News

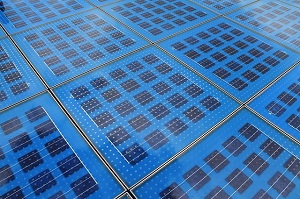

Australia's clean energy storage market is growing at a speed that other countries are struggling to keep up with. The market has always been forward thinking and proactive. Now, South Korean company, LG Chem is using Australia as their platform, to launch their new battery storage solution. LG Chem's energy storage units have already been previewed but are finally ready to launch to consumers.

The company had initially announced that it would make 600 Residental Energy Storage Units (RESU6.4EX) available to "local distributors" in Australia, last year. Now, the company is saying it will have produced 3,000 units in 2016 and will continue to produce more energy storage units in 2017.  This signals that the company is entering the market and is here to stay. They are convinced that the energy storage market will be growing in the upcoming years. The company has been quoted saying that Australia is in a "critical solar decade".

This signals that the company is entering the market and is here to stay. They are convinced that the energy storage market will be growing in the upcoming years. The company has been quoted saying that Australia is in a "critical solar decade".

"We see a quiet solar revolution brewing and we strongly believe that LG Chem will be at the forefront of this transformation to help unlock the true value of solar storage and better enable the ecosystem. We welcome competition too. We are positive that when more people adopt the RESU6.4EX in Australia, the market will appreciate the quality, efficiency and cost competitiveness of our offering," said Changwan Choi, LG Chem's manager of Australian business development.

The battery storage units start at 3.2kWh versions and can be stacked to reach outputs of 9.6kWh and 12kWh in energy storage. The unit weighs only 132lbs (60 kg). The rumor that currently exists is that LG Chem's battery is the most affordable battery on the market, according to the dollar to kilowatt-hour conversion. The battery will reportedly cost close to $8,000.

LG Chem says their new energy storage units are lightweight and conveniently compact. The batteries are also stackable and connectable so that a stronger megawatt output can be achieved. The company claims to have the largest manufacturing facility in the world and are certain that that will drive the prices of their battery storage units down. They will also integrate their battery technology into utility and business operations as well.

Volkswagen has also been rumored to be working with LG Chem in a joint venture that could see their cars being powered by the battery technology. The auto manufacturer could be looking to put batteries into between 2 million and 3 million vehicles by 2025. According to Bloomberg, four Asian companies including Panasonic and LG Chem own 80% of the battery market in Asian-Pacific territories.

"Batery technology is a key competence for electric mobility, which will see its breakthrough toward a mass market in coming years," Volkswagen said in a statement.

Now for the engineers that are interested in installing one of LG Chem's home storage units, there is already an installation video for it:

The global smart energy market will see seven vendors rising up above the rest, to capitalize on the new era of clean energy production with an added layer of digitization as the Industrial Internet of Things. The seven leading vendors were determined by a study done by Technavio, which considered energy companies that provided services in "smart-grid, HEMS, digital oil fields" and leading solar technologies, all in the name of clean and smart energy production. The efficiency of these power companies was also considered. Technavio estimates that these seven vendors will lead the market from 2016 to 2020. Thus, we begin our series titled Global Smart Energy 2016 to 2020 and catch up with these seven energy companies to see the work they are doing in energy sectors and to see what qualifies them as the top vendors for global smart energy.

Sensus

Sensus

Sensus' daily concerns are utilities, cities, industrial complexes and campuses. The company prides itself on taking energy infrastructure into the fourth industrial revolution. Now, for the third year in a row, the company has been named the Best Smart Grid Solution. This is according to multiple municipalities offering their opinions at the Municipal Smart Grid Summit (MSGS).

Sensus offers utilities a solution named the FlexNet Communication Network. The network is a utility management system that includes management software which employs systems of smart meters, encouraging more efficient output for municipalities. Sensus claims the network leads to two-times the amount of power output, compared to cities that don't use smart-alternatives. The company supplies smart water networks called AquaSense. Additionally, there are smart metering applications for gas and electricity as well.

The director of the electric market and smart grid technologies at Sensus, Greg Myers, said: "The Sensus FlexNet communication platform is the foundation that all the applications are built on, that enable gas, water, and electric utilities to achieve operational efficiencies and resource conservation."

Sensus says the smart metering, distribution automation and IoT-connected mechanisms within their FlexNet system ensures that two-way communication between provider and consumer is possible - all in the name of efficiency. Joining multiple industries together in one collaborative network is something that needs to happen so that a city can be considered a smart-city, and Sensus is allegedly the choice for some of the top municipalities.

"The FlexNet system has the proven ability to easily adapt to evolving standards like ANSI C12.19, encryption, smart energy profile, DNP 3.0, and IPv6 which provides comfort that as new standards evolve, FlexNet can evolve with them," Myers added.

The FlexNet system also claims it can perform optimally during hurricanes and tornadoes, making their system attractive to American utilities. Through the analysis of immediately available data, smart cities can ensure premium efficiency for their smart grid solutions. For more clarity on how this is possible, see the video below:

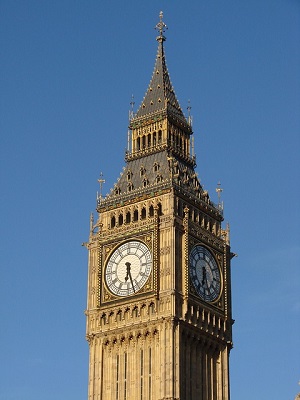

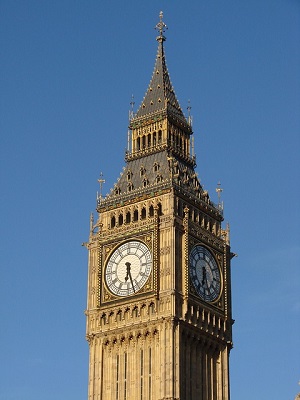

Amidst an Australian election and a British exit from the European Union, engineering has never been more relevant to politics. Engineering industries are the ones that keep a country running, and those industries need to stay afloat in uncertain political environments. We have recently reported on how important STEM-related industries and education is to the future of Australia's GDP. We have also recently focused on how a Brexit has forced engineering industries in the UK to link arms and negotiate the best possible deal in the EU-Exit. What is apparent in the current political climate, is that engineering is one of the more important societal mechanisms.

Malcolm Turnbull has secured a second term as Prime Minister of Australia, along with the Liberal Party of Australia. During his campaign trail, he asserted that STEM subjects would be made compulsory for all students in Australia. The importance of STEM industries for Australia's economy has been made known - multiple times - in the lead up to the election. Price Waterhouse Coopers warned that if STEM industries faltered, Australia could see losses of up to $43 billion in the annual gross domestic product. Australia's engineering industries that have notably influenced policies within politics have been the liquefied natural gas industry and the clean, renewable energies market.

Malcolm Turnbull has secured a second term as Prime Minister of Australia, along with the Liberal Party of Australia. During his campaign trail, he asserted that STEM subjects would be made compulsory for all students in Australia. The importance of STEM industries for Australia's economy has been made known - multiple times - in the lead up to the election. Price Waterhouse Coopers warned that if STEM industries faltered, Australia could see losses of up to $43 billion in the annual gross domestic product. Australia's engineering industries that have notably influenced policies within politics have been the liquefied natural gas industry and the clean, renewable energies market.

The Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, in the latest episode of his YouTube series, The Engineering News Network, spoke of how engineers could play a significant role in their respective communities. He said: "As engineering professionals, you really do need to get involved in politics, local community affairs from a technical, engineering point of view. You do have a major contribution to make, whether it's your local community, your little small village or town, whether it's working on the sewage works or helping with decisions of power."

An example of engineers making decisions that could affect policy was seen in Europe in the last two weeks. In the current market of uncertainty, Siemens decided to halt any new orders whilst the aftermath of the Brexit referendum was measured. This cast a cloud of doubt on the future clean energy policies of David Cameron's government. Siemens eventually reversed their halt on new orders and have gone forward with engineering operations in the country. However, the decisions of engineers could have caused Britain to go through a tumultuous time in regards to keeping their clean energy policies in check.

An example of engineers making decisions that could affect policy was seen in Europe in the last two weeks. In the current market of uncertainty, Siemens decided to halt any new orders whilst the aftermath of the Brexit referendum was measured. This cast a cloud of doubt on the future clean energy policies of David Cameron's government. Siemens eventually reversed their halt on new orders and have gone forward with engineering operations in the country. However, the decisions of engineers could have caused Britain to go through a tumultuous time in regards to keeping their clean energy policies in check.

"You have to get involved because you as engineering professionals have something more than most of these people in these parliaments have and that is that you are considerably more objective in what you do. A lot of the parliaments are riddled with lawyers, accountants and people that perhaps don't have the necessary technical knowledge to make considered technical decisions. Obviously, engineers have got potential problems ; building nuclear power plants, contaminating water and things like that, that we need to avoid. But really, you do have a major contribution," Mackay concluded.

Want to go work in Singapore? According to veteran engineers, Singapore's engineers are flocking to other industries. This has caused a shortage of engineers in key industries that require them, most notably in telecommunications and railway engineering applications. The dean of the engineering faculty at the National University of Singapore, Professor Chua Kee Chaing, has said there is a lack of engineering talent in critical infrastructure industries such as broadband and power networks. There has been a host of train breakdowns due to power issues across Singapore.

The problem, according to Singapore's Prime Minister Lee Hsien Loong, is the tertiary engineering education in the country. At the 50th anniversary celebration of the Institution of Engineers Singapore, the PM warned of the dire situation the country was experiencing.

The problem, according to Singapore's Prime Minister Lee Hsien Loong, is the tertiary engineering education in the country. At the 50th anniversary celebration of the Institution of Engineers Singapore, the PM warned of the dire situation the country was experiencing.

Experts have suggested that other industries are needing the expertise of engineers. Finance and business industries have been luring students in with higher salaries, leaving critical infrastructure industries without engineers. A better pay cheque is a significant factor that could see prospective engineers lending their skill sets elsewhere, taking on other professions.

"Other factors include the lack of effective career planning and job rotation. For instance, not all engineers want to remain engineers, but may want to become senior managers," said the president of the Institution of Engineers Singapore, Edwin Khew. He added that banks could probably pay engineers 30 percent more than critical infrastructure industries.

Professor Chua also mentions that infrastructure industries are not able to produce the same salaries as banking and finance industries.

According to the Straits Times, even when engineering was chosen as a field of study, the students still landed in banking-related jobs. Engineering students in Singapore have confirmed that no matter what their qualifications were, some industries were just hiring to hire, as long as qualifications were held. Veteran engineers are now saying that government needs to pump more money into engineering salaries in critical infrastructure so that there is not a lack of engineers in industries that need them the most.

"A lot of students I talk to say they want to do good in society. Maybe we don't do our outreach well enough. For example, when engineers bring clean water technology to underdeveloped economies, eliminating diseases, the impact is tremendous. Increasingly, we want our students to go out to more disadvantaged communities," Prof Chua concluded.

Source: The Straits Times

Advanced Microgrid Solutions (AMS) is a company that integrates clean renewable energy into buildings through supplying energy storage units. Their solutions ensure that businesses use less utility grid energy. The company operates out of San Francisco, California. They are teaming up with Macquarie Group, an investment banking, and diversified financial services group. Macquarie will be supplying the energy giant $200 million to kick-start new energy storage projects.

Chief Executive of AMS, Susan Kennedy, says the funding will ensure that large infrastructure development in energy storage will take place as a result. The projects will see California getting energy storage technologies. The first projects for the two companies will be building 300 megawatt-hour energy producing facilities. According to Clean Technica,the global annual storage market last year reached 700 megawatt-hours. Therefore, the facilities that will be built as a result of the collaboration are going to be quite sizeable. AMS have been taking business office space into the hybrid future. Using Tesla PowerWalls, the company powers buildings through alternative methods, leading to less grid demand. The energy storage market is expected to grow to a demand of 14 GWh by 2020. Thus, deals like these need to become more frequent if the world is to keep up with stationary storage market demand.

Chief Executive of AMS, Susan Kennedy, says the funding will ensure that large infrastructure development in energy storage will take place as a result. The projects will see California getting energy storage technologies. The first projects for the two companies will be building 300 megawatt-hour energy producing facilities. According to Clean Technica,the global annual storage market last year reached 700 megawatt-hours. Therefore, the facilities that will be built as a result of the collaboration are going to be quite sizeable. AMS have been taking business office space into the hybrid future. Using Tesla PowerWalls, the company powers buildings through alternative methods, leading to less grid demand. The energy storage market is expected to grow to a demand of 14 GWh by 2020. Thus, deals like these need to become more frequent if the world is to keep up with stationary storage market demand.

Rob Kupchak, the head of US Power, Utilities and Renewables for Macquarie Capital said: "AMS's focus on contracted, grid-scale energy storage projects stands out amongst developers forging a path in the energy storage space. The next decade is likely to see huge changes in the mix of energy consumed across the globe, and we see energy storage rapidly emerging as a growth market in the next generation of energy infrastructure."

A month ago, Bloomberg's New Energy Finance New Energy Outlook Report 2016 report was released and indicated that the energy storage market would be valued at $250 billion by 2040. The report indicated that the falling prices of lithium and the falling price of battery technology would mean the market would grow considerably.

"Macquarie Capital is the gold standard for investment in critical infrastructure. Combining our innovative designs and technology with Macquarie's development and financing expertise will enable us to deliver best-in-class storage solutions and build tomorrow's energy grid," said Kelly Warner, President of AMS.

The Hay Group division of Korn Ferry, a recruitment firm dedicated to supplying people and organizations with work advice, has conducted research into how much more engineers make than their peers. The study looked at 42,500 graduate engineers and students in 770 different organizations in the United Kingdom. The study found that those who had graduated with STEM  (science, technology, engineering, and mathematics) degrees earned 20% more than their peers. The study found that engineers and software developers were the highest paid STEM professionals in the UK. The average starting salary for a graduate was $34,208, however for engineering professionals, their salaries saw increases of 17%. Meaning engineering graduates could look forward to about $39,936.

(science, technology, engineering, and mathematics) degrees earned 20% more than their peers. The study found that engineers and software developers were the highest paid STEM professionals in the UK. The average starting salary for a graduate was $34,208, however for engineering professionals, their salaries saw increases of 17%. Meaning engineering graduates could look forward to about $39,936.

The top five countries that promise the best starting salaries after graduating from university are:

| Country of Graduates | Salary |

| Germany | $52,997 |

| United States | $47,711 |

| Australia | $46848 |

| Netherlands | $45,098 |

| United Kingdom | $34,236 |

Theoretically, every country's engineers should make 20% more than their peers. So all of the aforementioned salaries can be increased, however, there are many other factors to consider. The study illustrates this by saying an engineer in the United Kingdom would make more money working in London than they would in the West Midlands.

Where is the demand for STEM graduates in the UK? In the digital sector. Vivienne Dykstra, the global graduate practice leader for Korn Ferry said that the digital sector currently makes up 10% of the United Kingdom's gross domestic product and is sorely in need of STEM-graduates.

"This demand is being reflected in the salaries that newly qualified students can command. With digitally savvy talent at a premium, the graduate recruitment market is a competitive place. Employers need to look at ways to differentiate themselves. Alongside providing opportunities to develop and grow, it's critical businesses offer strong starting salaries to really stand out of the crowd," Dykstra added.

Thus, it depends on what kind of engineering you go into and where you get into it. Some branches of engineering make more money than other branches. And, if you're looking for employment and a big salary, being willing to relocate might also be something to consider.

Source: Korn Ferry

Industrial workers have to operate some heavy machinery and carry some heavy equipment. Now, a new glove that makes it easier to do those things is here. Engineers from General Motors have shown off a new innovation they have been working on for quite some time. A robotic glove turned industrial glove. The glove is a collaborative project between General Motors and NASA. The glove is called the RoboGlove. It was a joint venture between GM and NASA that took nine years to perfect. The gloves were initially designed for the use of the Robonaut 2 that works aboard the International Space Station. The gloves were designed four years ago but are now being re-purposed for industrial operations.

Marty Linn, GM's Principal Engineer of Robotics, said: "This was really inspired by the work that was done on the hands of R-2. The unique thing about R-2 is its hands and its ability to manipulate objects and to do work. We've taken the same sort of technology, the tendon driven actuators and the sensors and translated that from the robot into a glove that a human operator could wear."

Marty Linn, GM's Principal Engineer of Robotics, said: "This was really inspired by the work that was done on the hands of R-2. The unique thing about R-2 is its hands and its ability to manipulate objects and to do work. We've taken the same sort of technology, the tendon driven actuators and the sensors and translated that from the robot into a glove that a human operator could wear."

The gloves will be used by workers with the purpose of reducing the amount of fatigue that occurs in heavy lifting and working with tools. The technology was trademarked under the name 'SEM' which translates to Soft Extra Muscle technology. Another company that wants to utilize the technology is Bioservo Technologies. They intend to use the glove for biomedical and industrial purposes.

In a statement, Tomas War, CEO of Bioservo Technologies, said: "Combining the best of three worlds – space technology from NASA, engineering from GM and 'medtech from Bioservo – in a new industrial glove could lead to industrial scale use of the technology."

"This glove provides additional grip force on the order of ten pounds to be able to help the operator do their job longer and better," Linn added. The engineers say the gloves have a grasp force that makes industrial heavy-lifting much easier. It significantly reduces the force a worker needs to exert in industrial operations.

To see how the RoboGlove could be used in the industrial world, take a look at the video below:

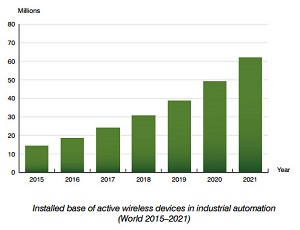

Research group Gartner tell us that 6.4 billion devices are soon to be connected to the Internet of Things this year. That will be 30 percent more than 2015. This would mean that 5 million devices will be connected to the internet every single day. In 2020, the number is expected to grow to 20.8 billion connected things. Some of these devices will be connected to the Industrial Internet of Things. IIoT-connected devices will ensure that industrial automation reaches new heights, redefining industrial operations and leading to new levels of efficiency.

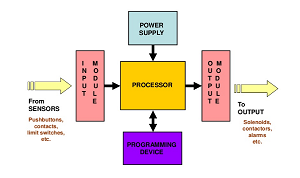

Honeywell has launched a new programmable logic controller (PLC) called the ControlEdge. It is equipped to deal with the IIoT and ensure that industrial devices all work in tandem with unprecedented efficiency. With built-in cybersecurity, the PLC promises to capitalize on the IIoT and take industry into what has been defined as Industrie 4.0.

Honeywell has launched a new programmable logic controller (PLC) called the ControlEdge. It is equipped to deal with the IIoT and ensure that industrial devices all work in tandem with unprecedented efficiency. With built-in cybersecurity, the PLC promises to capitalize on the IIoT and take industry into what has been defined as Industrie 4.0.

Andrew Brodie, Global Controls Leader, in a roundtable discussion on the future of IIoT, said: "IIoT has the potential to be the most significant development in automation systems since the introduction of distributed control systems. It offers a wide range of potential uses and benefits, enabling business to leverage the vast amount of data provided by modern automation and control systems."

He lists the benefits of an IIoT-controlled set up within an industrial operation. He summarizes the huge advantages:

- Providing operations personnel with improved remote monitoring

- Diagnostic and asset management capabilities

- Enhancing data collection - even in the most dispersed enterprises

- Improved decisions about the actual health of assets

- Reducing the time and effort for configuration and commissioning

- Minimizing the need to troubleshoot device issues in the field

- Bringing new production fields online faster and improving collaboration across the company

Honeywell says their new PLC will assist industrial operations with all of the aforementioned necessities. Access to immediate data makes this PLC a productive tool that engineers can work with. The company has sold the Experion PKS automation systems to industrial operators, most notably to an Oil and Gas company named Kuban in Russia. The automation systems will assist with performance and promises to cut costs. The automation system employs the ControlEdge PLC, which reportedly assists with secured connectivity and integration with multiple devices across vendors. It also ensures that industrial operations can continue at an efficient level in an uncertain shift towards IIoT-connected warehouses, factories and industrial complexes.

The embedded security reportedly reduces the risk for the companies who employ the PLC. The PLC boots with something called 'Safeboot'. This scans industrial systems for any unauthorized software before industrial operations continue to ensure that no dangerous software is imposing on the systems. The PLC also has a firewall that ensures security.

Robert Alston, a cyber security technical lead at Honeywell, in a roundtable discussion on IIoT-connected PLCs, said: "Honeywell offers Industrial cybersecurity solutions and managed services that help protect the availability, safety, and reliability of industrial control systems and site operations."

Source: Honeywell

Conflict is a key part of our lives as engineering professionals. Especially these days with so much change occurring. Conflict is a verbal (or indeed non-verbal) expressed disagreement between individuals or groups. It may occur, for example, between an engineering supervisor and employee, or manager and supervisor.

Dear Colleagues

Conflict is a key part of our lives as engineering professionals. Especially these days with so much change occurring. Conflict is a verbal (or indeed non-verbal) expressed disagreement between individuals or groups. It may occur, for example, between an engineering supervisor and employee, or manager and supervisor.

And, as you all know, conflict can even exist within an individual – for example, when one part of you wants to stay at home and rest while another part of you knows you should get up and go to work (a feeling I have, when I know ‘all hell’ is breaking loose at work).

Conflict needs to be dealt with quickly and firmly. It can often be a positive thing (yes) and improve relationships, refine processes and procedures. The absence of all conflict is not necessarily a good thing. In my book, it could be the equivalent of reclining on the Titanic enjoying your daiquiri while a major catastrophe is about to unfold. When people argue and conflict is in the air, it often means that they have a stake in the outcome and deeply care about the overall team and project.

Root it out

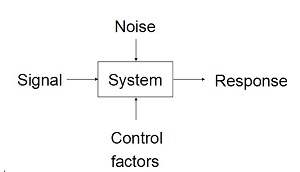

Root cause analysis is a step-by-step technique to identify the cause of the failure or problem and in dealing with it. This is done by bringing together a team of people to investigate the failure or conflict by reviewing the evidence and building up a fault tree based around examining the last failure and tracing backwards each cause that led to the previous cause until the trail can be traced back no further. At this point, changes can be effected to eliminate this happening again.

We always blame someone else

Bear in mind in dealing with conflict an interesting piece of psychological research (from Fritz Heider) which is: We tend to attribute the successes of others and our own failures to external factors (i.e. outside our control). On the other hands, our own successes and failures of others are attributed to internal controllable factors.

Suggestions on dealing with team conflict

- Define the problem carefully

- Avoid targeting a person but focus on the problem

- Gather data and look for objective evidence

- Analyze the data

- Choose the best solution

- Implement the solution quickly and keep refining it

Some additional tools to use for your team to resolve the conflict quickly and effectively

- Attack the problem and not the person

- Focus on what can be done and not on areas where you have no control

- Encourage a team contribution and frank exchanges of opinion

- Express feelings in a way that does not blame but solves the problem

- Accept ownership appropriately for all or part of the problem

- Listen carefully and understand the other person’s point of view before stating your own

- Show respect for the other party

- Solve the problem whilst building the relationship

And if things get very heated; take a break and look for a lateral solution to the conflict or problem.

As Garth Brooks says: The greatest conflicts are not between two people but between one person and himself.

Yours in engineering learning

Steve

Mackay’s Musings – 12th July’16 #608

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

South Australia is getting the push the rest of the world is in desperate need of. 25 primary schools will be the first to get a host of new upgraded science, technology, engineering, and mathematics equipment in November. The hope is that the new equipment will inspire children to continue to pursue STEM careers later on in life. The funding for the project will top AU$250 million and will be coming out of the State Budget. 77 primary schools and 44 high schools will reportedly see upgrades to their STEM labs once the project is complete.

Every primary school gets up to $1 million, whilst every high school gets up to $2.5 million. The move comes at a time where Australian education has been criticised for its recent poor mathematics results. According to Adelaide Now, some schools will be constructing classrooms with the money and others will be using the money to upgrade equipment needed to teach STEM-related content to students. The website says this will include "robotics labs, laser cutters, 3D printers, web cameras, touchscreen TVs" and spaces for civil engineering construction projects. Looks like we've got the next wave of successful engineers coming our way.

Every primary school gets up to $1 million, whilst every high school gets up to $2.5 million. The move comes at a time where Australian education has been criticised for its recent poor mathematics results. According to Adelaide Now, some schools will be constructing classrooms with the money and others will be using the money to upgrade equipment needed to teach STEM-related content to students. The website says this will include "robotics labs, laser cutters, 3D printers, web cameras, touchscreen TVs" and spaces for civil engineering construction projects. Looks like we've got the next wave of successful engineers coming our way.

"These schools are overdue - they deserve this. We need robotic equipment, we need technological equipment, we need electronics and facilities that can ignite children's enthusiasm about STEM (courses)," said Dr. Susan Close, Education Minister.

The move could curb the amount of children who retain an interest in engineering and avoid the engineering spiral of death. The spiral of death is when a student loses interest in engineering before high school and cannot recover the love for engineering, which potentially hurts their future employment prospects. The other worry is that there are not enough teachers in Australia who cater to STEM-related fields.

In addition to the 250 million project, the Australian Academy of Science is in the process of implementing a ten-year plan to implement mathematics after the Australian Mathematical Sciences Insitute reported that only 14 percent of Australia's STEM degrees have maths as a prerequisite for students. PWC Australia also recently published a report that said if STEM was not focused on soon, Australia could lose AU$57.4 billion in gross domestic product in a year.

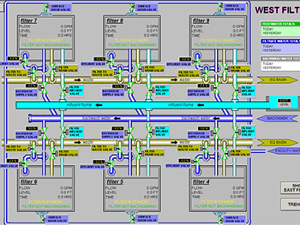

Transparency Market Research has issued a new report on the global supervisory control and data acquisition (SCADA) systems market. They have been tracking the market since 2014 and will continue to do so until 2020. The report is titled 'Supervisory Control and Data Acquisition (SCADA) Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2020'. SCADA systems run all of the major players in industry. They're used in substations, oil and gas, water distribution, telecommunications, manufacturing, the list goes on. They are brutally important to industrial operations.

The report says that the market was valued at $23 billion in 2013. By 2020, the report estimates the market will reach a value of $32.7 billion by 2020. This would mean the market would have a compound annual growth rate of 5% between 2014 and 2020.

The report says that the market was valued at $23 billion in 2013. By 2020, the report estimates the market will reach a value of $32.7 billion by 2020. This would mean the market would have a compound annual growth rate of 5% between 2014 and 2020.

To indicate how important SCADA systems are to the future of industrial control systems, a recent report by BCC Research can be quoted. They say the industrial robotics market will be valued at $31.5 billion by 2021.

What industries are utilizing SCADA systems to their full potentials in the current market? First of all, the electric power generation sector, powering smart grids and turning cities into efficient energy consuming territories. The report says countries that have been incorporating smart-energy with SCADA systems are India and China. Then oil and gas, manufacturing, automotive, pharmaceuticals, telecommunications, food and beverage, water and wastewater, and transportation. The report says substations and energy applications account for 17.7% of the market in 2013. That number will undoubtedly grow due to the amount of energy-producing applications that are being invented in the smart-grid age.

The United States was found to be the top buyer in the market due to having 38.8% of the market share. The market share has been explained by the U.S's craving for automation within factories, and the energy sector growing rapidly. Furthermore, the U.S.'s oil and gas sectors are still very active. All of these industries require SCADA systems.

Asia Pacific areas were the second biggest market for SCADA systems. China's investment into industrial automation will see the SCADA systems market growing as well. Europe was third and the rest of the world followed after that.

Structural engineers work in the field of analyzing structures. They are the hunter-gatherers of finding forces, stresses and deflections that all work towards building a strong structure. They also study the design of structures. They will know which materials work best and how they need to be positioned to ensure that a structure doesn't come tumbling down. This means analyzing the distribution of load in a structure. The functionality of a structure also needs to be considered so that it is not built in a place where it does not serve a function.

There are also design principles in structural engineering. Once again, choosing which materials a structure will be able to stand on is imperative. The engineer needs to think of the most efficient building materials that will ensure a sturdy structure. The structural engineer needs to focus on the safety of the project as well.This is something that wasn't done in South Africa in 2015. On October 14th, a temporary steel structure came crashing down onto a busy M1 freeway in Sandton, Johannesburg. It was said that a strong westerly wind caused a collapse. The collapse killed two people and injured 19.

Now, months later, the results of an investigation into the bridge collapse is being made available to the media. The company in charge of the build was an engineering and design construction company named Murray and Roberts. Professor Roelof Mostert, the head of the department of material science and metallurgical engineering at the University of Pretoria has issued his report of what happened to the structure based on his investigations.

Now, months later, the results of an investigation into the bridge collapse is being made available to the media. The company in charge of the build was an engineering and design construction company named Murray and Roberts. Professor Roelof Mostert, the head of the department of material science and metallurgical engineering at the University of Pretoria has issued his report of what happened to the structure based on his investigations.

"Essentially, the structure appeared to separate at the median supports. That is the center of the highway, where the lattice girders on the eastern side remained stationary for a while but the lattice girders on the western side moved towards the west and separated from those on the eastern side and landed on the road," said Gregory Harington, a structural engineer, speaking to Moneyweb about Prof Mostert's report.

The report further said that the swivel clamps used in the operation were not able to keep both sides of the scaffolding upright. The swivel clamps were supposed to connect scaffold tubes together. But, a collection of older clamps and newer clamps led to the structures collapse. The older clamps had a kind of thread that led to less clamping force. The force of the wind was too much for the clamps to handle, and due to the lack of tightening on-site, the temporary structure collapsed. The professor is saying "poor workmanship" led to the collapse, along with the strength of the wind.

Video Source: Moneyweb

The global smart energy market will see seven vendors rising up above the rest, to capitalize on the new era of clean energy production with an added layer of digitization as the Industrial Internet of Things. The seven leading vendors were determined by a study done by Technavio, which considered energy companies that provided services in "smart-grid, HEMS, digital oil fields" and leading solar technologies, all in the name of clean and smart energy production. The efficiency of these power companies was also considered. Technavio estimates that these seven vendors will lead the market from 2016 to 2020. Thus, we begin our series titled Global Smart Energy 2016 to 2020 and catch up with these seven energy companies to see the work they are doing in energy sectors and to see what qualifies them as the top vendors for global smart energy.

Landis + Gyr

It's easy to see why Landis + Gyr are word leaders in global smart energy production. The company has provided a host of countries smart electricity technologies. Their slogan is, "manage energy better," and it is clear to see they do that through giving the consumer the power. They offer a host of smart metering technologies to ensure that the consumer knows and understands how much electricity is being used, and how much can be saved.

They have a global portfolio that encourages increased efficiency in energy management. In the Netherlands, they have installed smart street lighting to ensure lights are only being used when brutally necessary. They have installed smart-grid technologies including large-scale battery and PV technologies in Japan and the United States. In Estonia, they have installed 630,000 residential metering points to ensure consumers get the right amount of electricity based on how much they have paid.

They have a global portfolio that encourages increased efficiency in energy management. In the Netherlands, they have installed smart street lighting to ensure lights are only being used when brutally necessary. They have installed smart-grid technologies including large-scale battery and PV technologies in Japan and the United States. In Estonia, they have installed 630,000 residential metering points to ensure consumers get the right amount of electricity based on how much they have paid.

In Slovenia, the company employs what they call a "virtual power plant" that supplies 60MW to the cyber-grid. The transmission system operator installs the virtual cyber-grid which assists with regulating and balancing power that gets sent to industrial and consumer-based demands.

In France, a $77.8 million project has ensured that Landis + Gyr's smart meters make their way into French customers' houses. The meters are built in an automated factory based on engineers' designs. The money for the project was provided by the European Regional Development Fund, that is ensuring the smart metering technology makes it further into France.

“Landis+Gyr is proud to have been selected by ERDF as one of the main suppliers for this ambitious programme to bring smart meter technology across France”, said Andreas Umbach, Landis+Gyr’s President and CEO.“We look forward to helping them realize the goal of empowering their customers to better manage their energy consumption.”

The deal sets the record for the world's largest smart metering rollout.

The company also assists cities in becoming smarter. In Yokohama City, Japan, Landis + Gyr is in charge of making the city smarter, energy wise. They have installed home energy management systems, central management systems for smart grids, electric vehicle charging stations and SCADA systems that keeps an eye on the energy production of the city. The company also supplies advanced metering options to Denmark, Rome, Spanish customers. They also specialize in smart gas technologies in Britain.

Source: Landis + Gyr

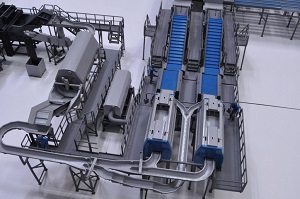

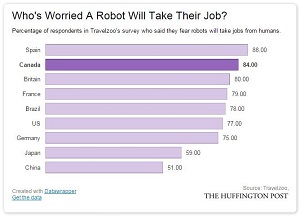

The Twinkie is America's snack. Or, at least it used to be. If anything, it is a wonderfully engineered bit of a pastry for people who desire a cake with a bit of stuffing - or is that icing? Regardless, the company who make Twinkies, Hostess, almost went bankrupt twice. Just imagine if you were an American living in a world without Twinkies. In 2013, as Hostess admitted to bankruptcy due to employee and union "arrangements", the company was bought by another company named Apollo. Now, the company is going public and is valued at $2.3 billion. How did they turn it around? The answer is: Automation.

The company now at the helm of the Twinkies brand has let go of most of their employees. Five years  ago the company had 8,000 employees, now they have 1,170. The money that would've gone to those other 6,830 people was spent on revamping their industrial machinery and industrial ovens. $130 million was pumped into automation, making the company re-fire ovens that used to be used by 22,000 workers (in 40 bakeries) when the company was in its heyday.

ago the company had 8,000 employees, now they have 1,170. The money that would've gone to those other 6,830 people was spent on revamping their industrial machinery and industrial ovens. $130 million was pumped into automation, making the company re-fire ovens that used to be used by 22,000 workers (in 40 bakeries) when the company was in its heyday.

A robotic takeover of food industries is not a foreign idea and is happening every day. Hostess was crippled by employing humans. According to Forbes, the company had 372 bargaining contracts for workers, 5,500 delivery routes and "a vast production system" all headed up by humans. Now, with letting go of 94% of their employees and employing automated industrial food technology, they have saved the company.

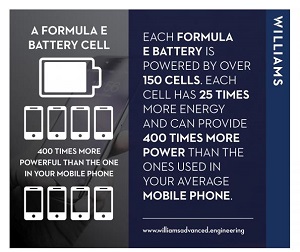

The new factories that Twinkies are made in use a $20 million piece of automation tech called the Auto-Bake system. The industrial ovens use state-of-the-art PLC (programmable logic controller) systems to fully automate the production line. Robotic arms are also used to package the Twinkies into boxes and ensure that 1 million Twinkies make it out of the factory per day. That's 400 million a year. That was a year ago, the CEOs want to now employ a second Auto-Bake system and double the output. This would ensure that they produce more Twinkies than ever before in history.

Back in May, former CEO of McDonalds Ed Rensi said: "I was at the National Restaurant Show yesterday and if you look at the robotic devices that are coming into the restaurant industry -- it's cheaper to buy a $35,000 robotic arm than it is to hire an employee who's inefficient making $15 an hour bagging French fries -- it's nonsense and it's very destructive and it's inflationary and it's going to cause a job loss across [the United States] like you're not going to believe."

The harsh criticism of the food industry by Rensi can explain why it is is more lucrative for Hostess to employ robotic employees instead of union-affiliated employees that sent the company into a death-spiral years before.

To see how the Auto-Bake system works, take a look at the video below:

The global smart energy market will see seven vendors rising up above the rest, to capitalize on the new era of clean energy production with an added layer of digitization as the Industrial Internet of Things. The seven leading vendors were determined by a study done by Technavio, which considered energy companies that provided services in "smart-grid, HEMS, digital oil fields" and leading solar technologies, all in the name of clean and smart energy production. The efficiency of these power companies was also considered. Technavio estimates that these seven vendors will lead the market from 2016 to 2020. Thus, we begin our series titled Global Smart Energy 2016 to 2020 and catch up with these seven energy companies to see the work they are doing in energy sectors and to see what qualifies them as the top vendors for global smart energy.

ABB

The hottest town in Australia is said to be Marble Bar. It is in the Pilbara region in north-western Australia. The town set a record when the temperature reached 100oF and stayed there for 160 consecutive days. So, needless to say, the town get's a lot of sun. It seems to be the perfect spot for solar panels.

ABB supply microgrid solutions - named ABB Microgrid Plus technology- that combine the power of diesel generators and the power of solar panels. It ensures that mining operations and endeavours of the like are mostly powered by renewable energy. The ABB engineers say that the town can now be powered by renewable energy 60% of the time, with their microgrid applications. The solar array supplies 320 kilowatts to the town, whilst the diesel generators supply 320 kilowatts.

"Traditionally, we would have had a diesel power station here, supplying the grid. In a microgrid you've got multiple sources of energy, in this case here, you've got solar power plus the diesel. The goal here is for our microgrid control system to minimize the diesel and maximise the solar," said Heath Lang, a senior engineer from ABB.

"Traditionally, we would have had a diesel power station here, supplying the grid. In a microgrid you've got multiple sources of energy, in this case here, you've got solar power plus the diesel. The goal here is for our microgrid control system to minimize the diesel and maximise the solar," said Heath Lang, a senior engineer from ABB.

ABB say that they have 80 similar installations operating all over the world. In the case of Marble Bar, the town saves 40% of the diesel fuel it would have used (240,000 litres of diesel fuel) if they didn't have the solar panels. This microgrid solution ensures that 1,100 tonnes of greenhouse gases are avoided.

ABB's Microgrid Solutions are bringing clean, renewable power to remote, hard-to-reach places in the world. They estimate there are 1.3 billion people living in remote parts of the world, and those are the ones they want to reach.

"ABB's unique microgrid solutions enable very high levels of wind and solar power penetration in isolated diesel-powered grids. This solution calculates the most economical power configuration, ensuring a proper balance of supply and demand that maximizes renewable energy integration, providing for up to 100% renewable penetration and the highest level of stability and reliability," ABB said in a statement.

Their solution can be used for microgrid communities (much like Marble Bar), integrated solutions for businesses or microgrids for industry applications like mining operations etcetera.

Source: ABB

A recent report by Research and Markets indicated that wind and solar generated 77 percent of the global renewable energy in 2015. The American Wind Energy Association says that wind energy currently powers up to 20 million homes in the United States. Wind farms are gaining popularity all over the world, equipped with row upon row of wind turbines. Even companies like Walmart now have stakes in wind farms that generate some of the electricity they power their buildings with. Ikea has also invested into clean renewable technologies to power their stores.

So, the demand for wind turbine technology is high. Siemens is one of the top 10 manufacturers and have just announced a new offshore wind turbine. The new turbine is named the SWT-8.0-154 and uses Siemens' direct drive wind turbine technology. The technology is used in both onshore and offshore applications. When the direct drive technology was announced in 2011, the engineers said that they had revolutionized the entire wind market.

So, the demand for wind turbine technology is high. Siemens is one of the top 10 manufacturers and have just announced a new offshore wind turbine. The new turbine is named the SWT-8.0-154 and uses Siemens' direct drive wind turbine technology. The technology is used in both onshore and offshore applications. When the direct drive technology was announced in 2011, the engineers said that they had revolutionized the entire wind market.

Siemens says installations of the new turbine will kick off in early 2017. The turbine will produce 10% more energy annual energy production due to being an 8MW model. This is a step up from their 7MW model. Siemens currently operate 1,240 direct-drive onshore turbines and 150 offshore turbines.

Michael Hannibal, CEO for Offshore at Siemens' Wind Power and Renewables Division said: "We are relentlessly working on the levelized cost of energy, and the offshore direct drive platform enables us to do this with the lowest possible risk. With the same proven reliability as our successful 6 and 7MW models, the SWT-8.0-154 will be the new benchmark for gearless offshore wind technology on the market."

Siemens' direct drive technology is respected as one of the more innovative wind turbine technologies available today. However, what about a wind turbine with twelve blades?

The twelve-bladed behemoth has been proposed by a company named Vestas. The company needs to prove to investors that twelve blades are better than three and can equate to more efficiency. The company has had the proposal on ice whilst they figured out how a twelve-bladed turbine would actually work. The worry is that if one set of blades stops working or an internal error occurs, then the entire thing will stop functioning.

Perhaps the answer isn't more blades, but, maybe longer blades. A wind energy firm named Adwen and LM Wind Power have created the world's longest wind turbine blade. The blade is 88.4 meters long and will fit on Adwen's own AD 8-180, 8MW, wind turbine.

Perhaps the answer isn't more blades, but, maybe longer blades. A wind energy firm named Adwen and LM Wind Power have created the world's longest wind turbine blade. The blade is 88.4 meters long and will fit on Adwen's own AD 8-180, 8MW, wind turbine.

Roel Schuring, the CTO of LM Wind Power said: "The rotor is the motor and to put it simply, longer blades extract more energy from the wind. Increasing the annual energy production from each offshore wind turbine is a key driver to reduce the levelized cost of offshore wind energy which is decisive for a large-scale deployment. The blade is the single most influential component for increasing energy yields and its design and aerodynamic features can make a huge difference for the turbine's power production."

Source: Clean Technica

The Economics and Statistics Administration within the United States' Department of Commerce have sent out their report titled Women in STEM: A Gender Gap to Innovation. The report alludes to what multiple reports in the first six months of 2016 have alluded to -- there are not enough women in science, technology, engineering and mathematics workforces. The Economics and Statistics Administration have crunched the numbers and have provided a clear picture of how big the STEM gender gap is.

According to the report:

- Although women fill close to half of all jobs in the U.S. economy, they hold less than 25 percent of STEM jobs. This has been the case throughout the past decade, even as collegeeducated women have increased their share of the overall workforce. Women with STEM jobs earned 33 percent more than comparable women in non-STEM jobs – considerably higher than the STEM premium for men. As a result, the gender wage gap is smaller in STEM jobs than in non-STEM jobs. Women hold a disproportionately low share of STEM undergraduate degrees, particularly in engineering. Women with a STEM degree are less likely than their male counterparts to work in a STEM occupation; they are more likely to work in education or healthcare.

- Women hold a disproportionately low share of STEM undergraduate degrees, particularly in engineering.

Source: http://www.esa.doc.gov/

The results are even worse in India. Kelly Services, a global workforce staffing industry who specialize in engineers and accountants, have released a report titled Women in STEM. The report indicated that 81 percent of women who have STEM jobs in India quit their jobs 10 to 15 years into their careers.

The results are even worse in India. Kelly Services, a global workforce staffing industry who specialize in engineers and accountants, have released a report titled Women in STEM. The report indicated that 81 percent of women who have STEM jobs in India quit their jobs 10 to 15 years into their careers.

The report reinforces the sentiments of a recent report by Engineers Australia that showed that the women who do make it into engineering workforces usually leave within 10 years. The report also shockingly stated that one percent of Australian women past the age of 50 years old are currently working in the engineering industries.

"To begin closing the talent gap, we must create an inclusive environment that facilitates greater engagement and retention of females in STEM. We must make it a priority to eliminate bias and barriers, to deliver top-down support and institutional accountability," Kelly Services said.

One of the reasons the Deccan Chronicle gives to make sense of the grim statistics in India, is that women in India find it difficult to balance both taking care of family and managing employment at the same time. The website defines this as the 'double burden syndrome'. Other reasons for drop-out numbers around the world are directly related to gender bias and gender discrimination within engineering industries.

What is the way forward for getting more women into STEM careers? Kelly Services writes that mentorship and increasing diversity levels. The raising of diversity scores in tertiary institutions was recently celebrated after Dartmouth College produced more female graduates than men graduates. In 2016, in Dartmouth engineering courses, female attendance made up 54 percent of the class.

Making a diverse workforce in engineering still has a long way to go in the global context, however, any progress is progress.

The Association for Advancing Automation has released a white paper that deals with how robotics is fueling the next wave of productivity and job growth in the United States. Some industries are experiencing the robot revolution first hand, where industrial robots are starting to take jobs away from humans. Automation in industrial sectors is constantly improving the efficiency of several manufacturing industries The white paper calls the recent development in robotics an "integral part of manufacturing's redemption".

The National Association of Manufacturers says that in the United States, the manufacturing industry employs 12 million Americans, representing 9% of the country's workforce. What the Association found was that in 2001, when industrial operations started seeing more robotics involved, employment rose. Similarly, in the years 2010 to 2014, the amount of robotics the U.S. bought skyrocketed, however, employment numbers actually rose. The concern being that more robots being sold would equate to more retrenchment, but the opposite has been true for the United States.

The Association for Advancing Automation said: "There are three important trends that must be examined to clarify how robotics is shaping the U.S. manufacturing industry: the reversal of offshoring, the use of automation for repetitive and dangerous tasks, and the domestic shift to a service economy. The industry also has an opportunity to impact future growth through new education initiatives."

Using automation in manufacturing operations has ensured that some companies stay afloat due to the efficiency of the robots. The white paper quotes a Drew Greenblatt, a CEO and owner of Marlin Steel. He says that automation has had a positive impact on his company. He has apparently doubled his workforce and employed engineers in his company since going automated. Allowing automation to take care of the repetitive task and letting humans work on higher quality work has saved his company from bankruptcy.

Using automation in manufacturing operations has ensured that some companies stay afloat due to the efficiency of the robots. The white paper quotes a Drew Greenblatt, a CEO and owner of Marlin Steel. He says that automation has had a positive impact on his company. He has apparently doubled his workforce and employed engineers in his company since going automated. Allowing automation to take care of the repetitive task and letting humans work on higher quality work has saved his company from bankruptcy.

Even Deloitte got in on the action of measuring how technology is apparently stealing our jobs and found similar results ; automation has created more jobs than it has destroyed. The researchers studied every level of automation that stretched as far back as 1871.

"The dominant trend is of contracting employment in agriculture and manufacturing being more than offset by rapid growth in the caring, creative, technology and business service sectors. Machines will take on more repetitive and laborious tasks, but seem no closer to eliminating the need for human labour than at any time in the last 150 years," the researchers said.

The Association for Advancing Automation concluded the current problem with education as a result of automation. They wrote: "The majority of the careers that the skilled labor force has been seeking in recent years are service-related, which suggests a harsh reality: Manufacturing is no longer one of the nation's most coveted career paths for those entering the workforce."

And that is their warning to students. Their warning is that if people want to work in the service-related fields they will find that automation and robotics are slowly taking over those industries and are not beneficial to try and get into anymore. Rather a STEM-focused career path that teaches you skills that an automated process won't be able to replace.

Source: Robotics Tomorrow

The safety helmet seems to be the worldwide symbol for engineers. If you go to Google Images and type the word 'engineers', almost every single image that comes back is of people with hard hats on. To an average joe, engineers wear hard hats in their occupations. However, a new report indicates that engineers are tired of the hard hat as the worldwide symbol for engineering. Engineers want the symbol to be changed in educational works that emphasize the stereotype that all engineers wear hard hats.

The report is known as the Sainsbury Management Fellows' 2016 Hard Hat Index that measures the number of times a hard hat appears in editorials or advertisements. In 2014, the Hard Hat Index saw a 20% increase in the number of hard hats in "key engineering publications". In 2014, hard hats were featured in 229 advertisements and 143 editorials.

The report is known as the Sainsbury Management Fellows' 2016 Hard Hat Index that measures the number of times a hard hat appears in editorials or advertisements. In 2014, the Hard Hat Index saw a 20% increase in the number of hard hats in "key engineering publications". In 2014, hard hats were featured in 229 advertisements and 143 editorials.

SMF say they invented the Index to show how pervasive the use of hard hats has become in "influential media". They believe that the image "limits the profile of engineers". So, has the Index worked and minimized the amount of stereotypical hard hats in mainstream media? The answer is: No. This year alone, hard hats have appeared 257 times in engineering media. The number is the highest it has been since the SMF Index was launched in 2013. The current Index shows that images of hard hats have risen 39% since 2013.

The President of SMF, David Falzani said: "The Hard Hat Index points out how the engineering community is choosing to represent itself in terms of image and emotional value. Generations Y and X are far more image and brand conscious than before. Image and emotional value are vital in our ability to attract, inspire, recruit and retain bright young people. This is a serious national challenge which we must all embrace."

SMF actually conducted a workshop with engineering graduates to discuss the use of the hard hat as a symbolic image for engineering. In the group of respondents, there were seventy students from the Royal Academy of Engineering. They showed the students 30 different advertisements that featured hard hats in them. Only 20 percent of the ads received positive feedback. Meaning, engineers feel underrepresented by advertising of engineers.

The question that remains is how to visually show what an engineer looks like. The multiple industries engineering caters to makes it impossible to secure one image.

"The Hard Hat Index is therefore designed to highlight how our industry is representing itself. It is disappointing to see that despite the question of the engineering brand being debated in the engineering media over the last 18 months, the hard hat representation in editorial is on the increase. This begs the question whether our industry is open to reinvention in order to persuade the public that engineering is an exciting, dynamic and rewarding profession," Falzani said.

Industrial control system cybersecurity continues to be an elusive concept to companies who have not made advancements in securing company assets that are connected to the internet. The guys at Automation World have you covered, though. They have compiled a very simple 3 principle approach to protecting your industrial operations that will or do function with the Industrial Internet of Things.

One of the issues for industrial operations is that attacks can be performed on the Supervisory Control and Data Acquisition (SCADA) systems. A study by Booz Allen Hamilton showed that the US Department of Homeland Security dealt with 295 industrial incidents in 2015. Energy utility companies  were the most heavily attacked. Other companies included manufacturing facilities in the car, electrical and metal industries. The utilities said the attacks were by ransomware criminals that tried to access their enterprise networks. The director of Industrial Security at Booz Allen says enterprise networks are the first to get hacked. Once enterprise networks have been accessed, the actual operational technology of an industrial operation is targeted. Once the operational technology is targeted, things like SCADA systems and other industrial control systems are at the mercy of hackers. The report indicated that more hacking incidents happened in 2015 than any other year, however, 2016 could eclipse that statistic.

were the most heavily attacked. Other companies included manufacturing facilities in the car, electrical and metal industries. The utilities said the attacks were by ransomware criminals that tried to access their enterprise networks. The director of Industrial Security at Booz Allen says enterprise networks are the first to get hacked. Once enterprise networks have been accessed, the actual operational technology of an industrial operation is targeted. Once the operational technology is targeted, things like SCADA systems and other industrial control systems are at the mercy of hackers. The report indicated that more hacking incidents happened in 2015 than any other year, however, 2016 could eclipse that statistic.

Automation World's 3 point policy for securing industrial systems with cybersecurity is as follows:

- A top-down security approach with centrally-defined plant-wide policies that are automated to ensure consistent shieldign of all field assets.

- A focus on security essentials, i.e. securing what matters and doing the basic things right, repeatedly, to shield industrial assets from risk.

- Prioritize protection of field assets, which are key for production safety and integrity.

Eli Mahal, who wrote the three point cybersecurity policy, works for a cybersecurity company named Next Nine. He says: "Both the NIST framework and NERC-CIP v5 say that asset identification is foundational for knowing what must be protected. A comprehensive and up-to-date asset inventory is vital to developing and maintaining an appropriate defense of an industrial network and infrastructure. The owner/operator needs clear visibility into what devices are on the network; what they communicate with and how; the characteristics of the devices; and the presence of any known vulnerabilities.

Some companies believe that employing air-gapped industrial equipment is the answer. This would include using equipment that has never been exposed to the internet or a previous network. This is not a viable option due to the Industrial Internet of Things surging forward and bringing in a new era of efficiency for industrial operations.

However, those companies shouldn't have to worry because now there is a gap in the market for private cybersecurity firms. Post-Quantum, a cybersecurity firm in the United Kingdom just secured $10.4 million of investment. The company specializes in cybersecurity for "enterprises and organizations", which include: banks, government, and healthcare. Another company this week named Darktrace secured funding of $65 million, and another company named SecurityScoreCard received $20 million. The cyber-protection of industries has never been more lucrative for engineers than it has been today.

"Organizations should address the security essentials and focus on doing the basic things right, such as applying qualified operating system patches and anti-virus signatures, collecting and analyzing devices logs, and scanning IP address ranges to look for unexpected changes," Mahal concluded.

Australia's construction market is doing quite well. In the Performance of Construction Index, Australia rose by 6.5 points in June, giving them an average score of 53.2. Their score in May was 46.7. A healthy score is above 50.0 which separates the line of expansion versus contraction. Therefore, Australia's construction is looking healthy. Recent reports indicate that the Australian construction industry has taken a dip since March 2013. Sourceable confirmed that construction activity had dropped by 25 percent since 2013 when it was at its peak. Nonetheless, the latest construction numbers are quite surprising.

The numbers were crunched by the Ai Group, as usual, delivering the news that Australia's construction industry was at the highest level in ten months. The report showed that all construction subsectors (house building, commercial buildings, and engineering construction) have improved in June. Expert analysts say they haven't seen this impressive of a turnaround in many years. They say the improvement could be signaling further improvements in the months in the remainder in the year.

The numbers were crunched by the Ai Group, as usual, delivering the news that Australia's construction industry was at the highest level in ten months. The report showed that all construction subsectors (house building, commercial buildings, and engineering construction) have improved in June. Expert analysts say they haven't seen this impressive of a turnaround in many years. They say the improvement could be signaling further improvements in the months in the remainder in the year.

The AiG manufacturing index reported more worrying numbers, however. Manufacturing in Australia fell to 51 from 53.4 in April, during May. However, being above the 50 mark means manufacturing is still expanding in the country, which is a good sign. Australia has not dipped below the 50 mark since September 2006.

"The residential sub-sectors of house and apartment building were the standout performers," said Peter Burn, the head of public policy at Ai Group. However, the commercial engineering construction has been seeing drops in new orders. House and residential is carrying all of the weight for the construction industry in Australia.

A country that couldn't brag as much, was Germany. Their Purchasing Managers' Index fell from 52.7 in May to 50.4 in June. Despite the drop, Germany has been faring well. Oliver Kolodseike, an economist at Markit said: "The recovery in Germany’s construction sector appears to be losing its legs at the end of the second quarter, with latest survey results pointing to a marked slowdown in growth of German building activity. The PMI is now close to a level that is normally consistent with a stagnation of construction output, dragged down by declines in both commercial building and civil engineering activity. Although housing shortages and the inflow of refugees should help maintain growth of residential building activity in the near-term, companies were the least optimistic about their future since the end of last year."

Source: The Construction Index

The global smart energy market will see seven vendors rising up above the rest, to capitalize on the new era of clean energy production with an added layer of digitization as the Industrial Internet of Things. The seven leading vendors were determined by a study done by Technavio, which considered energy companies that provided services in "smart-grid, HEMS, digital oil fields" and leading solar technologies, all in the name of clean and smart energy production. The efficiency of these power companies was also considered. Technavio estimates that these seven vendors will lead the market from 2016 to 2020. Thus, we begin our series titled Global Smart Energy 2016 to 2020 and catch up with these seven energy companies to see the work they are doing in energy sectors and to see what qualifies them as the top vendors for global smart energy.

Itron

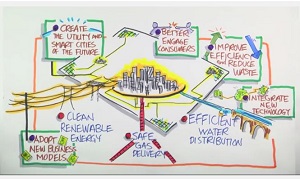

Itron is a company that will play a big part in Internet of Things connected smart grids in the near future. The company provides end-to-end smart grid and smart distribution solutions for electric, natural gas and water applications. The company says that in the current global energy market, more needs to be done than just securing a smart-grid. They believe that with the oncoming interconnectedness from the Internet of Things will ensure that a new smart distribution system can be created.

They are coining a new term pertaining to global smart energy. They're calling it the 'Active Grid'. This grid layout will combine the smart grid and smart distribution solutions in one well-oiled machine. The company explains that clean renewable energy, safe gas delivery, and efficient water distribution working in tandem with each other and with the digital connection of the Internet of Things will help the company provide efficiency and reduce waste. The company says through combining these solutions, the smart-cities and the smart utilities of the future can be born.

"Smart grids are no longer enough. While they collect and move more data than ever, in today's fast-paced world, more data doesn't mean better outcomes. We need a grid and distribution networks that are more than smart. With the right technology and analysis, applied in the right places, we can create something beyond the smart-grid. We can create the Active Grid," Itron said in a promotional video.

"Smart grids are no longer enough. While they collect and move more data than ever, in today's fast-paced world, more data doesn't mean better outcomes. We need a grid and distribution networks that are more than smart. With the right technology and analysis, applied in the right places, we can create something beyond the smart-grid. We can create the Active Grid," Itron said in a promotional video.

Itron outlines a simple three-point plan for their proposal of the Active Grid:

- A network fueled by an open, standards-based and the interactive network that uses intelligent technology. This would relate to Industrial Internet of Things connected technologies.

- Automation with devices, sensors, routers, and applications will make real-time analysis and the making of decisions far easier. No unnecessary data will apply.

- Machine to machine learning and problem-solving that makes sense. However, the active grid will have human intervention where necessary.

The company says an active grid connected to the Internet of Things and connecting distribution systems to an eco-system of interconnectivity will mean that problems and outages will be detected 50 percent faster. Smart metering, smart cities, connected by a smart distribution system is Itron's aim for a future with cleaner energy, cleaner water and an efficiently run country.

Source: Itron

A wearable. A word that has a very simple definition. It is an item/s that can be worn. When we think about wearables, we think about the current applications available in the media; smart-watches, head-mounted VR gear etc. However, wearable technology has become valuable to engineering industries. Wearables for industrial operations, coupled with modern day automation with the Internet of Things , will ensure that everyone attached to a project or a factory - or even a mine - will all be on the same page with data that is freely and immediately available.

A 3D real-time industrial operations dashboard is available from a company named Vandrico Inc. The company currently shows off how it interconnects miners and engineers, but can also be used for other industrial endeavors. It connects all the engineers and workers attached to an industrial operation across platforms. Smart watches, smartphones, tablets, and laptops. The company calls it Real-Time Operational Intelligence. As an example, Vandrico shows off their smartwatch technology, which accounts for on-site safety. Once a fire alarm goes off at an industrial operation, the smart watch can ask questions like: "Are you safe?", "Is everyone near you safe?" This way a fire or industrial problem can be quickly contained and lives can be saved. This assists with site security and safety, something that engineers need to focus on as they begin a project and whilst the project is ongoing. Their safety-smart-watches were announced last year, with the help of a company named Illumiti. They call the watch the MineSafe smartwatch, which also assists with the response-time of life-threatening situations in mines. It could ensure that safety in mines is paramount, especially in a mine collapse.

According to the companies the full list of uses the smartwatch has are:

- Safety alerts: Notifications of safety issues and events

- Incident Reporting: Let workers document issues quickly

- Safety monitoring: Automate lone worker checks & procedures

- Safety checklists: Verify proper procedures are followed

The company says their wearable technology would be able to save mines millions and could even save lives.

IoT-connected dashboards for industrial operations could be the most useful way of keeping a close eye on the efficiency of a workforce, and can give engineers a good idea of how far a project is.

Vandrico says their platform can be used for many different applications:

- Virtual barricades: Alert miners that they are near an unsafe area and prevent them from going there

- Lone worker: Individual miner and engineer tracking for safety check-ins and immediate ramifications for missed check-ins

- Real-Time Safety Reminder & Safety Forensic Logs

- Real-Time Incident Reporting: Any injuries can be reported immediately. Any mine maintenance issues can be reported instantly

- Mementos: The miners can deliver voice notes or text messages to other workers that would improve efficiency.

- Automated coordination of work orders: A checklist of what needs to happen during the day. A virtual "to-do" list.

Source: Vandrico

Online education has grown in leaps and bounds in the last decade. However, the legitimacy of gaining an online tertiary degree has been questioned by several employers all around the world. The issue being that the trusted universities sometimes don't offer their most important courses online. What we're left with are online speciality courses that don't hold much water in the world of employment, but are encouraging to an employer, granted you have a degree from a respected university that you physically attended. However, the legitimacy of online degrees is finally beginning to become visible to high-ranking universities.

Experts agree that online education's feasibility in securing employment will be happening in the next five years. According to a report by the BBC, due to the successes of initiatives like Coursera, full degrees could make their way to the internet. Coursera offers short courses from the world's top universities, namely, MIT and Stanford. However, Daphne Koller, chief executive of Coursera says that undergraduate degrees could be happening within five years time. The platform currently has 20 million students registered and the list of universities that contribute now sits at 145 universities.