News

- Details

- Written by: Quintus Potgieter

- Category: Industry

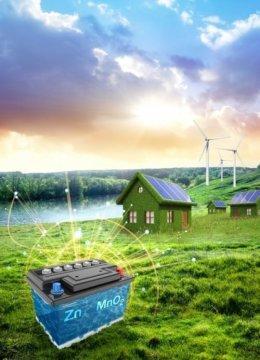

It has taken a while but finally the Clean Energy Council of Australia (CEC) has released guidelines that will tighten home battery storage reliability in terms of installations. A picture of an 'exploded' lithium-ion battery was circulating on Australian social media channels back in March which spurred an ongoing push for more reliable installation methods.

In Australia, specifically, installation standards have not been upheld and installation training has not been prioritized as of yet. In the United States, the National Fire Protection Association has been training firefighters to respond to fires caused by energy storage systems, according to MicroGridKnowledge. The fires synonymous with home energy storage units is caused by thermal runaway. This is where one cell fails and catches fire which causes the rest of the cells in a unit to also catch fire, causing an explosion. A firefighter, Matt Pais, explains: "When lithium-ion burns, it creates its own oxygen. It can create a violent explosion depending on the chemistry. The cells can explode why they overheat. If you take 20 or 30 of those cells and subject them to heat when you're testing the cells, you can have huge amounts of toxins and flammables."

Thus, the CEC in Australia has released the installation and safety guidelines for installing home energy storage units. The CEC now has Solar Accredited Installer cards that an installer is required to have to ensure that an installer is proficient in the tools of installing home energy storage unit systems. They have currently accredited 4,800 installers in Australia alone. Recently, you did not have to have any form of formal training to install energy storage units inside homes.

According to One Step Off the Grid, the Installation Guidelines for Grid-Connected Energy Systems with Battery Storage would be able to ensure secure installations that are done correctly and minimize the chance of accidents occurring with the installation of the estimated 50,000 battery storage systems to be connected in Australia in the next year.

CEC Chief Kate Thornton said: "Everyone is excited by the potential future of a future created by a combination of renewable energy, home energy storage and smart energy technologies. The new guidelines are an important step in making that vision a reality. It is obviously important that industry professionals take these risks extremely seriously and operate in a way that ensures the safety of themselves, their colleagues and consumers."

These guidelines also rely on the energy storage unit companies to engineer reliable products that don't malfunction and explode. To emphasize reliable engineering, the Dean of Engineering at the Engineering Insitute of Technology, Steve Mackay, broached the topic in the nineteenth episode of the Engineering News Network. The reliability is not limited to energy storage units, but it would be a good reminder to energy storage unit manufacturers to build reliable systems. And most of the electronic devices we use today are powered by lithium-ion, so the reliability of lithium-based products needs to be emphasized.

Mackay says:

A lot of devices exhibit the 'bath tub' reliability curve which you're probably familiar with. Which means at the beginning of the life cycle of a product, high failure rate and then it settles down and then most of the product lifetime there is a low failure rate. Then, near the end of the lifetime you get that tweak upwards of high failure rate.

No product is going to be manufactured with a 100% reliability, for the simple reason that it would cost too much. Manufacturers and vendors wouldn't be able to sell their products. A lot of products - such as phones - do have a lower than 100% reliability. That is the way of the commercial world.

Mackay concludes by saying the only industry that needs to have complete, one hundred percent reliability is in the manufacturing of aircraft parts. However, it is clear that policymakers cannot keep up with the speed of invention in the battery storage industry, but, the Clean Energy Council of Australia are monitoring the situation and ensuring that installation methods are safe and reliable.

To receive accreditation in Solar PV installations, visit the Solar Accreditation Australia website.

- Details

- Written by: Quintus Potgieter

- Category: Industry

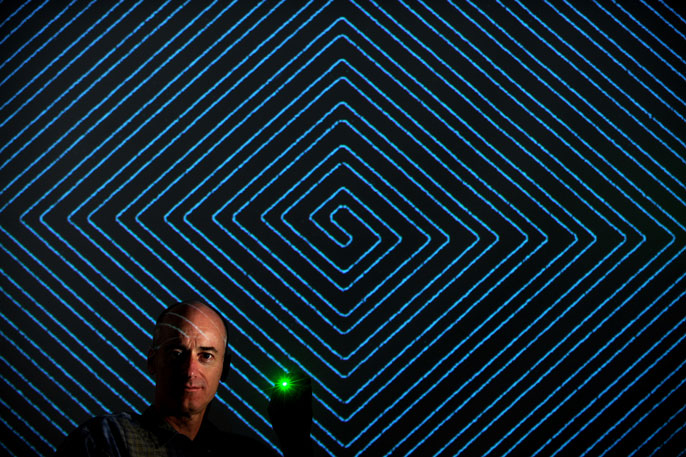

The civil engineering, defense, forestry and agriculture industry have been adopting LiDAR (Light Detection and Ranging) technology. A trend that started in 2014 and will continue to 2020. This according to a report by Allied Market Research that has published its findings in a journal titled Global LiDAR Market - Size, Industry Analysis, Trends, Opportunities, Growth and Forecast, 2013-2020.

Explaining the benefits of LiDAR, Director of Remote sensing at Dewberry, said: "The laser ranging device sends out millions of pulses - today they can send out over four hundred thousand pulses in one second. That technology gives you the distance and the range to the target." The technology also uses global positioning systems and IMU systems as well. It is the most reliable way of navigating terrain that currently exists in the world of today. It is the technology that allows self-driving cars to navigate and avoid obstacles that come across its path. Hence, the LiDAR market is growing rapidly.

The Indian government also spoke of how they will be adopting more LiDAR technologies in the near future. The Surveyor General of India spoke to The Hindu, saying: "Use of LiDAR technology is quite beneficial and it gives quality data in digital form in a short time. This data can be used in many projects related to roads, canals, surface transport, city planning, landslides, irrigation etc,"

The report by Allied Market Research says that the LiDAR market is expected to rake in $3.22 billion by 2022. The reason for the spike in the market, analysts say, is due to the automotive sector and civil engineering industries continuing to make use of LiDAR technology.

LiDAR technology has been estimated to have the biggest CAGR (compound annual growth rate) in the UAV (unmanned aerial vehicle) sector due to the number of drones being purchased by the media, entertainment, precision farming and personal hobbyist industries, including the governmental use as well. The market will grow most in the Asia-Pacific regions between 2016 and 2022, the report said.

However, North America currently owns 45% of the current market in 2015, with Europe trailing them with a 33% revenue share, according to DirectionsMag.

Ford has recently used LiDAR to allow a self-driving car to see in the dark. To see what a self-driving car utilizing LiDAR technology would 'see', check this video out:

- Details

- Written by: Quintus Potgieter

- Category: Industry

The competition for space on your wall in your garage or in the basement of your business is heating up in the energy storage battle as more companies bring out their answer to renewable, clean energy units. Tesla's Powerwall caught the attention of the public globally, whilst in Australia, Redflow's ZCell impressed audiences. Now, Mercedes-Benz and Lockheed and Martin are entering the game, to confuse consumers even more as to who to give their money to.

Mercedes-Benz says:

Innovative new energy storage systems for businesses and private customers -- powered by lithium-ion batteries commonly found in electric vehicles -- are now able to efficiently store and release energy on demand. Lithium-ion energy storage systems are at the ready to provide complete freedom to consumers

Therefore, Daimler AG with the contributions of Deutsche ACCUMOTIV have developed their own home energy storage systems and have begun shipping them. The companies supply the latest Mercedes-Benz models with their electric systems.

Harald Kroger, the Head of Development Electrics/Electronics and E-Drive Mercedes-Benz Cars said: "There is tremendous interest in our energy storage units and we have already received numerous orders. Over the coming months, we will continue to step up and expand both sales in Germany and on the international market."

Daimler can reportedly connect up to 8 battery modules that have 2.5kWh each that would add up to 20kWh, which would provide a good backup system for grid peak times. According to their press release, the price for the photovoltaic cells would be calculated based on the customized package a customer would order. These would include the photovoltaic system, battery inverter, energy management services from Daimler and the Mercedes-Benz energy storage unit. Then installation costs as well.

In Daimler's press release they spoke of the reliability of the product they are launching:

Their network of qualified specialist installers take care of providing the end customers with on-site advice, planning, compiling an individual quotation for all components and the actual installation. Stationary battery storage units are generally installed together with a photovoltaic system. Some 500 installers throughout Germany have already undergone training in collaboration with partners.

Lockheed Martin also wants in on the action, it seems. They are launching an industrial-sized photovoltaic system that trumps the current Tesla Powerpack. The Powerpack currently pushed out 100kWh, but Lockheed Martin's will achieve both 250kWh and 500kWh depending on which one is purchased. For now, it doesn't look like they will be doing private (home) energy storage systems, however, it seems they are trying to assist electricity grids around the world so that cleaner energy can be produced.

Whether or not Lockheed Martin becomes a major competitor remains to be seen due to their focuses on aerospace engineering that seems to be getting more attention than energy storage. Thankfully, the more entrants into the private and public energy sector mean more security training and further development in the industry which relates to safer batteries and a good selling price point.

- Details

- Written by: Quintus Potgieter

- Category: Education

Have you ever been in the position where you've had to communicate with a person from the deaf community? It is a daunting task for some to attempt communication with a person who has that disability due to not understanding sign language. Two students from the University of Washington intend to redesign the way deaf people communicate with tech-gloves called Sign Aloud. The students (Thomas Pryor and Navid Azodi) won a competition named the Lemelson-MIT Student Prize that searched the United States for new inventions from students. The Sign Aloud gloves can be worn by a deaf person, who then would talk sign language and the tech attached to the gloves would convert the sign language movements into text or speech.

Talking to UW Today, the students said: "Our purpose of developing these gloves was to provide an easy-to-use bridge between native speakers of American Sign Language and the rest of the world. The idea initially came out of our shared interest in invention and problem solving. But coupling it with our belief that communication is a fundamental human right, we set out to make it more accessible to a larger audience."

To see what it is capable of, check out this video:

The two students are calling it an American Sign Language Translator. The gloves have sensors connected to the hands and the wrist that measure hand position and movement. Then through Bluetooth, the data is sent to a program coded by the students that convert the movements into actual text or speech.

Some online commenters are saying $10,000 is not enough money to jumpstart the project and have encouraged the students to either start a Kickstarter page or take the idea to Shark Tank - a reality program for inventors - to get their gloves funded.

Pryor and Azodi say that the gloves for right now are a prototype and require clunky elements like a laptop and the gloves themselves. The students say that the future of the product could be an app on a smartphone. However, their prototype right now seems to be a working, functional method of converting sign language into text and speech, that is understandable to able-bodied people.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Product engineers reinvented the wheel this week. Okay, maybe they just redesigned the hair dryer. Dyson known for their vacuum cleaners, hand dryers, fans, and heaters has now entered the beauty game with their new design, that reportedly cost $71 million to develop. The company has called it the Dyson Supersonic and will cost $400. The price tag is astounding for a hair dryer, however, the fashion industry is probably going to latch on to the premium product quite quickly, getting the money to those engineers who arguably reinvented the hair dryer.

Tom Crawford, the Head of Product Development for New Categories at Dyson told TechCrunch, "When Dyson goes into a new category, we always think about how we can make it better. Part of the challenge is making sure we invest in the right technology and testing to do so. The first part of this was to learn the science of hair. How to test it, how to make it repeatable, and then how to measure it. We built our own state of the art laboratory dedicated to investigating the science of hair."

Yahoo spoke to Dyson as well, revealing that the company sent their engineering team to beauty school to gain inspiration before developing the new hairdryer. How many engineers can say they've been to beauty school in their illustrious careers? Dyson said, "We are experts in all things airflow, fluid dynamics, hardware...all things engineering. But we surely aren't style experts. Having a group of young engineers attend styling classes made them see the end benefit of this machine and how the hair dryer can truly be improved."

What is under the hood, you ask?

Dyson says they have created the Dyson digital motor V9 . It is a small motor that the engineers managed to fit in the handle of the dryer, instead of the usual head placement of the motor in other dryers. They have also developed a glass bead thermistor which transmits data to a microprocessor which the company says "intelligently controls the patented double-stacked heating element."

We're starting to understand why this engineered hair dryer costs $400.

Check out this video that shows off the technology - the part we care about most, right engineers? - of the new Dyson Supersonic.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Researchers at the University of Minnesota have written a report in Physics of Fluid that make a case for a change of methodology when studying turbulence pertaining to jets.

The researchers say that fluid flows in predictable patterns with high-speed jets which explain why jets are so loud. The team wants to use their findings to influence the dynamics of jets to minimize the volumes they produce.

Joseph W. Nichols, an assistant professor of aerospace engineering and mechanics at the University of Minnesota, spoke to Eureka Alert, saying, "Back during the 1960s, it was shown that coherent parts of turbulent fluctuations inside jets are connected to instability wavepackets, which are linked to noise radiation. A wave packet is an oscillation that repeats if you look at it over a short time and length scales, but when you zoom out you can see it varies slowly over a long distance."

The abstract published by the team explains:

For supersonic jets, the optimal response closely resembles a wavepacket in both the near-field and the far-field such as those obtained by the parabolized stability equations, and this mode dominates the response. For subsonic jets, however, the singular values indicate that the contribution of sub-optimal modes to noise generation are nearly equal to that of the optimal mode, explaining why the PSE do not fully capture the far-field sound in this case.

Mihailo Jovanovi, an associate professor of electrical and computer engineering, said: "We treat high-speed turbulent jets as amplifiers that take fluctuations inside the jet as inputs and give back sound. And we use this mathematical framework to identify modes that induce large-output amplification and generate loud noise."

Mihailo Jovanovi, an associate professor of electrical and computer engineering, said: "We treat high-speed turbulent jets as amplifiers that take fluctuations inside the jet as inputs and give back sound. And we use this mathematical framework to identify modes that induce large-output amplification and generate loud noise."

The studies into quietening down jet planes could lead to healthier airport staff, say the researchers. It was confirmed by health professionals last year that exposure to loud aircraft could lead to heightened blood pressure.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Aerospace engineering will reach another milestone when SpaceX and NASA launch the Red Dragon on a mission to reach Mars. Elon Musk has announced that by May 2018, they want to be prepped and ready to go to Mars. The mission will see a bigger version of the Falcon 9 - which successfully landed itself on a barge earlier this year - known as the Red Dragon, enable a capsule to land on the surface of Mars.

The end game for SpaceX would be getting more spacecraft to Mars and starting a colony on the planet. Musk is planning to let the media in on their plans for colonization of Mars in September. This keynote will happen at the International Aeronautical Congress in Mexico.

The 2018 launch will be an unmanned launch and will see the Red Dragon travel to Mars and attempt to land on the surface. According to Musk's twitter, the engineer said: "Dragon 2 [the spacecraft travelling to Mars] is designed to be able to land anywhere in the solar system. Red Dragon Mars missions are the first test flight." This means that Mars is not the only planet SpaceX is considering.

"Building on an existing no-funds-exchanged collaboration with SpaceX, NASA will provide technical support for the firm's plan to attempt to land an uncrewed Dragon 2 spacecraft on Mars. This collaboration could provide valuable energy entry, descent, and landing data to NASA for our journey to Mars while providing support to American industry," NASA said in a statement.

NASA intends to take humans to Mars by 2030, hence their involvement in the SpaceX launch. Both companies want to theoretically entertain the idea of sending humans to the Red Planet and the data that comes from this mission would be beneficial to both of them.

SpaceX has also announced they were successfully awarded an $83 million contract to launch a GPS satellite into space, funded by the US Air Force. Lockheed Martin, an aerospace engineering and design company - who are busy working on the next Concord-like aircraft - used to be the only company entrusted with space launches but it seems SpaceX's recent successes in the industry has changed the game up.

A Lieutenant General Samuel Greaves, head of the air force's Space and Missile Systems Centre, told the Guardian: "This GPS III launch services contract award achieves a balance between mission success, meeting operational needs, lowering launch costs, and reintroducing competition for national security space missions."

- Details

- Written by: Quintus Potgieter

- Category: Industry

The United States' first shipment of liquefied natural gas (LNG) has made its way to Europe this week. The U.S. has always been a big LNG producer but not big on export. Now that the country is becoming an exporter, analysts are saying it will be causing competition in the LNG market.

The market has been dominated by Russians companies. However, Thierry Bros, an analyst at Societe Generale told Wall Street Journal: "It's the start of the price war between U.S. LNG and pipeline gas."

The U.S. delivered the LNG to Portuguese company Galp Energia. Analysts say that the U.S. will become a key player in LNG exporting by 2017.

Russia is currently shipping LNG that is 35% more expensive than the U.S, but according to WSJ, the suppliers were prepared for a price war and would be able to cut rates in half. Russia cannot afford to lose business in the LNG sector due to the export being one of the most profitable exports the country has.

An energy analyst from Strategy&, Rui Almeida, spoke to SputnikNews about the Russians' situation:

Gazprom [the Russian energy company] will be faced between losing market share or lowering prices. And Gazprom has publicly said they will defend market share so the best is on lowering prices. What we may see play out in gas is not dissimilar to Saudi Arabia's strategy in crude market - going for market share, maintaining production to price out higher marginal cost producers namely US oil. We may witness a similar strategy by Gazprom as it protects market share in Europe.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Cybersecurity engineering is quickly becoming a lucrative field to become well educated in due to the digital exodus that companies are making into cloud-based solutions. Entire companies and even power utilities that service an entire country are moving their operations and interfaces into the cloud, using the Internet of Things to access data output they were previously never able to observe. These systems need security and that is where cyber security engineers come in.

Tertiary institutions now offer modules that would assist individuals with becoming proficient in securing companies, and in turn, protecting them from cyber attacks. To lay the groundwork for being qualified as a cyber security engineer, an individual - for example - could take a six-week Cybersecurity for automation, control, and SCADA systems course.

CloudPassage, who offer cyber security to enterprises, say that cyber security education in U.S. tertiary institutions got an 'F' for cybersecurity education. The group says that they conducted research of 121 top-ranked U.S. universities and discovered shocking revelations.

Their findings regarding the top 50 universities [out of the 121 surveyed] revealed:

- None of the top 10 U.S. computer science programs require a cybersecurity course for graduation. In fact, three of the top 10 university programs don't even offer an elective coourse in cybersecurity

- University of Michigan (ranked 12th) is the only one of the U.S. News & World Report's top 36 U.S. computer sccience programs that requires a security course for graduation

- Only three of Business Insiders' top 50 U.S. computer science programs require a cybersecurity course for graduation: University of Michigan, Brigham Young and Colorado State University

CloudPassage also quoted Commerce Secretary, Penny Pritzker, who said that there are 210,000 unfilled cybersecurity jobs in the U.S.

CloudPassage also quoted Commerce Secretary, Penny Pritzker, who said that there are 210,000 unfilled cybersecurity jobs in the U.S.

Robert Thomas, the CEO of Cloudpassage said: "There needs to be a fundamental shift in the cybersecurity paradigm; we must get to a point where every university requires computer science majors to complete cybersecurity training as a graduation requirement, so that the programmers and developers of the next generation have security front-of-mind when delivering products to the market."

These revelations reported on whilst the Government Accountability Office of the United States issues a warning about cybersecurity of vehicles. The fact that self-driving cars can be hacked into is becoming a concern for the GOA and the current capability hackers might have to hack into vehicles.

"Researchers have shown that these interfaces -- if not properly secured -- can be exploited through direct, physical access to a vehicle, as well as remotely through short-range and long-range wireless channels. For example, researchers have shown that attackers could compromise vulnerabilities in the short-range wireless connections to vehicles' Bluetooth units -- which enable hands-free cell phone use -- to gain access to in-vehicle networks, to take control over safety-critical functions such as the brakes."

- Details

- Written by: Quintus Potgieter

- Category: Industry

Engineers are often presented with an opportunity to create something they never thought they'd be attempting due to the way humans integrate with technology. Humans are constantly staring down at their smartphones whether it's the increasingly dangerous texting and driving in a car, or walking down the street, with their eyes glued to the screen.

Engineers in Germany noticed that when people look at their smartphones at traffic lights, they tend to ignore the traffic lights.

According to the Washington Post, the city of Augsburg will be looking into implementing traffic lights built into the pavement. This way, people who are looking down at their phones will see an illuminated pavement and know when it is safe to walk over the road. The light-up pavements have been tested at tram stations in the town, and may lead to further development if proven to be successful.

According to the Washington Post, the city of Augsburg will be looking into implementing traffic lights built into the pavement. This way, people who are looking down at their phones will see an illuminated pavement and know when it is safe to walk over the road. The light-up pavements have been tested at tram stations in the town, and may lead to further development if proven to be successful.

Stephanie Lermen, a spokeswoman for Augsburg, said: "It creates a whole new level of attention."

But some of the German residents of the town are not convinced pavements that light up with the colour of the traffic lights are good to have. The greater public are not convinced taxpayer money should be spent on the pavement lights.

Multiple reports in several countries have alluded to the fact that smartphone distraction in public areas is killing humans, which makes the case for engineered solutions for life-saving inventions.

Should other countries follow suit or are the light-up pavements a waste of taxpayer money?

- Details

- Written by: Quintus Potgieter

- Category: Developments

The immediate future of energy storage is not the full replacement of the grid but rather the alleviating of strain on the grid through the use of batteries. Territories such as the United Kingdom, the United States, and Australia have been early adopters of energy storage technology and are looking forward to using battery technology during peak grid times, thereby, saving money and allowing the grid to operate optimally.

However, Germany is not as convinced that battery storage technology is for them. According to GreenTechMedia, a study named Merit Order for Energy Storage Systems 2030 was conducted over a three-year period by the Federal Ministry of Economic Affairs and Energy.

Christoph Pellinger, who led the study, says that they believe energy storage batteries will not be able to meet Germany's energy requirements in the next ten years. He went on to say, "I can think of lithium-ion battery storage for primary frequency control: however, the market is rather small, with less than 600 megawatts in Germany and 3,000 megawatts in Europe. So far we do not see batteries on the grid scale for load-shifting purposes in Germany."

Christoph Pellinger, who led the study, says that they believe energy storage batteries will not be able to meet Germany's energy requirements in the next ten years. He went on to say, "I can think of lithium-ion battery storage for primary frequency control: however, the market is rather small, with less than 600 megawatts in Germany and 3,000 megawatts in Europe. So far we do not see batteries on the grid scale for load-shifting purposes in Germany."

The report - to be published soon - will suggest practical energy saving methods to ensure Germany stays on track in terms of energy goals. Other countries weighing up their energy options might be able to learn from Germany if they can produce renewable energy without the oncoming onslaught of battery technology.

The three suggestions to the German government, in the case of energy conservation, will be:

- Residential and industrial power-to-heat systems

- Demand-side management of industrial and residential energy consumption

- Vehicle-to-grid technologies - which has also recently been suggested at train stations in the United Kingdom. The idea is that electric cars would be parked in train stations the entire day, hence, they would be plugged into a network that would assist the grid using the energy storage technologies inside the cars.

Demand-side management is used around the globe to encourage consumers to change their usage practices to alleviate strain on the grid. The process of demand-side management is usually performed during peak hours when everyone is at home and utilizing energy-heavy appliances.

If countries continue the demand-side management methods of grid balancing far into the future, the Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, says there are methods of energy saving which are severely underrated.

In the twenty-first episode of the Engineering News Network, Mackay says that the use of energy saving bulbs has been a successful idea with a good approach, however, he believes energy saving bulbs have been a yardstick that is possibly not long enough for how much energy saving actually has to happen in the world. "Humans tend to have a psychological effect called the 'anchoring effect' and we tend to focus on the little things. One should also expand one's horizon and perhaps think of larger things," he said.

In the current world where affording home energy storage batteries is a pipe dream for some, energy saving solutions still need to be considered. "For example, if you look at your home, one of the biggest savings you could make is not so much the light bulbs, but the heater or the dryer for your clothing. If you cut back on that, you are looking at significant savings because it chews up quite a lot of power. The same thing for your pool pump and lots of other power consuming devices," Mackay said.

Pellinger - who is soon to publish findings on grid balancing in Germany - has his doubts about residential batteries become the norm in the near future. He said: "Batteries for residential storage might have an impact, but they are even less economically viable than most analysts think. Home storage units often consume a surprising amount of electricity themselves in standby mode, and this is rarely taken into account."

- Details

- Written by: Quintus Potgieter

- Category: Education

As the world becomes more fast paced and more interconnected through the internet, some students decide that online tertiary institutions would probably fit them more than an on-campus solution to engineering studies. These students are usually cautioned and told that online qualifications do not lead to employment in the industry and that online studying still has a long way to go before it is fully recognised. However, engineering qualifications over the internet have become more respected over time. Open distance learning in the engineering field is becoming more frequent in the world where engineers are required to be on site, working, and broadening their knowledge as their industry changes.

USNews spoke to Jack Cullen, president of Modis, a tech staffing agency. He said: "Now that you're seeing more and more people in that hiring chair that have come from perhaps their own online education, you're seeing a lot more acceptance of it."

Cullen believes that online engineering education solutions are beneficial due to an engineer being able to "work and pursue a degree at the same time". He also says engineers studying towards a master's degree usually apply what they are learning to the work they are currently doing.

Cullen believes that online engineering education solutions are beneficial due to an engineer being able to "work and pursue a degree at the same time". He also says engineers studying towards a master's degree usually apply what they are learning to the work they are currently doing.

Dani McDonald, vice president of national engineering recruitment at Kelly Services, said: "The degree at the end of the day is really just a credibility statement. They're looking for your experience and what you've contributed and what you will contribute to their organization." However, she also says employers like to see a name of a university they are familiar with.

Charles Muwandagara, an engineer who is currently working on power stations across Africa, recently graduated with his advanced diploma in mechanical engineering from the Engineering Insitute of Technology (EIT), an online institution. Through broadening his knowledge in the industry he was currently working in, he was promoted to project supervisor.

When asked about his diploma and whether he felt it was a necessary addition to his skillset through online education, he said: "It was very practical. To run a project you need those basic skills."

Muwandagara also says that studying engineering whilst already in an engineering role can lead to promotion. He said: "There is promotion. I could be superintendent on my next project." He also said that he is setting his sights on a master's of industrial automation through online institutions whilst working in the field, certain that it would boost his career. Colleagues of Muwandagara have also taken to online institutions due to noticing how beneficial it can be to further build on their curriculum vitae.

- Details

- Written by: Quintus Potgieter

- Category: Education

The G7 (Group-of-Seven) nations have vowed to uphold a promise that would see agricutural innovation and investment be prioritized around the world.

The statement made by the G7 read: "Motivated, skilled and enterprising farmers are essential for the growth of the agricultural sector. We will help farmers enhance their capability and skills by facilitating access to information and communication technologies, precision farming and agricultural innovations."

That's where the agricultural engineers come in. Farming technologies need to be developed to assist food security in the world of today so that in the future, there is enough food for the growing population.

Makiko Tsugata, a senior analyst at Mizuho Securities said: "There are no other options for farmers but to rely on technologies developed by companies if they want to raise productivity while they are greying. The government should help them adopt new technologies."

The University of Georgia's engineers are warning that food production in the agricultural industry cannot keep up with the rate at which humans are being born. According to OnlineAthens, the world's population will spike from the current 7 billion people, to 9.5 billion in 2050.

UGA agricultural engineer, K.C. Das spoke at one of the university's conferences and said that food production needs to increase by 70 percent if the world intends on accomodating 9.5 billion people by 2050. Das spoke to the American Society of Agricultural and Biological Engineers, saying that changes will have to be made in food production in order for the industry to survive with that heavy of a demand.

"We have to do it by increasing the intensity of production, and this can have all kinds of unintended consequences for the environment," said Das.

"We have to do it by increasing the intensity of production, and this can have all kinds of unintended consequences for the environment," said Das.

Another concern for agricultural engineers is that to produce these foods and to transport them around the world, fossil fuels are still being utilized. Clean, renewable energy is the logical step forward. Das said, "You're using as much gasoline in the food you consume as you are using driving."

He says 19 percent of all U.S. energy and 70 percent of the world's water is used up by the agriculture industry. Another incredible statistic from UGA is that 8 percent of greenhouse gas emissions are also as a result of food production.

Changying Li, a scientist at UGA, said: "The amount of agricultural land is stagnant, and turning more land into agricultural use isn't really the answer -- but greater efficiency can help the world meet the challenge. Increasing food production is one of the greatest challenges facing producers and engineers."

- Details

- Written by: Quintus Potgieter

- Category: Industry

Tesla has announced the price information on its commercial and utility-scale products. They will be selling what are known as 'Powerpacks'. Is it time to replace that old generator powering your workplace once the lights go down? Perhaps you should hold onto it a little longer. Critics are saying Tesla's Powerpacks are on the expensive side.

The minimum amount of Powerpacks you can order today is 2 Powerpacks at the price of US$47,000 each. That is just for the Powerpack itself. The batteries come with a US$65,000 Bi-directional 250 kW Inverter and support hardware that will set you back US$3,000. Then you pay extra for installation.

Electrek confirms the least expensive Powerpack solution will set a business/customer back US$162,000 for 200 kWh of energy and 100 kW of peak power.

If an industrial complex is interested in clean, renewable energy, there is a 54 Powerpack solution from Tesla, which would set a company back US$3,217,000.

Tesla says the Powerpack is ideal for peak shaving which discharges "at peak demand to avoid or reduce demand charges" as well as serving as an emergency backup in grid interruption circumstances and load shifts so that a customer can avoid hefty energy prices.

A supposed customer utilizing the Powerpacks has written a testimonial, vouching for the energy solution. The customer in question is Jackson Family Wines and they wrote:

With Tesla Energy, we have taken a two-fold approach to energy management at our wineries by improving operational efficiency across all lvels of our organization and reinvesting those savings in onsite renewable energy systems.

Will you be getting these Powerpacks for your company?

- Details

- Written by: Quintus Potgieter

- Category: Developments

The interconnectivity of the components in a factory. This used to mean all the engineers and assembly line workers being on the same page. These days it means connecting the robots on the assembly line to an Internet of Things network so that they can talk to each other and ensure the assembly line keeps working in accordance with its coding.

Dynamic Group is a medical devices and precision products manufacturer in the United States and is also in the process of automating some of its assembly lines with the help of robotics. They have installed three robots that take care of repetitive tasks.

Joe McGillivray, the CEO of Dynamic Group said: "One of the main reasons we needed to look towards automation was difficulty with staffing. We're lucky enough to live in a place that has high wages and low unemployment which is great on a daily basis, normally, but it's difficult as someone who runs a business."

Dynamic Group says that the robots have increased productivity by 400% inside the factory. McGillivray says that this is because usually there would have to be three operators in the factory on a shift but now with the robots present there can be one operator on one shift.

"We essentially quadrupled our production capacity," said McGillivray.

The industry robot they utilize is the UR10 robot from Universal Robots. It is the largest industrial robot arm that Universal supply and can lift weights of up to 22 lbs.

The fact of the matter is that if multiple robots are going to be installed into a factory, they must be interconnected through the Industrial Internet of Things. To calculate what effect the automated industrial revolution might have on the industrial industry, Morgan Stanley Research, and Automation World investigated.

It resulted in a statistic that stipulated that industrial companies' IIoT (Industrial Internet of Things) expenditure would increase from its current 8 percent to 18 percent over the next five years. The report also said that "discrete automation is expected to see the greatest [IIoT-related] growth opportunities given faster upgrade/replacement cycles and lower penetration of software compared to the process industries."

- Details

- Written by: Quintus Potgieter

- Category: Industry

Siemens have announced their entry into the fourth industrial revolution (Industrie 4.0) at Hannover Messe this week. The company is releasing a solution for companies of all sizes in every industry in what they are calling their 'digital expansion' solution. They indicate that they are bringing the virtual world and the real world together in a fully functional 'eco-system' of industrial automation, which a lot of companies are now doing to accommodate the oncoming IoT revolution.

Member of the Managing Board of Siemens AG, Klaus Helmrich, said in a statement: "To support our customers on their way to attaining Industrie 4.0, no matter what size their company and not matter in which industry, we have undertaken further development of our Digital Enterprise portfolio. We are now in a position to offer them even more and even better solutions to address their needs.

Siemens's strongest industries they are currently operating in - that they are showing off at Hannover Messe - are energy for industry, additive manufacturing (3D printing), automotive industry and the fiber industry. For these industries, Siemens says a Totally Integrated Automation (TIA) Portal V14 can be utilised to automate processes in a company and thrust their business forward into Industrie 4.0.

Furthermore, data and analytics services are being offered, which Siemens says will lead to "higher quality, more efficient products, and processes."

"It is precisely in this data consistency that we envisage the opportunity to realize the demands of Industrie 4.0," says Helmrich.

Their media brief also said:

Using "Integrated Mechatronincs Engineering for Automation" will also enable components to be used as complete units when developing a machine or plant: for instance, motors, drives, valves or entire modules containing detailed information about all the involved engineering disciplnes.

Helmrich concluded by saying: "For companies in the process industry, there are different ways in which digital transformation can be implemented. They can draw existing facilities into the digital world one step at a time, enter into integrated operation or also carry out the transformation of documentation into digital data."

- Details

- Written by: Quintus Potgieter

- Category: Industry

The 3D printing industry has been reported on recently due to its successes in the market. It was said that the 3D printing industry would grow by another billion dollars due to personal 3D printers being purchased by enthusiasts. Moreover, an instructor from an Engineering Design Graphics department at San Jacinto College says that 3D printing could be thrusting the world into another industrial revolution.

William Buel, the instructor in question, in an interview with Chron, said: "In the future you will see whole factories running only 3D printers to design, run, modify and finish products. 3D printing is already becoming very useful for rapid prototyping. Now if a company wants to build a new product, we can draw and print the prototype within hours to see if it works, rather than sending it to a machine shop, waiting months and then having to start over. In 10 years, every home will have one."

However, a small hitch for companies who supply 3D printers was highlighted this week. A company that many had hope in called Makerbot, who actually built 3D printers, announced that they would stop production and outsource the making of printers to another company named Jabil.

However, a small hitch for companies who supply 3D printers was highlighted this week. A company that many had hope in called Makerbot, who actually built 3D printers, announced that they would stop production and outsource the making of printers to another company named Jabil.

The announcement blog post written by the CEO of Makerbot, Jonathan Jaglom, stated: "To achieve our long-term goals, we also need to be able to navigate the volatility of an emerging market. Working with Jabil will position us to better manage rapid change in our industry and reduce our manufacturing costs to compete more effectively in a global marketplace."

The CEO further confirmed that the 3D printing market "has been very volatile". Strange, considering the Wohlers Report 2016 said that the 3D printing industry grew by 25.9%, and assured the public that the industry is not in decline.

Makerbot was initially the company that gave hope to the industry and said that your regular joe would be printing a plethora of items in the luxury of his/her own home. Then the company retrenched 20% of its staff, and it has struggled to surface due to the amount of printers being ordered since then.

In other 3D printing news, a Chinese startup company is releasing a material known as Polysmooth. Allegedly, the new material can be used by any third party printer to ensure that whatever is printed has no rough edges or any other issues. The idea is to refine the process due to current 3D printing practices churning out objects which are rough to the touch. The company says that their new material 'self-polishes' the materials when put it into the printer. Check out their: Kickstarter

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

As engineering professionals, we are surely closer to the driverless car than the paperless toilet.

An old jibe amongst pilots concerns what you need to fly a modern plane. The answer is a computer, a pilot and a dog. The computer flies the plane; the pilot’s sole task is to feed the dog and the dog’s job is to bite the pilot if he tries to touch anything.

Dear Colleagues

As engineering professionals, we are surely closer to the driverless car than the paperless toilet.

An old jibe amongst pilots concerns what you need to fly a modern plane. The answer is a computer, a pilot and a dog. The computer flies the plane; the pilot’s sole task is to feed the dog and the dog’s job is to bite the pilot if he tries to touch anything. Well, according to cynical pilots. And indeed; today most long haul flights are handled by auto pilot. Although, I am a little twitchy about the A330 which broke up over the Atlantic; seemingly the computers (and presumably pilots) were bamboozled by erroneous speed readings due to iced up pitot tubes. Most instrument engineers will sigh when they read this; as they would have been exposed to the same situation many times over, in plants of every description.

Interestingly enough autopilots have been around since 1912. Many of the modern autopilots still use the old Intel 80386 processor from 25 years ago (remember DOS and no odd operating system crashes). Trains are also highly automated (they only move backwards and forwards at the right speed and watch for red lights) with no drivers and people are comfortable with this. You only need to look at the London Dockyard trains/ various world city monorails and Malaysian Airport to see this in evidence. Although what mystifies me is the continual series of accidents with driver led-trains – for example, one driving into into the back of another or collisions at point crossings.

But the big prize to really automate the car has two obstacles – technical (obviously) and a harder one – psychological. Roads are enormously complex places compared to railways and planes with relatively empty skies (and massively human controlled airports when they want to land).

Already the car is a massively digital and computerised animal with over 200 on-board sensors with a high end one possessing over 70 microprocessors (and even the lowly Tata Nano having a dozen). Satnav is a key part of many drivers’ daily lives allowing them to get around cheaply with satellite navigation in strange locations. Internet connectivity is achieved with a smart phone allowing all sorts of interesting information to be gathered (such as real time traffic information and indeed even the location of speed traps).

As we all know from personal experience; a driverless car has to deal with a myriad of issues – unexpected objects rolling into the road (a ball); giving way to emergency vehicles; other accidents; drunken pedestrians; sudden road diversions. But the payback will be enormous – a machine can react far quicker than a human to a hazardous situation. And if the cars on the road can “chat” to each other via wireless; they could minimise traffic jams and dangerous overtaking.

As far back as 1994, a driverless car drove through the manic traffic infested streets of Paris at speeds up to 120km/h for over 1000 kms. So the technology is almost here. Several cars (Mercedes and Volvo) now will brake automatically if they detect an imminent collision. And the Lexus (amongst others) does its own parallel parking with panache.

What should we do about this?

- Read and talk to as many of your peers as much as possible

- See the business opportunities unfolding here – whether you are mechanical/electrical/IT or electronically oriented, with millions of cars on the road, the re-engineering required is wide ranging and huge opportunities are evident

- Apply these new proven automobile technologies to your next project

- Ensure that whatever is done; that all cars and support gear is super safe

- Think of the Law of Unintended consequences and figure out unexpected results which may need to be dealt with – either from an opportunity or safety point of view

Hopefully the humorous remark about the safety in cars, by Dudley Moore is not true: The best car safety device is a rear-view mirror with a cop in it.

Thanks to the Economist for references in writing this.

Yours in engineering learning

Steve

Mackay’s Musings – 26th April’16 #597

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

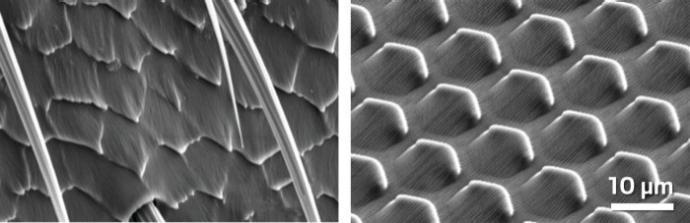

Engineers and birds have an odd relationship. There is a recent fascination with what birds could teach us about building new aircraft or drones for that matter. Stanford University has joined the craze and has built a wind tunnel for birds and drones to test aerodynamics and how birds react to turbulence.

Dan Quinn, a postdoctoral research fellow says, "Birds are masters of maneuverability in ways that we are only beginning to understand."

"Birds can dramatically change the shape of their wings almost instantly and respond in that way very quickly. Flying in turbulence, avoiding obstacles and also flying very effectively over long distances," says David Lentink, mechanical engineering professor at Stanford.

"Birds can dramatically change the shape of their wings almost instantly and respond in that way very quickly. Flying in turbulence, avoiding obstacles and also flying very effectively over long distances," says David Lentink, mechanical engineering professor at Stanford.

The wind tunnel that the team of researchers built can alter turbulence and will cause birds to avoid and dodge the winds in the tunnel. This would allow the researchers to understand how they do this and perhaps publish the findings which could lead to drones dodging turbulence in expert ways in the future, inspired by nature.

The wind tunnel will push out gusts of winds up to 15 metres per second at maximum. Then a host of windows around the tunnel allow the researchers to peek inside the wind tunnel but they have also set up high-speed cameras so that they can capture slow motion video. A fluoroscope is used to observe the skeletal movements that are occurring in birds during flight in the wind tunnel. The fluoroscope is basically an X-ray machine that will show the bird in real time.

"The tunnel is designed to be super low turbulence but we also want to study how birds fly in turbulence and how we design vehicles that are more stable in turbulence. We can actually not only control how strong the turbulence is but where the turbulence is inside the tunnel," said Quinn.

Similarly, UCLA and its engineers are also studying bird flight to eventually try and turn into aircraft design.

Daniel Inman, a professor of aerospace at the University of Michigan, is working with the team over at UCLA, who have been given a $6 million grant to observe bird flight and invent materials that are flexible enough to react to wind like bird wings do. He said: "With new materials, advanced sensing and control techniques, and inventive methods for observing birds in flight, our team will begin to bring avian efficiency and agility to aircraft."

- Details

- Written by: Quintus Potgieter

- Category: Education

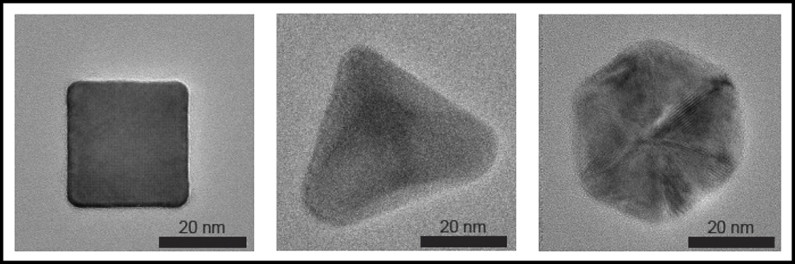

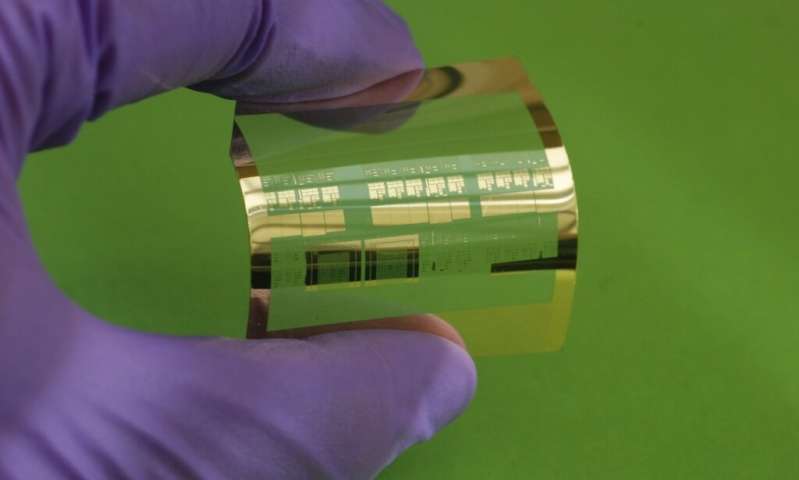

Engineers are obsessed with reducing computing down to the size of one solitary chip these days. The smallest of transistors can operate at gigahertz far greater than computing speeds. The buzzword around engineering is 'nanoscale'. Everything is smaller and more efficient, engineers are always looking to minimize the amount of space something takes up. However, the smaller the object, the more 'nanoscale' some of the materials have to be to accommodate the size.

Researchers at Stanford University have investigated phase-changing nanoparticles to observe how their shape changes due to the arrangement of atoms within the crystals inside. They relate this to the charging and discharging of energy storage systems. This research would be valuable to any companies currently working with lithium-ion, hoping to release energy cells to the public.

Researchers at Stanford University have investigated phase-changing nanoparticles to observe how their shape changes due to the arrangement of atoms within the crystals inside. They relate this to the charging and discharging of energy storage systems. This research would be valuable to any companies currently working with lithium-ion, hoping to release energy cells to the public.

The work published in the Nature Materials journal was named Reconstructing solute-induced phase transformations within the individual nanocrystals.

Nanoparticles within energy storage systems enable the systems to charge faster and last longer. This process inspired the researchers to look into how deformed the crystals within the nanoparticles become during this process. They rationalize that if they can discover a breakthrough, they could improve charging and discharging and lifespan of batteries.

The abstract said:

Strain and defects can significiantly impact the performance of functional nanomaterials. This effect is well expemplified by energy storage systems, in which structural changes such as volume expansion and defect generation govern the phase transformations associated with charging and discharging.

The rational design of next-generation storage materials therefore depends cruciailly on understanding the correlation between the structure of individual nanoparticles and their solute uptake and release.

Jennifer Dione is an assistant professor of materials science and engineering at Stanford and worked on the project. They took lithium-ion batteries and tested the reactions of individual particles during charging. Using an environmental transmission electron microscope, they were able to observe the nanoparticles and at what hydrogen pressures they were reacting under. They found that the structure of a nanoparticle does have an effect on how an energy storage unit would perform. The difference is how hydrogen is absorbed in the center of a nanoparticle, which causes performance issues.

Tarun Narayan, a lead co-author of the study, told Stanford News: "This instrument is one of only a handful of its kind and allows us to study materials in their working environment.

Andrea Baldi, a postdoctoral co-author and faculty member of the Dutch Institute for Fundamental Energy Research (DIFFER) said: "Each technique offers different information that can be combined to gain a complete, multi-dimensional understanding of the system."

Robert Sinclair, a professor of materials science and engineering who also wrote alongside colleagues at Stanford said: "We could not have envisaged making in situ observations like this at the atomic level even a few year ago, and so what the teams had demonstrated and achieved is remarkable in the materials imaging field."

Dionne concluding by saying: "With this ability to peer inside nanoparticles during their operation, we can help design champion materials for next-generation energy storage devices."

- Details

- Written by: Quintus Potgieter

- Category: Industry

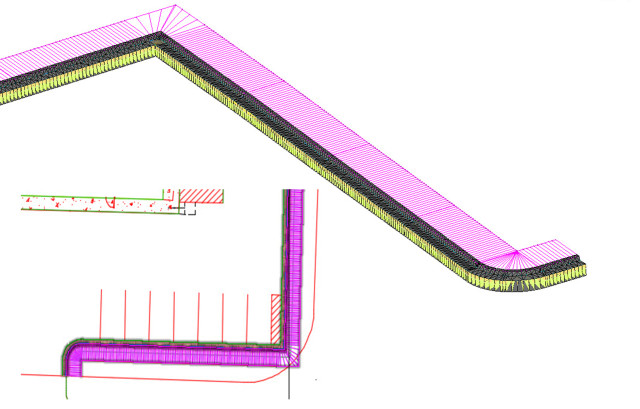

Civil engineers would be pleased to know an update for AutoCAD Civil 3D will be available to them soon. The software gives engineers the ability to give a virtual showcase of what a certain addition to a town might look like. The new AutoCAD Civil 3D 2017 is an updated version of Autocad boasting new additions that will assist civil engineering and infrastructure designs.

The new version will team up with InfraWorks 360 to keep tabs on work progress in engineering teams. This plugin allows InfraWorks infrastructure objects to be imported into the program.

Corridor design has also been reupholstered into the new version of the software. Greg Dixie, an application specialist for Excitech Ltd, previewed the new corridor design abilities in a YouTube video. He said: "You can make short-cut corridor models. I can import my corridor models into the program and it looks slightly different than it did before." Another addition is the extraction of corridor properties, which is also something new in the 2017 iteration of the program.

According to Engineering.com, pipe design is also an updated feature. The program includes a larger library of "pressure pipe content" for HDPE, PVC and steel pipes.

Theo Angelopoulos, director of infrastructure industry business strategy and marketing at Autodesk said: "Today's civil infrastructure professionals face huge challenges to build new or retrofit our communities' infrastructure for transportation, land use, water, and energy in ways that are more economical, practical, resilient and attractive." They are confident that the program will assist civil engineers in creating the best possible virtual representations of how to engineer something that is of worth to the community and that can be built according to the digital guidelines that the software provides.

What program is essential to your engineering career? Let us know in the comments section.

- Details

- Written by: Quintus Potgieter

- Category: Industry

German watchdogs combing through carmakers' technology to uncover emissions test cheating software have discovered that automobile manufacturers are using other methods that lead to lower emission counts. These revelations from German Transport Minister, Alexander Dobrindt. Allegedly, the carmakers "tweak engine performance" which results in more emissions but less data on those emissions when the software is checked.

According to Reuters, Germany's KBA Federal Motor Transport Authority tested 53 vehicles to find out if carmakers followed the same practices that Volkswagen did, in order to manipulate emissions testing. The results of the tests found that VW was the only manufacturer that made use of cheating software, but, the other manufacturers dabbled in what is being called a 'thermal window'.

Due to the 'thermal windows' findings, the German government is set to recall 630,000 vehicles. Government officials talking to the media said: "The recall is aimed to ensure that a legal loophole allowing manufacturers to throttle back emissions treatment systems under certain circumstances is tightened to make sure lower levels of pollution going forward."

Due to the 'thermal windows' findings, the German government is set to recall 630,000 vehicles. Government officials talking to the media said: "The recall is aimed to ensure that a legal loophole allowing manufacturers to throttle back emissions treatment systems under certain circumstances is tightened to make sure lower levels of pollution going forward."

The 'thermal window' approach - most probably coaxed up by very clever automotive engineers - reportedly works around the process of condensation build up in catalytic converters and the throttling back emission management systems to protect the engine from that build up.

Switching off or throttling back emissions treatment systems, however, has the added benefit of improving engine performance and stretching the interval between refilling vehicles with urea, a subtance needed to extract NOx from exhaust fumes

- Markus Wacket, Reuters News Agency

The German government is trying to cut down on the amount of nitrogen oxide (NOx) that is polluting the air and that is part and parcel as to why they are recalling 630,000 vehicles so that this work-around 'thermal window' solution can be investigated.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Brexit, or rather known as the possible British Exit of the European Union, could damage engineering in a big way, say industry experts. Engineering UK has heard that a vote for Brexit could lead to a slump in "vital research funding" and add to a shortage of skilled engineering workers in Britain.

According to The Telegraph, companies such as Rolls-Royce, Airbus and Caterpillar are behind the vote not to leave the European Union due to the companies saying it will cause "unknown and unquantifiable transition risks."

Naomi Climer, president of the Institution of Engineering and Technology said: "British engineering is deeply integrated with global markets and companies. If Britain votes to the leave the EU, the period of uncertainty about the terms on which access to these markets would be granted would a threat to the sector. The interests of engineering and technology may be best served by the UK remaining within the EU, and we are calling for urgent discussion on the impact of an exit decision on a sector that is so vital to our country's economy."

The vote has been set for the 23rd of June, 2016. The companies who have encouraged a 'NO' vote collectively employ 100,000 skilled engineering professionals. The companies maintain that job losses would occur on the back of the decision to leave the European Union. In the letter that the companies drafted together, they say: "While the UK could tackle this problem by introducing a fast-track visa process for engineers and technologists, it is unclear how this would sit alongside the tighter border controls anticipated following an exit from the EU."

The vote has been set for the 23rd of June, 2016. The companies who have encouraged a 'NO' vote collectively employ 100,000 skilled engineering professionals. The companies maintain that job losses would occur on the back of the decision to leave the European Union. In the letter that the companies drafted together, they say: "While the UK could tackle this problem by introducing a fast-track visa process for engineers and technologists, it is unclear how this would sit alongside the tighter border controls anticipated following an exit from the EU."

The Mayor of London, Boris Johnson, is adamant that consideration must be made for the scenario of a British exit. He told SkyNews: "We asked for very simple things, like people coming here should have a job offer before they arrive or if they can't get a job within six months then they should go back. Those very simple ideas."

The worry is that skilled engineers will not be able to make their way into Britain to address an engineering shortage due to the European Union exit which would tighten up border control and make it harder for those international professionals to make it into the country.

- Details

- Written by: Quintus Potgieter

- Category: Education

The delicate balance between engineering education and work experience has proven to be a conundrum in multiple engineering industries, where jobs are not being found. What engineering education should students then be getting to secure their engineering job in the industry? That is the question a lot of students have been asking, due to not finding employment in the industries they studied for.

Shady Hashem, a student from Egypt, travelled to Canada to study at the Halifax Dalhousie University and then tried to find a job at the University of Calgary. He admitted to applying to over 50 jobs in Canada but hasn't found success in employment thus far.

Hashem said: "I talk to a lot of engineers, and the expected time to get a job is between six months and a year. I'm applying everywhere, but I haven't heard back from anybody yet, not even an email that says: 'Sorry this position has been filled.' That's very frustrating."

Hashem is looking for a job in the oil industry, however, the Conference Board of Canda released a report saying that the demand for employment is double the national average of the last 17 years in civil, mechanical and computer engineering. Thus, the lack of jobs might only be in selective industries.

Colleen Bangs is the manager of career services at the University of Calgary and said that one-third of the university's 659 engineering students have not been employed since graduating.

Bangs said: "Something I've noticed, particularly in this last semester, is that there's a bit of an impending feeling of doom."

The report as published by CTVNews also states, that the University of Alberta has revealed that 70 percent of the 1,300 engineering students have in fact found employment in engineering industries. These revelations lead critics to believe that the situation is not as bad as it seems. Could it be that the University of Calgary isn't as respected as other universities are? Is their engineering education good enough?

In South Africa, a known civil engineering hiring slump has occurred since the end of the Fifa World Cup in 2010. The Sunday Times recently reported on a civil engineering graduate named Mfuneko Nomvalo, who has returned home after studying due to not finding employment.

Nomvalo told the Sunday Times: "It's been five years since I graduated, but finding work has been the hardest thing for me. I thought I had left and progressed in life. I've worked 18 months on contract on local construction jobs and it's not what I thought it would be like..."

How does a future engineering professional find the right education institution fit for them? Finding a university that will guarantee a hire in the industry, is a tall order it seems. What needs to happen in engineering education to produce more skilled, work-ready engineers?

How does a future engineering professional find the right education institution fit for them? Finding a university that will guarantee a hire in the industry, is a tall order it seems. What needs to happen in engineering education to produce more skilled, work-ready engineers?

The Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, addresses the topic of engineering education that works in the thirteenth episode of the Engineering News Network.

Mackay said: "We really need to focus on the basics, which is, having outstanding industry experienced instructors involved with the students. That's what really matters...people who have industry experience."

Regardless of the university, Mackay seems to believe that as long as engineers equip themselves with the necessary skills, they would be able to find employment in the industry. He believes:

The typical things you want to teach the students are things such as being entrepreneurial, creativity, being able to think outside the box, working in teams - the instructor and the students - forget about the good old professor on the stage it's actually the professor and the lecturers and instructors all working together on the project. There's no more guru that you have to listen to quietly, it's actually all about dynamic teamwork.

Other skills that are required are things like project management, which often as engineers and technologists we are involved with in our day to day jobs.

Communication skills ; reading and writing. Engineers need to jack up their communication skills.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Imagine having your own compact aircraft that you could utilize at any point. Or imagine calling an UberAir to come and pick you up and transport you across town. Those days could be upon us with the introduction of an 18-rotor electric aircraft named the Volocopter. An aircraft that looks like something out of a kid's party packet, the rotors are placed around a network of beams that are connected to a large round beam. The engineers at e-volo who are behind the Volocopter are boasting about the fact that it does not release any carbon emissions into the atmosphere.

The entire thing weighs 992 lbs at take-off and has nine batteries powering the motors that can propel the aircraft to achieve 62 miles per hour in the air.

Alexander Zosel, the managing director of e-volo (the company that designed and built the aircraft), got to take the Volocopter out on its first flight. After it, he said: "The flight was totally awesome, the machine was absolutely reliable. The Volocopter immediately converted every movement I made with the joystick. The special thing with the Volocopter is that it is actually an aircraft that flies by itself. I can take my hands off the joystick, it stays in the air as if nailed there."

The team got the go-ahead to operate the vehicle from the German aviation authorities in February of 2016. according to Engineering.com. The team is also interested in selling the Volocopter commercially by 2018.

The future of manned personal vehicle mobility seems to be drawing closer due to this seemingly safe Volocopter solution. For the journey from design to the first manned flight, check the video below.

- Details

- Written by: Quintus Potgieter

- Category: Education

Engineers have some of the most sought after skills in the world today. You could say they are necessary, most influential actors in our global society. Their contributions do not go undervalued seeing as though they place in the top 5 highest paying jobs of 2016.

However, engineering experts themselves admit that they are missing some necessary skills that their tertiary education and work experience didn't prepare them for.

Professor Lawrence Susskind, a professor at MIT in the Urban Planning sector and the head of environmental policy and planning group, wrote an article entitled The Key to Success: Negotiating 101 for Engineers, published by TheEngineer.

He writes, "It's one thing to come up with an innovative idea; it's another to take that idea to the market." Susskind says there is a typical engineering logic that gets in the way of marketing and maintains that engineers repeat the same mistakes every time they negotiate with potential investors and partners.

Susskind's list of how to avoid the mistakes of bad negotiation is as follows:

- Ego and emotion: When negotiations begin, it's vital to leave emotions out of it.

- Dealing with Uncertainty: When entering a negotation, it's key for inventors and innovators to be ready with contingent proposals that will minimse the risk to their investors.

- Handling technical complexity: It may be necessary for both sides to engage in joint fact finding to ensure that they have shared understanding grounded in mutually acceptable data.

- Building Trust and Working Relationships: To maintain good working relationships, sucessful negotiators know how to say what they mean and mean what they say.

Negotiation is not the only skill that engineers should add to their arsenal of skills, it seems. The Dean of Engineering at the Engineering Institute of Technology (EIT), Steve Mackay, also highlighted what skills - as basic as they might be - engineers could become proficient in to ensure engineering success.

Negotiation is not the only skill that engineers should add to their arsenal of skills, it seems. The Dean of Engineering at the Engineering Institute of Technology (EIT), Steve Mackay, also highlighted what skills - as basic as they might be - engineers could become proficient in to ensure engineering success.

In the sixteenth episode of Mackay's YouTube series, Engineering News Network (ENN), he underlines some key non-engineering skills engineers can quite easily pick up. Mackay speaks of a touch-typing course he took forty-two years ago, that was one of the most fantastic skills he ever picked up. The other skills he encourages, are the following:

- Time management: "Someone mentioned to me the other day that time is probably the greatest thing we don't have much of. Money we can get, time we cant.

- Basic finance and bookkeeping: "It's horrific how many engineers are in their 50s and 60s and they have no money because they didn't do any management of their finances when they were in their 20s

- How to negotiate effectively: "The ability to negotiate for anything you want to buy. A car, an item for your house or your factory or your shop.

- Write simply and decisively: Don't use big words when you write reports, make it simple and readable

- Presentations: How to present powerfully and simply. Don't use powerpoints with glitzy animations. Try to avoid being lost in powerpoint

- Capture with photographs: Taking photographs and looking at basic skills with lighting and framing...very important.

- Networking: All the time, all day, everyday. Keep up with what's going on in the job market, what's going on everywhere. Networking will keep you employed for the rest of your life.

Networking and negotiating are key areas that seem to be an area of concern to engineers around the world and is something that experts are encouraging engineers to perfect. Even the most basic of skills that could have gone unlearned during high school or tertiary education expansion can be beneficial to engineers, according to the engineering opinion makers.

- Details

- Written by: Quintus Potgieter

- Category: Developments

The Nevada desert seems to be the latest hub of energy generation. Tesla has built their new Gigafactory dedicated to the production of lithium-ion batteries and Crescent Dunes, a solar power facility, supplies energy to approximately 75,000 homes. It is both beautiful to look at and revolutionary for energy generation in the world today.

The company behind the behemoth facility is SolarReserve, that employs engineers around the clock to maintain the facility. According to the company's website they employ around 4,300 people with the running of the facility. The biggest draw card that highlights this facility's usefulness is that it can even store energy during overcast weather and even operate at night, which makes the plant invaluable.

SolarReserve's CEO, Kevin Smith, told TIME magazine, "This is the first utility-scale facility in the world with this technology. Our technology can truly replace conventional generation."

SolarReserve's CEO, Kevin Smith, told TIME magazine, "This is the first utility-scale facility in the world with this technology. Our technology can truly replace conventional generation."

Other solar facilities suffer under weather conditions, slowing down the storing and producing of energy due to the panels requiring sun.

The Crescent Dune plant uses its mirrors to reflect light into the central tower, which then heats up the liquid salt that stores the heat and turning it into a battery. TIME confirms that the plant produces "zero tons" of carbon.

Professor Jay Apt of the Carnegie Mellon Electricity Industry Center, said: "We're all hoping that, just like photovoltaic power, we'll start getting on the downward slope of the learning curve. If you crank a whole lot of those units, you'll learn to do it better."

The company is hoping that the facility can set an example for the rest of the world, and perhaps the world will follow suit and set up their own facilities that utilize molten salt power generation.

- Details

- Written by: Quintus Potgieter

- Category: Industry

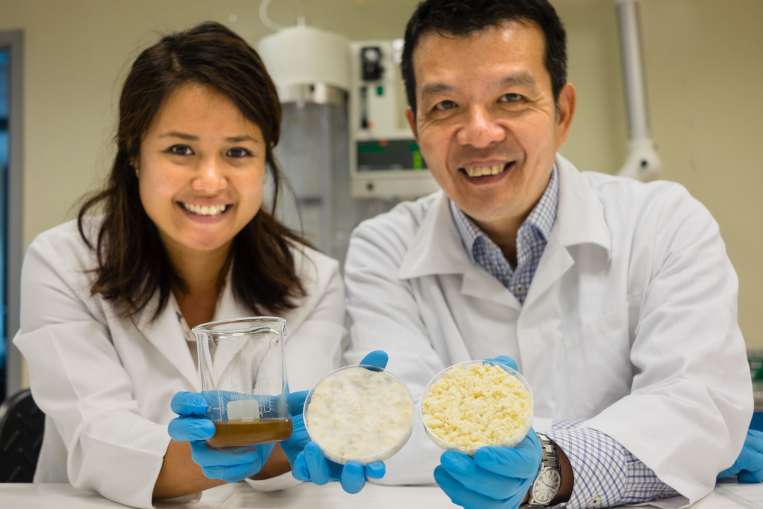

Biomedical engineers in Singapore are using what would usually be discarded to facilitate a renewable source of minimizing the amount of food waste that occurs. According to StraitTimes, 66139lbs of soya bean residue gets sent to the dump every year.

So, the biomedical engineers at Nanyang Technical University (NTU) went to work and used residue from soya milk and tofu production and utilized it to grow yeast. The team is confident it will minimize costs on the cultivating of yeast in Singapore.

Professor William Chen who works in the School of Chemical and Biomedical Engineering at NTU, and lead the research, said: "Our data shows that the culture medium we developed grows baker's yeast as fast as commercial media. So the impact is potentially wide-ranging."

An assistant of the project, Dr. Jaslyn Lee, said they take the residue (or as they call it 'okara') and add it to "food-grade" microorganism. An enzyme is produced and a breakdown of the residue occurs into a "wool-like product."

The process reportedly takes five days.

The engineers say a liter will cost $3 whereas yeast produced from crop plants such as potato and wheat cost $11-$36.

Ms. Loong Mann Na, director of the Food Innovation and Resource Center at Singapore Polytechnic, said: "The method of production is deemed to be cleaner, more efficient and natural."

- Details

- Written by: Quintus Potgieter

- Category: Industry