News

Tomsk Polytechnic University has put their computer engineers to work to create an algorithm for surveillance cameras that will detect a face in a crowd of people in high resolution. Allegedly, the algorithm would be able to calculate the number of people in the frame, the gender and age of the people being filmed.

Ilya Kalinovskii, the developer of the algorithm and a Ph.D. student in the Department of Computer Engineering at TPU, said, "In order to detect a person on his face image in the crowd, like on stadium or in subway it is required to work with an image in scene with very high detail. 4K resolution is suitable for this purpose. Because of the large amounts of data, it is difficult to even store these videos not only to process them, not to mention intellectual analysis."

CCTV is being revolutionized by the 4K, ULTRA HD movement which has equalled better quality video which is better for businesses that would need to identify criminals and see all of the details. Monitors cost less as well which makes buying a UHD CCTV setup is becoming inexpensive. However, there is a problem of exporting the video to other sources due to the sizes of the recorded video. Advanced data storage will also need to be factored in for businesses who opt in for a 4K solution.

Security Electronics and Networks speaks about the technical part of it, saying that running a UHD setup has more to it than meets the eye:

If the sensors are large enough, the lenses are good enough, the light levels high enough, the network is capable enough and the storage sufficient, then Ultra HD cameras will give end users a lot more detail than 3MP 1080p cameras can. But this capability has to be balanced against many things. Image quality is about more than megapixel count.

Vlado Damjanovski, an employee of ViDi Labs when asked whether 4K is the next CCTV standard, he said, "My answer is yes and no. 4K is a known development in broadcast TV but CCTV is only a little sister of broadcast technology, and eventually follows its trends. But unless the technology trend is developed by the larger broadcast industry, its very unlikely CCTV will develop a whole new standard on its own. So yes, it is the next big thing, but not so big as some may want to think."

However, according to IFSEC Global, who focus on companies that utilize factories with production lines and anything in the industrial sector say that 4K could be useful in manufacturing plants. They say:

The number of pixels across the image required to cover the production line is 5,120. So in order to cover that area with HD cameras (delivering 1920 X 1080 pixels), you would need three cameras.

However, if you instead specified the use of Ultra HD 4K cameras (delivering 3840 X 2160 pixels) like the new Sony VM772R, you would be able to cover the whole production line and associated components with just two cameras

They also say it would help with accident claims from employees and would be able to cover both the employee and the business sufficiently. The case for 4K surveillance is becoming more apparent in the world of production line factories.

However, a report released this year named 'The top surveillance trends for 2016' by IHS (a company that generates statistics and provides information from surveys) says that 4K has not yet convinced anyone in surveillance industries. They say, of the "66 million network cameras predicted to ship globally" this year, only one percent of the sales will be Ultra HD devices.

It is estimated that Ultra HD will only be further into becoming the next standard of CCTV in 2018. Until then, if you have the hardware and data storage space for 4K surveillance, it could help you in identifying something that could save your business and its assets.

Australia Post is following in the footsteps of Amazon with intentions to launch a drone delivery system. The post office tested out a drone delivery in a 'closed-field' trial to test the possibility of implementing drone delivery in the future.

A prototype drone built with four rotors, what ABC is calling a "suction device" for the parcels and a cable to hold it in place as well. This is a little different than Amazon's "clamp-on" system that its drones have. Australia Post says their drone is able to lift packages of up to 2.65 lbs.

The hope is that by the end of 2016, at least 50 Australia Post customers will receive packages via drone twice a week.

Australian Post chief executive, Ahmed Fahour, said, "The project was about complementing, not replacing, the way parcels were delivered. Just like vans, trucks, and aeroplanes, they didn't replace what we do."

However, Australia Post might have a host of other drones to fly around to get their parcels delivered due to new drone laws.

The trial seems to have happened quite soon after drone laws were tweaked, making drones available to commercial operators. According to Ten News, soon Australians will not need licenses to fly drones but only a certificate of registration from the Civil Aviation Authority.

Peter Gibson of the Civil Aviation Safety Authority, said, "People who want to fly drones commercially; if their drone weighs less than two kilograms they will now face less red tape, fewer costs..."

The Sydney Morning Herald is reporting that only 10 percent of Australians want drone delivery at all, which is not a big percentage. So maybe some convincing is needed.

Regardless, Fahour is insistent that drone delivery will form part of Australia Post soon. He said, "We're exploring the viability of adding this to our multiple methods of delivery. We're pretty confident that if we can get through this [trial] we'll be able to offer this experimental service towards the end of this year."

Engineering students from Zakir Hussain College of Engineering and Technology in Aligarh, India claim to have an answer to doing blood tests without the needle prick that some people fear. This was achieved reportedly using electrical properties of blood cells that to successfully count red blood cells (RBC) and white blood cells (WBC).

The researchers have used a laser that will count the blood cells when placed on superficial veins and according to HindustanTimes, the lower lip is one of the best areas of the body for this.

The students say this will be the first time blood tests are performed without a needle prick being necessary.

Rohan Maheshwari, the leader of the four students behind the new innovation, explained how it works:

Once the data is collected it will be transferred to software that analyses and compares the blood cell count with the standard data. Using the concept of cloud computing, the software will send a text message to the patient's phone. If it detects some considerable deviation, the doctor concerned will recieve the acquired data. The doctor will be able to treat the patient from home and notify the pharmacy about the prescribed medicines that have to be delivered to the patient's home

The students also walked away with the winning prize money at the GE Eidson Challenge 2016.

The prototype was also applauded for its other medical benefits it could provide in the future of biomedical care. A gynaecologist, Dr Jyotsna Mehta said, "Increase in the WBC count is indicative of acute bacterial infection. The prototype can be of great help in detecting such infections."

The Global Foundation for Ocean Exploration has taken to Kickstarter to try and crowdfund a project that would see a team of engineers building an underwater robot to explore Yellowstone Lake. Yellowstone Lake is the largest freshwater lake above 7,000ft in North America.

The leader of the team Dave Lovalvo, a keen ocean and large lake explorer for the last thirty years now wants to take on the lake. The team he presides over already has a robot called the Deep Discoverer robot. He has already sent a robot into the lake before in the '90s but now they are starting a new project.

Talking about the team he set up, Lovalvo said:

So I started the foundation. I made the commitment to build a team of young engineers who are passionate about this - as passionate as I was when I first started. In the last year the foundation has grown signficantly. We have mechanical engineers, we have electrical engineers, we have software engineers, we have video engineers.

Lovalvo's stance is that the only way to preserve Yellowstone Park is to study and understand it and that also involves studying the lake. The team say they need $100,000 in crowdfunding to make the robot happen, with a donor that will match every dollar that comes in.

According to TreeHugger, "the geothermal activity of Yellowstone creates an ecosystem that consists of a variety of organisms that exist nowhere else on Earth."

Once the Yellowstone project is complete, they will continue to use the robot to survey other lakes and oceans so that they can be studied.

To contribute to the Kickstarter campaign:

Researchers at the Missouri University of Science and Technology have invented a 3-D microwave video camera. The team says the camera would be able to conduct industrial inspection and security screening. The camera operates at 20-30 gigahertz and uses non-ionizing electromagnetic waves which are not harmful to humans.

Talking to Missouri S&T News, Dr. Mohammed Tayeb Ghasr, assistant research professor at Missouri S&T, said: "It's like an airport scanner but much smaller. It's portable, so it can be used on-site wherever it is needed." The microwave 3D camera can take photos and produce high resolution at 30 frames per second.

Ghasr has expressed his confidence in the camera and it said it could even serve a purpose for first responders in the medical field. He spoke of how a first responder could take photos of a burn victim and they would be able to determine the severity of the burn.

The researchers are also confident in its ability to find contraband within covered up compartments like bags that go through airport terminals. The portability of the camera compared to current cameras in airports might make this particular camera quite popular in the future.

The camera is ideal for inspection of composite structures that are increasingly used in the transportation, infrastructure, space, aerospace and other similar industries. Because microwave signals can penetrate non-metallic materials, this system is expected to find signficant use in inspecting ceramics, fiberglass, plastics and high-density polyethylene pipes

A company from the United Kingdom named Renewable Energy Systems (RES) has published what they say are five lessons they have learned since investing a lot of their time and money into energy storage involving lithium-ion batteries. The company has experience with solar and wind technologies but in 2014 started using lithium-ion in Ohio, in the United States.

1- Controls and monitoring are essential to ensure safety and maximise value for owners

2 - Integrated solutons are essential for cost-effective design, sucessful operations and commercial simplicity

3- Financing a large-scale battery storage project is possible

4- Regulations and (the lack of) market rules continue to create unceratinly, which places additional burden on the early projects

5- Long-duration lithium-ion is becoming viable

- Extract fom Five lessons from the storage frontline

The company says the lack of control and monitoring will lead to battery fires and that is the last thing the industry needs right now. The list of lessons should be a good checklist for other companies interested in getting into the lithium-ion game.

However, is lithium-ion the only sustainable element we could use for sustainable energy storage?

Canadian Manufacturing has reported that vanadium is another element that could be used to build sustainable batteries in the future as well.

Tim Hennesy, president and COO of vanadium battery maker, Imergy Power Systems Inc. said: "Vanadium is the only metal on the planet which can act in its own right - just as one metal - as a complete battery. Every other battery you need two elements...to create this difference which allows a battery to exist."

Another company involved in vanadium is Australian Vanadium (AVL) that in collaboration with Gildemeister Energy Storage will be selling a product named the CellCube. It is a vanadium redox flow battery.

AVL managing director, Vince Algar, told CleanTechnica, "The future of vanadium demand is strongly tied to the global need for large-scale energy storage."

The distinction that must be made is that vanadium batteries cannot power devices like laptops or cell phones like lithium-ion can. However, for large-scale energy generation, it is used because it can be recharged thousands of times without dying like lithium-ion batteries. The only issue is "low energy density". Could lithium's reign but over soon when engineers figure out how to utilize vanadium for commercial purposes?

More news as this story develops .

Engineering salaries are on the rise according to industry players publishing new reports. The Economic Research Institute released a list of jobs in engineering that seemed to have gotten pay raises from 2014-2015.

The results of the national salary increase:

- Electronics and computer engineers - salary raise of 8.31%

- Mechanical engineers - salary raise of 7.38%

- Quality engineers - 7.36%

Meanwhile, StraitsTimes is reporting that in Singapore, the starting salaries of engineers in the public service sector will see a 20% hike. They explain this by indicating that currently the engineers make $3,800 a month, but that will rise to $4,000 per month, especially in the information and communications technology industry.

Deputy Prime Minister Teo Chee Hean, who introduced the new hikes, said: "Salaries for engineers and ICT professionals vary across public agencies today. Some are already paying salaries that are largely competitive with the market while the salaries in other agencies lag significantly. In specific areas, we will pay a premium for engineers with skills that are in high demand and short supply such as cyber forensics and malware analysis, or those with niche skills that are critical and specific to the Government but for which there may be little market demand."

Richard Zambacca, president of HR company Randstad Engineering, said: "As a lot of industries are growing, the demand is rising and everybody's competing for a lot of the same talent. Experienced people definitely have a chance for higher wages."

The future of robotics is in the hands of the engineers currently working in automation and the children who are interested in pursuing a career in robotics. Moscow hosted Robofest 2016, which saw a host of young, budding, engineers show off their robots. From shirt folding robots to rough-terrain navigating robots, the event looked to be a treat. Here are some of the highlights thanks to RT:

According to RT, the robotics conference included:

- 3500 school children

- 1000 engineering teams

- Winners represent Russia at robotics competitions in the US, Europe, and Southeast Asia

- Ages 6 to 30

LG Electronics in collaboration with Korea Water Resources Corporation (K-Water) are taking solar to the seas. Okay, maybe just dams and rivers for now. The two are actively conducting research into floating solar power generation technologies. The companies have signed a memorandum of understanding at the K-Water HQ in Daejon according to BusinessKorea. They will utilize engineer employees to invent solar-water technologies in hopes that it will generate energy.

Their main aim is to build floating solar power panels that would be placed in seas, dams and open bodies of water to hopefully catch some sun. BusinessKorea says that solar power generation "is known to have about 10 percent higher energy efficiency compared to land solar power generation" due to the cooling effect that water has on a solar panel. The solar panel is kept cool by the water and does not consume as much land as land-based solar panels.

Part of the agreement stipulates that the companies must create an energy storage system together, must open water purification plants and a tidal power plant, among other small businesses that they must open as well.

President of K-Water, Lee Sang-bong, said: "Solar energy generation is one of the best systems that can create synergy with diverse water resource at reservoirs, dams, and beaches. We will push ahead with the global energy market with K-water."

In a recent video published by TechInsider, a floating solar farm in a reservoir outside of London was shown off by Thames Water. The claim by TechInsider is that they pay $144 million for power in London but the new solar farms could cut $28 million off of that bill.

Payscale has released their 2015/16 College Salary Report which takes a look at the highest paying graduate degrees by salary potential. The report focuses on graduates who have made it into their respective industries and reported back with the kind of money they are getting. The report factors in MBA, non-MBA masters' degree majors, bachelors' degree major and associate degree majors, according to the official Payscale website.

Here were the results of the highest paid positions:

| 1) Petroleum Engineering |

Degree type: Master's Early career pay: $96,500 Mid-Career Pay: $173,000 |

|||||||

| 2) Nurse Anesthesia |

|

|||||||

| 3) Strategy |

|

|||||||

| 4) General & Strategic Management |

|

|||||||

| 5) Finance & Real estate |

|

|||||||

| 6) Electrical & Computer Engineering (ECE) |

|

|||||||

| 7) Computer Engineering (CE) |

|

|||||||

| 8) Chemical Engineering |

|

|||||||

| 9) Biomedical Engineering (BME) |

|

|||||||

| 10) Economics |

|

|||||||

| 11) Economics |

|

|||||||

| 12) Finance & Economics |

|

|||||||

|

13) Electrical Engineering |

|

|||||||

| 14) Organic Chemistry |

|

|||||||

| 15) Computer Science (CS) & Engineering |

|

The fact that engineering factors quite a lot in the report is not surprising as the world continues to rely on the work of engineers. Petroleum engineering seems to be a lucrative career. "No matter what degree level you obtain in petroleum engineering, you'll probably have an easy time finding a high-paying job. It just depends on how much time you want to spend in school," Payscale says.

What are the lowest paying jobs for people with a master's degree? Payscale also worked that out:

- Early childhood education ($60,000)

- Library and information science ($57,100)

- Music ($56,900)

- Social Work ($67.900)

- Counseling ($52,300)

Good news for engineers in the piping industry. CAD Schroer, a 3D plant design software company has released a software called M4 ISO that would assist with the process. Also known for their MEDUSA4 software, the company gives mechanical engineers the ability to develop designs for practical uses in the industry.

The new program assists engineers with pipework fabrication, creating drawings with Creo 3D geometric data. If you already use PTC Creo Piping, fear not, M4 ISO is able to plug straight into the program.

PTC Creo Piping's software has many positive attributes. This is what happens

- Minimize errors and reduce time-consuming tasks by automating the capture of all relevant system information, such as the schematic design, virtual prototype, or manufacturing documentation

- Fully automate your routing so you can quickly determine the optimum path for manufacutring, cost, and serviceability

- Increase design speed through the reuse of standard symbols, connectors, and fitting contained in customizable library

- Reduce costs and design time by eliminating the need for physical prototypes, made possible through virtual interference checking and automated manufacturability verification

Talking about the new M4 ISO program, Mark Simpson, the product line manager at CAD Schroer, said that the software can accurately depict pipe spools "of all sizes, lengths and complexities on a single sheet." He added, "The advantage of our solution is that the Creo Piping user can, at the touch of a button, immediately obtain complete and detailed piping isometric drawings for either all or a selection, of the pipelines. Although one does not see a lot of M4 ISO, it delivers excellent results. All of the drawings, bills of materials, tube cutting lists etc. are made available in the blink of an eye, and they can be passed on to the production domain."

There also piping templates - which can also be modified - available to engineers so they don't have to draw from scratch. The software instantly makes the engineer's job easier and gives the entire team an accurate 3D documentation of what the piping network should look like and ensures safer practices by an entire team.

Lithium carbonate has gone from costing US$6,000 per metric tonne to US$14,000 in the last six months. These revelations from Breitbart News, who have investigated lithium prices since Tesla erected a US$5 billion factory in the Nevada desert causing markets to speculate on shares. The recent announcement of the Tesla model 3 also alerted the market that lithium is becoming important to consumers due to the 300,000 orders Tesla received on the back of the announcement.

Goldman Sachs has investigated lithium prices as well in their Emerging Market Radar report that makes the bold statement that: Lithium is the new Gasoline. The report states: "These unique properties [lithium as the lightest solid element on earth] ideally position it for portable energy storage applications that will be a key enabler of the electric car revolution and replace gasoline as the primary source of transportation fuel."

Elon Musk, CEO of Tesla, says the demand jump for the Tesla vehicles is staggering due to the spike in orders. Tesla only produced 50,000 cars last year, and now 300,00 orders for the Model 3 is piquing the interest of engineers everywhere. Musk says, "In order to produce a half million cars per year...we would basically need to absorb the entire world's lithium-ion production.

The Economist wrote about the "global scramble" that is hiking up the cost of lithium, proving that much like finding gold, lithium is on the top of industrial producers' lists of things to obtain.

2015 was a landmark year for liquefied natural gas, industry groups confirmed this week. According to the Houston Chronicle's Fuel Fix, Australia, and Indonesia are behind the rise in sales due to the shipments to Europe and the Middle East.

LNG shipments reportedly grew by 2.5 percent to 245.2 million tons per year in 2015. The stats come from the International Group of Liquefied Natural Gas Importers (GIIGNL). However, 2016 is not reporting as strong numbers in the first quarter of the year, but GIIGNL does not seem detered by the figures and are ready to report even more imports than last year.

CNBC is reporting that prices have hit an 18-year-low in the LNG market.

Graeme Bethune, chief executive of consulting firm EnergyQuest, spoke to CNBC, saying, "Cleaner and greener are part of it; lower prices are part of it. The other important part of it is also energy security."

GIIGNL president, Domenico Dispenza, said: "In a global context of lower energy prices and sluggish economic growth, the LNG industry is holding its breath for the impact of an export wave from the United States."

However, through the slump, companies are confident that new customers are on their way. Chairman of the French Gas Association, Jerome Ferrier, said: "We are seeing countries with a long...tradition in consuming and producing coal moving to natural gas."

OilPrice.com is more grim about the situation, however. They led with a headline saying: Why LNG Markets Might Not Balance Before 2025 . The website says the worldwide interest in LNG liquefaction capacity is reminiscent of "gold rushes" of the past. Wim de Vriend, who wrote the article over at OilPrice says LNG markets are reporting that the first 100 million tonnes per annum of production happening right now is expected to be absorbed by 2020. However, De Vriend thinks that is an unrealistic goal and cannot be done until at least 2025.

Who to trust? Who is right? Who is wrong? Only time will tell in LNG markets as business both looks positive and negative.

MIT is researching new methods of how to produce medicines more efficiently in case of disease breakouts that require mass amounts of pills to be dumped and would act as a portable assembly line for creating new drugs on demand.

In a new report named On-Demand continuous-flow production of pharmaceuticals in compact, reconfigurable system written by a host of engineers at MIT, "a fridge sized box" is reportedly the next step into meeting these goals.

In the abstract, the team writes:

Commodity chemicals tend to be manufactured in a continous fashion. However, the preparation of pharmaceuticals still proceeds batch by batch, partly on account of the complexity of their molecular structure. Adamo et al. present an appartus roughly the size of a household refrigerator that can synthesize and purify pharamceuticals under continous-flow conditions. The integrated set of modules can produce hundreds to thousands of accumulated doses in a day, delivered in aqeous solution

Producing pharmaceuticals is currently a long process due to the amount of chemical engineering that occurs at more than one venue. If there are any problems at any of the plants where pharmaceuticals are manufactured, it can slow the process down.

The researchers at MIT say that in the future this will not be a problem if their self-contained assembly line gains popularity. According to TechnologyReview.com, the machine can currently produce Benadryl, Valium, and Prozac. For now, these are the only drugs that will be accommodated due to the U.S. Defense Department funding the project, ensuring that only drugs available in Medic pack's would be available.

Klavs Jensen, a professor of chemical engineering and materials science and engineering at MIT is confident batch processing with continuous-flow technology is the way forward. He emphasized the cost benefits to making them with the machine, saying it would be far more economical. Jensen says, "The goal of this project was to build a small-scale, portable unit that was completely integrated, so you could imagine being able to ship it anywhere. And as long as you had the right chemicals, you could make pharmaceuticals."

Allan Myerson, an MIT professor of the practice in the Department of Chemical Engineering said: "Think of this as the emergency backup for pharmaceutical manufacturing. The purpose is not to replace traditional manufacturing: it's to provide an alternative for these special situations."

Australia continues to impress with their advanced stance on energy storage and how it will be factoring into the future of energy generation. The Australian Renewable Energy Agency (ARENA) has announced two solar+storage projects for residential areas in Western Australia.

According to PV-Magazine, 170,000 households have rooftop photovoltaic energy solutions installed in Western Australia as of this year. In Perth, ARENA is once again backing energy storage by introducing a new energy storage solution to an entire suburb. A housing estate called Alkimos Beach will see 100 PV systems with a 1.1 MWh lithium-ion battery connected to their rooftops. The project cost ARENA AUD$3.3 million.

ARENA CEO Ivor Friscknecht told PV-Magazine: "Combining community-scale battery storage and rooftop solar presents a win-win for energy retailers, developers, and consumers and can provide households with the benefits of storage without on-site installation and maintenance. Solar will work alongside battery storage to lower Alkimos Beach's demand for electricity from the grid. This model has the potential to offer residents cheaper electricity bills and reduce grid connection costs for future new developments."

Australian company Redflow recently announced the ZCell battery which would be a competitor to the Tesla Powerwall in the country. However, it seems the order of the day for energy storage in Australia is not to completely jump off of the grid but rather to preserve energy on the grid that could see some protection for the power utilities in the country who are not working on energy storage solutions.

A robotic kangaroo that emulates actual kangaroo jumping is now being previewed at a worldwide automation company, Festo. The kangaroo isn't the only thing they are showing off. They have also just previewed a spherical, blue bottle looking bottle dispenser. The videos below speak for themselves, but Festo seems to be wanting to show off what they have created and fantasize about the future of robotics among us, whether these robots assist us or not.

The delivery drone is reportedly filled with helium and - as is apparent in the video - controlled through a host of propellors that seem to smoothly move the sphere around space, navigating with GPS and cameras. It then laps up an object with a 'tongue', stores it inside the sphere and then carries the object and deploys it when it has reached its destination.

Then we get to the robotic kangaroo the company has made. The robot jumps around with 2 motors for the hips, one motor for the tail, a high-pressure accumulator, a compressed air reservoir for keeping the neck and back in place, a sensor system and a CECC control system and a whole bunch more stored within its shell of a body. It is all explained in the video below. The more important part of the video is where a human controls the robots actions through an Internet of Things wristband that connects to the robots network and gives it commands on what it should be doing.

Festo will be showing off its new range of robots at the industry event of the year Hannover Messe. But if this is the first preview of what Festo has up their sleeve, a robopocalypse is looking more likely before the end of 2016.

The Air Force Research Lab in the United States has asked engineering students to assist them in creating gloves that would simplify the process of abseiling (or 'fast rope') out of helicopters on ropes.

According to the NorthlandNewsCenter in the U.S., the Air Force says the gloves that already exist suffer from too much friction heat.

Air Force Major, John Zimmerman, said: "You put a guy my size on a rope with 150 lbs on my back, 20-90 feet in the air. That's a lot of energy that has to be dissipated before I hit the ground." The Air Force decided to make it a nationwide competition called the 'Air Force Design Challenge'.

Therefore, the University of Maryland went to work and got a team together to work on a product they could potentially sell off to the Air Force. What they came up with was something they're calling the 'Pyroglove'.

The project manager of the team, Ryan Farrely, said: "We wanted something that was simple, that wasn't going to break when someone steps on it." The design team manager, Nick Tokar, showed the glove off. The glove consists of "insulated pads" that are in the palm of the hands and will prevent any burns when grabbing rope up to 44 millimetres in width.

Zimmerman is optimistic about the invention, saying, "Getting that glove in the hands of battlefield airman who are at the tip of the spear could be a game changer. And giving them the ability to safely get down the rope, dissipate the heat and immediately engage without having them fumble and get their gloves off is a game changer."

Self-healing concrete might soon be a reality. In October, in 2015, researchers at Cardiff University were attempting to formulate the concrete in Wales. By November, the team was testing three different kinds of self-healing concrete formulas. The team intends to make a case for building with self-healing concrete around the world that could repair itself when damaged .

So...autonomous concrete?

Professor Bob Lark, the principal investigator for the project at Cardiff University's School of Engineering, said, "These self-healing materials and intelligent structures will significantly enhance durability, improve safety and reduce the extremely high maintenance costs that are spent each year. The major trial, the first of its kind in the UK, will provide us with important insights to help transfer the technologies from the lab into the real-world settings."

A year later, the idea of self-healing concrete is so appealing an idea, the University of Victoria in British Columbia is also trying their hand at creating it.At the steering wheel of the team is Professor Rishi Gupta. According to ConstructionDive, the team is looking at concrete that would heal the cracks in but is also trying to make a crack-free concrete that would last longer than the current standard.

Also speaking to PHYS, Oliver Teall, a civil engineer at Costain, said: "We are supporting this innovative research to unlock the many potential benefits of self-healing concrete for use within the infrastructure. From this trial, we should gain an insight into the feasibility of constructing a full-scale structure using these techniques and their early-stage effects on structural properties. We will be monitoring properties such as stiffness, permeability and the mechanical damage recovery of the trial walls in comparison with conventional reinforced concrete walls."

Zhenan Bao is a professor of chemical engineering at Stanford University who is on a mission to invest the next-generation of artificial skin that would be able to act like normal skin. The research team from Stanford is using the idea that when a fingertip touches something it transmits a signal to the brain, and then trying to mimic that process with an artificial material that could replicate the process.

"In my lab, we are trying to understand how we can design organic electronic materials. The current electronic devices are rigid, but in the future, we want to make them flexible, stretchable biodegradable and self-healable, just like human skin," Bao said.

One of the teams aims is to give patients who have prosthetic limbs, the sensation of skin reacting to something that has touched it through the organic electronic material. The piece of material looks like a piece of plastic but Bao says that the electrodes can turn the touch signal into electrical pulses.

The team also researched how to make the plastic slivers heal once they were scratched. Bao told NPR, "Some repair very quickly, with a minute, some take hours or days to recover. But now we also have a new version that can stretch to eigh times its original length.

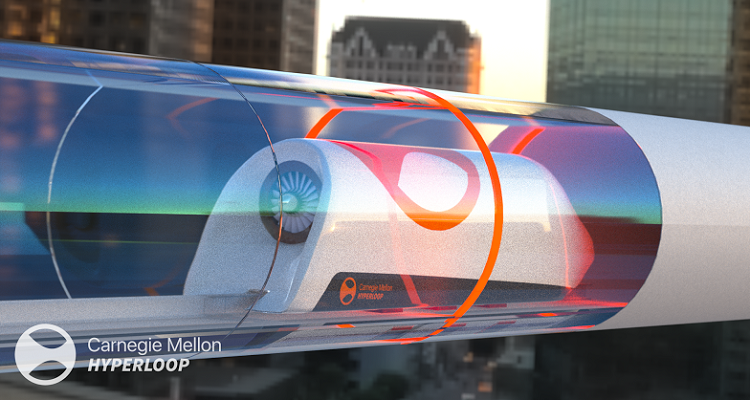

Carnegie Mellon University students have made it to the final round of the SpaceX Hyperloop competition. In January 2015, 100 teams made their way to Texas A&M University to pitch their designs for the case of engineering a super-fast form of public transportation. Now, a year later, they have been whittled down to 22 semi-finalists, after 1,500 student engineers and engineering teams who were up for it thought about the future of public transport.

On the 14th of April, the students will be showing their designs off in hopes that CEO of SpaceX, Elon Musk, will crown a winner and move forward with building the Hyperloop.

"We do need sponsors to help fund building and transporting it," says Rahul Iyer, who is working on corporate sponsorship and development for CMU Hyperloop. "The information reception will give us a chance to see what we're working on and how far we've come, but also to see if we can attract more sponsors," he told NextPittsburgh.

The team working on the project consists of 75 members that are all in engineering, designing or business roles in their lives outside of the Hyperloop team.

The team's final design looks like a pod that would move through a tube. "It's a really low-pressure environment, and the pod essentially levitates in the tube, kind of like a puck on an air hockey table," says Iyer, talking to NextPittsurgh.

The Daily Mail reported that the Hyperloop would cost between US$200 to $300 million and would be past its first stage of completion in 2020. The speed they are trying to reach is 745mph (1,200km/h).

Courtesy: Carnegie Mellon University - High speed pod design

The most sustainable building in the world has been crowned. Who decides these kinds of things, you ask? The Building Research Establishment Environmental Assessment Methodology (BREAAM) has said an office building in Haelen, in the Netherlands, has won the award and scored 99.94 percent on their rankings.

Now you can change your offices accordingly so that it might compete for the most sustainable building of all time.

According to Gizmodo, the building has a solar power system that produces 50 percent more energy than the building consumes. The building is made from wood and was designed to deliver the best "daylight infiltration and air quality".

Engineering and Technology Magazine said it has been made with the health of employees in mind. They spoke to Sander Geleen, managing director of Geleen Counterflow, she said, "So when we build a new office it only makes sense to respect these laws and limits of nature, too. This office another step on our journey to phase out fossil fuels. The next step is to develop a new generation of dryers that will use renewable energy only."

Timber is becoming quite the sought after material in terms of building office space. A wooden skyscraper has been presented to the Mayor of London, Boris Johnson. It would be 80 storeys and stretch 300 metres high. Dr Michael Ramage, director of Cambridge's Centre for Natural Material Innovation says, "The fundamental premise is that timber and other natural materials are vastly underused and we don't give them nearly enough credit." This on the back of revelations from the steel industry that is currently struggling in Britain. Does your office space line up with sustainable practices? If not, perhaps it will soon as the world moves towards sustainable workplaces.

Timber is becoming quite the sought after material in terms of building office space. A wooden skyscraper has been presented to the Mayor of London, Boris Johnson. It would be 80 storeys and stretch 300 metres high. Dr Michael Ramage, director of Cambridge's Centre for Natural Material Innovation says, "The fundamental premise is that timber and other natural materials are vastly underused and we don't give them nearly enough credit." This on the back of revelations from the steel industry that is currently struggling in Britain. Does your office space line up with sustainable practices? If not, perhaps it will soon as the world moves towards sustainable workplaces.

A rare incident left NASA's aerospace engineers scratching their heads. The Kepler spacecraft in charge of finding new plants went into what NASA calls, 'emergency mode'. Allegedly the mode only switches on when it goes through some sort of turmoil and as a result, according to ArsTechnica, "limits its activity and burns through the probe's limited fuel supply at an accelerated pace."

NASA's official website reported that mission operation engineers had successfully recovered the spacecraft from the Emergency Mode and also saved the amount of fuel it was starting to burn through.

On Sunday morning, the spacecraft reached a stable state with the communication antenna pointed toward Earth, enabling telemtry and historical event data to be downloaded to the ground. The spacecraft is operating in its lowest fuel-burn mode.

Kepler was supposed to perform a maneuver to line up with the center of the Milky Way but entered Emergency Mode fourteen hours before it got the chance to. NASA says this is the first time in seven years in space that the spacecraft has gone into Emergency Mode or performed strangely. In a statement, NASA said:

It was the quick response and determination of the engineers throughout the weekend that led to the recovery. We are deeply appreciative of their efforts, and for the outpouring of support from the mission's fans and followers from around the world. We also recognize the tremendous support from NASA's Deep Space Network, managed by the Jet Propulsion Laboratory in Pasadena, California, and to NASA's other missions that surrended their scheduled telemtry links in order to provide us with the resources needed to protect the Kepler spacecraft.

Now the task of figuring out exactly what forced Kepler into it's Emergency Mode must happen through logging into the spacecraft now that communication has been reestablished.

Perhaps, aliens don't want us to find their home planets? Who knows what might have sent into Emergency Mode but at least they got it back. A win for aerospace engineers.

A sixty-six-page report by the Institution of Mechanical Engineers, with support from the Royal Academy of Engineering, has told schools that they should be encouraging students to pursue STEM careers. The groups say the renewed call for schools to get behind making STEM appealing is because the United Kingdom is experiencing a shortage of engineers. The report is called Big Ideas: The Future of Engineering in Schools.

The report says, it is their belief that "by working together to get children immersed in STEM subjects from an early age," they can fill out more engineering jobs in the future.

Professor John Perkins, CBE, and part of the Royal Academy of Engineers - in the foreword to the report - said, "Of course, this is by no means a new goal, but there is a growing awareness that more radical approaches will be needed if we are to achieve the step change in supply that all involved agree would be desirable."

Stephen Tetlow, the CEO of the Institution of Mechanical Engineers and one of the authors of the report says, "Demand for engineering skills is growing, as big projects such as High Speed 2 and new nuclear initiatives come closer to becoming reality, alongside exciting innovation in less traditional mechanical engineering such as the expanding medical sector."

The Nitty Gritty

Tetlow says the UK as a whole needs more engineers due to the skills shortage costing them more than US$38 million per year.

Peter Finegold, one of the lead authors and head of education and skills at the Institution of Mechanical Engineers says that the skills shortfall is happening at a very important time due to how far technology is progressing past human skills. He added, "Our schools need to adjust to this reality, both by increasing the number and breadth of young people choosing engineering careers, and by empowering those who do not. This means ensuring that primary school children are taught not just about the natural world but also taught about the manufactured world too."

Boeing rival, Airbus, is reporting that the first quarter of the year wasn't a good one for them. The company is saying the slump they have found themselves is the slowest start to the year compared to 2011. Airbus was also said to be retrenching some of its aerospace engineers from within in the country in February.

According to Reuters, Airbus reportedly only made 32 aircraft sales and delivered 125, which equals to 74 percent down compared to the same time last year. Airbus were also unable to sell two A380s superjumbo jets, which would have seen an 840 seater plane make its way to commercial passenger flights. Known as the "flying sardine cans," the planes would have been sold to Air Austral but the order fell through and was cancelled. However, they did receive two orders from - what Reuters is calling - an 'undisclosed customer'. So, soon you could be flying in an A380 with 839 other passengers.

According to Bloomberg, the 125 Airbuses that were delivered to customers this year pales in comparison to the 176 aircraft that Boeing have delivered, showing who has won the first quarter of the year.

However, Boeing has also said they expect to be in a slump very soon as they look toward implementing a new model of plane.

To make matters even worse an Airbus 320 belonging to Air India fell out of the sky during an alleged training center fly by.

Industrial network security is a rapidly growing problem. It impacts on all of us - ranging from the president of a company to the electrician or tech installing a PLC or instrument. Although, everyone is shrieking about the desperate shortage of cybersecurity experts and lack of training; this does not appear evident in job adverts or requests for training in this area – but that is a topic for another day...

Dear Colleague

Industrial network security is a rapidly growing problem. It impacts on all of us - ranging from the president of a company to the electrician or tech installing a PLC or instrument. Although, everyone is shrieking about the desperate shortage of cybersecurity experts and lack of training; this does not appear evident in job adverts or requests for training in this area – but that is a topic for another day.

However, we have all been exposed to hack attacks and viruses and are very much aware of how tough it is out there protecting your industrial assets. In the future, security will be one of those metrics that you talk about in the same breath as safety and quality.

What is Happening

What is the evidence for a growing challenge with cybersecurity? There a number of things coming to a head with the inevitable “Perfect Storm” resulting. These are:

1. Internet of Things

The Internet of Things (IoT) is rapidly growing with a huge 50 billion smart objects connected - all appearing in the next decade (the Fourth Industrial Revolution). These are all connected with networks in applications ranging from your car, home to factory. Easy prey to a hacker wanting to access valuable know-how and having the ability to cause ferocious damage to you and your business.

2. Connectivity is the new Must-Have

Connectivity from the industrial plant to the internet was scorned a decade or so ago. The “air gap” firewall (i.e. no connection) was the dominant form of protection. However, today – everything is being connected to the internet so that information can be accessed anywhere. The insidious price of progress.

3. No longer is there the wonderful Obscurity in Industrial Networks

Industrial networks used to have proprietary standards making it difficult to break into. Nowadays, everything is based around Ethernet or Wireless which are considerably more universal, well known and accessible.

4. Cloud Computing is the Name of the Game Today

Cloud computing is rapidly becoming the technology everyone is basing their offices and now industrial plants around. Before, at least you had your industrial networks reasonably hidden behind a firewall – now – unfortunately, you are considerably more visible as your traffic has to traverse a far more public network.

Security must be designed in from the get-go

No longer is security something you add in once you have installed the system. It must be a key attribute built into the initial design. Concepts such as security in depth – what do you do when the hacker gets through your first line of defence? - are all concepts which are key to the overall design.

Consideration of security of the overall system and the individual components are also key elements in a good design.

Where do you find Cybersecurity Experts?

The other challenge with finding people to work on projects here is that most people with cybersecurity skills are focussed on office or commercial IT networks rather than industrial. There are subtle differences between the two types of networks – such as the speed of response on an industrial network needs to be of the order of milliseconds as against that of commercial networks where an email message can take minutes before anyone gets uptight about delays.

Cybersecurity will touch you soon

I believe (as with renewable energy issues) that understanding and working with cybersecurity will be a key skill everyone working in industrial plants needs to have.

Start building your skills and know-how today by actively looking around and learning about the topic. It will touch you sooner or later.

Thanks to Terry Costlow of the IEEE for an interesting article on web connectivity and security.

James Scott makes a good point: “There’s no silver bullet solution with cyber security, a layered defense is the only viable defense”

Yours in engineering learning

Steve

Mackay’s Musings – 12th April’16 #595

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

Another day, another concern for autonomous cars. At the end of the day, the policy makers of the world are the ones who are going to be allowing autonomous cars to take to the streets globally, and the fight is heating up.

Dr. Ian Noy, a policy maker in the Canadian government has expressed his distrust in autonomous cars. He said, "There's no factual basis for the claim that autonomous cars will prevent 90% of traffic accidents." According to Globes, Noy was a guest at the annual Or Yarok safety convention. Noy is also a civil engineer who focused on safety and transportation during his career.

The claim had originally been made back in 2015 that autonomous cars would equal fewer accidents on the world's road. The claim was made by the ENO Center for Transportation, that pointed out in June 2015, thirty-two thousand people had died in car crashes with driver error believed to be the main reason. Ryan Haggeman is a civil liberties policy analyst at the libertarian advocacy organization Niskanen Center and had advocated for self-driving technology in 2014. He said, "In theory if you have 100 percent fully autonomous vehicles on the road while you still might have accidents on the margin in rare situations, you're basically looking at anywhere from a 95 to 99.99 percent reduction in total fatalities and injuries on the road." (Source: TechTimes).

Noy has now rejected these notions in 2016, saying, "If only that were true. But the truth is 'human error' is the default explanation for every accident. It's what police officers and accident investigators write on their reports because they cannot prove the cause, not because facts show a misjudgement by the driver."

Noy has a point, due to the recent Google Volvo that caused a crash between itself and a bus, leading to an entire hearing in Congress as the option of self-driving cars is weighed in America as a whole.

Enter: Ford's self-driving, see-in-the-dark car.

In a project called Project: Nightonomy, Ford enters the gauntlet of companies trying to create the next self-driving, safe, vehicle. Jim Bride, Ford's technical leader for autonomous vehicles, says, "To do something as ambitious as making a car drive itself, you need lots of testing and lots of places so you can cover all the scenarios you might ever expect to see."

One of the more complex issues for self-driving cars was the ability to see in the dark and drive in the dark. It seems that Ford is nailing the ability to do that and could be saving people those risky night trips of driving in horribly dark areas, thereby making autonomous cars even safer - statistically - and making the case for cars that save lives.

Researchers from the North Carolina State University and the U.S. Army Research, Development & Engineering Center have developed something that sounds like it comes out of Call of Duty: Advanced Warfare. They allegedly built a "super-strong" foam that would protect anyone who wears it from bullets.

The layer of foam introduced by the researchers is said to be unheavy due and is possible through "composite metal structures" abbreviated as CMFs that ensures its light-weightedness. The video the researchers have released shows an armor-piercing bullet being fired at the foam and obliterating the bullet to nothing more than dust. The 'armor' is just an inch thick.

According to WashingtonNewsWire, the foam is composed of a "blend of fired strike confront, a center layer of CMF and a Kevlar backing."

The man behind the metal foam is Afsaneh Rabiei, a professor of mechanical and aerospace engineering at N.C. State and has spent quite a few years testing out the CMFs. He says, "We could stop the bullet at a total thickness of less than an inch while the indentation on the back was less than 8 millimeters."

The research team says the CMF plating has many uses that would include space travel, transporting of nuclear waste and the obvious kevlar to protect people in the military. Allegedly, the CMFs can also function in high temperatures and block x-ray, gamma-ray, and neutron radiation, according to Discovery News.

Robogals is an organisation that tries to recruit females into the STEM (Science, Technology, Engineering, Mathematics) industry by letting them complete complex projects in robotics during secondary school across Australia, the United Kingdom, Europe and the United States. There was a workshop in Toronto last week that saw the girls break down the stereotypical image of what an engineer looks like.

Vice President of Robogals Newcastle (Australia), May Hane, said, "If you ask someone to picture an engineer, many people will picture a big dude in a hard hat and overalls." The Newcastle University hosted the workshop that was held in the Toronto Library for girls aged 10 to 14.

Hane said, "The team believes that every girl deserves an opportunity to explore and strengthen their science, mathematics, and robotics side, whether they are at school or not." She pointed this out due to - for the first time - the attendees were all either home schooled or long distance educated girls.

Watch the girls in action:

"We start the workshops with a five-minute presentation explaining what engineering is, how we do it, and what it involves. We tell the girls that in Australia, less than 8 percent of engineers in Australia are women. But the message is that anyone can do it and that girls just have a different approach," said Hane.

The Philippines is encouraging their engineers to get more equipped for the current construction industry. This means other engineers should be brushing up on their skills as well to compete with ever-expanding skillsets from the Philippines. The construction industry is allegedly performing quite well, whilst globally, it is struggling to gain momentum in some areas like Australia. Megawide Construction Corporation is putting their weight behind training "construction professionals" in hopes that they would work both in the Philippines and abroad.

"Filipino engineers, architects and other construction professionals should improve their skills and stock up on construction project management knowledge to better compete with their counterparts from abroad. In the next few years, most of the large-scale multi-billion-peso construction projects would come from public-private partnerships and foreign investors who want to put up world-class hotels and other facilities. These will need more competent construction project managers to ensure higher quality of work," said Megawide President and Chief Operating Officer Engineer, Edgar Saavedra.

The growth of the industry was reported by the Philippine Statistics Authority (PSA). Reportedly, from January to September 2015, in the Philippines, there were 92,788 projects which totalled more than US$13billion in the country.

Saavedra, talking to MB.com, said, "The global construction industry is constantly developing new sets of challenges and better standards of quality, but unfortunately, Filipino construction professionals, including construction project managers, are being left behind with only their industry work experience to show as credentials."

A series of seminars is reportedly being formulated to bring the construction engineers a wider and more updated education. It would apply to civil engineering and architecture professionals and will teach the business side of construction to the engineers as well.

Digital transformation is a hot topic in companies right now. Companies are under the pressure of moving their entire operations into the industrie 4.0 and automating a lot of things that used to be done manually. At the Huawei Global Analyst Summit 2016, the mood was no different than the industry's. Change is coming whether its agreed upon or not. Huawei's current CEO Eric Xu said that they would be moving into an "All Cloud" strategy that would be accommodating the latest industry trends.

The latest moves by telecommunications and data companies are to ensure that the end user is accounted for and everything runs smoothly for them twenty-four-seven. According to DQIndia, Huawei is, "committed to becoming an advocate, promoter, and leader of the full cloudification of productions and solutions," and implementing those additions to the company in the next two to three years.

"In the All IP era, we proposed our Single strategy, which effectively supported the development of operator customers. Nowadays, as we face the digital transformation of different industries, we advocate full cloudification to build efficient networks and agile competitiveness," Xu said, at the summit.

So companies should get more comfortable with the word 'cloudification' it seems. The ideology seems to be, "Adapt or die."

Darren Cunningham, Vice President of Marketing at SnapLogic, in an article he wrote for EnterpriseTech, said:

Some traditional IT organizations are eager to move apps to the cloud. Some younger companies have only used cloud-based apps and nothing else. And those who haven’t yet embraced a cloud solution are likely to find themselves with no choice but to move apps to the cloud, in order to take advantage of the same speed, simplicity, and flexibility that their competitors are enjoying.

Therefore, Huawei is moving the entire operations that the end-user experiences, into the cloud. Xu explains, saying, "This year we have introduced the "All Cloud" strategy, which focuses on delivering a ROADS (Real-time, On-demand, All-online, DIY and Social) experience. A ROADS experience cannot be achieved without support from services, networks, and operations systems."

The move to cloud-based apps and a full cloud experience means that companies can now build even more products and all of those products can interact with each other and create an entire 'ecosystem' of devices belonging to one carrier. All of this, in the same place. As 2016 progresses we should be seeing more and more companies jump on the bandwagon.

Pyrotechnic engineering is an important job and also a risky one due to the health and safety measures that must be taken to ensure that pyrotechnics do not put humans at direct risk of being harmed. Mike Tockstein is a pyrotechnician with his M.S. and B.S. in Electrical Engineering. He spoke to Payscale.com back in 2007 and said, "Pyrotechnicians are considered 'independent contractors' in most cases. So there is no set pyrotechnician salary." Tockstein also said, "I consider this a hobby that I would do for free in most cases, so getting paid is just a bonus."

That might be the problem with fireworks shows globally, after an incident in India left 110 people deceased. The voluntary work of engineers at events that could end in disaster. An accident occurred on Sunday in Kollam, India, involving an unauthorized pyrotechnic display, according to FireEngineering.com.

A police officer on the scene confirmed 110 had perished whereas 380 people had been injured. Witnesses confirmed that the blast caused a power outage and flames and debris flying down from the sky. They also said people were trapped as the crowd tried to disperse. The event was being held in a Hindu temple at the Puttingal Devi complex in Paravoor.

Krishna Das of Paravoor, said, "It was complete chaos. People were screaming in the dark. Ambulance sirens went off, and in the darkness, no one knew how to find their way out of the complex."

Allegedly, one of the blasts sent concrete slabs flying through the air that landed up to half a mile away, Jayashree Harikrishnan said.

The top official in the district, A. Shainamol, said, "They were clearly told that no permission would be given for any kinds of fireworks." Allegedly, the first round of fireworks exploded other fireworks that were in a building nearby to the festival and caused the devestation.

This, just another statistic in a long line of pyrotechnic disasters that should be investigated. Pyrotechnic engineers are important in cases like this one and only authorized shows should go forward.

Here is footage of the blasts that happened on the weekend:

It was just the other day we reported on SpaceX's mission to deliver inflatable rooms to the International Space Station. The mission held, even more, significance because of SpaceX's constant mission to land a spacecraft after it had launched it. The Falcon 9 - the rocket in question - took off on April 8th, 2016 from the Cape Canaveral Air Force Station and with it, the Dragon cargo spacecraft that had the supplies, experiment material and new hardware. The program that delivers supplies to the International Space Station is called the Commercial Resupply program.

SpaceX has been toying around with the idea of landing rockets back onto platforms after their mission objectives were met for some time now. According to ScientificAmerican, this was the "fifth attempt in 15 months by SpaceX". Unfortunately, the last attempted landings ended in a ball of flames, but this one was successful, except for one that did land on concrete in June 2015. This landing was done in the ocean, where the company had found little success in the past. An all-around win for aerospace engineering. The landing of the rocket on the barge opens a new chapter in aerospace engineering that could see the recycling and reusing of space-ready materials.

The cargo has already reached the International Space Station, to which Tim Peake, one of the astronauts on board, said, "It looks like we've caught a Dragon."

President Barack Obama tweeted: "Congrats SpaceX on landing a rocket at sea. It's because of innovators like you & NASA that America continues to lead in space exploration."

The engineers over at SpaceX were initially cautious to call the landing a success, due to the amounts of checks they had to do on the rocket itself to conclusively say whether the rocket could be used again.

About the hypothetical successes of one day landing a rocket on a barge in the sea, Elon Musk said, "We'll be successful, ironically, when it becomes boring. When it's like, 'Oh, yeah, another landing. No news there.'"

Later this year, Musk and the team at SpaceX plan to launch the Falcon Heavy, which has three times the number of engines compared to the Falcon 9. According to WashingtonPost, Musks's intention is to eventually fly the rocket to Mars.

Watch the undoubtedly impressive footage of the Falcon 9's landing below:

A company named Wohlers Associates Inc. that specialized in additive manufacturing/3D printing has published their 2016 Wohlers Report. The report is respected in the engineering industry as a clear picture of what is happening in the industry and how well it is performing. According to, 3Ders, Wohlers looked into 51 industrial system manufacturers, 98 service providers, 15 third-party material producers, various desktop 3D printer manufacturers, and 80 3D printing experts from 33 different countries.

The results were positive for companies currently working or thinking of working with 3D printing technology. The additive manufacturing industry grew by 35% in 2014 but has struggled to increase any more in 2015. Wohlers says that the market will reach $10 billion only by 2017. The official number is that the 3D printing industry has grown by a billion dollars for the second year in a row.

However, Wohlers did report that the industrial metal additive manufacturing and desktop 3D printing industries did see a bigger growth in popularity than other industries.

Desktop 3D printers rose a staggering 70% in 2015 which was explained due to the affordability of 3D printers as the years progress. It is becoming possible to buy a printer instead of having to rely on universities or schools to have one. Personal printers are becoming more and more of a reality.

Desktop 3D printers rose a staggering 70% in 2015 which was explained due to the affordability of 3D printers as the years progress. It is becoming possible to buy a printer instead of having to rely on universities or schools to have one. Personal printers are becoming more and more of a reality.

When you think of mushrooms and the most sought after ones, of course, you think about truffles. Pardue University isn't looking for truffles to eat, but rather a wild mushroom that could aid in the future of lithium-ion batteries for energy storage. Allegedly, the university is taking the carbon fibers from the wild mushroom and altered it with nanoparticles, which has resulted in interesting observations.

Vilas Pol, an associate professor in the School of Chemical Engineering and the School of Materials Engineering, says, "Current state-of-the-art lithium-ion batteries must be improved in both energy density and power output in order to meet the future energy storage demand in electric vehicles and grid energy storage technologies. So there is a dire need to develop new anode materials with superior performance."

The mushroom in question is the Tyromyces fissilis and will form electrodes for lithium-ion batteries according to the researchers.

"Both the carbon fibers and cobalt oxide particles are electrochemically active, so your capacity number goes higher because they both participate," Pol added. The team took the carbon fibers from the mushroom and attached it to cobalt oxide nanoparticles and created the battery that allegedly has 530 milliamp hours per gram.

Jialiang Tang, a student from Pardue University and assisting Pol on the project, said, "The methods now used to produce carbon fibers for batteries are often chemical heavy and expensive. I was curious about the structure [of the mushroom] so I cut it open and found that it has very interesting properties. IT's very rubbery and yet very tough at the same time. Most interestingly, when I cut it open it has a very fibrous network structure."

According to Power-EETimes, the network that runs within a fungus like a mushroom would ensure "faster electron transport" which would lead to faster battery charging if it could be implemented into an energy storage unit.

Read Pardue University's report: Wild Fungus Derived Carbon Fibers and Hybrids as Anodes for Lithium-Ion Batteries

Copper prices have fallen, according to news agency Reuters, causing engineering and technology companies to reassess what's happening in the industry and attempt to rectify the situation. The annual World Copper Conference conference (named Cesco/CRU) that took place in Chile this week, found that copper prices will remain low for the next three to five years.

The price of copper is almost at a six-and-a-half-year low due to Chinese growth slowdown which is forcing the mining sector to retrench staff and limit output globally.

Hennie Faul, the head of Anglo American's copper sector said, "The downturn has really made us think differently. It had woken us up...We want our assets to be low cost."

Pertti Korhonen, chief executive of Finnish mining technology company Outotec, told Reuters this past week, "The focus for the industry over the next two years will be on productivity improvement, and all the mining companies trying to reduce their cash costs. There is a lot of opportunity in modern technology, including digitization and automation."

Juan Rayo, CEO of renowned Chilean engineering firm JRI, said, "All engineering companies have needed to adjust themselves in order to get through this rough time...we're anticipating a difficult market, with no more than 5 to 6 million man hours of engineering for mining during the year."

The current price of copper is US$4,650 a ton. This is compared to February 2011's results of US$10,000 a ton, Reuters points out. This would explain why cuts are being made and why jobs are being lost; they have lost more than half of the money in copper in a matter of years.

Korhonen has the solution, however. He says, "If you reduce your energy consumption, you reduce your water consumption, you improve your throughput, you can get immediate opex savings, you can get immediate advantages. So I think if the numbers talk for themselves, they will find the money."

China is prioritizing their focus on smart buildings, smart homes and everything of the sort with their annual Smart Home and Intelligent Building Expo. The focus of automated components of homes and how they interact with each other and with the vehicles we drive and the cell phones we use is a particular interest of engineers from China.

Elsewhere in the world, the need to sufficiently prepare for the oncoming change of homes, offices and buildings a whole is being underlined. In Texas, Jim Sinopoli, architect, and founder of Smart Buildings says, "Building owners are having to adapt to technology that wasn't available just five years ago. And that's going to change the way we approach building. The question will be how design engineers and architects respond. Making buildings smart will be disruptive. But it's inevitable."

IDC Energy Insights, an industry analysis company reported that $5.5 billion (USD) was used on smart building improvements to buildings in 2012, but estimates but 2017 the amount spent will be $18.1 billion (USD).

According to DigitalSpy, retailers in the United Kingdom, John Lewis, are starting to have installations in their store that emulate a smart home and are starting to sell 'smart home' packages to people.

Johnathan Marsh, John Lewis's Buying Director for Electrics and Home Technology said, "We are seeking to demystify the latest, smart technology for our customers. In-store experiences are now key as we've seen customer demand for physical experiences before committing to purchase increase."

Sinpoli's stance - speaking to SCMP - also thinks about the human before anything else. He said, "while smart architecture is about making buildings cheaper and greener, it's important to recognise that it's also about making them better for their occupants." At the end of the day if it is not a smart home or smart building a regular person would be able to live in then there is no reason to keep building on this industry.

Betsey Dougherty, a co-founder of Dougherty+Dougherty Architects in California says, "Something as subtle as the colour of the walls, the acoustics, and reverberation, glare - all these affect the quality of life inside a building. A smart building should allow you to get better faster if it's a hospital, learn more if it's a school, be more creative if it's an office. Of course, buildings will get generally smarter as cell phones do - that's to be expected. But we have to raise the bar on the idea that a building is essentially a box."

A group of engineers from New Zealand has been awarded a prestigious award for their work in the Canterbury Earthquakes that started on the 4th of September, 2010 and continued into 2011. After the earthquake, the engineers started to research liquefaction damage to hopefully earthquake-proof roads and buildings for any future seismic activity. Liquefaction damage refers to the breakdown of soil during an earthquake that splits roads in two and causes some devastation for houses and buildings.

The leader of the team, Sjoerd Van Ballegooy, walked away with the Outstanding Paper Award from the Earthquake Engineering Research Institute in San Francisco.

According to Stuff, their research consisted of 81,000 visits to the homes that were damaged as a result of the earthquakes and did tests on "ground motions and depth to groundwater."

Van Ballegooy said, "Much of eastern Christchurch has been built on sand and silty soil, with shallow ground water, setting the stage for extensive liquefaction damage to occur following strong earthquake shaking. To make matters worse, thousand of homes were built on non-robust concrete slab foundations, resulting in a significant portion of the residential building portfolio being damaged beyond economic repair as a result of the liquefaction."

According to Voxy, the Canterbury earthquakes caused the most extensive liquefaction damage ever seen in built up urban areas.

"When we began analysing all of this information we discovered that in some areas, the damage caused by liquefaction was much worse after the shaking on 13 June 2011 and 23 December 2011 despite those earthquakes being significantly smaller than the previous ones on 4 September 2010 and 22 February 2011," Van Ballegooy said.

He went on to relay their findings, saying, "A combination of lateral spreading, removal of the sand and silt that was ejected to the ground surface, densification of the subsurface materials and tectonic subsidence occurring over four main events were the major factors that contributed to the reduction in thickness of the non-liquefying crust."

The researchers concluded their findings by urging private insurers, policy makers, architects, engineers, urban planners and other professionals to "reduce the economic and social impact of liquefaction related damage" for the future earthquakes that could possibly happen.

Data communication engineers are on high alert after Whatsapp enabled something that only apps like Telegram, Signal, and other apps had; end-to-end encryption of messages. You might have seen it enabled on all of your chats - activating it on their platform. There are a billion people using Whatsapp in the world so it is quite the stance for privacy in the world of today. The sudden stance comes on the back of the revelations that the FBI were able to unlock the iPhone of the San Bernadino shooter that Apple refused to unlock.

Whatsapp (owned by Facebook) spoke about the move to encryption, saying, "When you send a message, the only person who can read it is the person or group chat that you send that message to. No one can see inside that message. Not cybercriminals. Not hackers. Not oppressive regimes. Not even us."

IBTimes, however, published a list of apps that people could further look into, to ensure that their privacy in data communications is secure. Something that a lot of people want with recent scandals like the Apple case, the Panama Papers et al:

Their list named the following apps that could be installed for extra privacy with data communications:

Signal: Publicly endorsed by former NSA spy Edward Snowden

iMessage and Facetime

Telegram

Wickr

Very soon you could be sending your own satellite into space. Researchers at Arizona State University are, in their own words, "making the price of conducting a space mission radically cheaper." It sounds too good to be true right?

The work has been done in a lab called the Space and Terrestrial Robotic Exploration Laboratory. Jeken Thanga, assistant professor and head of SpaceTREx said, "With a spacecraft this size, any university can do it, any lab can do it, any hobbyist can do it."

The satellite in question is called the SunCube FemtoSat . The team has worked for two years on the cube and measures 3cm by 3cm by 3cm. Thanga thinks that one day hundreds of these cubes could be sent into space and they could inspect damaged spacecraft.

There is only one catch. The price of launching these cubes into space. According to ASUNOW, the current cost of launching crafts into space lands $60,000-$70,000 per kilogram.

However, per cube, the team says it would cost $1,000 to take to the International Space Station or $3,000 to send into "low-Earth orbit."

Thanga says, "That was a critical price point we wanted to hit. That's part of our major goal -- space for everybody."

The researchers don't think the SunCube will be overly expensive and sees the price for one only reaching the hundreds.

"It's the prototype of a fully functioning spacecraft," Thanga says in the announcement video (as seen below). "On board you have cameras, you have power systems, you have computers and you have a fully functioning radio."

For more information check out: femtostat.asu.edu

Software engineers are the mighty guardians of keeping Google up and running 24/7. In a report written on Wired, Google uses three words in explaining how it stays up: Site Reliability Engineering. According to the report and Google's own numbers, in 2015, Google's App Suite - which includes Gmail, Google Docs, Google Drive et al - were up 99.97 percent of the year.

The Vice President of Engineering at Google, Ben Treynor Sloss, said, "The result of our approach is that we end up with a team of people who will quickly become bored by performing tasks by hand and have the skill set necessary to write software to replace their previously manual work."

Site reliability engineers are up for more hires around the world due to site maintenance that exists in the world due to the chance of a site being a victim of cyber-crime or just general maintenance that keeps the website functioning with all of its bells and whistles.

One of the site reliability engineers at Google, Andrew Widdowson detailing what its like to be an SRE - as it is abbreviated - said, "Our work is like being a part of the world's most intense pit crew. We change the tires of a race car as it's going 100mph."

The team that works for Google has worked with a publisher to release a textbook that is now available for purchase named Site Reliability Engineering: How Google Runs Production Systems.

Here's an application form to be a Software Engineer for Google.

"I think robotics is a new manufacturing and it can help people to do some high-risk work and go to top of the mountain and deep ocean to realize our world adventure," said Scarlett Johansson.