News

- Details

- Written by: Quintus Potgieter

- Category: Developments

Who is teaming up with the British government to test out the first energy storage systems that will assist the grid? Renewable Energy Systems (RES) will be working with the UK's National Grid and is expecting that it will be "fully operational" in 18 months. RES will balance the grid by supplying renewable energy in literal seconds, meaning this would be the first real picture of grid balancing, at least for the UK.

"This is the first time that battery storage will be used to provide such fast-acting frequency response service to the National Transmission Network in Great Britain. This innovating technology will enable us to respond to frequency issues in under a second, helping to maintain the integrity of the grid," said Adam Sims, Senior Account Manager at National Grid.

The company has already assisted with frequency services to Canada and the U.S. and now Britain is getting a helping hand in hopes that they might be able to move away from fossil fuel energy production. The U.K. National Infrastructure Commission (NIC) has published a report that claims that if Britain embraces clean energy they could save £8 billion.

We reported earlier in May that whisperings in the energy storage world indicated that Britain would 'quietly' become the leader in solar due to a £10 billion injection. So injecting 10 and saving 8. If the numbers are to be believed, there is a lot of efficiency coming to the British public in terms of energy storage.

RES will be supplying 20MW to the grid in less than a second. John Prendergast, energy storage manager at RES said: "Energy storage can play a large role in supporting the UK's transition to a secure, low carbon, low-cost energy system. We believe that this contract will play an important role in demonstrating this and will encourage policy makers and regulators to accelerate the removal of barriers to wider deployment of energy storage in the UK."

- Details

- Written by: Quintus Potgieter

- Category: Developments

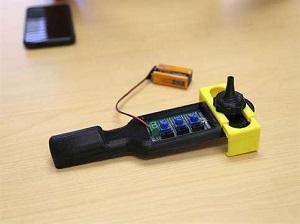

It seems this year (2016) is the year that biomedical engineers will show off the most. It's almost June and we've seen dozens of amazing new technologies being developed in the biomedical industry that pertain to wearable technology. The latest piece of gear that could be improving our lives is a device that would listen to the cracks in our knees. A Professor Omer Inan, who graduated from Stanford University and is now at the Georgia Institue of Technology has invented a device that uses sound sensors to listen to the sound of joints rubbing together. This would have benefits for doctors in terms of diagnosing the problems with a knee without having to x-ray as the first resort.

The following video will play an amplified sound of a patient's knee which might make you wince. You've been warned.

Omer Inan - from the School of Electrical and Computer Engineering at Georgia Tech- says: "We use piezoelectric film microphones and these are contact microphones, they don't measure sound and air, but they measure the vibrations of the surface of the skin." The data that is measured into a computer displays similar traits to an EKG scan, and thereby the engineers and scientists would be able to determine the health of a knee.

The benefit of this sensory device will also lead to a future of tracking the progress of how an injured knee repairs itself. The device was funded through the Defense Advanced Research Projects Agency (DARPA) who were asking engineers to submit proposals for wearable technologies. DARPA is hoping that the devices will also assist soldiers in the military who have "repeat battlefield knee injuries." "What most people don't know is that musculoskeletal injuries of the knees and ankles are among the top reasons for discharge for active duty service members," said Inan. He also sees a future where it would help with athletes and elderly patients.

The researchers have published their findings in the IEEE Xplore Library under the title, Novel Methods for Sensing Acoustical Emissions from the Knee for Wearable Joint Health Assessment.

The good thing about the human body is that the right and the left knees have similar acoustic measurements. Thank goodness. Otherwise, the engineers might have had their work cut out for them. They say in the abstract of their journal:

Conclusion: We reccommend using air microphones for wearable joint sound sensing; for practical implementation of contact microphones in a wearable device, interface noise must be reduced. Importantly, we show, that airborne signals can be measured consistently and that healthy left and right knees often produce a similar pattern in acoustic emissions.

- Details

- Written by: Quintus Potgieter

- Category: Education

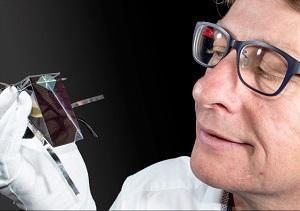

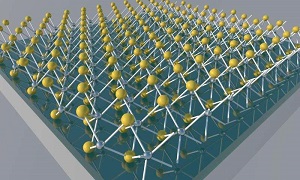

MIT seeks to innovate again. This time, researchers are attempting to make electronics out of coal. The only way this would be possible is if the coal was repurposed from what we use it for today to thin coal films. The researchers say they've developed four thin films of coal: anthracite, lignite, and two bituminous types. They have used the repurposed coal to make electrical heating devices that the researchers say can defrost "car windows or airplane wings". They say it could even be a biomedical implant. What is this world coming to?

The researchers in question are Jeffrey Grossman, Brent Keller, and Nicola Ferralis. They published their repurposing of coal findings in the NanoLetters journal under the title, Rethinking Coal: Thin Films of Solution-Processed Natural Carbon Nanoparticles for Electronic Devices.

Grossman works in the Department of Materials Science and Engineering (DMSE) at Morton and Clair Goulder and Family. He says: "When you look at coal as a material, and not just as something to burn, the chemistry is extremely rich." This would mean that coal is far more than just a fuel source for the world.

The electronic properties of coal have never really factored into engineering until now. The researchers are showing that coal does not need to be taken down to the atomic level to be applicable to the chemical world of engineering. In MIT's labs, all they did was grind the coal down and alter the temperatures until they got the results they desired. The researchers explained the process of using the coal films in the abstract to their journal:

Here we show a flexible solution-based method of preparing thin films with tunable electrical properties from suspension of ball-milled coals following certifugation. The as-prepared films retain the rich carbon chemistry of the starting coals with conductivities ranging over orders of magnitude, and thermal treatment of the resulting films further tunes the electrical conductivity in excess of 7 orders of magnitude.

The researchers say that the hopping energies that they observed were close to that of amorphous carbon materials and "reduced graphene oxide." This means that these coal films could have many applications. The researchers think the coal films could assist solar panels, batteries, and other electronic devices.

"This is a significant step - probably the first - to utilize nanocarbon materials, directly from unrefined coal, with controllable electronic properties and excellent stability and scalability," said Shenqiang Ren, an associate professor of mechanical engineering at Temple University, who was not part of the team but was very impressed by their efforts.

- Details

- Written by: Quintus Potgieter

- Category: Industry

A group of engineers from New Zealand have started a small start-up company named Invert Robotics. Their specialty? Robots that inspect industrial facilities. The engineers, originally from the University of Canterbury, patented the world's first climbing robot. The robot (pictured in the video below) can check industrial tanks for cracks, whilst an inspector controls it from a remote location. This means health and safety inspectors don't have to put their health or lives in danger. In turn, identifying unstable structures within industrial tanks will ensure that a business preserves the health, safety, and wellbeing of its employees

The robot uses sensors to maneuver around a tank whilst sending a high definition video stream to the screen the operator has in their possession. According to Scoop, the old way of doing this would be letting inspectors abseil down an industrial tank and survey any damage that might have occurred to the innards.

Now, what is being called a "multi-billion euro turnover company" is seeking the technology. The strange bit is that they are not being named as of yet.

Invert Robotics, James Robertson, told Scoop: "To be sought out by this European company, who could find no equivalent technology anywhere else in the world, is a massive vote of confidence for Invert Robotics and the team that has supported and guided us." The engineers are also focusing on the European dairy market next due to their successes of inspecting industrial dairy tanks in New Zealand. "We have been perfecting our inspection robots, working with trans-Tasman dairy companies, and over the past5 four years, we have carried out more than 250 inspections. We know we have a product that is truly market changing."

Elsewhere in the robotics world, SoftBank Robotics America is getting their Pepper robot ready for consumers to start tinkering with. Mastercard has jumped on the bandwagon and introduced an application that would assist with making digital payment to a merchant. Pepper will assist people when making purchases at a store and facilitate the digital payment.

"Consumers have come to expect personalized service, customized offers and simple and seamless processes both in-store and online. The app's goal is to provide consumers with more memorable and personalized shopping experience beyond today's self-serve machines and kiosks, by combining Pepper's intelligence with a secure digital payment experience via MasterPass," said Tobias Puehse, vice president, innovation management, Digital Payments & Labs at MasterCard.

The developers behind the Pepper are allowing other companies to see what they can improve the robot with, and MasterCard seems to be the first company that is keen.

- Details

- Written by: Quintus Potgieter

- Category: Developments

The Ivanpah Solar Power Facility is the world's largest solar plant. It is stationed in the Mojave Desert in California, United States and generates 377 MW of clean solar power that powers up to 140,000 homes in the area. It has 173,500 heliostats that have two mirrors each. It is relatively new, it was opened in 2014, and for the first time has unfortunately caught on fire. The fire was purportedly caused by "misaligned mirrors" which the plant uses to reflect the sun into a boiler tower instead of utilizing photovoltaic solar cells.

The Associated Press reported that poorly-aimed heliostats "focused the sun's energy about two-thirds of the way up the tower instead of at the boiler at the top of the tower." Electrical cables caught on fire as a result and damaged water pipes within the tower. The tower is since non-operational and there is no clear picture of when the tower will be back online. Another tower is down for maintenance, leaving only one tower operational at the facility.

The Associated Press reported that poorly-aimed heliostats "focused the sun's energy about two-thirds of the way up the tower instead of at the boiler at the top of the tower." Electrical cables caught on fire as a result and damaged water pipes within the tower. The tower is since non-operational and there is no clear picture of when the tower will be back online. Another tower is down for maintenance, leaving only one tower operational at the facility.

Talking to WIRED, Adam Schultz, a program manager at the UC David energy Institute, said: "Ivanpah has been such a mess. If the fire knocks them offline, it's going to further dig them in." He is, of course, referring to the pressure on Ivanpah to meet its targets for energy production, which it hasn't been doing.

The California Public Utility Commission has been warning the facility that they have not hit the targets that were set out for them. However, there is a petition making the rounds that will fight for the plant to continue to produce solar energy to the utility. The tower down for maintenance and the tower that caught fire was an unexpected hurdle in their plans, but they will continue to petition to retain their contact with the Public Utility Commission.

Further complaints about the plant have ranged from the amount of birds that are being killed as a result of the mirrors and there have been complaints from pilots that say they are blinded by the reflections of the mirrors.

The Ivanpah Solar Power Facility is run through a collaborative effort between NRG, BrightSource, and Google (Alphabet). CleanTechnica spoke to David Knox, an NRG spokesman. He spoke of the engineering difficulties the plant has been experiencing. He said:

"We encountered the kinds of engineering problems that can really only be seen and solved in a first full-scale deployment. And in that first year, an inordinate number of partly cloudy days impacted not only the energy output, but also the plant's ability to commission and actually fine tune all of its control systems. But now we that we have leatrned the lessons that we have learned, and the industry has learned the lessons that we have learned; others don't have to. But the first large-scale installation needed to go through those steps."

Thankfully, the fire was put out in 20 minutes by the crew present on the day of the fire and nothing was burned down. More news as this story develops.

- Details

- Written by: Quintus Potgieter

- Category: Developments

India has successfully launched its first mini space shuttle. The shuttle is known as the Reusable Launch Vehicle - Technology Demonstrator (RLV-TD) which is an unmanned vehicle that the Indian space Research Organization (ISRO) successfully ascended to 41 miles after it had separated from the rocket. It is a winged body vehicle enabled it to make its way back to earth and attempted a runway landing. The virtual runway was a once off runway specifically cordoned off for the landing. One wonders whether the landing was as graceful as SpaceX's recent barge landings, nonetheless, it looks like Elon Musk might have some competition in the reusable rocket industry.

The re-usable vehicle was built by the Vikram Sarabhai Space Center by a team of 600 engineers in a space of five years and has finally launched. The Prime Minister, Narendra Modi, congratulated them by tweeting: "Launch of India's first indigenous space shuttle RLV-TD is the result of the industrious efforts of our scientists. Congrats to them."

America has abandoned their space shuttle programs, but it seems India is just getting started. In a statement, the ISRO said: "In this flight, critical technologies such as autonomous navigation, guidance & control, reusable thermal protection system and re-entry mission management have been successfully validated." The operation took 13 minutes to complete, showing that India's aerospace engineers are more than capable to launch small-scale rockets and space shuttles.

David Wireman, an aerospace specialist at consultancy AlixPartners, told Bloomberg: "While India's effort is behind the likes of SpaceX and Blue Origin, there are still others further behind and all of the solutions remain to be proven, both technically and from a cost perspective. Although the technical hurdles are quite high, it's reasonable to believe India can be successful."

- Details

- Written by: Quintus Potgieter

- Category: Developments

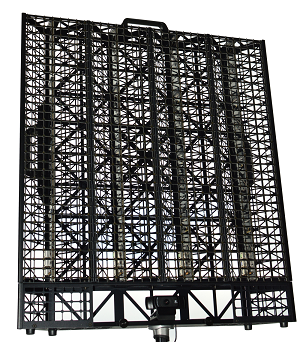

The Hannover Fair 2016 was quite the occasion, as we've reported before, but it seems like a distant memory. We saw industrial automation take the centre stage at the event, however, there were other engineering feats that weren't reported on as much. One eye-catching innovation was from a company called Sorama which concerns itself with visualising sound and vibrations. They have built something that looks like you should be barbecuing on it, but it is the latest, top-of-the-line product that uses cameras and microphones to measure the sound pollution that cars are emitting on the road today.

Their engineering technology has assisted other companies in reducing the sound pollution an object makes. They worked with ResQTec to create rescue and recovery tools that are the quietest on the market. An employee for ResQTec spoke said: "Communication between rescue services and the victim should not interfere. Also, high-stress levels should be avoided. The Sorama cameras show noise pollution as a heat signature on their cameras so that designers can attempt to reduce sound once the camera has shown how much of it is emitting on a particular product.

Noise pollution can cause health problems in humans, that is why it is imperative that engineers design products - which include cars, buses, anything in transit - that do not emit enough noise to elevate stress levels or damage hearing.

The new camera they showed off at Hannover Fair is called the CAM1K. The camera is 10.8 pounds in weight of which the microphones are 80% of the weight. That is because there are 64 microphones connected to the device and they have an even bigger CAM with 1,024 microphones attached to it. The microphones can also be found in smartphones, but here they are used to map sound and display it as if it were a heat signature (see the video below).

Sorama's Rick Sholter said: "We've developed sound cameras to tackle noise pollution. You can use the cameras to detect riots on the streets - so that's observation of a large street in a smart city environment. But noise pollution is much more than that: cars driving in the streets make a lot of noise, and your central heating system makes noise, which is all bad for your health."

Sorama says their potential to infiltrate the market is growing. Philips Electronic, Bosch and truck designers have asked them for the expertise in noise pollution measuring so that the future engineering designers are quieter and safer for the mass market to consume. Quieter vehicles mean less noise pollution and less stress on the highways and freeways of the world and would ensure that there is minimal noise for neighbouring areas that live close to them.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

A woman enquired of Herbert Hoover (later to be US president) whilst on a ship what he did for a living and he replied “An engineer”. She apparently responded: “But I thought you were a gentleman”. Since then, the practice of engineering has changed considerably over the past hundred years, and I want to explore a few trends and how you can grab advantage of them.

Dear Colleagues

A woman enquired of Herbert Hoover (later to be US president) whilst on a ship what he did for a living and he replied “An engineer”. She apparently responded: “But I thought you were a gentleman”. Since then, the practice of engineering has changed considerably over the past hundred years, and I want to explore a few trends and how you can grab advantage of them. There is still no doubt in mind, that there are some constants in engineering such as strong skills in maths and science (and the associated need to be meticulous and precise). And the ability to troubleshoot and to transform mere ideas into real useful objects.

Some of the current trends that are obvious are discussed in the next few paras. I do clearly see today, the need to be obsessively multiskilled and highly receptive to and embrace new ideas and approaches. There has been a merging of professions – mechanical/electrical/ IT and the emergence of new ones. In this ruthless world of change, some engineering professionals have been resistant to change and quickly find their skills redundant (e.g. one colleague of mine - a technician working in the industrial data communications area refused to move beyond RS-232 and RS-485 into the realms of Ethernet and reluctantly retired).

As Sujeet Chand from Rockwell remarked: there are many more constraints when designing; so one has to be quite adroit in dealing with these (and getting one’s head around them). This includes such issues as energy efficiency, cost, climate change, safety and ergonomics.

One has to be able to collaborate widely and communicate continuously and well. And often in a virtual way using email/ the web/ web and video conferencing with different cultures located all over the world. There is a merging of collaboration with people and the resources on the web. All information is available on the web today in a searchable format meaning very complex designs can be quickly put together.

Outsourcing of non-core functions has often seriously emasculated engineering companies with loss of great engineering talent. This has left many companies with the only remaining ability to repackage old technology which eventually runs out of steam in this highly competitive market.

A lot of the very satisfying hands-on experience is not with us any longer, with James Truchard of National Instruments remarking that the mathematics has isolated us from grounded reality in many cases. We have lost the intuition due to this high level of abstraction. Fortunately with the new approaches to simulation and representing data in realistic simulations, we can move back to the hands-on intuitive approach again.

So what do we do about this:

- Strengthen our communication skills in collaboration with other cultures and engineers from throughout the globe.

- Strive for retaining the hands-on intuitive approach to doing engineering using the new 3-d simulation approaches

- Embrace multiskilling and regard engineering as one vast interlocking field where your skills extend across the entire spectrum and your skills are not in silos.

- Be wary of outsourcing and losing core resources and functionality

- And I know I sound fixated but keep learning and absorbing

Thanks to Terry Cousins of TLC Software and Machine Design for giving me the incentive to write this.

And a brilliant quotation which I love today, from Christina Baldwin: “Change is the constant, the signal for rebirth, the egg of the phoenix”.

Yours in engineering learning

Steve

Mackay’s Musings – 24th May’16 #601

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Industry

A new report made available by MarketsandMarkets has estimated the amount of money the industrial robotics industry will make from now till 2022 is US$79.58 billion. That would mean a growth rate of 11.92 percent combined annual growth rate from this very second until we reach 2022. The report was titled Industrial Robotics Market by Time (Articulated, Cartesian, SCARA, Cylindrical, Parallel), Application (Automotive, Electric and Electronics, Metal and Machinery), Component (Controller, Sensors, Drive) and Geography- Analysis & Forecast 2022. So it is safe to say it covers the vast majority of industrial markets robots are currently applying to. No surprise then that the number of $79.58 billion is so high.

The report just cements the fact that industrial automation and the Industrial Internet of Things that will work in tandem with the industry is the next step forward. The report claims that the market is being dominated by the Asia-Pacific areas ; China, Japan, South Korea and India. The demand for robots is incredibly high. Also we have seen recently that Chinese companies are buying out European robotics companies to utilize the technology currently being developed. Kuka Robotics' purchase shows that the demand is high and billions will be forked out for the current technology.

The report actually names Kuka, amongst other companies that are currently performing well in the industrial automation industry:

- ABB Ltd. (Switzerland)

- FANUC Corp (Japan)

- Kawasaki Heavy Industries Ltd. (Japan)

- Yaskawa Electric Corp (Japan)

However, $79.58 billion is a very big number. It cannot seriously be true. But, then you remember, that there's even a robot that cuts marshmallows. Honestly, all we need is a taffy-pulling robot and then we've put Willy Wonka out of business. Check below for the kind of robotics that ABB supplies the food industry. If you notice how many different tasks robots can currently be doing in our world already, perhaps the estimates of how much money the industrial robotics industry might make by 2022, isn't that far off.

Source: Engineering.com

- Details

- Written by: Evangeline Newby

- Category: Developments

By Edwina Ross

“The scientists of today think deeply instead of clearly. One must be sane to think clearly, but one can think deeply and be quite insane.” These are the words of Nikola Tesla (1856 – 1943) physicist, engineer and inventor.

Elon Musk, another scientist, engineer and inventor, may have recently set up his desk at the end of the Model X production line at the Tesla Motor factory in California (with his sleeping bag not too far away), but I don’t believe for a minute that he is insane. Absolute clarity of thought and passion, driven by a belief in the product, is a much more likely scenario.

And his dedication is not misguided. The company's first electric sedan, Model S, won the 2013 Car of the Year by Motor Trend magazine – it was capable of covering 265 miles or 426 kms between charges. It has more recently been refreshed and now Model X and Model 3 are hot on its (w)heels.

The company is, however, facing a hurdle - the sort of hurdle, I must just add, that every company would like to have to leap. To fill their enormous number of orders in a timely fashion is proving challenging, but then the orders are around the 400,000 mark. Even with the highly automated Tesla Factory’s 5.3 million square feet (325160.00 square meters) of manufacturing and office space this would take some doing.

A sign of the changes in the automotive industry (a change that is seeping into many others too), saw Musk, in January of this year, on a mission to recruit 1600 software engineers for his factory. They are to help develop the cars’ autopilot system with capabilities that would allow Tesla owners to summon their cars.

Their employment is part of a thrust by the company to have a fully self-driving car by 2018. (If I remember correctly this was a part of a slightly daunting, but tantalising discussion on the 2016 EIT Roadshow?) Clearly there will be avid observers of developments here.

Naming the all electric motor company after Nikola Tesla is a worthy posthumous badge of honour for the creator of the induction motor and alternating current (AC) power transmission.

According to an old post on the automaker’s website, the founders wrote, “Without Tesla’s vision and brilliance, our car wouldn’t be possible. We’re confident that if he were alive today, Nikola Tesla would look over our 100 per cent electric car and nod his head with both understanding and approval.”

Unsurprisingly Tesla and Musk have similar views on risk and innovation; accounting for their very individual, but fearless drive and determination. In Musk’s words, "Failure is an option here. If things are not failing, you are not innovating enough." And then as Tesla is recorded as saying, “Our virtues and our failings are inseparable, like force and matter. When they separate, man is no more.”

There is a less than a subtle difference here though: Musk embraces failure to further and strengthen his ideas, whereas Tesla was referring to the essence of his nature.

Tesla’s clarity of thought was almost certainly combined with that depth of thought which he associated with insanity and which he warned against. His ‘virtues’ were his ingenuity, imagination and inventiveness. But his ‘failings’ involved an unhealthy preoccupation with his ideas, an obsessive scrutiny which ultimately led to his downfall and in his later years, a life lived in obscurity and relative poverty.

It does suggest that the genius inherent in inventors needs nurturing. Perhaps by those who can harness the creativity and bring a big dose of commercial wisdom to it. The problem of course is that those with this capability may also contain the greed that often drives commercial success and which could result in the exploitation of the creator. Nikola Tesla used numerous patents to help defend himself against unscrupulous people and behaviour, but without success.

Elon Musk, on the other hand, has both the inventor’s flair and the requisite commercial talent. But this man, who appears to have it all, has added good old fashioned hard work to the mix to ensure his star is in the ascendant.

Thanks to the following for their assistance in writing this:

http://www.businessinsider.com.au/who-is-tesla-named-for-2013-8

http://inventors.about.com/od/mstartinventions/p/Elon-Musk.htm

http://www.smithsonianmag.com/history/the-rise-and-fall-of-nikola-tesla-and-his-tower-11074324/?no-ist

http://www.biography.com/people/elon-musk-20837159#an-earnest-entrepreneur

http://www.dailymail.co.uk/sciencetech/article-3398236/Tesla-bulks-IT-talent-car-future-fight.html

http://www.explainthatstuff.com/induction-motors.html

http://www.biography.com/people/nikola-tesla-9504443

- Details

- Written by: Evangeline Newby

- Category: Developments

A recent article (detailed below) in Engineering.com titled Engineering Implantable Devices for the Brain, caught our eye. It looks at the collaboration of a Paediatric Neurosurgeon and an Electrical Engineer determined to help eliminate brain disease by building brain implants. Biomedical engineering is in growing demand with shortages of both biomedical engineers and technicians in every part of the world. EIT's Advanced Diploma of Biomedical Engineering starting the week of June 06, 2016 is designed to impart solid knowledge in the area of biomedical engineering; to advance work skills and further job prospects. IN THIS INTENSIVE PART-TIME 18-MONTH LIVE ONLINE PROGRAM YOU WILL GAIN: Practical guidance from biomedical engineering experts in the field 'Hands on' knowledge from the extensive experience of the lecturers, rather than from only the theoretical information gained from books and college reading Credibility as a biomedical engineering expert in your firm Skills and know-how in the latest technologies in biomedical engineering Networking contacts in the industry Improved career prospects and income An Advanced Diploma of Biomedical Engineering To view full program details, click here. To apply for this program, email us at

- Details

- Written by: Quintus Potgieter

- Category: Developments

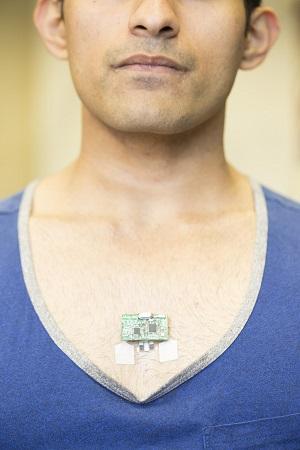

Wearable technology is slowly making its way into the world of today thanks to the engineers in the research and development centers all around the world. Engineers at the University of California San Diego are now announcing that they have the world's first, flexible, wearable device that can monitor "both biochemical and electric signals" that the human body emits. They're calling it the Chem-Phys patch and it records EKG (electrocardiogram) heart signals and other biochemicals the body emits when doing physical activity. The device can be worn in the center of the chest and connects wirelessly to a source that extracts the data (smartphone, smartwatch, laptop).

The study of wearable technology is growing at such a rate that UC San Diego has their very own Center for Wearable Sensors where their nanoengineers and electrical engineers do all the work. The engineers say the device they have built will have many uses from monitoring physical activity to measuring data on a patient who has heart disease.

"One of the overarching goals of our research is to build a wearable tricorder-like device that can measure simultaneously a whole suite of chemical, physical and electrophysiological signals continuously throughout the day," said Patrick Mercier, an electrical engineering professor at UC San Diego.

A tricorder being a fictional hand-held device used in Star Trek that would scan a person's body and do a data analysis, eventually spitting out what would be physically wrong with a character in the form of a medical diagnosis. If you didn't know these engineers were nerds before, you surely know now.

Dr. Kevin Patrick, a physician and director of the Centre for Wireless and Population Health Systems at UC San Diego has been watching the engineers at work and thinks the tricorder-like device could be super beneficial to the sports world. He said: "The ability to sense both EKG and lactate in a small wearable sensor could provide benefits in a variety of areas. There would certainly be interest in the sports medicine community about how this type of sensing could help optimize training regimens for elite athletes."

The next step for the engineers could be to try and take the device to the Qualcomm Tricorder X Prize competition that was set up for the sole purpose of actually trying to build a tricorder as seen on Star Trek. The competition will wrap up in 2017 and the prize money will be $10 million. However, it seems as if the competition has already found its finalists.

Source: Eureka Alert

- Details

- Written by: Quintus Potgieter

- Category: Education

Universities in the United States are going to great lengths to prove that their engineering courses are female-friendly. The University of Wyoming recently held an event called Women in STEM, that saw 500 young women from grades 7 to 12 interact with fields that in recent history have been overrun by men. The event is one of many events that have been held across the United States to attempt to further convince young women that a career in a STEM field would be beneficial to their futures.

"Women are still under-represented in the science and engineering fields, and we want to give young women information about career opportunities and college majors in these fields and expose them to all the opportunities out there in terms of science and engineering," said Shawna Mcbride, an associate director of the Wyoming NASA Space Grant Consortium, speaking to Wyoming Business Report.

Notably, professors of electrical and computer engineering held workshops for the girls, showing off robotics and Raspberry Pis, things that would hopefully pique their interest.

The University of California has also tried to bring young adult women into engineering by hosting a week-long summer camp called The UC Berkeley Girls in Engineering Week that explored the different kinds of engineering that exist in the world. The girls seemed to enjoy the biomedical engineering workshop, the robotics displays, civil engineering workshops and the software development workshops. All of the instructors at the event were women, which inspired confidence in the girls seeing as though they could see that some women do thrive in the engineering industry.

Shocking statistics

An Ohio State University study has investigated how much females who have obtained P.h.Ds earn one year after graduation. The results showed that women earn 31 percent less. The results were published in Science Daily under the title Young women in STEM fields earn up to one-third less than men.

Bruce Weinberg, co-author of the study and professor economics at Ohio State said: "There's a dramatic difference in how much early career men and women in the sciences are paid. We can't get a sense of some of the reasons behind the pay gap, but our study can't speak to whether or any of the gap is due to discrimination. Our results do suggest some lack of family-friendliness for women in these careers."

The data has confused the authors due to inconceivable reasons as to why women are earning less than men in STEM fields. The data was compiled by the U.S. Census Bureau with help from the American Institutes for Research. It is concrete evidence that women are earning less in STEM fields. The STEM career compensation data has been recently unavailable however 150 institutions will hopefully be publishing their data soon. Only 16 universities have provided data for researchers to comb over that have produced the above-mentioned results.

- Details

- Written by: Quintus Potgieter

- Category: Developments

What is the next ultra-strong building material the world is going to use in its structures? You've been using it since you were a child, it's been under your nose the entire time. Sand. The stuff sand castles are made out of. However, whenever you've made a sand castle it's usually ended a crumbling mess even if you built it well. This is where geotechnical engineering comes in. The aim is to make regular sand/dirt a stronger material so that we could eventually sturdy structures on the inexpensive ground we stand on. We already use some of the technology in highway projects in our world today. But there could be a fruitful future in mechanically stabilized earth.

A YouTube channel called Practical Engineering has shown how this is possible. They foresee a future where instead of the molecular bonds that steel and concrete require (which produces fossil fuels in its creation), sand is could be an all natural alternative. But how do we strengthen something so 'fluid' as the sand that immediately falls away when we scoop a handful of it up from the beach? Practical Engineering points out that when a force is applied to soil, the sliding planes are infinite and therefore something cannot stand on it without making the soil's rigidness fail.

Reinforcing elements are the answer. Sand requires more reinforcing elements because it cannot stand up vertically with causing a slope. Concrete can stand at a vertical face due to the mechanical stabilizing that the engineers have secured within it or around it. So the YouTube channel explains that flat pieces of fabric are layered between the soil which creates a reinforcement and strengthens the sand. This in a real life example would obviously translate to a sturdier soil reinforcement method with sturdier materials. They show that MSE (mechanically stabilized earth) walls are used in highway projects and then covered up with patterned walls that are quite nice to look at but are always an example of soil that has been stabilized with reinforcements and are actually super-sturdy pieces of engineering.

Steel reinforcements - that can be layered in between soil - are utilized in the civil engineering world today, but the future of a cost-effective fabric that could be layered between soil could be the future of reinforced soil. The current issue with using steel reinforcement is that corrosion can occur, however, the patterned panels can preserve some of the corrosion that would occur due to wind and water, however, most engineers point out that the panels are basically just for decoration. However, some galvanized steel reinforcement blankets can last up to seventy-five years according to industry insiders, and that can be layered in between soil to mechanically reinforce it.

Do give the video a watch, they balance a car on a cube of reinforced soil to show how sturdy it can actually be.

- Details

- Written by: Quintus Potgieter

- Category: Developments

What software do you use to make incredible, engaging engineering designs? Are the products you're designing ready to connect to the Internet of Things? Autodesk Fusion 360 looks to be a mechanical engineer's dream software and they have now updated it to include something they call Fusion Lifecycle and Fusion Connect. Yes, Autodesk is embracing the Internet of Things, which was quite apparent since they bought out a company called SeeControl that specialized in cloud-hosting and IoT. Now, thanks to technologies from SeeControl, Autodesk now gives engineers the freedom to design whilst their program analyses and manages performance data for you.

"Both Autodesk Fusion Lifecycle and Fusion Connect are existing products, but they're now dramatically enhanced. Fusion Connect captures, analyzes, and manages performance data, so you can improve your design. It monitors products remotely. It can even push out new features over the internet. The fundamental mission for Fusion Connect is to identify failures before they occur," said Ron Locklin, Autodesk's director of business development for Fusion Lifecycle.

Thanks to their new Fusion Connect platform, engineers can create IoT infrastructures and see how the products would behave in those sorts of connected networks. This could be invaluable for industrial complexes that are moving towards the Internet of Things but need an example of how their machinery would work alongside it.

The software utilizes the Industrial Internet of Things and can produce the data the engineers need so that an industrial process can be refined to the point that it improves the product that is being made. It will also connect smartphones to the software so that the engineers and bigwigs of a company can keep an eye on production rates and data that pertains to how efficient a factory is working.

Autodesk's Fusion platform claims it can do more than just IIoT work, it can also deal with industrial additive manufacturing (3D printing) designs as well. They are certain their cloud-based, non-hardware solution will ensure that products get designed and manufactured much quicker.

Autodesk also wants to encourage engineers to design products that can connect to the Internet of Things and they have eight tips on how to achieve that goal:

- Identify IoT value: Determining what information customers will value in an innovation.

- Build product model: How the product creates value.

- Build product app: An app that monitors and interrogates built models and accesses the real time analytics. System data must be available. Point & click approach to making IoT analytics easy for anyone to read.

- Set up analytics: Real-time analytics (rules engines that make decisions in the present), predictive analytics (what a product may do in the future and how efficient it may be), descriptive analytics (makes sense of the past) and prescriptive analytics (based on a rule, how would the product react).

- Choose networking equipment: After choosing the sensors the industrial machines will work on, the network fabric is decided on. Operational Technology Network: Connects the sensors within the product. Then the Information Technology Network connects the OT network to the product-cloud so that the analytics can be presented to anyone who would like to see them.

- Connect network and product cloud with backhaul connection: WiFi/4G connections to ensure the sensors and products talk to each other and upload their data to the cloud.

- Security & privacy: Saving the system from external hackers or internal factors.

- Connect external systems: Standalone third party analytics measuring systems could be possibly be installed so that a company doesn't need to make sense of the analytics themselves, a third party can tell them what is happening with their machines and how to improve them.

Autodesk says that their Fusion products are perfect design tools to perfect all of the above-mentioned guidelines on how to create a product that is fit and ready for the Internet of Things. However, whether the cloud-based software is used or a different program is used, once a product has been designed, then manufactured, the only logical way forward in the world of today is to get it to connect to the Internet of Things.

- Details

- Written by: Quintus Potgieter

- Category: Education

The University of California, Davis and Santa Cruz branches, have accepted a twelve-year-old student who already has three degrees behind his name. He might be enrolling for biomedical engineering but doesn't know which university he wants to attend. What he does know is that he has aspirations to become a doctor and medical researcher when he finishes his studies at the ripe age of eighteen-years-old. His name is Tanishq Abraham

"I think I'll be 18 when I get my MD," Tanishq told reporters.

It was earlier this year that a girl of 15 aimed for a bright career in engineering in South Africa. Tapiwa Shendelane was accepted into the Univeristy of Witswatersrand for her Bachelor of Science in Industrial Engineering after achieving six distinctions in her final year at school.

"I used to get 100% in tests all the time without even putting in an effort. Even in my matric year, I didn't expect to do as well as I did, because I did not put in an effort," she said to News 24. "Age means nothing to me. I believe that education creates success and I want to encourage every young person to work hard despite their circumstances."

You might be thinking: Twelve years old, fifteen years old, that is far too young for a child to have left school and start studying. However, they get even younger than that. Before the end of last year, the Independent reported a story about a boy named Ayan Qureshi who became the youngest qualified Microsoft Computer Specialist. He was five years old when he completed the exam at Birmingham University. The qualification includes a deep understanding of Microsoft operating systems and how they can be turned into networks and the technology behind them.

These children are on their way to becoming superstar engineers because they have the mind for it and the resilience to continue working towards careers in the industry. Most children get disinterested in engineering at a young age in what the Dean of the Engineering Institute of Technology calls the engineering valley of death. To ensure the disinterest of STEM subjects don't happen, nonprofit groups in the U.S. have started up. A group called 100Kin10 was founded back in 2011 and, according to Fortune, has trained 28,000 STEM teachers that will attempt to inspire students to continue pursuing their STEM career dreams.

The stories of children who are persevering through engineering at a young age are so rare and isolated that we almost never hear of them but when we do it makes us wonder about how we could keep children interested in STEM subjects and get them to have fruitful engineering careers in the future. One benefit for children would be having a parent who is already an engineer who show them how it is done and bring them up in an engineering household. However, children should dictate their own destinies but as is apparent, some kids decide from a young age that engineering excites them and they go on to achieve some amazing things.

- Details

- Written by: Quintus Potgieter

- Category: Industry

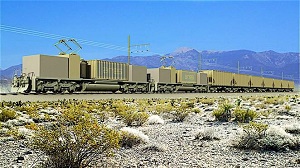

Civil engineering at its finest. Mayerthorpe in Canda experienced a series of arson attacks that saw a railway trestle bridge engulfed in flames. A crew went straight to work on the bridge after the fire of April 26th and was completed by May 15th. It took a record 20 days to rebuild the bridge after a full redesign of the bridge, then using steel span and concrete tubs they began work. It took 190,000 metric tons of steel and concrete to rebuild the bridge. The bridge is now longer than before.The bridge is now longer than before and harder to destroy due to the bridge that burned down completely made of wood. The bridge was ready for the next train to pass over it under a month after it had burned down. These civil engineers deserve a beer.

Charges were laid against a man named Lawson Michael Schalm, a 19-year-old Mayerthrope man. He was charged with 18 counts of arson. Funnily enough, Schalm was one of the firefighters who assisted with dousing the flames of the trestle bridge he had been suspected to have set alight.

Charges were laid against a man named Lawson Michael Schalm, a 19-year-old Mayerthrope man. He was charged with 18 counts of arson. Funnily enough, Schalm was one of the firefighters who assisted with dousing the flames of the trestle bridge he had been suspected to have set alight.

The swiftness of the engineers that rebuilt Mayerthorpe's trestle bridge were under pressure to do so due to the demand of the railway industry that runs on quick turnaround times and cannot afford to be delayed.

Watch the fly-by footage of the burning bridge from April 26 to the twenty days that followed wherein the bridge was rebuilt:

- Details

- Written by: Quintus Potgieter

- Category: Developments

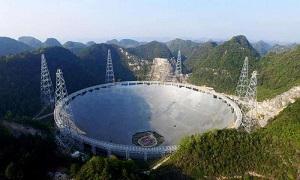

China has just about completed the world's largest radio telescope named the Five-hundred-meter Aperture Spherical Telescope (FAST). The telescope has been built by the National Astronomical Observatories of the Chinese Academy of Sciences (NOAC) with the assistance of Australian CSIRO engineering. Don't question the rationale behind building it, because you will end up listening to a conspiracy theory of how this dish might actually lead to a conversation with an alien race. However, it is a serious effort into finding radio signals within galaxies and investigating dark matter. Essentially, China is looking for radio signals buried far out into the stretches of the universe a radio signal has never reached before. The telescope cost $184 million and is positioned in China's Guizhou Province. There is one snag that is delaying the launch of the telescope. China confirmed to the Xinhau News Agency that it first needs to relocate up to 9,000 people before the telescope can be operational in the area. As a result, an electromagnetic wave environment will descend on the land without any chances of people getting in the way.

Dr. Larry Marshall, Chief Executive of CSIRO told PHYS: "Global collaboration is an integral part of CSIRO's Strategy 2020, as it maps out our desire to deliver science, technology, and innovation to new customers and markets while also delivering benefit back to Australia. This is a really exciting project and builds on 40 years of CSIRO collaboration with Chinese industry and research organizations."

The telescope - which stands at 30 soccer fields in length - will be able to outperform current telescopes by seeing several simultaneous beams as it measures for distant and hidden galaxies. Acting director of CSIRO's Astronomy and Space Science wing, Dr. Douglas Beck, said: "The powerful receiver we've created for FAST is the result of our long history developing cutting-edge astronomy technology to receive and amplify radio waves from space. Extending our technology and collaboration to China and working on what will become the world's largest radio telescope really cements our position as a global R&D leader in this space."

They expect to have FAST fully operational by September, 2016. To see the progress that had been made as of January, check the video below:

- Details

- Written by: Quintus Potgieter

- Category: Industry

Electrical, mechanical and biomedical engineering come together once again. Researchers from MIT, the University of Sheffield and the Tokyo Institute of Technology have been working on a robot that you could soon be ingesting. You read that right. They're calling it an origami robot, in the sense that after swallowing it, it is supposed to unfold when it is inside the body. The robot will then be able to follow a specific order as programmed into it by an engineer.

Daniela Rus, a director at MIT's Computer Science and Artificial Intelligence Laboratory, said: "The robot can remove foreign objects, it can patch wounds, or it can deliver medicine at designated locations."

Daniela Rus, a director at MIT's Computer Science and Artificial Intelligence Laboratory, said: "The robot can remove foreign objects, it can patch wounds, or it can deliver medicine at designated locations."

The researchers showed the robots off at the International Conference on Robotics and Automation in Stockholm this week. They worked with the case studies of children who had swallowed tiny button cells (used in watches, and electronic devices). These batteries that children ingest have harmful side effects and have to be removed through surgery, however, the researchers are confident that the origami robot could solve the need for surgery.

What about stomach acid? Rus explains: "The challenge with designing an ingestible robot is finding biocompatible materials that are easy to be controlled and amenable to the types of operations that are needed from the robot." The researchers used a pig-intestine casing for the robot so that a human body would not reject the robot upon ingesting it. The researchers built this second version that, according to Engadget, propels itself using the stomach's surface.

- Details

- Written by: Quintus Potgieter

- Category: Industry

MIT and the University of Edinburgh were recently awarded some of NASA's Mars-bound Valkyrie robots to test out and improve. The University of Edinburgh has given the world an idea of how challenging the robots are to work with in a new video they have released. The robot is 1.8-metres tall and weighs 275 lbs, equipped with 200 sensors. NASA wants to essentially deliver the bots to Mars in one of their upcoming missions in conjunction with SpaceX. The hope is that the robots will be more efficient and dexterous than the rovers that are currently circumnavigating Mars.

Robert Platt, as an assistant professor at Northeastern University who is working on the project, said: "The rovers get their instructions uploaded at the beginning of the day. Those instructions amount to, 'Go over there,' or, 'Check out that rock.' It's a completely different ballgame when the job for the day is to assemble a couple of habitats." Which is something the Valkyrie robots might have the task of doing.

The University of Edinburgh has shown the initial progress with Valkyrie and it seems the mechanical engineering behind the robot is increasingly complex and slow.

Another university that got one of the four robots to play around with was the University of Massachusetts-Lowell who are working in tandem with Northeastern University. Taskin Padir, a professor at Northeastern University expressed his dismay with the robot's awkward walking and mechanical issues, saying for a price tag of $2.6 million, there's still some progress to be made.

Holly Yanco, a computer science professor at UMass-Lowell's said: "It needs to be able to communicate back to Earth, very clearly and concisely what's going on." However, if it cannot climb over rocks or show dexterity by then, the robots would be mostly useless on Mars. What does look positive is its dense visual mapping, that sees the robot virtually mapping out the terrain that might be necessary for it to navigate around.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Mechanical engineering and biomedical engineering are furthering their bosom-buddy status through a world first testing of HER technology. It means Haptically-Enabled Robots and Australia's Deakin University could be bringing them to the world with Telstra quite soon. The robots would be able to conduct ultrasound imaging diagnoses to remote locations where medical help is few and far between. The robots come out of the Deakin University's Institute for Intelligent System Research and Innovation, and will be connected through a 4G wireless network by the help of Telstra.

The 4G wireless network will also allow a doctor to be sitting 620+ miles away whilst they control the robot and use the technology on a patient that is in another part of the country. The institute's director, Professor Saeid Nahavandi said the partnership would result in a world-first application of the HER technology that had previously been a pipe dream for some companies to achieve. He said: "Our aim is to develop advanced haptic, or force feedback, and stereovision capability for remote ultrasound procedures. It will increase the availability of ultrasound for regional patients, which is incredibly important, but it will also minimise potential errors, saving time that might be spent having the patient rescanned or transported to a regional hub."

Telstra needs to ensure that the network will be operational twenty-four-seven if this kind of technology is to work on 4G networks. "We're certainly not looking to lock up this technology just for domestic use, we think it has global applicability and certainly we will work with some of our international partners to see how we can license and deploy this for the greater good of the world," said Vish Nandlall, Telstra's chief technology officer. "This can help in improving patient outcomes at the end of the day because we're basically allowing skilled operators to get access to those remote patients without having to travel to those remote locations."

The haptic feedback on the doctor's side will allow them to physically feel what the robot is doing under their command from hundreds of miles away.

Source: ZDNet

- Details

- Written by: Quintus Potgieter

- Category: Education

Getting your honours degree in chemical engineering should lead to employment regardless of the country you got in, right? In South Africa, chemical engineers are taking to the streets to physically beg for jobs in the industry. Social media has sparked a conversation about graduates not being able to get jobs after two photos purportedly showing graduates begging for jobs found their way onto Facebook and Twitter this week.

Both pictures show citizens of the country that claim to have B-tech degrees in chemical engineering. In the first photo that emerged a woman wrote, "I have B-Tech Chemical Engineering. Please help!!! I NEED A JOB. CV in my possession," on a piece of cardboard and stood at traffic lights which is an action synonymous with beggars in the country. Her name is Anthea Malwandle and stood at an intersection in Rosebank, Johannesburg. According to EWN, she completed her degree at the Vaal University of Technology in 2015 and has been looking for a job ever since. The silver lining is that after the picture was shared on social media, she finally got an interview at Sasol.

Both pictures show citizens of the country that claim to have B-tech degrees in chemical engineering. In the first photo that emerged a woman wrote, "I have B-Tech Chemical Engineering. Please help!!! I NEED A JOB. CV in my possession," on a piece of cardboard and stood at traffic lights which is an action synonymous with beggars in the country. Her name is Anthea Malwandle and stood at an intersection in Rosebank, Johannesburg. According to EWN, she completed her degree at the Vaal University of Technology in 2015 and has been looking for a job ever since. The silver lining is that after the picture was shared on social media, she finally got an interview at Sasol.

Then another picture emerged onto social media of a man named Sello Mokate, who graduated from the University of the Free State with his B-tech in chemical engineering as well. He too took to the streets with a cardboard stating his qualifications and asking for a job.

Mokate spoke to Times Live, saying: "It pains me that I rely on my older brother and parents for provisions but I have a B-tech. I thought I would be employed by now but I have sent countless emails and I went to a number of interviews with no success."

Where the divide is occurring is due to the fact that a BSc (Bachelor of Science) or B.Eng (Bachelor in Engineering) degree is research and development oriented and seemingly highly regarded, whilst a Btech degree is implementation oriented. Nonetheless, both  should equate to a job in the industry, however, BTech degrees seem to be ignored by employers. This could be due to the fact that BSc and B. Eng degrees sometimes come from highly regarded universities compared to some BTech students who get their degrees - starting with a national diploma - through a technikon or technical college.

should equate to a job in the industry, however, BTech degrees seem to be ignored by employers. This could be due to the fact that BSc and B. Eng degrees sometimes come from highly regarded universities compared to some BTech students who get their degrees - starting with a national diploma - through a technikon or technical college.

The country has tried to level the playing field and make the qualifications made at technikons equal to those of universities but as is apparent due to the social media postings, that has not been the case. As a result, you get a gap between engineering graduates and employers that seem to exercise preference. However, the situation is changing in a country which is desperately looking for engineers in certain fields. Qualifications from all sorts of institutions are slowly but surely becoming more relevant to employers who require engineers in the industry.

- Details

- Written by: Quintus Potgieter

- Category: Industry

It's an aerospace and aircraft maintenance engineer's worst nightmare. An Airbus 320 belonging to EgyptAir has gone down in the Mediterranean Sea. At around 2:30 a.m. Cairo time (UCT +2), the plane disappeared from radar tracking and by 4:26 a.m. the rescue operations received a distress signal from the plane's emergency devices. MS804 was being tracked by Greek air traffic controllers who said they had spoken to the pilot and ensured that everything was in order and then an hour later the plane made a sharp left turn and then a 360-degree spin to the right. The plane had taken off from France at around 11 p.m. and headed for Egypt.

There is a list of things that could have gone wrong but what engineers are hoping is not true, is that the plane went down for mechanical reasons or for maintenance reasons.

Rescue operations started off the Greek island of Karpathos in Egyptian airspace.

Airbus confirmed the following facts on their Facebook page:

- The aircraft was delivered to Egyptair in November 2003

-Accumulated 48,000 flight hours

-Powered by IAE engines

Egyptian prime minister, Sherif Ismail, a former engineer, said it was too early to say whether or not the crash was linked to terrorism or if it was a mechanical failure that took the plane down.

Egyptian prime minister, Sherif Ismail, a former engineer, said it was too early to say whether or not the crash was linked to terrorism or if it was a mechanical failure that took the plane down.

Associated Press reported that Russia's domestic security chief says structural failure was unlikely. Major General Robert Latiff, who is an expert on aerospace systems and emerging weapons technologies at the University of Notre Dame said the chance of structural failure was: "vanishingly improbable."

Later on in the day, Egypt's aviation minister spoke to media and said that the possibility of a terror attack as a cause for the Egyptair crash was "stronger" than technical failure.

Greek sources had confirmed that they saw "large floating objects" in the ocean and were going to investigate further.

Bloomberg reported at 6:22 p.m. UCT+2 that they had also joined the search for MS804, a report that was preceded by a Reuters report that airplane lifejackets had been found by search teams that were investigating in the area.

CNN was the first news agency to lead with headlines that mentioned any form of bombs possibly taking the plane down. The @cnnbrk (CNN Breaking News) Twitter page wrote: "2 U.S. officials: Initial government theory is that EgyptAir Flight 804 was taken down by a bomb"

The plane had 66 people on board who have been presumed dead, according to Egyptian aviation authorities.

More news on the engineering aspects of the crash will follow as that information becomes available.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Google's annual I/O conference kicked off yesterday. This conference is used as a platform for the engineers of the company to announce new products, show off the engineering behind these new products and give the industry a window into what is coming up in the company's future. The first day kicked off with a few updates to some of the preexisting technologies from the company but also brought a host of new consumer products that the world can be looking forward to. Some of what will be shown at the conference will display exactly how the Internet of Things will soon be integrated into our daily lives and shows just what engineering can achieve. Here are some of the highlights:

Google Home: A voice-activated home assistant device that will bring Google Assistant into your homes. Essentially, you would be able to surf the internet and get information by just talking to the device. A competitor to Amazon's Alexa, the device will also assist in playing music and automating some home tasks. They are being referred to as 'smart-speakers' for the home.

Allo & Duo: A Whatsapp competitor for mobile that has a host of new, innovative ways of text chatting, including a chat service with Google Assistant that seems to border on Siri-like behaviour. Duo is a Facetime/Skype competitor that will allow face to face video conversation over a network, that allegedly will even work when a network is slow.

Android N: The update to the operating system came with a host of new announcements that included the announcement of something called the JIT Compiler which would lead to app installations at a speed that is 75% faster than it currently is on Android.

To see further development in virtual reality and wearables, check out the full I/O keynote:

- Details

- Written by: Quintus Potgieter

- Category: Developments

Engineers at the University of South Wales have just set a new world efficiency record for solar cells. It's allegedly all about the solar cell configuration that allows sunlight-to-electricity conversion efficiency to be pushed up to 34.5%. Dr. Mark Keevers and Professor Martin Green work inside the UNSW Australian Centre for Advanced Photovoltaics and have configured the solar cells in such a way that when sunlight hits it, it splits sunrays into four bands that manage to extract more electricity from them.

The United States National Renewable Energy Laboratory confirmed that the system is 44% more efficient than the last record.

"This encouraging result shows that there are still advances to come in photovoltaics research to make solar cells even more efficient. Extracting more energy from every beam of sunlight is critical to reducing the cost of electricity generated by solar cells as it lowers the investment needed, and delivering payback faster," said Keevers.

UNSW says that the system devised by Keevers and Green using no concentrators and uses pure sunlight, whereas the last record was set by concentrator photovoltaics that utilizes mirrors that concentrate the light.

"What's remarkable is that this level of efficiency has not been expected for many years. A recent study by Germany's Agora Energiewende think-tank set an aggressive target of 35% efficiency by 2050 for a module that uses unconcentrated sunglight, such as the standard ones on family homes," said Green.

The good news is that solar cell efficiency is moving faster than expected, however, Green cautions that photovoltaic research must continue in Australia so that the country can also benefit from the engineering marvels they create. Australia has been progressing past many countries in being the first to subsidize photovoltaic cells for home use in some of its suburbs. The Clean Energy Council has also been very advanced in its setting of guidelines for installers in Australia. Now, with added efficiency, renewable energy is progressing quicker than previously thought. Additionally, the Australian Renewable Energy Agency has been funding solar concentration methods of photovoltaic cells. Recent reports on funding have indicated $1.4 million has already been funded.

Source: UNSW Australia News Room

- Details

- Written by: Quintus Potgieter

- Category: Developments

China wants to be in charge of building service robots if the latest bid for a robotics company is any indication. A Chinese group named Midea Group has just put in their bid for Germany's Kuka Robotics. Their offer to the company is around $5 billion, which should show the seriousness of the market of service robotics. Kuka's current focus is how robotics will factor into the Internet of Things and assist the expansion of Industrie 4.0.

An automated welding robot is what one of their recent videos has shown off, a robot they also displayed at the Hannover Fair 2016. China, already synonymous for their robotic pioneering, will cement themselves as the number one importer of robotics if their deal for Kuka goes through. The International Federation of Robotics has reported that China currently utilizes 36 robots to every 10,000 humans. They lag behind the United States, who has 164 robots per 10,000 humans, who then lag behind South Korea who have 478 robots per 10,000 humans. The group also report that industrial robot sales have jumped up by 8% in 2015, with the greatest demand being in the automotive industry.

Midea Group says that they are not interested in a full takeover, which might bode well for some engineers working in the background at Kuka AG. It looks like their expertise is being chased here, but their $3 billion a year business might also be an attractive draw card. Nonetheless, experts are saying that Midea's purchase of Kuka could put them in the driver's seat of industrial automation in the world.

The Wall Street Journal has released the figures, showing how many Chinese companies have exacted takeovers of international companies. The results are staggering:

| Date announced | Target | Country | Industry | Acquirer | Deal value excluding debt, in billions |

| Feb 3 | Syngenta | Switzerland | Agribusiness | ChemChina | $44.1 billion |

| Feb 17 | Ingram Micro | United States | Technology | Tianjin Tianhai Investment Development | $6.1 billion |

| Jan 15 | General Electric | United States | Consumer Products | Qingdao Haier | $5.4 billion |

| May 18 | Kuka | Germany | Robotics | Midea Group | $5 billion + |

| Jan 12 | Legendary Entertainment | United States | Leisure and recreation | Dalian Wanda Group | $3.5 billion |

The biggest Chinese takeover of a company this year is ChemChina's mammoth $44.1 billion takeover of Syngenta in agribusiness, however, the biggest robotics takeover is Kuka's purchase by Midea Group. It should be interesting to see what kind of industrial robotic technologies come out of the deal but some analysts believe that Midea Group might want to venture into the home-robot industry for consumers to purchase. Time will tell.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Wearable technology is the current trend that has led to a plethora of engineers that are investing their time into creating incredible innovations. Building batteries for devices that can be worn on a body is a challenge due to the need for a battery that powers wearables without being clunky and getting in the way. Smart watches are getting it right to some degree but what if we want truly skin-tight wearables? Researchers have looked into the flexibility of batteries and have come up with something that could revolutionize the field of wearable technology.

At the University of Illinois, in the Department of Materials Science and Engineering, researchers have been working on flexible power systems. They have published their findings in the Proceedings of the National Academy of Sciences under the title Soft, thin skin-mounted power management systems and their use in wireless thermography.

In the abstract of their report, the researchers say the current options for wearables are "incompatible with thin geometries" and aim to change that with their new flexible alternatives. They have created millimeter-scale solid-state batteries, along with solar cells into "electrically interconnected arrays".

Explaining the electrically interconnected arrays, the engineers in their statement to the press, said: "The components are electronically connected via flexible copper-polymer interconnects, mounted on a highly elastic silicone core, and enclosed within a silicone shell. The resulting system could stretch up to 30% without detectable loss in solar power generation."

At the helm of the project is Professor John Rogers, at the Department of Materials Science and Engineering at the University of Illinois. He said: "If you think about conventional electrical devices they are all rigid as a consequence of the fact they are all formed on wafers of silicon. The question is how do you get from that to something that looks like the skin that matches the shape of the physical body."

The researchers then came up with the interconnected arrays that are connected through what they called 'spring-like wiring'. The result is something that can be worn and is stretchy enough to fit over a surface and then tightens up like a piece of clothing.

The research will be invaluable to the wearables industry as technology further integrates with humans and their bodies.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Germany. May 8th, 2016. Renewable energy in the country was utilized more than it had ever been utilized in the past. The country almost operated completely on renewable energy and left fossil fuels wondering what had happened. According to Bloomberg, at 2 p.m. on Sunday renewable energy sources supplied 45.5 gigawatts of the 45.8 gigawatts that were being demanded.

"Events like this highlight that eventually we may need to start curtailing because of market-wide oversupply. In the long-run, that may provide a case to build technologies that can manage this oversupply -- for example more interconnectors or energy storage," said Monne Depreaetere, an analyst at Bloomberg.

The contributing factor, that cannot be reproduced at the drop of a hat, unfortunately, was weather conditions. There was a lot of wind on Sunday and that send wind turbines a-spinning. Germany is, however, currently getting a third of its energy from renewable energy sources. Additionally, solar, hydro and biomass plants factored into the amount of renewable energy that was supplying the country with energy for a few hours. At 2 p.m. the cost of energy was in the negative numbers in Germany, which means Germans were making money by using electricity.

The contributing factor, that cannot be reproduced at the drop of a hat, unfortunately, was weather conditions. There was a lot of wind on Sunday and that send wind turbines a-spinning. Germany is, however, currently getting a third of its energy from renewable energy sources. Additionally, solar, hydro and biomass plants factored into the amount of renewable energy that was supplying the country with energy for a few hours. At 2 p.m. the cost of energy was in the negative numbers in Germany, which means Germans were making money by using electricity.

Germany is focusing on 100% renewable energy by 2050, pushing forward and hoping to achieve most of the goals by 2030, which some critics have their doubts about.

And then out of nowhere, Portugal joined the party as well. They ran on competely renewable energy for four consecutive days. They ran from Saturday, 7 May to Wednesday, 11 May. Portugal has put a lot of funding behind solar energy to ensure that these sorts of feats of engineering are possible.

- Details

- Written by: Quintus Potgieter

- Category: Education

The World Health Organisation has said that 360 million people in the world are suffering with some sort of hearing loss. The most affected areas are South Asia, Asia Pacific and parts of Africa. Medical experts say that hearing loss is avoidable if diagnosed early on through primary prevention. However, the areas aforementioned are third-world areas and don't always have access to primary prevention processes in avoiding hearing loss.

Thankfully, engineering students are coming to the rescue and proposing a cheaper alternative to octoscopes that would involve plugging an item into a smartphone then taking photos of inside the ear. Students at Texas A&M University in the Engineering World Health department designed a model LED otoscope that will hopefully recieve funding so that anyone can keep a tab on the health of their ears.

This is not a foreign idea, there is a product called the Cellscope Oto that serves a similar purpose. With more and more engineers working on this technology, we could see the tool distributed globally for the health of ears everywhere.

Tessa Bronez, a biomedical engineering graduate, said: "We have a lot of electrical engineers on the team, and they were really excited about doing something with optics."

The engineers decided to use a cell phone to make the otoscope cheaper due to the camera on the phone being instrumental in the process. "A lot of people are surprised to hear that many people in developing countries have smartphones, particularly in the more urban areas where hospitals are," Bonez said.

The team of engineers used a 3D printer, a normal otoscope lens and a motherboard. Then the smartphone can be attached to the device and be ready to monitor ear health. The researchers say the cost is $6.42. This is far cheaper than the estimated price of $299 for the otoscope by Cellscope, that will sell an iPhone case with the attachment on it. The low price point makes the students at Texas A&M University's otoscope design the most economical one that would apply directly to impoverished communities.

Source: Medical Xpress

- Details

- Written by: Quintus Potgieter

- Category: Industry

Suzuki Motor Corp and its engineers have decided to come out with the truth due to a scandal that has been spreading through the automotive engineering world. The car maker divulged details that led to certain discrepancies in fuel efficiency reporting, indicating that the company had not abided to Japanese guidelines, and rather worked around them.

- All 16 vehicles currently available used data that did not accurately report emissions through the correct processes leading to improper testing. The improper testing affects 2.1 million cars. Instead of using the proper coasting test of the entire car, individual parts of the car were tested and factored into the final reports.