News

If you haven't seen the new Michael Moore documentary 'Where Do We Invade Next?' then make sure you give it a watch this weekend. The documentary centers around what policies countries around the world enjoy that America may benefit from. One of the countries focused on in the documentary is Norway. Moore shows that Norway does not endlessly punish its criminals and rather tries to legitimately reintroduce them into society, the maximum prison sentence in the country is 21 years. What was apparent through the documentary is that Norway is led by a progressive thinking government that gives its citizens the best they can offer.

Now, Norway may change the way they power cars as well. News company CNBC spied a headline from a Norwegian newspaper named: Dagens Næringsliv. The headline translates to: "Stop sales of diesel and gasoline vehicles in 2025. It is understood that four political parties are joining hands to support the prohibition of cars powered by diesel and gasoline. If the sales of gasoline and diesel powered vehicles are banned it would be a world first and a shocking move from Norway considering that the country is one of the largest exporters of oil.

Now, Norway may change the way they power cars as well. News company CNBC spied a headline from a Norwegian newspaper named: Dagens Næringsliv. The headline translates to: "Stop sales of diesel and gasoline vehicles in 2025. It is understood that four political parties are joining hands to support the prohibition of cars powered by diesel and gasoline. If the sales of gasoline and diesel powered vehicles are banned it would be a world first and a shocking move from Norway considering that the country is one of the largest exporters of oil.

Elon Musk, CEO of Tesla and SpaceX, tweeted as if the law is a done deal: "Just heard that Norway will ban new sales of fuel cars in 2025. What an amazingly awesome country. You guys rock!!"

According to Electrek, Norway also holds the "highest percentage of electric vehicle market share of any country" meaning that banning the gas-powered vehicles will not be difficult for the country, however, they might want to cause a domino effect where other governments follow suit. CNBC confirms that Norway has the smallest driving population in Europe, with only 150,000 cars being sold in 2015.

The official draft document is named the 2018-2029 National Transport Plan and will make a case for completely eliminating emissions by vehicles by 2025.

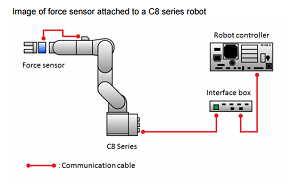

The Japanese electronics company, Seiko Epson, have announced that they have technology in their possession that would enable robots to be incredibly precise. Tasks that their robots can perform range from putting a key into a keyhole to knowing how much force is necessary to open that door. The technology could grow to the point where robots thread a needle. The company revealed a piezo force sensor that utilizes technology that they have used in their inkjet printing technology before.

The sensor that they have built accurately calculates what is needed to do a task and then performs that task at the amount of precision it would require.

"It changes the way robots can be used. We think the market potential for the force sensor is enormous. To perform complex tasks like this with robots, it has needed really complex software, which has made it impossible for many people. This makes the software a lot simpler, which makes it easier to actually introduce the robots," said the President and Chief Executive of Epson, Minoru Usui.

"It changes the way robots can be used. We think the market potential for the force sensor is enormous. To perform complex tasks like this with robots, it has needed really complex software, which has made it impossible for many people. This makes the software a lot simpler, which makes it easier to actually introduce the robots," said the President and Chief Executive of Epson, Minoru Usui.

Epson is confident that the robots could be used in the biomedical, agricultural and manufacturing industries. They use their sensor technology, which includes "placing a capacitor or resistor in an integrated circuit" that will enable the robot to notice what needs softer care. The sensor costs $7,200 and will work on any Epson robot. They have named the sensor the S250 series and is an efficient addition to assembly robots.

"The new force sensors are a significant development for Epson and for the manufacturing industry in general. As a company dedicated to manufacturing innovation, the new sensors help to expand the applications for robots, and bring us a step further towards achieving our goal of creating the world in which robots support people in a wide variety of situations," said Yoneharu Fukushima, the COO of Epson's Robotics Solutions Operations Division.

Industrial robots are taking over factories, especially in China. Last week Foxconn (in Vietnam) replaced 60,000 of their human workers with robots on their assembly line. Now, with Epson's technology, even more, assembly line factories could look into robotic replacements due to the precision chips that Epson are now selling.

Source: Yahoo Tech

Paris is under water and the situation seems to be worsening. Today the French government has confirmed the closing of the Louvre in Paris. The staff will move selected works to higher ground in the gallery to ensure that the water causes no damage. The floods were caused by extended rainfall in the area and the weather service has warned that the rain won't slow down over the weekend. 25,000 people will be left without power. Germany has also been hit hard after constant rainfall had caused up to 5 deaths and left several people missing. Europe is becoming commonplace for floods in recent times making civil engineers wonder what is to be done. Flash flooding is something that engineers are researching so that damage to property and valuables is far less than it is in the world today.

Flash floods are also occurring in the U.S. in Texas. Analysts are saying that the flooding could continue for weeks to come. The flood has already claimed the lives of five soldiers and another four are missing in what is being considered historic floods for the state.

Flash floods are also occurring in the U.S. in Texas. Analysts are saying that the flooding could continue for weeks to come. The flood has already claimed the lives of five soldiers and another four are missing in what is being considered historic floods for the state.

An engineer foresees more floods in the future and wants to help with a new app that could benefit the entire world. A professor of civil engineering at the University of Texas at Arlington, D.J. Seo, has coded a new app named iSeeFlood. The app would assist in real-time reporting of flash flooding that could inform motorists and household owners that water could be rising wherever they are. On top of the user generated data, Seo's team have installed wireless sensors that will model urban water systems with Collaborative Adaptive Sensing of the Atmosphere which will also alert the engineers if water levels rise to the point of flash flooding.

"We will integrate the information that people send us using the app and the data from the sensors and the CASA system with flash flood forecasting models...Urbanization means we have changing land surface conditions such as increasing impervious land cover, which changes how rain may be running off and accumulating," said Seo.

The CASA systems are a relatively new technology but will be invaluable to severe weather warnings that could lead to flash floods. The technology works by scanning areas prone to heavy storm systems so that predictions can be made on how severe the storms are going to be due to atmospheric pressure.

Researchers hope the technology will be proven successful so that countries all around the world can warn their citizens that severe storms might cause flash floods. The technology could prevent deaths and save valuable property due to fair warning that storms are on their way.

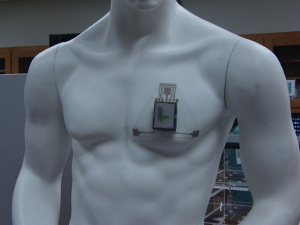

Another week, another wearable. It seems like every week some university shows off its biomedical health trackers off to media outlets. This time is no different, the US National Science Foundation's Nanosystems Engineering Research Center for Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) that operates out of North Carolina University is showing their Health and Environmental Tracker (HET). The researchers propose a patch-like device that a person would wear on their chest which would enable vital signs to be observed and data to be produced.

"Our goal was to design a wearable system that could track the wellness of the subjects and in particular provide the infrastructure to predict asthma attacks, so that users could take steps to prevent them by changing their activities or environment," said Alper Bozkurt, a professor of electrical and computer engineering at NC State and who is at the helm of the project.

"Our goal was to design a wearable system that could track the wellness of the subjects and in particular provide the infrastructure to predict asthma attacks, so that users could take steps to prevent them by changing their activities or environment," said Alper Bozkurt, a professor of electrical and computer engineering at NC State and who is at the helm of the project.

The researchers have published their work in the IEEE Journal of Biomedical and Health Informatics under the title: Low Power Wearable Systems for Continuous Monitoring of Environment and Health for Chronic Respiratory Disease.

"This system will permit a better understanding of the impact of increased ozone levels and other pollutants on chronic asthma conditions," the researchers write in their journal. The device will therefore also assist in measuring how a person who doesn't have asthma can develop asthma due to pollutants in the air. The setup also has a microphone that will listen to the amount of wheezing someone does and will be able to diagnose their conditions more accurately along with the sensors that connect to the head and chest.

"The data from each sensor is continually streamed to a peripheral data aggregation device and is subsequently transferred to a dedicated server for cloud storage. Future work includes reducing the power consumption of the system-on-chip including radio to reduce the entirety of each described system in the sub-milliwat range," the researchers wrote.

What we are seeing in the wearables industry is that biomedical research and the monitoring of health is the modus operandi of a lot of researchers right now. Tracking health and technology is something that might save people's lives one days and that is what the engineers are essentially wanting to achieve.

Hey budding engineer! Want to work for Total, Chevron, BP and even OPEC? Become a petroleum engineer. However, the oil world is a tough business to get into right now. Should you even get involved during the oil slow-down that is happening due to the push for renewable energies?

OPEC is currently holding talks to debate the oil crisis looming over the world as oil prices continue to plummet. A French analyst, Abhishek Deshpande talking to the Wall Street Journal said: "If oil prices go back to $100, then demand goes down the drain. OPEC should be worried." OPEC now has an oversupply of oil and doesn't know what do with it, with petroleum engineers still making their money (having to engineer the output limits of oil) but the oil in question not being sold. OPEC is seeing a lack of investment into the industry on unprecedented levels.

Uptal Gosh, CEO and president of the University of Petroleum and Energy Studies would encourage students to strive to be petroleum engineers.

"To be a petroleum engineer you need to have knowledge of disciplines like computer science, instrumentation and control and safety, health and environment management among others. Petroleum engineers, especially those working in the upstream sector, need to be as sensitive towards the environment would be. In your quest to find oil, you should not harm the environment," said Gosh, speaking to the Hindustan Times.

"To be a petroleum engineer you need to have knowledge of disciplines like computer science, instrumentation and control and safety, health and environment management among others. Petroleum engineers, especially those working in the upstream sector, need to be as sensitive towards the environment would be. In your quest to find oil, you should not harm the environment," said Gosh, speaking to the Hindustan Times.

Payscale says a petroleum engineer can make up to $98 an hour. Interested yet? IF you do happen to be interested, then so are many other graduates who are queueing up to get into an industry that is seeing job cuts due to the crisis. The Society of Petroleum Engineers in the United States reported that in 2014, 95% of graduates with their bachelor's in petroleum engineering found work. The following year (2015) only 64% of graduates found work. What will the results be in 2016? Time will tell. Is it a good time to get into petroleum engineering?

Additive manufacturing is being used in many engineering industries, and there are still improvements being made in the way 3D printers do what they do. The University of Oklahoma has a lab where the latest in 3D printing technology is being used. Bizzell Memorial Library Innovation @ the Edge is the pride and joy of the budding engineers who would come and print their projects on the 3D printers. It is not uncommon for universities to have 3D printers on hand for engineers to test out.

"In places like car factories, they already use it to make models. In the future, it will come more into homes. If you have an idea for what want, you don't have to wait for someone to go and make it. It's getting to a level where everyone can use it," said Joris Juru, a junior computer engineering major. Juru wants to make 3D printing faster and points out that printer software is becoming more industry specific.

For example, an industry-specific 3D printing technology has been used at Airbus. They have just successfully printed a drone at an aerospace expo in Berlin. Donning the name "Thor", Airbus's drone is 4 metres long and has a 4-meter wingspan and weighs 55lbs.

One of the more interesting advancements in the 3D printing world comes out of Cornell University. They have been working with faster printing systems and have noticed that they could alter 3D prints whilst they were printing. They started to experiment with "edits" during the printing process and found that they were successful with a Wireprint 3D printer. The printer they used is different from a conventional printer but the research could prove useful even to the current 3D printers.

"On the fly print allows the user to check the design in a real usage context and to continue to design and print afterwards," the researchers said in their video. First prints are sometimes failed prints, therefore, this new method by Cornell University could refine the first print processes of a project.

The printer can begin on a project whilst the designer continues to design the rest of the project on the software. The researchers said: "[The on the fly printing] opens new opportunities for rapid prototyping and has great potential to improve the overall quality of the design process."

The UK construction industry continues to slip as the looming Brexit vote draws nearer. The 25th of June will be the deciding day to whether or not Britain stay with the European Union or opts out. Since the vote was announced, engineers have been keeping their eyes on the Markit/CIPS construction purchasing managers' index (PMI). The theory is that due to the looming vote no one will be investing in the construction industry, and those critics would be right.

The PMI data made available indicates that the manufacturing sector did see some improvement, however, the construction industry is at a three-year-low. The numbers in the index went down from 52 in April, to 51.2 in May. June could be seeing a further slip in numbers due to the vote. A senior economist at Markit, Tim Moore, told The Telegraph: "My data signalled the worst month for commercial building since June 2013, while residential work and civil engineering activity both saw a renewed loss of momentum. Survey respondents noted that the forthcoming EU referendum has disrupted new order flows and the timing of client decision making in particular."

The PMI data made available indicates that the manufacturing sector did see some improvement, however, the construction industry is at a three-year-low. The numbers in the index went down from 52 in April, to 51.2 in May. June could be seeing a further slip in numbers due to the vote. A senior economist at Markit, Tim Moore, told The Telegraph: "My data signalled the worst month for commercial building since June 2013, while residential work and civil engineering activity both saw a renewed loss of momentum. Survey respondents noted that the forthcoming EU referendum has disrupted new order flows and the timing of client decision making in particular."

The neighbours across the pond are also interested in what is going to happen on the 25th. Donald Trump said that he would be visiting the UK the day the referendum happens. Trump has invested in the civil engineering endeavours in the UK, notably buying the Turnberry Hotel that has just been opened to guests. Trump says that Britain should leave the EU, which he confirmed in an interview with Fox, where he said: "I know Great Britain very well. I know the country very well. I have a lot of investments there. I would say that they're better off without it [the EU]. But I want them to make their own decision." He also said that the UK would not be in the back of the line for trade deals if he were president. President Obama notoriously said that Britain would be at the back of the line in trade deals if they opted to leave the European Union.

The Guardian caught up with the chief UK and European from IHS Global Insight, Howard Archer. He said: "The government will be particularly disappointed to see housebuilding growth could only edge up for the third month running in May and is around its lowest levels since early 2013, given that it is looking to address the UK's accurate housing shortage."

Other analysts are saying even if Britain remains in the EU, the damage has been done and the slow-down will continue. "The official data clearly shows that public sector construction is squeezed, while the revival in housebuilding has run into skilled labour shortages," said Samuel Tombs, chief UK economist at Pantehon Macroeconomics.

Industrial control systems (ICS) will be under threat of being infiltrated by cyber criminals says the Allianz Global Corporate & Speciality group. The company supply companies with insights into risk factors and how that might impact their future business. They have now released a press release to warn engineers that they might want to put extra security measures into their industrial control systems as Industrie 4.0 continues to grow into an interconnected network of industry.

"Continuous monitoring and predictive maintenance of automated production lines will reduce small scale frequency losses and increase equipment lifetime. Supply chains will be better monitored, more predictable and visible with improved tracking options and losses reduce from spoilage or expiration," said Michael Bruch, Head of Emerging Trends at AGCS.

"Continuous monitoring and predictive maintenance of automated production lines will reduce small scale frequency losses and increase equipment lifetime. Supply chains will be better monitored, more predictable and visible with improved tracking options and losses reduce from spoilage or expiration," said Michael Bruch, Head of Emerging Trends at AGCS.

Nigel Pearson, global head of fidelity at AGCS said: "A number of ICS still used by manufacturing and utility companies today were designed at a time before cyber security become a priority issue." This has been proven by the taking down of a utility's power in the Ukraine. AGCS also point out that cyber-attacks have also happened on the Israel National Electricity Authority and recently a German nuclear power plant was also targeted.

The AGCS's concerns were published in a magazine named Global Risk Dialogue which focuses on "corporate risks and insurance", cyber risks and smart factories. "Overall loss potential is rising significantly, creating high accumulation potential with larger and more complex claims," Bruch added.

Warning factories is all good and well, however, what measures can these factories take to protect their industrial control systems from being attacked?

Kaspersky group have been quite vocal about the fact that they are working around the clock on securing smart factories and their Industrial Internet of Things networks. The United States Industrial Control Systems Cyber Emergency Response Team has detailed what areas to look at and secure in their own attempts to influence more security in smart-factories. They say: "Organizations should isolate ICS networks from any untrusted networks, especially the internet. All unused ports should be locked down and all unused services turned off. Organizations should also limit remote access functionality wherever possible. Modems are especially insecure."

"An ICS may be interconnected with other systems, such that failures in one system or process can easily cascade to other systems within or external to the organization. Impact propagation could occur due to both physical and logical dependencies," said the US National Insitute of Standards and Technology.

For now, the advice is lock-down on any internet-connected items while you can and hope that a cyber attack doesn't happen. Companies are releasing their Industrial Internet of Things packages that will include security. Some factories have tried to be ahead of the game and bought unsecured industrial setups that were taken down by hackers, as we have seen in the last year and a half. However, there are steps a factory can take by themselves but soon the security will be done by a third party and you won't have to worry about it. There on out you will be able to reap the benefits of using the Industrial Internet of Things.

In the recent weeks, we have been following China's takeover of multiple companies in 2016, notably, the takeover of Kuka Robotics. The Midea Group has been trying to make offers to German robotics firm, Kuka, but it seems there is a stalemate occurring. According to the Wall Street Journal, Germany is hoping to buy Kuka before Midea does, and retain the company's European ownership. They would have to provide a counteroffer of more than $5 billion, which Midea was prepared to pay.

In even stranger developments, Chinese robotics experts are starting to speak out against the country's attempts at building a robot empire. The South China Morning Post (SCMP) ran a story with the title: How the world's largest market for industrial robots is allegedly propped up by deceit . In the article, Wang Cairong, the executive director at the China Artificial Intelligence Robot Industry Alliance said: "The industry is now in a subsidies-driven bubble. It's time to launch a nationwide campaign to investigate these companies which have received subsidies through deceit or illicit connections."

If these claims are true and substantiated, perhaps Kuka would prefer being bought by European investors instead. However, China is banking on industrial robotics, with a five-year plan that is currently in full swing. 66,000 industrial robots were sold in 2015, which was 16 percent higher than sales in 2014, says the International Federation of Robotics. SCMP did confirm that local governments "at the provincial and city levels" have been garnering funds with government granted subsidies to improve the operation of robotics industry in the country.

"Many robotics companies obtained subsidies by claiming they have key technologies on par with those of foreign competitors," Wang maintained. "It has been an open secret within the industry that many Chinese robotics firms, including some companies that are listed, have cheated to obtain subsidies. Some have even formed several new companies to apply and receive one-off subsidies."

The whistle has been blown, it seems. Wang is calling for an audit of these 'so-called' robotics companies so that any corruption can be uprooted.

Nevertheless, industry experts are saying the sale of Kuka to Midea Group should go ahead. Daimler AG's chief executive Dieter Zetsche said: "There's no evidence that a sale of Kuka to China would be a risk." Furthermore, anonymous sources in the automotive industry said: "We don't understand the uproar about this. There are enough German automotive and other industrial operations in China that the Chinese government surely knows already how we produce things."

Here's a

| Date announced | Target | Country | Industry | Acquirer | Deal value excluding debt, in billions |

| Feb 3 | Syngenta | Switzerland | Agribusiness | ChemChina | $44.1 billion |

| Feb 17 | Ingram Micro | United States | Technology | Tianjin Tianhai Investment Development | $6.1 billion |

| Jan 15 | General Electric | United States | Consumer Products | Qingdao Haier | $5.4 billion |

| May 18 | Kuka | Germany | Robotics | Midea Group | $5 billion + |

| Jan 12 | Legendary Entertainment | United States | Leisure and recreation | Dalian Wanda Group | $3.5 billion |

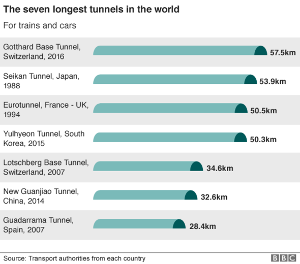

It's the year 2016 and we are still seeing marvels of engineering being built all around the world. Switzerland has just taken the crown from Japan for having the longest railway line in the world. The previous record was 33,49 miles, a railway tunnel known as the Seikan rail tunnel. The United Kingdom and France Channel tunnel is now the third longest in the world. The new Gotthard tunnel is 35 miles long and cuts under the Swiss Alps connecting north and south Europe. It goes from Erstfeld to Bodio and will see 325 trains passing through the tunnel every day.

Gotthard's tunnel is now open for business and is functioning. The first trains packed with ticket winners set off today, officially opening the tunnels. The construction took 17 years to complete with a team of 2,600 workers tirelessly engineering the tunnel.

40 million tons of freight will pass through the tunnel every year (starting in December 2016) and will minimize the need for trucks on the roads, which will, in turn, reduce congestion in Switzerland and be better for the environment in the long term. The government officials of Switzerland have been saying this connection through Europe is coming at the right time due to the push for cleaner and more eco-friendly engineering.

The drilling of the tunnels kicked off with four humongous drills that broke through the mountains in 2003. Sevens years later the civil engineers and the construction workers had blasted through 73 different kinds of rock. 28 million tons of rubble was produced. Euro News confirmed that 9 workers had died in the 17-year long process. The tunnel cost $12.3 billion and was fully paid off through taxes and other investment endeavors.

Swiss President Johann Schneider-Ammann said: "The new tunnel fits into the European railway freight corridor, which links Rotterdam and Genoa. Aside from saving time, more merchandise can be carried through the Alps."

Have you ever been out of power for long stretches of time, making you reach for your phone and shout down the municipality's ear? It might have been a grid fault that took a while to find and repair. Sometimes the equipment at the utility has been damaged as a result. However, thanks to engineers at Binghamton University these faults will soon be found quicker due to SSA (Singular Spectrum Analysis).

"Theoretically, the SSA algorithm is an optimal approach for accurate and quick detection. However, it had not been adopted in real-world engineering applications. We adapted and improved the algorithm for the new application in power grid areas," said Yu Chen, an associate professor of electrical and computer engineering at Binghamton.

Yu Chen and another engineering co-author worked on a paper that makes a case for a grid system that goes down if even one circuit malfunctions. Grids that are currently operating can continually supply energy when circuits go down, which then forces engineers to look through multiple sources for where the fault could be. If one thing failed and made the entire system fall down, they could tell what failed quicker. The engineers have tested their system and say that they would be able to find faults much quicker than the current way of sifting through multiple circuits to find what could be wrong on multiple complete circuits that make up a grid.

"At the current stage, the algorithm can only detect and locate problems, and it cannot predict the future problems. It laid a solid foundation for the next step: prediction. Being able to detect subtle changes in the power grid promptly, our approach has the potential to predict future problems by including a power system model," said another one of the authors, Ning Zhou.

The paper is titled Singular Spectrum Analysis based Quick Online Detection of Disturbance Start Time in Power Grid .

Source: Science Daily

In just seven days you can make a man, all you have to do is ask Tim Curry. However, how long would it take to make a self-driving car? Engineering students from the Waterford Institue of Technology (WIT), Ireland, have the answer. Twelve weeks. The engineers utilized the university's Applied Robotics Lab and as a result, got a Toyota Corolla to drive itself down a street on campus.

Jason Berry, a lecturer at the university said: "One of the coolest sounds we ever heard on a project was listening to the car increasing revs as it gets ready to go. The project is the bread and butter of what any engineer is all about - figuring stuff out for yourself."The students are currently doing their BEng qualifications in Electronic Engineering which will take a year whilst doing their two-year higher certificate courses in Electronic Engineering.

How the engineers did it:

- Developed a console that accelerates the car through a command that tells the engine the accelerator has been pressed down

- Utilizing the same technology, they developed commands that instructed the car's engine management system to turn

- The car saw where it was going thanks to a webcam

- A servo motor that pushed the brake when it knew it needed to stop

So, lecturers and mentors of engineering, are you ready to build self-driving cars with your students? Only a twelve week process. What you're left with is a rewarding feeling of having actually engineered something.

Source: RTE

The CEO of Amazon, Jeff Bezos, has said that the industrial economy is key to expanding into space.In an interview at the Code Conference in California, he spoke about Blue Origin, the SpaceX competitor company that he is a part of, and why Mars is the next frontier. He also said the answer to energy is in space and industry would move into space instead of staying on earth. Ready to become astronauts, engineers?

Bezos spoke candidly to an interviewer overseen by a large audience. He said: "Energy is limited here. In at least a few hundred years...all of our heavy industry will be moved off-planet. Earth will be zoned residential and light industrial. You shouldn't be doing heavy energy on earth. We can build gigantic chip factories in space. We don't have to build them here."

Then Bezos referenced solar energy and the future it has: "The Earth shades itself...in space you can get solar power 24/7. The problem with other planets...people will visit Mars, and we settle Mars, and people should because it's cool, but for heavy industry, I would actually put it in space." He does have a point, however. If enough solar panels can be put into space - and in perfect positionings - 24/7 solar power could be a possibility. Engineers, get to work!

It's not just you...it does sound like Jeff Bezos is rambling. However, this is just Bezos talking candidly about things that Elon Musk is trying to do and hoping he can be in that golden circle of engineers that are pushing our world forward..

Meanwhile, SpaceX and Elon Musk have successfully landed another Falcon (which can be seen here) on a barge and have reiterated that they plan on getting to Mars as soon as 2018. Tech Insider has put a good video on YouTube, showing the exact type of rocket that SpaceX wants to send to Mars.

Telkom is South Africa's premier telecommunications company who supply wireline and more recently wireless communication solutions. The company's latest attempts at supplying telecommunications to the country involve LTE technology and fiber internet solutions. Introducing new technologies has translated into needing more engineers to assist with building an infrastructure that facilitates uninterrupted internet to the greater South African public. Telkom was one of the first companies in South Africa to offer uncapped broadband to the country through asymmetric digital subscriber line (ADSL). This meant that the country would get faster internet on copper lines. Only one problem. Copper Cable theft ran rampant in the country.

It is estimated that cable theft has cost South Africa $321 million (ZAR5 billion). In the last year alone, Telkom has forked out $12.8 million (ZAR200 million) to repair cable theft damage and to organize security companies to safeguard their copper facilities.

Telkom's group executive for communications, Jacqui O' Sullivan said: "It is clear that the price of copper and its strong demand in international markets are catalysts of this crime." She went on to say, "These criminals now target our manholes armed with customise heavy duty vehicles, allowing them to hitch the cable to the vehicle and drive out kilometres of cable, cutting off thousands of customers, in a single incident."

The company is trying it all it can to ensure their customers migrate to wireless technologies that are less of a target for criminals, namely, LTE and fibre technologies. Even Usain Bolt has joined the migration:

However, just as 4G/LTE becomes the norm for South Africans, 5G is being tested by engineers in the United States. 5G will be the powering force behind the Internet of Things. Huawei has reportedly said that their tests have been successful. The company said that they were able to successfully improve spectrum efficiency. We should be seeing the advent of 5G becoming part of our daily lives perhaps as soon as 2017, according to network engineers in the industry.

Source: The Citizen

In the fast-changing world of engineering, staying afloat in terms of qualifications, credentials and knowledge is a tough business. Luckily, it is becoming easier to remain in an industry, work hard at it, but at the same time gain more knowledge on the side that will further you in your industry. The other scenario is, you may be later on in life and not able to go all the way back to university to gain the credentials that would get you a job in an engineering career right now. What do you do? Who do you turn to? With reference to what individuals are doing around the world, you might be able to have a deeper understanding of what your next move could be in terms of gaining more knowledge and in turn being a viable option for an engineering job, or keeping that engineering job you already have.

Singapore:

Singapore:

Ms Poh Li Ping wanted to change up her credentials in the kind of civil engineering she was doing. She felt as if she had settled for a cubicle job and rather wanted to get out there and oversee actual civil engineering in practice. She was able to take a bridging course at the Institution of Engineers, Singapore (IES). On top of that, she had to take a master's programme in civil engineering, a six-month course from the National University of Singapore. As a result, she can now get out of the office and go and oversee civil engineering construction projects and can be involved in the design process of projects.

"By attending all these extra courses, this has opened up one more door for me for future opportunities," said Poh.

Poh Li Ping's extra layers of qualifications will come in handy due to recent studies in Singapore that revealed engineering services in the country - especially in the civil industry - are experiencing retrenchments.

Experts in Singapore are warning that remaining employable in engineering industries will depend on whether or not the engineers build on their knowledge. Nanyang Technological University professor Chew Soon Beng told TODAY that the nature of engineering work has changed and thinks engineers should build on their "financial and econometric" skills.

South Africa

In South Africa, if you already have qualifications in engineering and want to stay up to date with what's happening as the industry changes, there are online institutions that offer bridging courses or just general video courses to become even more proficient in the type of engineering that is being done. Some engineers cannot afford to go all the way back to university to continually build on their credentials and know-how. You can get professional certificates of competency and advanced diplomas in a certain kind of engineering that could lead to a job in an engineering industry.

- Preparation Maths, Physics, and Chemistry

- Fundamentals of Engineering Chemistry

- Fundamentals of Engineering Maths

- Fundamentals of Engineering Physics

You can do these courses globally seeing as though it's online education. However, specifically in South Africa, if you wish to go to another institution and continue to build on your engineering qualifications after doing an advanced diploma, you would have to go to the South African Qualifications Authority and convert your qualifications to the South African standard.

The Dean of Engineering at the Engineering Insitute of Technology (who host the fundamentals courses mentioned above), Steve Mackay, spoke about engineering education that works, recently. He said: "We really need to focus on the basics, which is, having outstanding industry experienced instructors involved with the students. That's what really matters...people who have industry experience."

What remains clear is that people who are already in engineering jobs should continue to build on their experience in the industry but at the same time stay fresh with knowledge whilst the engineering industries change with the times.

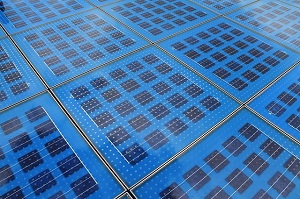

Apple Inc has opened a new store in San Francisco's Union Square and are following in the footsteps of Ikea, Walmart and others that will be running their stores on completely renewable energy. The store would be their flagship store which will be showcasing the Apple brand. The store spent $23.6 million on the new store's construction.

"The store is powered by 100 percent renewable energy, including power produced by photovoltaic panels integrated into the building's roof," said the press release from Apple announcing the opening of the store. Photovoltaic panels that are integrated into the roof instead of being positioned on top of it are called Building Integrated Solar Photovoltaic (BIPV). However, a writer for Electrek thinks Apple is up to something else based on the photovoltaic panels that have been put up at the new flagship store. It was the pricing that intrigued the writer. He pointed out that, according to Buildzoom, the photovoltaic array that was integrated into the roof cost Apple $800,000 and would push out 50kW of solar energy. Why would they need that much energy connected to one store? His question is: "What did they build?"

The discrepancy - to the curious few - of this new flagship construction is that a normal 50,000W solar system retails for $150,000, however, Apple used $800,000. Some analysts say that Apple could be selling the power they generate in their new flagship store back to the grid to assist with renewable energy that can be then sold to customers through utilities or will eventually sell their own energy to consumers. Based on the cost-effective construction of the building - or at least that's what it looks like - the hefty price tag on the photovoltaic system they are using is either a case of over-reporting how much was spent for tax purposes or they have built something cool.

Did you know?: The City of San Francisco had made it law that any construction under ten stories has to have photovoltaic panels connected to it. This would make them the first state in the United States to implement such a law, and it will be fully implemented in 2017.

Regardless, the new flagship store is a wonderfully minimalistic look at a company that continues to engineer some of the most sought after products:

Computex 2016 has kicked off in Taiwan and who better to kick the show off than Taiwanese company ASUS? Throughout the week, companies will deliver keynotes and show off advances in consumer technology. A recurring theme from most of the companies showing off their new devices is virtual reality, but another subject is coming up quite a lot; home robots.

ASUS has unveiled Zenbo , their answer to the home robot. A potbellied, two wheeler, vacuum-like robot with a head that juts outwards with a screen for a face. It will cost $599. ASUS chairman, Jonney Shih, said: "For decades, humans have dreamed of owning such a companion: one that is smart, dear to our hearts, and always at our disposal. Our ambition is to enable robotic computing for every household."

What will this robot assist with in the house? Obviously not coffee making. But its other uses include:

- Being a fun and educational playmate for children

- It can assist the elderly with keeping up to date with meetings they may have or things they need to remember

- It can take photos

- "I am a robot of many talents, I can sing and dance," Zenbo said.

- Can assist you with tasks around the house

- It can even turn on your lights and turn your TV off

Here is the very strange video from ASUS that shows why exactly you might need the Zenbo robot. It's a mini-movie but it's worth seeing what kind of uses this little robot might have:

How many minutes did you manage to watch?

Meanwhile...

SoftBank, the company behind the Pepper robot that a host of companies are wanting to partner with, has added a strange line to their user agreement. "The policy owner must not perform any sexual act on the robot or engage in other indecent behaviour." The warning is probably necessary.

The Pepper robot will also support the Android operating system now that the SDK (Software Developer Kit) has been released. You can obtain the SDK from the Pepper Partnership Program so you can get started on developing apps for Pepper.

Nonetheless, Pizza Hut has also ordered themselves a Pepper robot that will be taking food orders, with the collaboration of MasterCard's MasterPass. In Japan, the Pepper robot is being used as a coffee machine salesman in one of Nestle's branches. What a time to be alive.

Computex 2016 has kicked off in Taiwan that will see keynotes from several companies including ASUS, Intel, Microsoft and more. The big thing at the conference this year? The Internet of Things and how it is changing computing.

First of all, Intel is sacking 12,000 employees in their industry due to what the New York Times is called the "PC Demand Plummet". Intel is restructuring their company to not only limit themselves to semiconductors but try and compete as a multifaceted tech company. One of the focuses is interconnecting objects together with the Internet of Things.

Brian Krzanich, Intel's chief executive, alluded to the fact that ignoring the IoT industry wouldn't be wise due to the number of connected devices rising to 50 billion by 2020.

"We think this is going to grow to 50 billion devices and trillions of dollars of economic impact. It will change the way we live and work. As we go out talking, we see more companies investing in it. We are making a transformation from a PC-oriented company to one that powers things that are connected to the cloud and everything necessary to make that happen," said Doug Davis, the senior vice president of Internet of Things at Intel, talking to Venture Beat. "We've seen how the markets have evolved. We now use data to control things. There's an opportunity to extract that data and make use of it. We call this phase, like connecting wind energy farms, 'connecting the unconnected'.

To see some of the Internet-of-Things-connected devices that Intel is bringing out, watch this video from CNet. This is footage from Computex 2016:

Intel is also working towards completely wireless PCs as well. These have chips inside of them that would allow wireless charging of laptops and wireless data sending over connected WiFi networks. They are also working on self-driving cars, but more specifically the screens that will deliver infotainment on the inside of self-driving cars, but nothing they can show off just yet. Once again, all of these things will be connected to the Internet of Things.

German researchers from the Leibniz University of Hannover are conducting research into how to make a robot feel pain. Perplexingly, the researchers have been working with Kuka robots and programming some reactions to pain-inducing scenarios into robots. This disregards the entire premise of why robots would be employed. Do we not install robots in factories because unlike humans they cannot get tired and they cannot feel pain? Regardless, the researchers are making a case for installing an "artificial robot nervous system" into robots.

"Pain is a system that protects us. When we evade from a source of pain, it helps us not get hurt," said Johannes Kuehn, one of the engineers attached to the research. They have shown the research to panels of experts at the IEEE International Conference on Robotics and Automation (ICRA) that is taking place in Stockholm, Sweden.

The other engineer working alongside Keuhn is Professor Sami Haddadin. He said, "A robot needs to be able to detect and classify unforeseen physical states and disturbances, rate the potential damage they may cause to it, and initiate appropriate countermeasures, i.e, reflexes."

Reportedly, the researchers used a "nervous robot-tissue model" that was inspired by "human skin structure" that would be able to sense temperature and pressure. The engineers programmed the robot to have heat and pressure thresholds that if met, would then attempt to avoid whatever the engineers were throwing at it. The robot also sends out pain information for the engineers to peruse, when something infringed on its pressure thresholds.

As the researchers talk it starts to make more sense. Essentially, they don't want the robot to feel pain but rather to have reflexes to something that threatens their hardware as if they were feeling pain. So if the robot senses that it is in a room that is on fire and it has the ability to move out of the room instead of getting 'hurt', then it should be able to do that. However, perhaps robot helpers around the house should be given the ability to feel some sorts of 'pain' but industrial robots should have to tough it out. Yes? Maybe? No?

Stanford University engineers have also been experimenting with technology that would allow a robot to avoid a collision with something else. This particular avoidance system was programmed five years ago but will be invaluable research for years to come due to the increase of robot workers replacing factory workers in the world today:

Source: IEEE Spectrum

Sound engineering is not an easy feat. Neither is music engineering. Clarence Adoo is a trumpeter who was paralyzed from the neck down after a car accident two decades ago, rendering his arms unusable, thus playing the trumpet was going to be problematic. Seven years after his accident, an engineer named Rolf Gelhaar built him a breath-controlled instrument named Headspace. As the years passed they attempted to get the Headspace working but have now perfected some of the technology and built a new iteration named the HiNote.

Vahakn Motassian, Gelhaar's son, was the main engineer involved with building the new instrument. He said, "Most digital interfaces lack expression. Notes are just on or off. There are no off-the-shelf truly expressive devices." So, Motassian started a company dedicated to this field of research and development named Human Instruments.

The HiNote utilizes breath pressure sensors and a piece of software that Adoo can control and influence to make music with:

Talking to The Guardian, Motassian said: "The software has gone way up in sophistication - and that inspires me to be more creative. It will allow me to do things that I've never been able to do. Most importantly, it has a more natural way of blowing, so I can produce new effects." The video shows Adoo creating some very interesting musical sounds that sound a bit like an episode of the X-Files.

"The harder you puff, the harder the notes roll," says Human Instruments in the new video with Adoo. The engineers are hoping they could deliver a product to the music market that would enable disabled people to make music. The other technology they are working on is a sort of 'touch board' (see video below) that produces electronic sounds based on where the user is touching the board.

Human Instruments is one of many start-up companies that are working on musical instruments for disabled people, however, for a trumpeter like Adoo who lost his ability to play and use the trumpet, Human Instruments has breathed new life into his music making abilities with the new HiNote technology.

What do you get when you put drone technology and a Russian engineer into the same room? They build something out of a video game, apparently. A Russian YouTuber named Valplushka has shown off a drone resembling that of a city scanner from the game Half Life 2. The city scanners are used by the Orwellian government in the game and is used for the purposes of surveillance and protecting the city. The video shows a prototype the Russians have built that looks precisely like the city scanners in the game.

The YouTubers built a base frame for the quadrocopter out of carbon fiber. "The main materials used are: carbon fiber, expanded polystyrene. Flight controller DJI Nzaza-M Lite without GPS," their video description read. To get it into the sky they used AX-2810Q-750KV Brushless Quadcopter motors and were also equipped with a GoPro camera. The drone is now 2.7 feet long and 1.9 feet high.

Check the videos out and see how he utilized already engineered products to build a new drone that could very well be used as a film prop. Let's just hope the government doesn't get any ideas:

‘You see things; and you say Why? But I dream things that never were; and I say Why not? (George Bernard Shaw). I believe that one of the great signs of leadership is in questioning what you do, in identifying new ways of doing things and taking your team or organisation to incredible new opportunities.

Dear Colleague

‘You see things; and you say Why? But I dream things that never were; and I say Why not? (George Bernard Shaw). I believe that one of the great signs of leadership is in questioning what you do, in identifying new ways of doing things and taking your team or organisation to incredible new opportunities.

Leadership is something that all great engineering professionals should work on achieving. Business and life is extraordinarily turbulent at present. And I believe we often get swept along in an organisation because we don't take control of our lives and have some mediocre manager running our lives. As we all know - engineering professionals like working in the technical area and leadership is often not on the agenda. But it should be!

Why should you bother to read further? Well; leadership is something you should actively consider engaging in more aggressively to benefit your engineering career. No matter whether you are an electrician, technician or engineer.

Shackleton of the Antarctic was an incredible Leader

There are incredible leaders such as Shackleton of Antarctic fame who recruited his team with the incredible advert which drew thousands of applicants(‘Men wanted for hazardous journey. Low wages, bitter cold, long hours of complete darkness. Safe return doubtful. Honour and recognition in event of success.’). But leadership is most definitely not something that only a few people have. We all have these skills to some extent – some greater than others. It is about taking ownership and driving yourself further and “working” your leadership skills in your job with greater enthusiasm and showing a stronger questioning attitude about everything you do.

However at all levels engineers and technicians need to seize ownership - drive innovation and real improvements - thus benefitting customers and increasing profits and improving your day-to-day life and those around you.

There is a definite shortage of good leaders and there is thus an enormous opportunity. Obviously some of the disadvantages of being a leader is perhaps additional stress and the considerably greater responsibility in impacting on other people’s lives.

Engineers need to be influential. At all levels of an organization, engineers should play a significant role in driving innovations that will benefit customers and increase profits and opportunities for everyone.

What is leadership?

Leadership is simply the ability to get things done with a group of people. There are three key functions:

- Develop your team (Select the right people/coach and train ‘em)

- Motivate your team (Understand them and coach them to achieve)

- Equip your team (direct your team as well as identify and obtain the necessary resources for them)

As far as the distinction between management and leadership? Warren Bennis says: ‘Management is getting people to do what needs to be done. Leadership is

getting people to want to do what needs to be done. Managers push. Leaders pull. Managers command. Leaders communicate.’

The following are a few reasons why you as an engineering professionals need to apply your leadership skills:

- Being technical only is not sufficient for your career success

Technology changes all the time. And how many times have you seen someone who knows nothing about engineering taking a management or leadership position? However, your engineering know-how coupled with leadership puts you in an incredibly powerful position.

- Leadership is far more than being a manager

Managers are often appointed. Leading and managing are often different skill sets. They may have been bumped up to a higher level as they have been so long in the organisation. You can show real leadership and technical know-how and be far more successful.

- You can guide your less experienced peers.

- You can provide direction to lower level engineering professionals in your organisation. And influence them in a positive way.

- You can influence the decision makers. You understand engineering and technology better than most people and can help these high level managers make the right decisions to grow your organisation.

- Great projects only succeed with great engineering leaders. How many mediocre managers do you know that are in charge of engineering projects? Help these managers with great leadership.

- You get greater satisfaction (and dare I say, ‘fun and excitement’) in your day-to-day work by being a leader and showing creativity in driving your organisation to success.

Surely, you can get greater satisfaction in your career by showing imaginative new ways of taking your firm and career to new heights. Rather than being stuck in the same old way.

Yours in engineering learning

Steve

Mackay’s Musings – 31st May’16 #602

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

Is Canada in trouble of losing their status as an energy superpower? Were they ever considered an energy superpower to start with? Well, they would like to think so. However, the Canadian government has a draft report doing the rounds that indicates that the country is scared of the impending move away from fossil fuels in the world today due to the amount of money they may be losing.

The Canadian government used a company named Policy Horizons Canada, a strategic foresight organization, to measure what impact the change in the global energy landscape will have on their country.

"The world's energy is transforming rapidly as the cost of renewable-based electricity, particularly from wind and solar, declines to become competitive with or lower than the price of electricity generated by fossil fuel and nuclear power plants," the beginning of the executive summary of the report read. "The price of batteries is falling precipitously leading to their application at local and grid-level scales in the power supply system as well as facilitating significant electrification of transportation. The shift to an electricity-dominated global energy mix will be accelerated as decreasing costs combine with increasing government and private developing countries where the need for additional energy capacity is greatest."

"The world's energy is transforming rapidly as the cost of renewable-based electricity, particularly from wind and solar, declines to become competitive with or lower than the price of electricity generated by fossil fuel and nuclear power plants," the beginning of the executive summary of the report read. "The price of batteries is falling precipitously leading to their application at local and grid-level scales in the power supply system as well as facilitating significant electrification of transportation. The shift to an electricity-dominated global energy mix will be accelerated as decreasing costs combine with increasing government and private developing countries where the need for additional energy capacity is greatest."

Policy Horizons says there are three things forcing the hand of government to change from fossil fuels:

- Cost Reduction: Renewable energies becoming cheaper as a result of technology advancements

- Digital Economy

- Climate Change and Air: Developing nations embracing renewable energy to meet economic and development goals.

The Canadian government is now fully aware of the challenges that lie ahead, and really every government that is seeing the rise of renewable energies should be reading Canada's governmental report and making the relevant changes to their energy policies. Canda sees the impending doom of competition for energy markets and knows the best techbokogy is waht will win the hearts of consumers.

"Minerals and metals such as lithium and rare earths could replace oil, gas and coal as strategic resources based on their use in the batteries, electronics and photovoltaic cells of the emerging energy ecosystem," the Policy Changes section of the report said.

The foresight company said that storage solutions were "emerging and evolving" faster than the government thought they would. Enery storage really is the 'great disruption' the analysts have been talking about. The opening of Tesla's Gigafactory (and facilities of the same nature) is of particular interest to the Canadian government who sees lithium-ion slowly taking over. "Utility-scale energy storage techbologies are available now and may be a cheaper alternative to peaking power plants as well as new transmission lines by allowing public utilities to position battery plants near high demand areas like cities and industries and improve load-balancing while reducing GHG emissions," the company wrote.

They conclude the report by saying: "It is increasingly plausible to foresee a future in which cheap renewable electricity becomes the world's primary power source and fossil fuels are relegated to a minority status."

The full draft report can be read: HERE

Original source: CBC News

Engineers are seeing the business opportunities with the rise of the Internet of Things. The booming industry presents a chance for new companies to be created, new inventions and innovations to be brought to the world and for more efficient machines to be built. A former engineer from Google has even started his own internet-of-things startup company named Afero .

Joe Britt, the former Google engineer and founder and CEO of Afero, said, "Everybody who wanted to build a connected device had to reinvent multiple wheels. You have to decide what kind of hardware to use, what kind of operating system - if any - you're going to run on the device, how you communicate with the cloud, how you interact with a mobile app. You need a connected device engineer, you need cloud developers, and all those people have to coordinate your actions to make that device work." They have created a module that will interconnect machines to the Internet of Things and sync these processes across every platform imaginable.

They have four subcategories that define their idea of the Internet of Things:

- End-to-end security

- Complete scalability

- Valuable analytics

- Rapid deployment

As is apparent, the Internet of Things has given engineers and entrepreneurs and engineer entrepreneurs the inspiration to utilize the Internet of Things and produce something.

But what are the threats to the Internet of Things?

"At the moment, we are in 2016. At the moment, there are 25 billion devices connected. By 2020, there will be 50 billion devices connected. That will make a big difference whether you're in the renewable energy area, transport, energy production, homes, entertainment. It will make a big impact on gathering data. We will need someone to process this data and that's where engineers come in," Mackay added.

He also highlighted four key areas to focus on when building a relationship with the Internet of Things and how it can boost your engineering and technology career:

- People: Hopefully serving someone: Like Afero is doing, for example. They have built something that utilizes the Internet of Things.

- Process: What you want to do with that information. Millions of data points streaming in, you need processors to decide what to do.

- Data: The analytics that has been created that can be made available to the engineers and the consumers.

- Things: Where you gather information from and where you send it to

Mackay implies that all of these things will be important in the future of the Internet of Things because the world is going forward with building smart cities and connected cars. Security is a big deal but there are also countless opportunities to capitalize on the Internet of Things and jumpstart businesses, companies and corporations.

And now for something completely different. Here's a scenario that you may never have thought of but engineers have had to grapple with. A woman loses a limb and gets a prosthetic limb to replace it. She gets invited to a wedding that requires formal wear. How does the woman wear high-heels to this event? This is the big question that Johns Hopkins University students want to answer. A team of engineers recruited some physician students and prosthetics experts and got to work. What they produced was a solution named Prominence. The first prosthetic foot that is custom designed to fit into high-heels of up to four inches high.

"High heels have become an integral part of the female lifestyle in modern society, permeating through all aspects of life -- professional and social," said the students from the Whiting School of Engineering. "For female veterans of the U.S. armed services with lower limb amputations, that seemingly innocuous, but so pervasive, and decidedly feminine part of their lives is gone."

The researchers say that 2,100 American women have lost their leg or a foot in military service and wanted to give the women a chance to reexperience the feelings of going to a formal event and wearing the same clothes as able-bodied people did. The prosthetic feet that are currently available on the market are actually built for men's shoes without a woman's desire to wear a high-heel ever considered.

Here were some of the challenges that the engineering students faced when having to design a prosthetic foot that would also be able to contort itself so that it could fit into a heel without causing the wearer displeasure:

- A foot that is adjustable without a tool to help it adjust for different heel heights

- Ensure that it does not slip once adjusted

- Weighs less than three pounds so that it is not too heavy

"An adjustable ankle is useful in contexts even beyond high heels. Ballet, flats, sneakers, boots, and high heels especially, all vary in height, so an adjustable ankle opens up opportunities to wear a variety of shoes," said Alexandra Capellini, one of the students who had lost her leg to bone cancer who was participating in the study.

- A 28-layer carbon fiber foot plate was tested successfully

- There is still work to do, but they are closer to a working prototype

Nathan Scott, a senior lecturer in the Whiting's School's Department of Mechanical Engineering who is the advisor of the ongoing project, said: "I think the final prototype produced showed the way forward. As usual, we just need to go around the design and prototyping loop one more time."

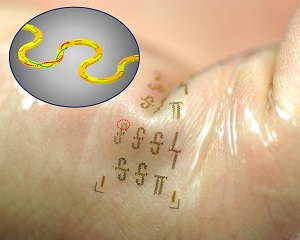

It's the year of engineering stretchable, wearable electronic devices for the impending future of wearing technology on our bodies, clothing etc. Nanoengineers, electrical engineers, mechanical engineers and computer engineers have never put this heads together quite like this before. Researchers at The University of Wisconsin-Madison are showing off their own flexible, wireless, wearable integrated circuits. Their studies were published on the Wiley Online Library in the Advanced Functional Materials journal.

Professor in Engineering at UW-Madison, Zhenqian Ma was the lead author on the study highlighted the fact that their integrated circuits could assist engineers in the wearables market that could potentially utilize their technology to further wearable technology. The big reveal from the engineers is that their circuits will operate at 40GHz and utilize 5G networks so that they are also interconnected and synced with each other thanks to the Internet of Things.

Ma said: "We've found a way to integrate high-frequency active transistors into a useful circuit that can be wireless. This is a platform. This opens a door to lots of new capabilities."

The researchers think their new wearable circuits could be particularly useful in the biomedical field due to the circuits being very skin-like in the way that they are worn. Health monitoring is one of the big things engineers have built into wearables which we can see in devices such as the Fitbit et al. The researchers have ten years of research and development in transistor active devices and are confident they are on to a winner with their stretchable circuits.

The researchers have used minuscule power transmission cords to power the circuits that sidewind on the surface of whatever it has been placed on. The s-curved nature of the power transmission cords means that it can be stretched, somewhat. Some analysts are calling the invention the fastest wearable devices currently available and will be very instrumental in studies pertaining to integrated wearable circuits.

A Canadian plant might hold the future of carbon emissions and what we could do with them. The hope is that we could remove carbon from the air everyone is breathing right now in a process called 'direct air capture'. The company has been actively working on the process for four years now. The company leading the direct air capture process is a company named Carbon Engineering Ltd. The company has gotten backing from Bill Gates, oil billionaire Murray Edwards and other deep-pocketed investors. What they are working on would equate to snatching carbon emissions from cars, planes and other small-emitting devices and reclaiming the carbon so that it does not further poison the atmosphere. The idea is that once the carbon has been captured, it can be repurposed into carbon fuels.

"What we're doing is opening up, in a more serious way, a pathway to synthetic fuels from air. That's something that people get excited about," said David Keith, Carbon Engineering Ltd's founder. That was a quote from the Globe and Mail - in Canada - from January 2016. What strides has the company made in the last five months? Let's find out.

The company is a finalist in Virgin's Earth Challenge, where if they won, they would earn $25 million for the facility. The competition is dedicated to removing greenhouse gases from the atmosphere. This would assist the facility in further purchasing the tools they need to build their Prototype Air Contactor. The prototypes remove carbon emissions from vehicles that emit carbon into the air.

Christophe Jospe, a chief strategist for the Center for Negative Carbon Emissions (CNCE) writing for Virgin Earth's competition recapped the importance of Carbon Engineering Ltd's plight and highlighted its importance in our world today:

- Their process is feasible and makes economic sense

- Air capture (technologically removing CO2 from air) is a crucial technology to get to a carbon neutral future and beyond; and

- The world is starting to wake up to the fact that we cannot continue to treat the atmosphere as a dump for fossil based CO2, and there will be more policies and incentives to reflect that reality.

- Christophe Jospe, Virgin Earth

The company has continued its work in trying to repurpose the carbon into fuel so that they can power buses in the town they operate in, Squamish, British Columbia. Geoff Holmes, Carbon Engineer's business development manager said: "It would basically be a closed circle. You're capturing CO2 from the air, turning it into fuel, the car burns it, and it goes back into the air."

Will the world latch on to the idea or are there other ways we can eliminate carbon altogether that could be more profitable than direct air capture? The engineers are hard at work to try and make it happen. What will the next innovation in greenhouse gas reduction be? Check the video below for how the direct air capture facility from Carbon Engineering actually works.

Ikea, the home furnishing store, made a pledge last June that it would be investing in the future of renewable energy. The intention is to only use renewable energy to power the chain of home improvement stores by 2020. According to the Guardian, Ikea enjoyed a comfortable profit of $33 billion in 2015 and will be using some of that to fund solar photovoltaic solutions and wind power. They will be injecting $660 million, on top of the $1.6 billion they have already invested into renewable energy. They will be accountable for 314 wind turbines and currently utilize 700,000 solar panels on shop roofs. If only more companies joined the queue of commercial entities wanting to better the future.

The company wants to have a "positive impact" on the climate through the investment of clean energy and say the only way to do this is to go "all in" and throw their weight behind the cause. They also want to export the energy to impoverished nations by becoming a net exporter within the next four years and currently produce 53% of its current energy on renewables. Companies operating their own wind farms and solar plants? Not unheard of. Walmart secured a deal with Pattern Energy who operate a wind farm. Walmart reportedly will buy up to half of the 200 megawatts the farm produces.

The company wants to have a "positive impact" on the climate through the investment of clean energy and say the only way to do this is to go "all in" and throw their weight behind the cause. They also want to export the energy to impoverished nations by becoming a net exporter within the next four years and currently produce 53% of its current energy on renewables. Companies operating their own wind farms and solar plants? Not unheard of. Walmart secured a deal with Pattern Energy who operate a wind farm. Walmart reportedly will buy up to half of the 200 megawatts the farm produces.

Perhaps Ikea could grow their renewable energy by tenfold and start releasing their very own home-based photovoltaic cells that can be sold just like the home furnishing items in their store. Companies have an irrefutable business opportunity in the renewable energy game and could capitalize on the market like the Tesla PowerWall and some of its competitors.

Speaking of Tesla PowerWall's competitors: Mercedes has released the prices for their very own photovoltaic cells. The cells are manufactured by Daimler ACCUmotive and will now be purchasable by the German public, with added territories soon. The price per unit will be between $9,000 to $10,000, which includes installation rates. But how does it stack up against the PowerWall and Nissan's latest battery announcement?

These are estimated numbers and will not be exactly correct, however, they are a good indication of the prices you can expect to be paying. Prices can change based on which country the batteries are to be purchased in.

| Tesla PowerWall | Mercedes | Nissan xStorage |

| Stores 6.4kWh | Stores 2.5kWh | Stores 4.2kWh |

| Storage stacking: 9 PowerWalls can be connected to equal 58kWh | Storage stacking: 8 Mercedes batteries to equal 20kWh | Storage stacking: 8 batteries to equal 20kWh |

| Price: Up to $7,000 each including installation | Price: Up to $10,000 each including installation | Price: $4,500 each including installation |

For reference, an average person in the United States uses 30 kWh per day.

Sources: The Guardian & Tech Insider

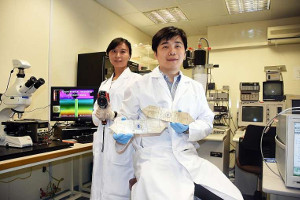

Researchers from the National University of Singapore have invented a new method of camouflaging sensors to the point where they are considered invisible. Professor Qiu Cheng-Wei from the Department of Electrical & Computer Engineering at NUS Faculty of Engineering was at the helm of a team that is slamming their flag down on the world's first "multifunctional camouflage shell" that is invisible in thermal and electric environments. This means that anything that produces heat or electricity while it operates can be "invisibility cloaked".

"We have designed a camouflage 'shell' that not only mimics surrounding thermal fields but also electric fields, both at the same time. The object under camouflage becomes truly invisible as its shape and position cannot be detected in terms of both thermal and electric images," said Cheng-Wei.

The military uses for this kind of technology would make quite a lengthy list. Cheng-Wei weighs in on the militarization of such a technology, he says, "This introduces a defence advantage, where the enemy cannot see the soldier, but the soldier can detect the enemy."

The shell could mask the heat signatures that would show up on any camera or sensor looking for heat signatures or signs of electrical behaviour or fields. The team utilized a thin copper shell that attempted to mask the several deviations and differences of heat and electricity.

"Our camouflaging shell will open up a new avenue for advanced sensing and security systems. Sensors which are used to monitor current and heat flow in strong voltage or high-temperature environments are easily damaged. Our camouflaging shell hence protects such sensors from the harsh environment and at the same time enhance the accuracy of the hidden sensor, as the shell will eliminate any distortion around the sensor. This attribute is significant in our study of other applications such as using the camouflaging shell on special mission fieldtrips. The team is working on developing multifunctional invisible sensors that have instantaneous stealth ability," Dr Qiu told PHYS.

The team of engineers used the camouflaging of chameleons as the natural inspiration for the project. Dr Qiu said, "The skin of a chameleon is made up of several layers of specialised cells containing various pigment while the outermost layer is transparent...Our team's invention can be seen as an improved 'skin' for the chameleon such that it will become invisible when it appears in front of thermal and electrical signal detectors."

Dubai is banking on 3D printing in a big way. The country has announced their 3D printing strategy. The strategy is being enforced by Sheikh Mohammed bin Rashid Al Maktoum, the Vice-President of Dubai, who is confident that additive manufacturing is definitely the way to go when it comes to civil engineering.

In a statement, Al Maktoum said: "We implement what we plan, and we pursue actions, not theories. The rapidly changing world requires us to accelerate our pace of development, for history does not recognise our plans bout our achievements." And what exactly have they been planning that is now being implemented? A fully 3D printed office.

This is just the first in many presumptive projects, due to the fact that Dubai wants to be the world leader in additive manufacturing by 2030, as explained in their strategy. The strategy also details three key areas of focus in the 3D printing world: construction, medical products, and consumer products.

"We announce today the opening of the first 3D-printed office in the world, after less than a month of launching Dubai 3D printing strategy which showcases a modern model of construction. This is an experience we present to the world on implementing future technology in our lives, and it represents a new milestone for the UAE as a global leader in strategic achievements," Al Maktoum said.

The engineers who worked on the 3D printed office reportedly used a "special mixture of cement" and building material engineered in the UAE and the United States which allegedly cut labour costs by 50%. The building utilized mobile industrial printers which printed the building in 17 days after which minimal interior and exterior work was done in 2 days.

The office looks beautiful in and out and is being dubbed "the office of the future".

The Dubai government says the printing strategy they have outlined will inject $300 billion into the world economy by 2025.