecast run by the Hadley Centre at Britain's Meteorological Office. This computer model calculates the likelihood of drought in the century to come. In 2007 he wrote the following:

"The results were deeply troubling. The incidence of moderate drought doubled by 2100 — but worst of all, the figure for extreme drought (currently 3 percent of the planet's land surface) rose to 30 percent. In essence, a third of the land surface of the globe would be largely devoid of fresh water and therefore no longer habitable to humans."

This prediction is based on global warming of higher than one degree. And according to a recent study published in the Nature Journal, the Panel on Climate Change (IPCC) believes that by 2100 the temperature will rise by 2 to 4.9 degrees Celsius.

Adrian Raftery, the author of the study, said:

"The likely range of global temperature increase is 2.0-4.9 (degrees Celsius) and our median forecast is 3.2 Celsius. Our model is based on data which already show the effect of existing emission mitigation policies. Achieving the goal of less than 1.5 C warming will require carbon intensity to decline much faster than in the recent past."

Importance of education and teamwork

Experts believe that if engineering disciplines come together to figure out a path forward, the looming water and energy crises can be solved. However, with universities still catering to individual subjects, a shake-up in education needs to occur.

This, according to a study entitled, Adapting to Engineering Education Vision 2020, published by the Multidisciplinary Digital Publishing Institute.

The authors say that in many countries universities have pursued curricula that teach students ‘soft skills' instead of the ‘professional skills' required for engineers. And yet the world needs competent engineers if they are to solve existing and growing crises.

Technological advancement is making it easier for humans to solve the world's most pressing issues. With the right education people will be well placed to manipulate these new technologies to create positive outcomes.

The authors of the report write:

“It is not possible without putting the emerging bio, nano, and info technologies together in power and energy research laboratories under interdisciplinary and trans-disciplinary approaches. Electrical engineers badly need the supportive hand of energy scientists and technologies to overcome global power, energy, food, and water crises. Engineers and scientists often find it difficult to tolerate each other and usually end up with duplicate resources without presentable output which requires motivation to develop teamwork spirit to succeed.”

The authors believe students who have an affinity for energy in chemistry subjects will eventually work in new fuel cells or solar cells. This would provide a great opportunity for engineers and scientists to work together. They say that scientists and engineers are stuck in ‘discipline defense politics' and are squandering this chance to collaborate.

Interdisciplinary curricula within degree programs are helping to equip students to tackle current world problems. The authors of the study point out that an updated engineering curriculum might see the following modules present in the coursework: renewable energy, molecular electronics, polymer solar cells, solar paints, and photochemistry.

The authors conclude:

“Future energy supply to society is a big challenge that individual disciplines cannot harness alone without developing a spirit of interdisciplinary research and development. Keeping in view world energy sources and global power needs, we must readjust our energy wasting attitudes and prepare our generation to cope with future power and energy crisis.”

Works Cited

Raftery, Adrian E., et al. “Less than 2 °C Warming by 2100 Unlikely.” Nature News, Nature Publishing Group, 31 July 2017, www.nature.com/articles/nclimate3352.

“Six Degrees by Mark Lynas.” Goodreads, Goodreads, www.goodreads.com/book/show/227477.Six_Degrees.

Yasmin, Musarat, et al. “Adapting to Engineering Education Vision 2020.” Proceedings, vol. 2, no. 21, 2018, p. 1365., doi:10.3390/proceedings2211365.

- Details

- Written by: Quintus Potgieter

By all accounts engineering remains a male-dominated industry.

In 2015, the U.S. Department of Commerce reported that women fill 47 percent of all jobs, while men take up the other 53 percent.

However, according to more recent figures from the National Science Board, women only filled 24 percent of STEM jobs in 2018. And the industry in which women are least represented? Engineering.

TechCrunch writer Dr. Ioannis Miaoulis, president and director of the Museum of Science in Boston, says the numbers are ‘startling.' He writes:

“At a young age, girls internalize long-lasting stereotypes that tell them that boys are better at engineering and computer science, and that girls simply aren’t engineers. And during these formative years, they never have an opportunity to imagine themselves as engineers.”

Dr. Jordan B Peterson, a professor of psychology at the University of Toronto, explains why that might be:

“Women are tilted towards empathizing and males are tilted towards systematizing. That seems to fall into alignment with other observations suggesting that, the biggest gender difference between adult humans is interest preference. Women are much more likely to express interest in occupations that involve a lot of social contact, whereas men are more likely to manifest interest in occupations that have to do with things.”

Peterson points out that even in the Scandinavian countries — considered the most gender equal societies in the world — the most striking gender differences exist, based on occupation. He reports that the ratio of male nurses to female nurses is 1:20, and the ratio of female engineers to male engineers is also 1:20.

Breaking boundaries

Dr. Ioannis Miaoulis notes that even with the advocacy groups and the many institutions prepared for increasing numbers of female engineers, the results are disappointing.

The Engineering Institute of Technology has seen more women apply to the institution as the boundaries of entry for women lowers in the education sector. A 24-year old female Advanced Diploma of Civil and Structural Engineering graduate from EIT, Oyama Khanyisile Vundla, is a driven young woman ready to take on the Engineering world. She says:

“Media plays a huge role in people’s perceptions of how men are equipped for engineering and women are not. Even the movies we watch display men as engineers, people end up believing that women can’t survive in these industries. I would definitely advise young women to pursue this industry and cast away all the negative spin that says we can’t survive in this industry.”

What else can the world collectively do to inspire more females to join the Engineering workforce?

Apparently the answer is to play video games!

A study published in the journal Computers in Human Behavior reports that girls who play a plethora of video games between the ages 13 and 14 are more prone to investigating STEM job opportunities in their future.

Through the demographics of the women polled in the study, it was clear that a majority of the women who identified themselves as gamers were studying STEM subjects at degree level.

The study conducted by Director of Ph.D. in Higher Education at the University of Surrey,

Anesa Hoesin said:

“Our research shows that those who study STEM subjects at degree level are more likely to be gamers, so we need to encourage the girl gamers of today to become the engineering and physics students and pioneers of tomorrow.”

Hosein is trying to pressure educators to introduce gaming to girls at a young age so that they become familiar with interacting with technology at a high level.

We could also use platforms such as YouTube to get girls interested in a digital future where an equal number of men and women are engineers. A YouTuber named GoldieBlox features a young female engineer showing off her skills to a wide audience of 561,345 subscribers.

Goldieblox is a digital media, publishing and consumer products company that is helping inspire girls in STEM fields. They target their content towards young girls, in the hope of encouraging them to pursue STEM opportunities in the future.

Currently, only 11 percent of engineering faculty in the US is women. The key to improving this statistic seems to revolve around getting girls involved in engineering at a younger age. New strategies must be tested so humanity can benefit from the contribution women could bring to the engineering industry.

Works Cited

“'Geek Girl' Gamers Are More Likely to Study Science and Technology Degrees.” University of Surrey, www.surrey.ac.uk/news/geek-girl-gamers-are-more-likely-study-science-and-technology-degrees.

Miaoulis, Ioannis. “We're Addressing Gender Disparity in Engineering Way Too Late.” TechCrunch, TechCrunch, 26 Oct. 2018, techcrunch.com/2018/10/26/were-addressing-gender-disparity-in-engineering-way-too-late/.

Ramble. “Jordan B Peterson: Why so Many Male Engineers and Female Nurses?” YouTube, YouTube, 7 Aug. 2017, www.youtube.com/watch?v=d7uZOAzVRgU.

- Details

- Written by: Quintus Potgieter

At the foot of the pyramids of Giza, a new museum is taking shape.

Five thousand Egyptian civil engineers are hard at work to complete the Grand Egyptian Museum. Construction began 16 years ago, and the doors are expected finally to open in early 2019.

One of the firms attached to the build is Buro Happold Engineering. They say the museum will be a construction where ‘mathematical precision meets elegant vision.'

The initial call for proposals for the museum was in 2002. The winning designers were Heneghan Peng from Dublin, Ireland. They worked alongside Arup, an independent firm of designers, planners, and engineers. The exhibition design was completed by Metaphor and Cultural Innovations Ltd.

It is expected to assume a 50 hectare stretch of land and will go down as one of the most audacious museum builds in world history. Director General of the museum, Tarek Tawfik told CNN:

“This will be the museum of the 21st century. All means of modern technology have been taken into consideration in order to make this an unforgettable experience for the visitor, but at the same time provide the best possible environment for the artifacts.”

The museum's construction is expected to cost US $1 billion. Inside it are the country's most marvelous relics and artifacts of the past. The Colossus of Ramses II, weighing in at 121 tonnes, (already transported across Egypt) is to be moved to the Grand Egyptian Museum. He will be standing tall above the visitors at the museum’s entrance.

A Horus God statue has also been transferred from Al-Masalah Garden in Zamalek to the Grand Egyptian Museum.

The building has been constructed to resemble a chamfered triangle — a homage to the pyramids. Built on a sand hill, engineers had their work cut out for them. Tawfik said:

“This made it a bit more difficult to prepare the location, but it had the big plus point that there was no fear to stumble over antiquities here because the ancient Egyptians didn’t build any temples or carve any tombs into sand.”

Another feat of civil engineering will be an 800 meter long, 40 meter tall translucent stone wall, erected just in front of the museum. When tourists approach from the Cairo side, the translucent stone will produce a natural, inviting entrance to the museum. An 800-seat auditorium is also to be opened inside the museum.

The museum is downwind from the Giza pyramids and perfectly adjacent to the Giza pyramids, just two kilometers away. Another phase of the construction includes building a Conservation and Energy Center (CEC) that will house a conservation center, conservation plant, and a fire station.

Conservation

While being an impressive feat of civil engineering, the museum will also be an enigma of conservation.

The museum will also include King Tut-Ankh-Amun's Treasure — the only complete set of royal belongings in Egyptian antiquities collections.

Two-thousand-and-six of King Tut's 5,300 possessions will be shown off in the Grand Egyptian Museum. Conservationists are in the process of polishing the artifacts with specialized techniques, ensuring not to cause any damage.

One of King Tut's sandals was said to be beyond restoring, yet it has been done and is now present in the collection. Consequently, the museum's construction has also spurred one of the most significant restoration projects in the world.

Other attractions include artifacts from Queen Hetepheres I’s tomb; these antiquities were discovered in 1925.

The museum's visitors will have the chance to look at artifacts that date back at least 3,500 years. The Egyptian government is hoping that the opening of the museum will reinvigorate its tourism industry after the instability caused during the 2011 Arab Spring.

Works Cited

The Grand Egyptian Museum, www.gem.gov.eg/index/Museum -Museum Building - Facade & Entrance.htm.

“Egypt's New $1 Billion Museum.” CNN, Cable News Network, 5 June 2018, edition.cnn.com/style/article/grand-egyptian-museum/index.html.

“Grand Egyptian Museum.” BuroHappold Engineering, www.burohappold.com/projects/grand-egyptian-museum/.

- Details

- Written by: Quintus Potgieter

Mechanical engineers are flexing their eco-friendly and business savvy muscles in the startup industry. Pratheek Palanethra was a mechanical engineering student in Bengaluru and is also passionate about cricket.

During his student years - studying for his Master of Technical Entrepreneurship at Lehigh University in Pennsylvania – he was sad to discover that there was really no cricket culture in the US. He struggled to find students who wanted to practice cricket with him. Instead of allowing it to perturb him it inspired him; he decided to engineer something to enable his practice.

He enlisted the help of his roommate Justin Jacobs, who was studying civil engineering at the time, and they began work on an affordable, non-electric bowling machine.

“We really wanted to be innovative the cricket market. Everyone’s going high-tech, we are going low-tech,” Justin said.

Usually, cricket bowling machines are quite expensive. In South Africa — where cricket bowling machines would be in high demand — a Paceman Pro Bowling Machine costs approximately US $932.

A new product ready to fly

Pratheek and Justin’s new mechanical engineering startup soon announced their eco-friendly, affordable answer to the bowling machine; they called it the Freebowler. The bowling machine is free from batteries, cords, and has no electricity ports on it.

What they produced was a purely mechanical product, fitted with a throwing arm operated via a spring, a ball cup, and more.

"The ball in the cup can be set at different angles and orientation using a knob that enables the batsman to play variations of lengths and swings," said Pratheek.

"The machine has wheels at the bottom to maneuver and is thus portable. It can be placed shorter than the normal 22-yard distance from the batsman. This way it enables the batsman to play different length and bounce at higher speeds."

The Freebowler costs approximately US $434. The Freebowler also matches, and in some cases, trumps other bowling machines' output speed: the Freebowler can launch balls at up to 140 kilometers per hour (87MPH). The Freebowler weighs in at only 23 kilograms. It's a perfect product for remote regions which do not have access to electricity or cannot afford conventional bowling machines.

The machine can take old cricket balls, new balls, indoor cricket balls, baseballs, and tennis balls.

Mechanical engineering for the betterment of sports could indeed be an area of growth with the Freebowler as the inspiration. The Freebowler website states:

“Machines that have this capacity to contort in a unique way, combined with an amount of storing convenience, environmental consciousness and adjustability not only show how far technology has come, but it also enhances the sport’s overall value.”

Works Cited

“Cricket Bowling Machine | Non-Electric Training Equipment.” Freebowler, freebowler.com/.

“This Startup Is Batting for Cricket Lovers with Its Portable Non-Electric Bowling Machine.” YourStory.com, 28 Oct. 2018, yourstory.com/2018/10/startup-batting-cricket-lovers-portable-non-electric-bowling-machine/.

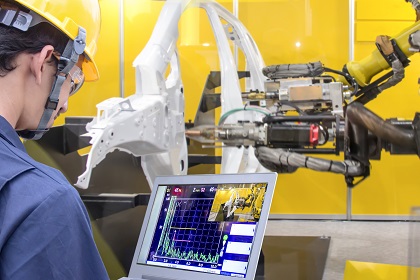

- Details

- Written by: Elyse Simich

As 2018 comes to a close, the industrial automation market is preparing to further digitize and automate industries into 2019.

McKinsey Global Institute (MGI) reports that by 2030 about 15 percent of workers around the world will be displaced by automation. However, they also note that employees are unaware that eight to nine percent of them will work in jobs that don't yet exist.

Consequently, automation will not only replace repetitive jobs, but also create new opportunities in many industries. This is why a culture of life-long learning is critical; a willingness to upskill and cross-skill.

Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, believes emphatically that automation will preserve the engineer, not replace him/her. However, Steve notes that they should take responsibility for their futures, by being aware of the changes occurring in the industry.

"You may be doing something today, but tomorrow you will be doing something completely different," he said, in a lecture.

"The most important message is that you should commit to continuous professional development. Look for the job demands of the country you are based in and be open to opportunities to learn and skill up. Every country needs certain kinds of engineer - in fact - every town has its own particular demands.”

Global innovation requires engineers

What should educational institutions be including in their curricula, to ensure students are equipped to tackle Industry 4.0? How much on-the-job training needs to occur in industries that have introduced more automated processes into their businesses?

Those are essential questions that organizations are collectively asking. However, getting the average person interested and skilled in using new technologies is a tall order.

The World Economic Forum has invested in the construction of 12 Fourth Industrial Revolution centers around the world that will familiarize the public with the kinds of technologies one would and will see in the Industry 4.0 world.

Professor Klaus Schwab, founder and executive chairman of the World Economic Forum said:

"The centers are looking at eight different technologies, such as artificial intelligence, blockchain, drone technology, big data, precision medicine and so on, to develop the necessary ethical views, policies and regulations around these technologies which can be applied on a global level."

Schwab, in a recent video by WEF, commented on how unprepared the world is for the current digital revolution. He points out that it is those with technical backgrounds who are vital to the growth of the fourth industrial revolution, and perhaps a better world for all.

And workers with technical skills are more likely to circumnavigate the hollowing out of jobs that Industry 4.0 technologies threaten. CareerBuilder’s CEO Irina Novoselsky explains:

“Most of the fastest-growing occupations have a technical component to them. Workers across all job levels will need to continually pursue opportunities to upskill in order to maneuver around accelerated shifts in labor demand. This is a particularly pressing issue for middle-wage workers who are at greater risk of becoming displaced and workers in general who want to move up into better-paying jobs.”

The World Economic Forum's 2018 Future of Jobs Report aptly said that 54 percent of all employees will need ‘significant re- and up skilling' by the year 2022, to meet the changes coming to workplaces.

Works Cited

Ellingrud, Kweilin. “The Upside Of Automation: New Jobs, Increased Productivity And Changing Roles For Workers.” Forbes, Forbes Magazine, 23 Oct. 2018, www.forbes.com/sites/kweilinellingrud/2018/10/23/the-upside-of-automation-new-jobs-increased-productivity-and-changing-roles-for-workers/#276a7b1e7df0.

Letsebe, Kgaogelo. “WEF to Establish Industry 4.0 Centre in SA.” ITWeb, ITWeb, 28 June 2018, www.itweb.co.za/content/VgZeyvJAONaqdjX9.

Morgan, Hannah. “To Fend Off Your Robot Replacement, Reinvest in Job Training.” U.S. News & World Report, U.S. News & World Report, money.usnews.com/money/blogs/outside-voices-careers/articles/2018-10-19/warning-you-need-to-reinvest-in-job-training.

- Details

- Written by: Quintus Potgieter

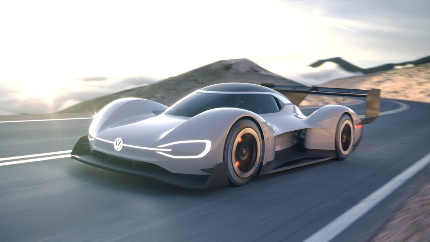

Is the move to electric vehicles on track?

Last year the UK government pledged that the manufacture of petrol and diesel cars would cease by 2040. In July, they then amended their pledge to also exclude hybrids (cars powered by electricity and petrol/diesel). MPs in the United Kingdom are, however, growing ever more skeptical about the viability of a majority electric vehicle future by 2040.

On the other hand, a new report has been released by the Business, Energy and Industrial Committee, ‘Electric vehicles: driving the transition.' They believe that the initial pledges by the government were ‘vague' and lacked ambition. They recommend that government ban the sales of fossil-fueled vehicles by the year 2032 and make the necessary investment to facilitate it.

Chair (and engineer) of the Business, Energy and Industrial Committee said:

“We cannot expect consumers to overcome ‘range anxiety’ and switch to electric vehicles if they cannot be confident of finding convenient, reliable points to regularly charge their cars. The government needs to get a grip and lead on coordinating the financial support and technical know-how necessary for local authorities to promote this infrastructure and help ensure that electric cars are an attractive option for consumers.”

The technical know-how across many facets of the global rollover to electric vehicles will be an essential focus in the next few years. Training a league of engineers to focus specifically on electric cars is vitally important.

Electric Car engineering courses, and Hybrid and Electric Vehicle Engineering Academies are popping up fast to meet the potential skills shortage that the automobile industry might face as 2040 approaches. Despite these efforts experts worry that deadlines cannot be met for a 2040 deadline, let alone one in 2032.

Mike Hawes, the chief executive of the Society of Motor Manufacturers and Traders (SMMT), as quoted by Verdict UK, said:

“The government’s 2040 ambition was already extremely challenging, so to fast-track that by eight years would be nigh impossible. We said we need world-class infrastructure and world-class incentives to have any chance of delivering so the recent cuts to the Plug-in Car Grand and lack of charging facilities - both of which are severely criticized by the Committee - show just how difficult it would be to accelerate this transition.”

The overarching reason for lessening the number of combustion engines on the road is to minimize emissions. The current government ambition is named the ‘Road to Zero Strategy.'

The current situation

EV Volumes analyses the electric car market - it has reported that there were 3 million electric vehicles in operation worldwide, by the end of November 2017. Another 2 million are expected to be on the roads by the end of 2018.

ABB have, however, released a new electric vehicle charger called the Terra HP. It can run three times faster than the current EV chargers on the market and can also service two vehicles at the same time. The development of faster EV charging technologies will encourage consumers and potentially fast-track the uptake of EVs. ABB confirms that in just eight minutes 200km (120 miles) of driving range will be added to the latest EVs on their new charging stations.

Works Cited

“ABB Powers e-Mobility with Launch of First 350 KW High Power Car Charger.” ABB Group - Leading Digital Technologies for Industry, 24 Apr. 2018, new.abb.com/news/detail/4439/abb-powers-e-mobility-with-launch-of-first-350-kw-high-power-car-charger.

Migliorato, Lorenzo, and Christopher Marchant. “Government Committee Considers 'Road to Zero' Petrol Ban by 2032.” Motor Finance, 19 Oct. 2018, www.verdict.co.uk/motor-finance-online/news/government-committee-considers-bringing-petrol-ban-forward-2032/.

“UK Government EV Plans Vague and Unambitious Claim MPs.” The Engineer, 19 Oct. 2018, www.theengineer.co.uk/mps-criticise-uk-government-ev-plans/?cmpid=tenews_6443514&utm_medium=email&utm_source=newsletter&utm_campaign=tenews&adg=5A0EAC12-A7C5-4FD9-9AA8-84D6979695B5.

- Details

- Written by: Quintus Potgieter

At this year's Dutch Design Week, the world's first 3D printed stainless steel bridge was unveiled.

The bridge was produced by a Dutch robotics company named MX3D. It will serve as a crossing over one of Amsterdam's oldest and most famous canals, the Oudezijds Achterburgwal.

Its construction utilized optimization software and a robotic additive manufacturing technology to layer molten steel repetitively. The traditional construction engineering approach to building a bridge has potentially been altered forever.

Six industrial robots equipped with ‘purpose-built tools' assisted in controlling welding machines that fused the bridge together. Reflecting on how the final design of the bridge changed, MX3D said:

“The initial design changed significantly due to the engineering concerns. The lightweight tree-like structure is built on four main bearers. The concern was that if one of these bearers gets hit by a boat, the structure could critically fail. Therefore a totally new concept was created that took into account everything we learned until then about the material, the local specifications and regulations.”

The bridge's structural integrity will be monitored via sensors, which will provide engineers with the data they need to ensure the bridge is structurally sound.

In a virtual space, the data will help build a ‘digital twin' bridge. A computer model will monitor the safety and performance of the bridge based on how many people have crossed it over time. This is something that structures around the world could benefit from. This technology allows engineers to simulate different situations to test out different stresses.

A new term is being coined in the midst of the technological development of bridges: smart bridges. MX3D is confident that construction robots will be widespread in the next five years.

"We have set a vision in which robots would be able to autonomously 3D print infrastructural interventions in our built environment," an MX3D spokesperson said. "The work on this 3D printed bridge will contribute to the future of safe, efficient and data-driven engineering by monitoring the structure as thousands of people and bicycles traverse the bridge hourly in place."

The feat of engineering won them the Dutch Design Award of 2018 in the Design Research category.

Works Cited

“MX3D Bridge.” MX3D, mx3d.com/projects/bridge-2/.

Yalcinkaya, Gunseli. “World's First 3D-Printed Steel Bridge Unveiled at Dutch Design Week.” Dezeen, Dezeen, 24 Oct. 2018, www.dezeen.com/2018/10/22/worlds-first-3d-printed-steel-bridge-completed-mx3d-technology/.

- Details

- Written by: Quintus Potgieter

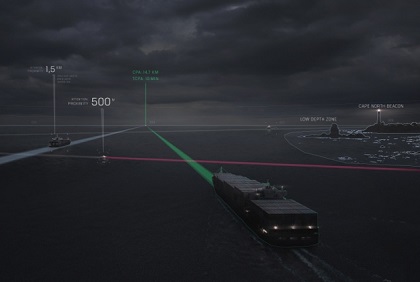

Rolls-Royce and Intel have joined forces to develop an Intelligent Awareness System for future autonomous shipping projects.

The first entirely unmanned, crewless ships, with the self-sailing tech, are set to hit the oceans in 2025.

Inevitably, they will see crewed vessels working alongside them.

Don’t assume that this technology has rendered the lighthouse useless though. In the official simulated pictures published by Rolls-Royce, the lighthouse remains the beacon announcing land that it has always been.

Nonetheless, the new system packs a punch in the technology department; the setup includes LIDAR, radar, thermal camera, High Definition cameras, satellite data and weather forecasts. With all of the data being generated by these technologies, Intel has fitted the system with their 3D NAND solid-state drives. The drives will store up to one terabyte of compressed data per day.

It’s possible that industrial-sized, autonomously controlled vessels could be greenlit by governments across the globe before autonomous vehicles! Only time will tell.

Kevin Daffey, director of ship intelligence at Rolls-Royce said:

“It presents an unparalleled situational awareness of what’s around the vessel to the watch-keepers on the bridge, including distances, the names of the vessels that are near them, or how far they are from land. Over the next three years we’ll begin to see the first commercially-operated ships with some degree of autonomous functionality on board, moving towards vessels that can make their own decisions from around 2025 onwards.”

A network of cameras with four interface modes will ensure security onboard these ships. The captain of the vessel will have 360 degrees of awareness, due to virtual reality, 2D and 3D, Augmented Reality and Precision mode.

When a ship is faced with a narrow route, the Precision mode utilizes the Rolls-Royce LIDAR system to measure distances between the ship and any obstacles. The Augmented Reality mode overlays graphics on a live camera feed provided with Intelligent Awareness sensors. The system recognizes markers and allows the captains to track virtually anything standing in its line of sight.

On the Virtual Reality and 2D and 3D maps, real-time awareness data is fed to the ship's systems. It gives the crew much more visibility and acts like a more sophisticated version of Google Maps. In the Costa Concordia shipwreck of 2012, the onboard radar technology was turned off by the captain who was sure he could use sight alone to navigate. With the new Rolls-Royce and Intel matchup, relying on the automated sailing software will be paramount for the onboard staff.

In time, however, the onboard staff will not be needed — the ships will drive themselves.

Works Cited

Vincent, James. “Rolls-Royce Is Partnering with Intel to Make Self-Driving Ships a Reality.” The Verge, The Verge, 15 Oct. 2018, www.theverge.com/2018/10/15/17979252/self-driving-autonomous-ships-drones-intel-rolls-royce-partnership.

- Details

- Written by: Quintus Potgieter

Innovation is sometimes all talk and no action. What actually gets engineers inventing and creating novel solutions to everyday problems? Handsome rewards, of course. The James Dyson Award is an international design competition that ‘celebrates, encourages and inspires the designers of new problem-solving ideas.'

A curious advent of engineering design has already won a team of engineers the Australian Dyson Award. They are now in the running to win the international James Dyson Award. These engineers managed to reinvent the tape measure, to showcase one defining characteristic: its accessibility to the visually impaired.

They are calling it the Macaron. The tape measure interfaces with a smartphone app that utilizes Bluetooth and audio feedback to assist with the measuring process.

The engineers explained that the tape measures accurately, records and stores your measurements. Inbuilt audio then reads them out.

The four engineers behind the design are Jake Dean, Yuma Decaux, Woo Sung Jung and Weng Hou Chan from the Queensland University of Technology. Team member Yuma Decaux is blind and served as their inspiration to invent the tape measure.

"Yuma would come in to the servo a lot and we'd talk," said Jake Dean.

"He wanted to be able to renovate his house but specialized talking tape measures on the market were expensive, and couldn't find anything that suited what he wanted to do."

In 2012, it was estimated that there were 285 million visually impaired people in the world. New technology, or novel applications of technology, could be used to improve their lives. The engineers believe that the work they are doing under their startup, OSeyeris, will help visually impaired people find employment in industries they otherwise would have never been eligible for.