News

- Details

- Written by: Quintus Potgieter

- Category: Industry

Flash floods have been plaguing the planet in 2016. In June, flash floods forced the government of France to close the Louvre in Paris and 25,000 people were left without power. 500 miles away, Germany also experienced flash flooding that caused 5 deaths and left several people missing. Lest we forget the 2015/16 floods of Ireland and Great Britain. Storm weather also battered South Australia at the end of September, this year. Engineering industries were shut down due to the weather. Power stations went down and 80,000 people were without power in Adelaide. The storm was thought to be a "one-in-fifty-year" weather event.

The fact that weather is delaying the work of engineering industries and leading to loss of life - in some countries - is not an understatement.

The fact that weather is delaying the work of engineering industries and leading to loss of life - in some countries - is not an understatement.

Now, South Africa has received a fresh bout of flash flooding due to stronger storms that are exacting cloudbursts over Johannesburg. The explanation behind why the sudden flooding events are happening relates to the weather cycle of El Niño's departure, and the onset of La Niña . Some are also pointing the finger at climate change to try and explain why the storms are so severe. South Africa has gone from unprecedented drought, and now is facing the same problem India is: replenishing water - but too much of it.

On Wednesday afternoon, severe storms caused flash floods in the South of Johannesburg. The South African Weather Service has said that extreme weather conditions will continue up until Friday. The N3 highway in Johannesburg saw flooding in both directions. Cars were swept away due to the high volume of water due to the rainwaters. A Twitter user @mandlamZA, wrote: "So clearly, our roads and highways were not built for the rain."

Flooding also cut off access to the country's main airport and forced airplanes to circle the airport before they could make a landing. As a result, flights were also delayed.

The City of Tshwane's Facebook account wrote: " Of late, four people died after a cloud burst at Midrand and OR Tambo, flooding the freeway at the Linksfield off-ramp. Massive water accumulated at low-lying areas of the freeway and many cars were caught up unexpectedly and covered with water up to their roofs."

Municipal governments and civil engineers are now debating how to avoid deaths in flash flooding events. Low-lying areas are unfortunately in the crosshair of a storm and are more prone to flooding than built up areas at the top of hills. Citizens in shanty towns built along the Jukskei River were displaced due to the rising floodwaters there. The area was the worst hit, 200 families lost their homes.

Municipal governments and civil engineers are now debating how to avoid deaths in flash flooding events. Low-lying areas are unfortunately in the crosshair of a storm and are more prone to flooding than built up areas at the top of hills. Citizens in shanty towns built along the Jukskei River were displaced due to the rising floodwaters there. The area was the worst hit, 200 families lost their homes.

A disaster management center has started investigations into the drainage systems and general destruction of the floods.

Johannesburg Roads Agency director Sean Phillips said: "When you get very unusual rainfall like we had last night then it overloads the drainage system. It would be possible to design the drains to be able to cope with these extreme rains, which occur occasionally." The water exceeded the stormwater systems' capability.

The question that remains, globally, is, should governments be looking at storm drain redesigns in preparation for climate-change-level volumes of rainwater?

The Department of Civil Engineering at McMaster University in Canada has researched the topic in their study entitled Climate Change Impact on Design Storm and Performance of Urban Storm-Water Management System. They write:

A number of future climate projections indicate a likelihood of increased magnitude and frequency of hydrological extremes for many regions around the world. The urban storm-water management infrastructures are designed to mitigate the effect of extreme hydrological events. Changes in extreme rainfall events will have a significant implication on the design of strom-water management infrastructures.

The study they conducted found that even Canada's infrastructure would suffer under "future climate condition."

Over-capacity drainage systems can also lead to sewage making its way into the waterways. Including the aforementioned: transport systems and residential flood damage are the main areas of focus for drainage systems that are being pushed past their capacity with the increase in water volume that the world is experiencing.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Sinkholes. They swallow houses, they devour cars. They eat up road, and they're happening around the world. A section of a five-lane street in Japanese business district Fukuoka was swallowed on Wednesday in what is being called a sinkhole. Subways were delayed and 800 houses were left without power. The sinkhole happened uncomfortably close to other buildings, so officials evacuated the people in the surrounding area to minimize the chance of any injury due to exploding gas lines or any further sinkholes. There were no injuries reported.

The Mayor of Fukuoka said that the sinkhole occurred due to construction on a subway line extension nearby the collapsed road. Exposed, severed sewage pipes leaked water into the sinkhole due to the collapsing of the street.

The United States has also had its fair share of sinkholes. The worry with sinkholes happening on roads, especially in America, is that gas transmission lines and subways could be affected by collapsing sections of road - very much like Japan. Donald Trump has promised that under his presidency, roads would be repaired.

Construction works play a part in making surrounding areas' ground unstable. A 2005 book named Sinkholes and Subsidence: Karst and Cavernous Rocks in Engineering and Construction details how sinkholes induced by ground disturbance occur.

Vibrations from construction traffic could conceivably induce sinkholes in unstable soil cover, but their effects appear to be masked by the greater influence imposed by drainage modifications.

Vibration caused by cars driving over unstable roads are also a contributing mechanism that can cause the roads to collapse. This happens if the road is already weakened by something like other construction work or more pressing issues like burst pipelines.

Water erosion is usually also factored in when explaining why a sinkhole happened, however, vibration seems to be what the municipal government of Fukuoka is going with.

Construction crews are working around the clock to have the street repaired by next week. Workers will also presumably get back to work once the street is repaired. Fukuoka's Municipal Government is patching the road up with cement. Government officials say that 7,000 cubic meters of soil are required to repair the street.

The certain kind of sinkhole observed in Japan is called a cover-collapse subsidence hole. It suddenly appears and continues to collapse. Engineers that are experienced in sinkhole remediation are now tending to the sinkhole in Japan. The support beams of buildings were exposed during the collapse, and as a result, engineers now need to ensure the foundations of buildings are still reinforced and not affected by the sinkhole.

- Details

- Written by: Quintus Potgieter

- Category: Industry

The U.S. Presidential Election has finally arrived after one of the longest campaign cycles in recent history. The winner of this presidential election will become the leader of the free world and have a monumental task ahead of them. There are only a few hours to go before the leader in the polls is announced, and as a result becomes the president. The stock market nervously waits in the wings to either congratulate or deflate depending on who wins. The reality is, some engineering industries, depending on who wins, could be seeing tough times ahead. The Economist magazine called a Trump presidency the third biggest “source of global risk”.

Engineers and business leaders should not make the mistake of thinking that politics doesn’t influence the outcome of their jobs in the future. In the final rally Donald Trump gave on his campaign trail, he promised that today’s election day would be called BREXIT PLUS after he won the presidency. The engineering implication of calling it BREXIT PLUS means that engineering industries are about to be clouded in uncertainty due to the conflicting opinions of both Hillary Clinton and Donald Trump.

Engineers and business leaders should not make the mistake of thinking that politics doesn’t influence the outcome of their jobs in the future. In the final rally Donald Trump gave on his campaign trail, he promised that today’s election day would be called BREXIT PLUS after he won the presidency. The engineering implication of calling it BREXIT PLUS means that engineering industries are about to be clouded in uncertainty due to the conflicting opinions of both Hillary Clinton and Donald Trump.

A post-Brexit engineering study conducted with the help of 424 engineering respondents, revealed some illuminating facts. The respondents were from “energy, transport, defence, oil and gas, agriculture and marine” industries. 64% of the respondents said that the EU was instrumental to their businesses. 62% said they were employing EU citizens. And once Britain opted to exit the European Union those relationships were in trouble. Worries about foreign investment into engineering industries also became very real.

Thus, the same industries in America could experience a slip-and-slide of emotions especially in energy, oil and gas, and defence. In truth, many industries are sitting on the edge of their seat to see if things stay the same with a Hillary Clinton presidency or drastically change with a Donald Trump presidency. Some engineers celebrated Brexit, others didn’t. Therefore, a study of how engineering industries will react to a Clinton presidency versus a Trump presidency is needed.

IF DONALD TRUMP WINS THE PRESIDENCY

Based on Trump’s campaign rhetoric, industry could be expecting major change and - in his opinion - a return to form. The industries that would see a massive, instantaneous bump in the stock market would be:

Military Defence industry: Lockheed Martin manufacture military defence equipment. Trump has famously said he will amp-up the military expenditure once he gets into office to ensure that America has the strongest military in the world. Aeronautical engineers would greatly benefit under this plan.

u>Infrastructure: Construction industries will see money coming in as The Don would say, “big league.” Trump has criticized the lack of road maintenance and the third-world state of America’s airports. Caterpillar is expected to benefit from a Trump presidency. Trump has said he wants to bring industry and jobs back to America, and in turn, make America great again.

Manufacturing: Trump also deeply criticized companies like Ford who had migrated some of their operations to countries like Mexico, and called for manufacturing to be brought back to America. Trade and immigration are very big question marks in Donald Trump’s America. To what extent, we don’t know. Many a time, engineering professionals immigrate to other countries to use their very specific set of skills on international projects. Would they be welcomed in Trump’s America?

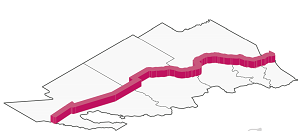

Construction: Not to mention that wall that Trump supposedly wanted to build. He eventually said that Mexico would be paying for it - to which the Mexican president said a resounding “no”. The 50-foot, 2,000-mile wall would require construction if they go through with it. CNBC estimated back in March that the wall would potentially cost $25 billion to construct. A Mexican architecture firm named Estudio 3.14 also produced this render of what the wall might look like./b>

Construction: Not to mention that wall that Trump supposedly wanted to build. He eventually said that Mexico would be paying for it - to which the Mexican president said a resounding “no”. The 50-foot, 2,000-mile wall would require construction if they go through with it. CNBC estimated back in March that the wall would potentially cost $25 billion to construct. A Mexican architecture firm named Estudio 3.14 also produced this render of what the wall might look like./b>

Moreover, The energy production industry will experience a shake-up due to Trump’s position on global warming. What will receive the bump it has been lacking will be the oil industry. Trump has also said that the Keystone XL Pipeline, that Barack Obama vetoed, will go ahead.

The concept of global warming was created by and for the Chinese in order to make U.S. manufacturing non-competitive.

— Donald J. Trump (@realDonaldTrump) November 6, 2012

In the last presidential debate in September of this year, Trump said: “Hillary Clinton wants to put all miners out of business.” Trump also swears by clean coal. He said: “There is a thing called clean coal. Coal will last for 1,000 years in this country. Now we have natural gas and so many other things because of technology. We have unbelievable -- we have found over the last seven years, we have found tremendous wealth right under our feet.”

F HILLARY WINS THE PRESIDENCY

Something that Hillary has, that Donald doesn’t, is a renewable energy plan. And this has an effect on what kind of engineers America will be employing. Clinton wants to cut U.S. oil dependency by one-third by 2027. She also wants the U.S. to generate 33 percent of its energy capacity from renewable sources by that date. $60 billion will be given to that initiative and will see engineers seeing the benefit of being involved in those industries. But what about the other energy engineering industries? Obama has been delaying the advancement of oil pipelines, most notably, the Keystone XL Pipeline.

Something that Hillary has, that Donald doesn’t, is a renewable energy plan. And this has an effect on what kind of engineers America will be employing. Clinton wants to cut U.S. oil dependency by one-third by 2027. She also wants the U.S. to generate 33 percent of its energy capacity from renewable sources by that date. $60 billion will be given to that initiative and will see engineers seeing the benefit of being involved in those industries. But what about the other energy engineering industries? Obama has been delaying the advancement of oil pipelines, most notably, the Keystone XL Pipeline.

In September 2015 Hillary Clinton said: “I don’t think we need to have a pipeline bringing very dirty oil, exploiting the tar sands in western Canada, across our border.” She said pipelines “distract [America] from the real challenges facing the the energy sector.”

Hillary also stated: “On my first day as President, I'll set two big goals. I want the U.S. to have half a billion solar panels by 2020. And I want us to generate enough renewable electricity to power every home in America in the next 10 years. With the right investments, we’ll create good-paying jobs and make America the world’s clean energy superpower.”

Furthermore, one of the industries Hillary would’ve single-handedly boosted during this election is the state-owned and private cybersecurity companies - some have already been established and are generating huge profits. Hillary famously said that Wikileaks had acquired the Democratic National Committee, her, and her campaign manager’s private emails from a Russian source. She said that the Russians were trying to interfere with the presidential election. Whether or not the emails were from the Russians, Clinton might have just handed a battalion of site reliability, network, and cybersecurity engineers new jobs due to her cybersecurity paranoia.

Ted Koppel, American journalist, who wrote the book Lights Out, focusing on cyber attacks on America’s electric grid, spoke to CNN, saying: “We live in an age where walls physically don't mean anything. Cyber attacks go right past walls. They can be enabled no matter where in the world you are.” Therefore, cybersecurity companies will be seeing an unprecedented level of investment.

Should engineers pursue politics?

The Dean of Engineering at the Engineering Institute of Technology, Steve Mackay, has spoken about where politics and engineers intersect. He said:

You have to get involved because [in politics] because you as engineering professionals have something more than most of these people in these parliaments have and that is that you are considerably more objective in what you do. A lot of the parliaments are riddled with lawyers, accountants and people that perhaps don't have the necessary technical knowledge to make considered technical decisions. Obviously, engineers have got potential problems ; building nuclear power plants, contaminating water and things like that - that we need to avoid. But really, you do have a major contribution.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Sherlock Holmes, that incredible detective, would be impressed with the new technologies and lateral thinking being employed to detect the ever more silent submarines (or subs) lurking below the surface of our oceans. Sonar (or acoustics) has been used in the past but is rapidly being ineffective.

Dear Colleagues

Sherlock Holmes, that incredible detective, would be impressed with the new technologies and lateral thinking being employed to detect the ever more silent submarines (or subs) lurking below the surface of our oceans. Sonar (or acoustics) has been used in the past but is rapidly being ineffective.

Sherlock Holmes, that incredible detective, would be impressed with the new technologies and lateral thinking being employed to detect the ever more silent submarines (or subs) lurking below the surface of our oceans. Sonar (or acoustics) has been used in the past but is rapidly being ineffective.

The thinking and approach to finding new technologies is quite inspirational and is not confined only to subs but could surely be used in a huge variety of other fields (e.g detecting sharks/rescuing people etc).

Debye Effect

Other approaches have been used to employ disturbances in the Earth’s magnetic field caused by the metal hull (referred to as MAD or magnetic anomaly detectors) but these require the detector to be relatively close to the sub.

A particularly novel approach in tracking subs is referred to as the Debye Effect and this relies on a magnetic signature of the sub’s wake. Sodium Chloride (NaCl) is the key component of sea water and physical movement (from a passing vessel) tends to shake the Na and Cl ions around with a resultant weak magnetic field created (called the Debye effect). The Russian, Chinese and American governments are racing against each other in coming up with a solution to apply this effect to a workable technology.

Technology Used to Beat Detection

On the other side of the fence, needless to say, the various navies around the world are spending a lot of money on new technologies to hide their very expensive submarines. One is use of fluid cloaking which alters the flow of water over the submarine to make them appear invisible. Acoustic cloaking on the other hand uses materials to refract sound waves (from a sonar) around the submarine and thus to hide it more effectively.

We can go far further than Subs – think of the incredible opportunities

I do realize that this is all specifically about detecting submarines but these technologies can be applied to a myriad of other uses. For example, detecting sharks near beaches or helping with rescuing people or tracking whales and general fish stock are all ideas that come quickly to mind.

Perhaps, a clever solution to hiding (subs, for example) is as per Robert Ferrigno’s (Sins of the Assassin) suggestion: Best place to hide was in a crowd.

Yours in engineering learning

Steve

Mackay’s Musings – 8th Nov’16 #625

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Evangeline Newby

- Category: Announcements

EIT is accepting applications to join the January 2017 intakes of each of the Master of Engineering Degrees as listed below. Applications are closing soon but will be accepted until December 16, 2016; apply today and secure your place on the limited places now available!

- Master of Engineering (Industrial Automation)

- Master of Engineering (Electrical Systems)

- Master of Engineering (Safety, Risk and Reliability)

Applications for the January 03, 2017 intakes will close December 16, 2016.

Proposed Master of Engineering Degrees

Our R&D team is working busily in the background to ensure we at EIT can offer you even more cutting edge Master degrees. There are six (6) new programs currently being worked on and we want to hear your thoughts on the proposed Master of Engineering degrees as listed below.

- Master of Engineering (Civil: Structural)

- Master of Engineering (Civil: Railway Infrastructure)

- Master of Engineering (Civil: Transportation)

- Master of Engineering (Mechanical)

- Master of Engineering (Electrical and Instrumentation in Oil and Gas)

- Master of Engineering (Chemical and Process)

View full details of these proposed degrees here: www.eit.edu.au/proposed-master-engineering-degrees.

We are excited at the prospect of being able to offer you even more Master of Engineering degrees in the future.

- Details

- Written by: Quintus Potgieter

- Category: Industry

A pipeline explosion in the United States on Monday has forced the Governer of Alabama, Robert Bentley, to declare a state of emergency. The pipeline explosion killed one and injured six workers. The subsequent fire as a result of the explosion has caused damage to what is known as the Colonial Pipeline which delivers gasoline to millions of customers. The South and Eastern United States regions will face gas price hikes and some will face shortages due to the pipeline's damage. The shutdown will affect 13 states.

The accident happened on October 31st, 2016, when a contractor struck a 36" below ground transmission gasoline pipeline. Repairs were being done on the pipeline after a previous pipeline rupture on September 9th, 2016. The previous rupture caused a big gas leak that was considered to be the pipelines biggest leak in 20 years.

The accident happened on October 31st, 2016, when a contractor struck a 36" below ground transmission gasoline pipeline. Repairs were being done on the pipeline after a previous pipeline rupture on September 9th, 2016. The previous rupture caused a big gas leak that was considered to be the pipelines biggest leak in 20 years.

"My thoughts and prayers are with the six injured workers and with the family of the fatally injured worker. An accident of this magnitude is tough for any community to deal with, and I want to personally thank the local first responders for their immediate assistance to this accident, as well as the first responders from surrounding counties," said Governer Bentley.

The Alabama Department of Environmental Management is now monitoring the air where the explosion occurred to ensure that the area is safe and not contaminated. It is the gasoline line that was ruptured, however, the other transmission lines are still operational, which deliver diesel, jet fuel, and other petroleum products. The Colonial Pipeline carries 2.5 million barrels of fuel a day - that fuel delivery is what has been delayed due to the explosion.

The State of Emergency will last until December 1st, 2016.

The pipeline explosion is not good news for the Energy Transfer Partners.The company is trying to emphasize the safety of oil pipelines to persuade the public that the Dakota Access Pipeline should be built. They have been assembling the pipeline that is to span four states wide. It will reportedly cost $3.8 billion and will transport 470,000 barrels of "light sweet crude oil" from North Dakota, all the way to Patoka, Illinois, twenty-four hours a day. The pipeline has been protested against for months. Business Insider confirms that since 1995, there have been 2,000 "significant" oil and gas pipeline accidents. They also reported that from 2013 to 2015, more than one hundred accidents happened every year. The Colonial Pipeline accidents have shown that human error very much an area of concern for the pipelines.

Here is footage of the Colonial Pipeline's damage and the subsequent fire that ensued:

- Details

- Written by: Quintus Potgieter

- Category: Developments

South Africa is celebrating their Wind Energy Week, this week. A week that will focus the minds of business leaders and engineers, all over the country, on the positive effect more wind energy infrastructure could have in the country. Most notably, a two-day conference is being held in Cape Town that will focus on the theme: Towards 100% Renewables. Three other events are also being held, all in the name of renewable energy with the specific focus on wind energy.

A report by Global Data predicted, by 2020, South Africa is looking to benefit from a further 3 gigawatts (GW) of  wind energy, that would bring the country to 5.6 GW. They are joining the 82 other countries in the world that benefit from wind turbine provided energy. South Africa is also in the top 10 renewable energy investment countries in the world, according to a report issued by Bloomberg last year.

wind energy, that would bring the country to 5.6 GW. They are joining the 82 other countries in the world that benefit from wind turbine provided energy. South Africa is also in the top 10 renewable energy investment countries in the world, according to a report issued by Bloomberg last year.

The country is currently chasing a goal of having 17.8 GW of production belonging to renewable energy, and natural gas supplying the other 3.1 GW. That would supply 82 percent of the power in the country. Presumably, the rest will be supplied via coal-fired power plants.

South Africa is moving towards natural gas and renewable energy production at a fast rate. A local ratings agency known as Moody's praised South Africa as the fastest-growing green economy in the world last year. Similarly, in the private sector, new malls and cities being built are all abiding by green standards.

South Africa's energy supply has struggled to cope with demand in recent years. Two coal-fired power stations - meant to bridge the gap - have seen construction delays for quite some time. As a result, loadshedding (forced rolling blackouts) had to be put into place to balance the grid. Therefore, engineers are looking to implement renewable solutions that could, in the future, power South African homes and businesses.

The demand from the public for further renewable energy innovation in South Africa reached a pinnacle this week, in the form of a protest by Greenpeace. The NGO's members protested outside of the Shoprite headquarters in Cape Town yesterday, to demand that the the retailer (Shoprite is South Africa's biggest retailer) power their stores with renewable energy. Greenpeace claims that Shoprite has the worst track record pertaining to the adoption of renewable energy. This according to their report, Shopping Clean: Retailers and Renewable Energy. In the report, the organization states that companies should be committing to an ambitious 100% renewable energy goal.

The demand from the public for further renewable energy innovation in South Africa reached a pinnacle this week, in the form of a protest by Greenpeace. The NGO's members protested outside of the Shoprite headquarters in Cape Town yesterday, to demand that the the retailer (Shoprite is South Africa's biggest retailer) power their stores with renewable energy. Greenpeace claims that Shoprite has the worst track record pertaining to the adoption of renewable energy. This according to their report, Shopping Clean: Retailers and Renewable Energy. In the report, the organization states that companies should be committing to an ambitious 100% renewable energy goal.

"If Woolworths, for example, were to be 100% renewable energy powered, this would liberate enough electricity for 55,000 households in South Africa. Pick n Pay's electricity consumption is enough to power 65,000 households while Massmart and Spar could power 53,000 and 5,400 households respectively," the NGO wrote. Therefore, their protest outside of Shoprite's headquarters begins to make more sense.

Thus, South African companies could look to the example being set by companies overseas. IKEA, the international home furnishing store, has made a pledge that would see all of the stores in their chain powered by renewable energy by 2020. According to the Guardian, IKEA enjoyed a comfortable profit of $33 billion in 2015. Some of the profits will go toward funding photovoltaic solar solutions and WIND POWER.

Companies making high profits could build their own wind farms and put solar panels on their roofs. Walmart secured a deal with Pattern Energy to power their stores through wind farms.Other companies have joined the RE100 climate group, along with IKEA, in pledging that they will power their buildings only through renewable means. The companies include Apple, BMW Group, Coca-Cola Enterprises, Facebook, General Electric, General Motors, Google, Hewlett-Packard, Microsoft, Philips, Tata Motors, Walmart and more.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

We are assailed on a daily basis with inventions that will break the laws of Physics. Some are hard to disprove although eventually they are generally discredited. One only needs to think of the devices that were invented to provide perpetual motion. All stuff, nonsense and quackery.

However, there is a new kid on the block with a claim to overturn the Laws of Physics. A rocket drive.

Dear Colleagues

We are assailed on a daily basis with inventions that will break the laws of Physics. Some are hard to disprove although eventually they are generally discredited. One only needs to think of the devices that were invented to provide perpetual motion. All stuff, nonsense and quackery.

We are assailed on a daily basis with inventions that will break the laws of Physics. Some are hard to disprove although eventually they are generally discredited. One only needs to think of the devices that were invented to provide perpetual motion. All stuff, nonsense and quackery.

However, there is a new kid on the block with a claim to overturn the Laws of Physics. A rocket drive.

The Third Law of Physics – Action and Reaction

As you will remember from high school physics: For every action there is an equal and opposite reaction. Rockets are a great example of this law in action. Gas pouring out of the rocket at high speed from combustion of the propellants results in the rocket being flung through space at a high speed in the opposite direction. Action and reaction at work and relatively easy to explain.

The propellants for the rocket are a huge disadvantage as they often require to be lifted up against the earth’s gravity with the payload being often a tiny 10% of the overall mass at lift off. So the question is thus: How can we dispense with the propellant and thus allow us to travel to the stars with panache?

Dr Roger Shawyer, in addressing this issue, has invented the EMDRive rocket which converts electrical energy into thrust with no need for a reaction mass. Microwaves are fed into the conically shaped EMDRive and bounce around giving a small net thrust.

NASA (through their Eagleworks lab) have recently verified thrust is being generated in contradiction to the laws of physics.

The laws of physics show that as nothing is actually emitted from the EMDrive, it surely cannot generate thrust.

So what gives?

My take on this is that it is likely to be experimental error as the thrusts that are being measured are extraordinarily tiny for the prototype. But at the present – it has been impossible to demonstrate anything other than something very strange happening.

Breaking the Laws of Physics

There have been many attempts at breaking the laws of physics. One of the most recent ones that had me surprised was a respected physics lab in Italy who reported subatomic particles were able to travel faster than the speed of light. However, after a lot of shouting and screaming, this was traced to some defective wiring in the test equipment (I think it was the fiber optics connectors at fault).

Another attempt at breaking the laws of physics was a space probe whose trajectory was unusual with some force pushing against it (thus changing its trajectory ever so slightly). It turned out that radiation pressure was the cause.

And indeed sometimes – very rarely – we do get something that breaks the Laws of Physics and results in a new theory. One only needs to think of the big conundrum of the orbit of Mercury which couldn’t quite be explained by classical physics of the time in late 1800s. It turned out that we needed Albert Einstein and the Theory of Relavity to explain the orbit. Certainly, the laws of Physics were overturned at this point. But this was an unprecedented event.

Perhaps the theory of Cold Fusion is another one – but this still has a long way to go.

A Universal Test

When assessing any idea (business, engineering or otherwise), I love to quote Robert De Niro’s aphorism: When there is any doubt, there is no doubt. An alternative piece of advice which is also very useful is: If appears to be too good to be true, then it is definitely too good to be true.

(And this quotation, I might add, can be applied to a company’s stock price as well).

Thanks to the Economist for an interesting discussion on this potential triumph in Modern Physics.

Yours in engineering learning

Steve

Mackay’s Musings – 1st Nov’16 #624

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

When Tesla bought solar panel manufacturing giant Solar City in August - for the cool sum of $2.6 billion - the benefits were clear. Tesla, who had been working on electric vehicles and the house and business-powering Powerwall and Powerpack needed the solar panels that would keep their batteries charged. The Chief Financial Officer of Tesla, Jason Wheeler, told Reuters, that the companies would save at least $150 million a year by merging. He also stated that Tesla and Solar City would be sharing "key technologies" if the merger went through - which it did.

The public was quite unaware of just how much and how quickly the two companies would be sharing their "key technologies". In Hollywood, on Friday, the 28th of October, Elon Musk (CEO of Tesla) delivered a speech in front of the old set of the hit show Desperate Housewives. Odd? Yes. Journalists walked amongst a collection of seemingly normal houses on a seemingly normal street. What they weren't ready for, was for Musk to tell them that all of the roofs were retrofitted with solar panels. Not just one or two solar panels. Every tile was a solar panel.

The public was quite unaware of just how much and how quickly the two companies would be sharing their "key technologies". In Hollywood, on Friday, the 28th of October, Elon Musk (CEO of Tesla) delivered a speech in front of the old set of the hit show Desperate Housewives. Odd? Yes. Journalists walked amongst a collection of seemingly normal houses on a seemingly normal street. What they weren't ready for, was for Musk to tell them that all of the roofs were retrofitted with solar panels. Not just one or two solar panels. Every tile was a solar panel.

In a response to rising CO2 levels, Musk has made it part of his life mission to make sustainable, renewable energy technologies that would be less harmful to the planet. NASA has published a report that said that 2016 would be the hottest year on record. Musk - and by association, Tesla - are hoping to make solar panels (disguised as roof tiles) and home-powering batteries as alluring as their electric vehicles have become. Musk believes that people need to do as much as they can to work towards a world powered by sustainable energy.

"The goal is to have solar roofs that look better than a normal roof, that generate electricity, last longer, have better insulation, and actually have an installed cost that is less than a normal roof plus the cost of electricity. Why would you buy anything else?" Musk said.

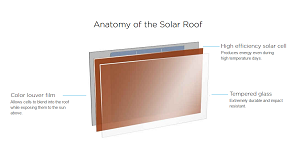

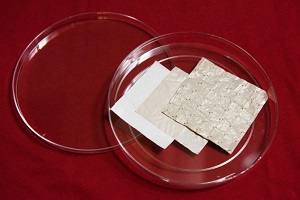

The tiles are made of a super-durable glass that allows light to penetrate the cell that generates energy when shone upon by the sun. When viewed at a front-facing angle, the tiles seem to resemble normal roof tiles you would find on any roof you see today, however, when you tilt them slightly they become more transparent, and you're able to actually see the solar cell.

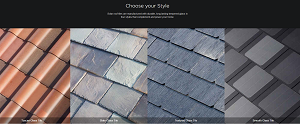

The tiles come in four different designs: Tuscan Glass Tile, Slate Glass Tile, Textured Glass Tile and, Smooth Glass Tile.

The tiles come in four different designs: Tuscan Glass Tile, Slate Glass Tile, Textured Glass Tile and, Smooth Glass Tile.

The tiles are hydrographically printed so that the different texture styles can be achieved. The glass Tesla is using is much more durable than conventional roof tiles.

The new Powerwall 2.0 will be powered by the Solar Roof. Customers will then be able to use the charged battery during dusk and dawn hours to minimize the amount of utility-provided grid-energy. The Powerwall 2 has twice as much energy as the first iteration. It will cost $5,500. The Powerwall powers lights, sockets, the refrigerator, and bedrooms of an average 4 bedroom house. Musk says with the Solar Roof installed, you would be able to power a house indefinitely. The company is also releasing the Powerpack 2 that will integrate with international power grids.

Will utilities go out of business once everyone is powering their houses with Solar Roofs and Powerwalls? Musk doesn't think so - he seems to think the "future is bright" for both the consumer and the utility.

Will utilities go out of business once everyone is powering their houses with Solar Roofs and Powerwalls? Musk doesn't think so - he seems to think the "future is bright" for both the consumer and the utility.

"The solution is both local power generation and utility power generation. It's not one or the other. Sometimes the Solar Roof is positioned as a competitor to utilities, but, we're actually going to need utility power to increase and we're going to need local power generation," Musk said.

The announcement of the shingles sent Australian hearts aflutter. Some Australian households have already been enjoying the benefits of the first Powerwall thanks to pilot programs that saw households receiving Powerwalls to test the feasibility of solar microgrids. Now with added capabilities, grid-independency is within reach for some households once the Powerwall 2 starts shipping in January 2017.

Australia aims to achieve 100% renewable energy by 2020.

- Details

- Written by: Quintus Potgieter

- Category: Industry

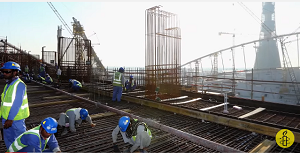

The first worker to die of a "work-related" incident at one of Qatar's World Cup 2022 stadiums, has been mourned by the organizers of the tournament. The worker was reportedly hit by a water truck at the Al Wakrah stadium and has become the first person to die whilst physically working at a Qatari stadium. "It is with deep regret we announce a work-related fatality on one of our projects. A full investigation is underway to determine the factors which contributed to the death of one of our workers," The Supreme Committee for Delivery and Legacy said on their website. Three workers had previously died at World Cup construction sites in what organizers claimed were non-work-related circumstances.

One of the non-work-related incidents involved a 52-year-old painter who died working on the main stadium, the Khalifa International Stadium. The organizers say he died of cardiac arrest in one of the site's dining halls a year ago.

One of the non-work-related incidents involved a 52-year-old painter who died working on the main stadium, the Khalifa International Stadium. The organizers say he died of cardiac arrest in one of the site's dining halls a year ago.

Qatar has been under constant scrutiny for the labor conditions the workers have had put up with since construction on the 2022 venues began. Ninety-four percent of the workforce involved in the construction of World Cup venues are of South Asian background ; Pakistanis, Bangladeshis. Indians and Nepalese people. There are 1.4 million migrant workers in the country. The country was criticized by the International Trade Union Confederation in 2013 who reported that 1,239 deaths had occurred from 2011 to 2013 in Qatar. They also said that 4,000 migrant workers would die before a ball is kicked off in 2022, irrespective of whether they work on World Cup venues or not. It is in their, and other groups like Amnesty International's opinion that a World Cup should not take place in a country where worker deaths happen at an unprecedented level.

"FIFA has not done enough to address the situation from the very beginning. It should have known even before it awarded the World Cup to Qatar, that this is an environment where labor abuse is endemic. In its bidding process, it made no mention of human rights, let alone labor rights," said Mustafa Qadri, a researcher for Amnesty International.

"FIFA has not done enough to address the situation from the very beginning. It should have known even before it awarded the World Cup to Qatar, that this is an environment where labor abuse is endemic. In its bidding process, it made no mention of human rights, let alone labor rights," said Mustafa Qadri, a researcher for Amnesty International.

Qatar's World Cup will bring engineering jobs to the country in industries including transport - a new railway system is planned - new hotels and of course, the new stadiums. They are also planning to install state-of-the-art air conditioning in the stadiums.

However, Amnesty International say the workers' situation has not improved since it was exposed in 2013/14. One of the workers, speaking anonymously to the NGO said: "I am an electrician, and I agreed to electrician's work. But when I came to Qatar, they only gave me electrician work for the first two months. After that, they said I had to do iron fitting work."

Engineering Innovation

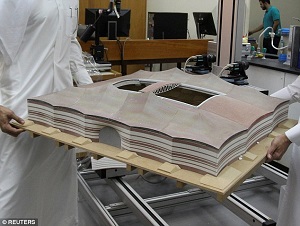

Engineers at Qatar University have been utilizing rapid prototyping technology to 3D print models of the stadiums. They will use these models in weather simulation tests in their labs to test their resilience to sand storms that might flare up during the World Cup. Regardless of their hosting in winter, the stadiums will be used in summer as well, and that is when most sand storms occur.

Engineers at Qatar University have been utilizing rapid prototyping technology to 3D print models of the stadiums. They will use these models in weather simulation tests in their labs to test their resilience to sand storms that might flare up during the World Cup. Regardless of their hosting in winter, the stadiums will be used in summer as well, and that is when most sand storms occur.

They will test the model by putting it in a wind tunnel and letting the wind run over it, testing both for weather and inside-stadium temperature. Qatar University Professor Dr. Saud Abdul Aziz Abdu Ghani, talking to Doha News, said: "We can see the temperature per tier, add in variants as sweat produced and amount of spectators, and then run simulation and see the effect on the temperature inside the stadium. For the cooling, we want a minimal amount of air to go in, and we want the air inside to stay there. We can change the direction and stimulate different directions at this facility."

According to the engineers, the aerodynamic testing and modifications have led to good results. One of the stadiums, after aerodynamic model testing, revealed that it didn't need as much steel as the designers initially thought.

The engineers lauded aerodynamics testing and said it is the future of building design.

- Details

- Written by: Evangeline Newby

- Category: Industry

The National Aeronautics and Space Administration of the United States (NASA) has said that after 136 years of global temperature record keeping, 2016 is irrefutably the hottest year on record. The revelations come after September’s data showed that the month was the warmest month in history, according to NASA’s Goddard Institute for Space Studies (GISS). They reported that September was 0.91 degrees celsius warmer than the mean September temperatures from 1951 to 1980. The warmer global temperatures have already caused long-lasting droughts in the United States, South Africa, India, and Australia.

It all started in 2015 with the El Niño climate cycle. Coupled with the global climate change phenomenon, air temperatures were altered and a drought ensued, which led to less rain and thus less water. It has caused one of the worst droughts South Africa has seen in 30 years. In India, 134 farmers have committed suicide in just two months due to a two-year drought that has led to crop loss. In South Africa, several provinces have had water shortages. The provincial governments have ordered water restrictions be put in place at the utilities and cautioned citizens to use water sparingly or face the consequences. The consequences being...complete water cut-offs.

Even with the El Niño’s natural regression, the realities of climate change have been apparent. The immediate issue is the lack of water. Engineers are hard at work to figure out how to bring technology to the drought-fight at the University of California, Los Angeles (UCLA). At a third-party moderated discussion, Madelyn Glickfeld, a member of the UCLA Water Group and Institute of the Environment of Sustainability said: “The technologies that are most promising are smart technologies - technologies that use smart sensors to help people know how much water they’re using. This helps change behavior.” A recent poll by a Californian company named Xylem revealed that 76 percent of people believe that recycled water is the step forward for the region’s water infrastructure.

In response, Eric Hoek, a civil engineering professor at UCLA said: “I can take any quantity of water and turn into any other quality of water. The technology is there. It has been there for 20 years. The question is how much you’re willing to pay. Reusing water should be completely uncontroversial. The reality is it’s much safer to intelligently implement technology than to put water back out into the environment and pray that nature magically cleans it up.”

Hoek is talking about toilet to tap technology and reservoirs that capture rainfall runoff which, in turn, runs the water through a water purification process and eventually produces drinkable and reusable water. These are inventions that engineers have been successfully implementing in several countries for many years. However, Californians are unfamiliar with Direct Potable Reuse (DPR)/the toilet to tap wastewater reuse method. This system could lead to more water being accessible in the drought-stricken state.

However, drinking water aside, the other issue countries will have with further drought climate conditions is in the hydroelectric power plants. In Daniel L. Calzi’s book Dams, Drought and Energy-water Interdependencies, he details how droughts have the potential to affect “the operation of dams in ways that can be detrimental to hydropower production.” Less hydroelectric electricity being produced means higher electricity costs for utilities and customers. This is specifically bad for the United States.

The country’s hydroelectric facilities generated 51% of the renewable energy in the U.S. in 2013, and continue to play a large role to this day. Calzi points out that hydroelectric plants are the least expensive source of electricity and produce no fossil fuels. The only issue is that the facilities rely on precipitation to continue running, which feeds the local water sources. Engineers also have to consider humidity, wind patterns and reservoir dynamics, which in a drought, is nothing less than difficult. Annoyingly, if there is too much water - in the event of a flood, or a related event - hydroelectric plants also stop working.

In an attempt to remedy the water scarcity crisis that is becoming prevalent in the world, Sir James Dyson the industrial designer, is encouraging engineers to lend their expertise to saving water. Speaking of the situation in his own country, Dyson said: “Parts of the country are waterlogged, while in others it’s illegal to use a hosepipe.” He says that the United Kingdom still relies on “antique infrastructure” handed down to them from the Victorian era. He says it is time for the latest generation of engineers to redesign the water system and improve it.

“It is politicians who should be leading this charge. They must think big, think long-term and they must reinforce the value and importance of great engineering,” Dyson said. Engineers in the UK have ensured that leaking pipes are replaced, Dyson adds, however, he says new technologies could be introduced that improve these water infrastructure processes.

Engineers have a plethora of options when entering water industries. A Professional Certificate of Competency in Programmable Logic Controllers & SCADA Systems could see you tackling the digital side of controlling a water utility that relies on automated processes to keep it functioning. You could get your certificate in Structural Design for Non-Structural Engineers and see how water and wastewater infrastructure is built. You could also pursue a certificate in Onshore and Offshore Pipeline Systems - the water has to be transported somewhere. And much more.

Contact us at the Engineering Institute of Technology today to enquire about which course would be right for you: http://www.eit.edu.au/course-enquiry

References:

Calzi, Daniel L. Dams, Drought and Energy-water Interdependencies. Print.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Steve Mackay, Dean of Engineering at EIT and sister company, IDC Technologies enjoys writing his weekly blog including useful tips and current industry matters for his fellow engineering colleagues. With a loyal and expanding following base reaching over 600,000 people around the world, click here to read all of Steve's blogs over at EIT's sister company, IDC Technologies.

Digitally Hunting for an Engineering or Technology Job

Have you experienced the frustration and futility of searching and applying online for hundreds of jobs – particularly in the engineering and technology space? Perhaps, you feel that you are casting your resume into the abyss whenever you apply online.

Unhappily today, you often have to get your resume past an army of robots looking for keywords before handing over a select few resumes to a human recruiter to look at. Some firms are even proactively scanning the web looking for personnel with the perfect characteristics matching a particular job profile. Other strategies are to require you to upload a video to the web with you answering specific questions.

This is all making it extraordinarily difficult for you to actually talk to a human. And it makes it critical for you to follow the right steps in dealing with this plethora of technology so that you can gain an interview.

Predictably the first step is simple

This is for you to review the job description and ensure your resume is aligned with what the recruiter requires in terms of experience and qualifications in a measurable way.

This is to make it easy even for an orang utan to see that you are the perfect match for the job. This doesn’t mean that you must lie but you must put effort in to visualise what the job requires and align your resume with the job. Ensure that you use the relevant key words so that they get picked up by the robots doing the initial scan of resumes. Perhaps put in the acronyms relating to the hardware or software requirements.

Stay up-to-date at all times

Keep everything relating to your online career up to date. This means not only your resume but LinkedIn profile and other social media sites.

Smile for the Camera

Many interviews are conducted online and through Skype. Ensure you are 100% presentable and prepared for any interview. Whether it is demonstration of your sales or technical skills or simply as an interview.

Assess your Performance and Consider Alternative Strategies

If despite all this work; you are still hitting the black hole in terms of results – sit down and consider what you are doing. Get a colleague to assess your resume or presentation and make suggestions. Consider that you may be applying for jobs in an overtraded area where demand is low and supply huge.

Perhaps you should be using other strategies to gain your dream job in engineering – such as gaining more credentials or experience or joining an online discussion group in the topic area. Actively networking with others in the industry is a strategy which engineers tend to be less enthused with but which can work wonders for a job search.

Above all – persist and don’t give up. Ultimately your grit and determination will prevail in your job search.

Yours in engineering learning

Steve

Mackay’s Musings – 16th August’16 #613

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

General Electric is considered to be one of the world's leading industrial companies, who have played a leading role in building energy infrastructure. They do this through their Power department, formally known as GE Power. They are one of the world leaders in power generation and water technologies, supplying utilities around the world. With the recent advancement of renewable energy technology, the company has made a big investment into what they think would further the renewable energy mandate in the world of today.

Yesterday, General Electric announced that they would be purchasing LM Wind Power, a company based in Denmark who manufacture and supply rotor blades to the wind industry. GE would be purchasing the company for a sum of $1.65 billion. A GE spokesperson said: "LM Wind Power has a terrific team, with a strong passion for their mission to power a cleaner world. Their values of customer focus, teamwork, trust, and ownership are harmonious with our own values. [GE] is very optimistic that together we will help shape the future of energy."

Yesterday, General Electric announced that they would be purchasing LM Wind Power, a company based in Denmark who manufacture and supply rotor blades to the wind industry. GE would be purchasing the company for a sum of $1.65 billion. A GE spokesperson said: "LM Wind Power has a terrific team, with a strong passion for their mission to power a cleaner world. Their values of customer focus, teamwork, trust, and ownership are harmonious with our own values. [GE] is very optimistic that together we will help shape the future of energy."

The figures speak for themselves. According to Business Wire, in 2015, 50% of new electricity infrastructure was made up of renewable energy sources, with wind accounting for 35% of those additions. GE has said that buying the blade manufacturer will catapult them into a habit of in-house blade design and manufacturing that will compliment their renewable energy business. In another report by Markets and Markets, solar and wind renewable energy technologies accounted for 77% of the amount of renewable energy produced in the United States last year.

Jérôme Pécresse, chief executive of GE Renewable Energy told Wall Street Journal: "We'll be more local, have more flexibility and knowledge in turbine design and supply, and more ability to innovate and reduce product costs while improving turbine performance." LM Wind Power currently has 13 factories spread across 8 countries including Denmark, Spain, Poland, Canada, USA, India, China and Brazil. So, the purchasing of the company will put GE in a good position for being a leading supplier of wind turbine blade technology.

Innovative wind turbine technologies

In a video below, you can see a company known as Icewind, who are engineering novel wind turbines according to a design named the 'Savonius vertical axis' wind turbine. These are turbines that can spin for hours with minimal wind and generate electricity. Apparently, the design of Icewind's turbines ensures that the turbines cannot spin at speeds too fast for the turbine to handle. Conventional wind turbines sometimes pick up too much speed and break the turbines.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Seemingly, the word is out that millennials (born from 1980 to 1996) are gaining a reputation for job-hopping. According to a recent Gallup report, 21% of millennials changed jobs in the past year. This is a huge number and considerably more than for older generations. Apparently the belief is that this rapid move in jobs can boost one’s career with greater salaries and more learning possible with this strategy.

Dear Colleagues

Seemingly, the word is out that millennials (born from 1980 to 1996) are gaining a reputation for job-hopping. According to a recent Gallup report, 21% of millennials changed jobs in the past year. This is a huge number and considerably more than for older generations.

Seemingly, the word is out that millennials (born from 1980 to 1996) are gaining a reputation for job-hopping. According to a recent Gallup report, 21% of millennials changed jobs in the past year. This is a huge number and considerably more than for older generations.

Apparently the belief is that this rapid move in jobs can boost one’s career with greater salaries and more learning possible with this strategy. Perhaps, in working for a short time with a start-up , for example, you can hit the mother lode with a big payout when the company is bought or listed on the stock exchange.

Supporting this argument for rapid job movement is a survey from Payscale which found a ferocious turnover with tech companies such as Amazon and Alphabet (owner of Google) with a workforce median tenure of slightly more than one year. Quite unbelievable. The amount of change in these companies would be incredible requiring a totally different approach to running the business.

With all the restructuring and downsizing (or rightsizing as the economists may refer to it) going on in industry, the move from job to job seems quite believable. And many senior managers have seen the booms and busts before and are probably sympathetic to someone who hasn’t been long with a company.

It’s all a Myth

Most assuredly, however even today, if you walk into a hiring manager’s office and tell her that you have been through three jobs in three years, you won’t exactly enhance your odds of getting the position. So, job hopping isn’t a good idea or an easy story to tell a would-be employer. So if you have been through a flurry of jobs – you better have a good story to tell the hiring manager.

For example, it is quite understandable if you worked for a company that went bust (e.g. a start up) or you worked as an intern for a year to get experience in a particular technology. Or you set up your own business which didn’t work out. Or you worked on a series of projects as a contractor.

The Unmentionables

However, if you start mentioning reasons for moving quickly from company to company which included such items that you had a loser for a boss or couldn’t handle the company’s culture or similar explanations – you are probably not going to be giving a good story to get you that job you are after.

There has been a change of Philosophy

There is no doubt that only 20 years ago; jobs were hugely stable and engineering professionals often stayed for whole careers with one company. However, the last decade or two has seen company restructurings and failures reach epidemic proportions. Aided and abetted by the massive technology change going on.

So managers today are more sympathetic to job hopping but nonetheless you still need to have a carefully rehearsed story if you have been through a plethora of jobs in a few years. Good luck.

Thanks to an interesting article by Dawn Kawamoto of the IEEE for some of the references above.

Yours in engineering learning

Steve

Mackay’s Musings – 11th Oct’16 #621

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

I had a chuckle when I saw my old colleague (and sparring partner), Michael Brown, recently noting that process dead time is one of the most misunderstood issues in feedback control loops. Absolutely true - there is so much gibberish spoken about this topic. No matter what discipline of engineering you are in – you would have come across the problem of dead time.

Dear Colleagues

I had a chuckle when I saw my old colleague (and sparring partner), Michael Brown, recently noting that process dead time is one of the most misunderstood issues in feedback control loops. Absolutely true - there is so much gibberish spoken about this topic. No matter what discipline of engineering you are in – you would have come across the problem of dead time.

I had a chuckle when I saw my old colleague (and sparring partner), Michael Brown, recently noting that process dead time is one of the most misunderstood issues in feedback control loops. Absolutely true - there is so much gibberish spoken about this topic. No matter what discipline of engineering you are in – you would have come across the problem of dead time.

Probably even if you are a hippie (do we still have any around?) living in a commune you would also have come across the issue (as I will explain below in regards to hot water).

Some myths in process control which abound and which are strongly evident are ones such as:

- Tuning is the most critical element of a process loop and one needs to spend most time on this issue.

- Instruments always work correctly and feed the right data into the control system and we don’t need to worry too much about them. Tuning is where we need to spend all our time.

- Advanced Process Control techniques will solve all our difficult control problems.

What is Dead Time?

As a reminder - dead time is the amount of time it takes for the process variable to start changing after the output from the controller is changed (to a control valve for example).

Lag time, on the other hand, is the amount of time (after the dead time has elapsed) that the process variable takes to move 63.3% of its final value after a step change to the valve position.

Dominant Processes

A dead time dominant process occurs when the dead time is greater than the dominant lag.

An example, I always love to quote is when a feeder discharges ore onto a conveyer belt. Some distance away from where the ore hits the belt is the weighing instrument. This means that when the feeder controller makes changes to the amount of ore discharged onto the belt – there is still some significant dead time before anything happens on the weightometer (so the controller is ‘flying blind’ for a while).

Another example, is when you having a shower in an old hotel where the hot water geyser is some distance away from the shower – you will make adjustments to get the right level of hot water and find out that there is no response so you end up with significant instability as you twiddle the tap vigorously in both directions trying to get the right balance. And with the oscillatory action – you have instability.

Rules and more rules

As Mike says – the rule for dealing with dead time is simply this: The longer the dead time, the slower the tune. The trick is to set the integral term correctly and then reduce the proportional gain until the response is stable. You should be able to get to the new setpoint within two dead times.

How Does One Deal with Other Disturbances?

If there are other ongoing disturbances – well – there is nothing much you can do. Perhaps, try feedforward control or fix the main problem – move the measuring point or control action (e.g. valve) to reduce the dead time.

Myths and More Myths

The critical thing is to avoid the myth about using the derivative term to ‘speed up the response’. Totally incorrect. The core of the problem, as I understand it, is that you don’t have sufficient process data from your process to make a good quick decision with the controller. Hence the need for a slower tuning action.

If you want some solid robust process engineering stuff relating to this rather superficial summary of mine go to Mike Brown’s site (www.controlloop.co.za).

Yours in engineering learning

Steve

Mackay’s Musings – 4th Oct’16 #620

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

Additive manufacturing is the process of manufacturing a material object through layer-by-layer technology enabled by computer-aided design technology. Or at least it used to be. A new kind of rapid prototyping is on the rise. Rapid prototyping is a useful process for scientists and engineers alike, who use 3D printing technology to rapidly manufacture objects for both theoretical and practical uses. Rapid prototyping allows for the creation of models and parts that could be used in engineering applications. In some applications, it used to take an idea and display it as a working model or prototype. A tool for engineers to envision what the end product of something might look like, or actually manufacture a tool necessary for their projects, or even produce the product they are going to be selling.

According to T.S. Srivatsan and T.S. Sudarshan's book: Additive Manufacturing: Innovations, Advances, and Applications, rapid prototyping has achieved for big successes in the development of products:

1. Reductions in both time and costs

2. Enhanced human interaction

3. Possibility of creating any shape that would otherwise be difficult to produce

4. A shortened development cycle

However, the technology has progressed to the point where rapid prototyping could forever be changed. In 2015, Michael Breme, the head of Audi's tool design, described how 3D printing was benefitting their business. He said: "It enables us to produce the parts faster

and more cost-effectively. For example, with a 3D printer, we don't have any waste like we would with metal cutting, which means we're faster and more effective." However, back in 2015, there was only one problem with 3D printers. They weren't fast.

The 3D printing start-up company, Carbon, has received $81 million in funding from global investors this year. The investors include BMW Group, General Electric, Nikon and JSR Corp, amongst others. The company now has $222 million in funding that it will use to further their particular kind of 3D printing. The company utilizes Continuous Liquid Interface Production (CLIP). Their printer, the Carbon M1 printer produces a solid object from a small tub of liquid plastic through new stereolithography (SLA) rapid prototyping technology. They're making rapid prototyping even more rapid.

How do they do it?

Well, what this printer does differently to other printers is all in the ultraviolet (UV) light projector. The projector purportedly 'projects' what the end product should look like and then pulls it out of the liquid polymer (resin). Instead of a laser physically redefining the CAD (computer-aided design) pattern over and over again, the CLIP technology uses UV light and oxygen to produce a mechanically sound object without the need for layer-by-layer technology. As a result, a chemical process known as photopolymerization occurs.

The CEO of Carbon, Joseph DeSimone, said: "This product lays the groundwork for addressing major gaps in additive manufacturing as we work with our customers to continually innovate and push the boundaries of product design and production."

Carbon says their method of rapid prototyping is one hundred times faster than conventional printers available on the market today.

Speaking of the 3D printing market. The rapid prototyping materials (the actual resins used to print) market is expected to grow at a compound annual growth rate of 26.8% from 2016 to 2021. Markets and Markets estimate that the rapid prototyping materials market will reach USD 903.8 million by 2021. According to another report by Wohlers Associates, the entire 3D printing market will peak at $10 billion by 2017. They also confirmed that last year, 278,000 desktop 3D printers were purchased, showing that 3D printing is also becoming popular among hobbyists.

- Details

- Written by: master-engineering-and-bachelor-science-degrees

- Category: Announcements

Applications Now Open!

EIT is pleased to announce that we are now accepting applications to join the January 2017 intakes of each of the Master of Engineering Degrees:

- Master of Engineering (Industrial Automation)

- Master of Engineering (Electrical Systems)

- Master of Engineering (Safety, Risk and Reliability)

If you hold a Bachelor Degree, you can apply for a place on one of these two-year part-time (100% online) study programs - accelerate your career into high gear.

Due to the demand for the limited places on these degrees, you should act now; our window for accepting applications will be short.

You can obtain fees, payment options and copies of the application forms by completing the course enquiry form here: www.eit.edu.au/course-enquiry.

The live, online method of teaching will ensure that engineers and graduate technologists can begin the two year programs wherever they are in the world. Furthermore, the qualification is attained part time, allowing students to study alongside work and family commitments.

The EIT interactive platform of learning provides students with two vital benefits. The first is the option, during every live session, to question their lecturers. The second is the ability to form networks within the virtual classroom with other master students based around the world.

Give your career and your self-esteem a massive boost. Contact us today.

Bachelor of Science (BSc) Degrees

We are also delighted that the Bachelor of Science (BSc) degrees have been accredited by TEQSA, Australia’s regulatory authority. These BSc degree programs fit in seamlessly to EIT’s other program offerings allowing you to progress from a post school certificate (e.g. trades certificate) to 18-24 month Advanced Diploma, 3-4 year BSc, culminating in a 2 year Master of Engineering degree.

FREE Information Session

If you are interested to know more about the BSc and Master programs, attend our live, online information session with EIT's Dean of Engineering, Dr Steve Mackay. For full details and to register your place, please click here.

Applications are now open for the January 03, 2017 intakes for the following degrees:

- Bachelor of Science (Industrial Automation Engineering)

- Bachelor of Science (Electrical Engineering)

- Bachelor of Science (Mechanical Engineering)

- Bachelor of Science (Civil and Structural Engineering)

One of the concerns that students may have is: "Will I be able to finish the program?”. Yes you will! You will receive full support from the lecturers and your Learning Support Officer and mentor; we want you to complete the degree, as much as you do. The dedicated learning coordinators and knowledgeable lecturers will all focus on providing you with the know-how to help you through the degree program, which will benefit you throughout your engineering career.

You are assuredly getting the most effective online education available. Our highly interactive sessions with experienced passionate engineering lecturers, supported by keenly interested learning coordinators for each class, is a key to our ongoing success and industry high graduation rates. We believe this is by far the best way to achieve outstanding results in your engineering education.

Read more on our Bachelor of Science programs here.

Applications will close December 16, 2016.

Do not miss out on a place – APPLY NOW!

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

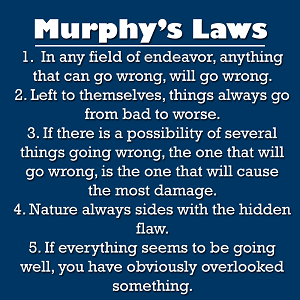

Murphy’s Law is especially quoted in engineering and as most of you would well know says: “If anything can go wrong, it will”. Often, we add: “and at the worst possible time, in the worst possible way”.

Origin of Murphy’s Law

The Law’s (supposed) origin was in engineering where Captain Ed Murphy, an engineer at Edwards Air Force Base, was dealing with a technician who incorrectly wired a strain gauge bridge...

Dear Colleagues

Murphy’s Law is especially quoted in engineering and as most of you would well know says: “If anything can go wrong, it will”. Often, we add: “and at the worst possible time, in the worst possible way”.

Origin of Murphy’s Law

The Law’s (supposed) origin was in engineering where Captain Ed Murphy, an engineer at Edwards Air Force Base, was dealing with a technician who incorrectly wired a strain gauge bridge (wired backwards) for doing gravity tests which as a result gave a (totally wrong) zero reading. There is vigorous debate about whether the engineer gave the incorrect wiring diagram to the technician or whether it was just mistakenly wired up. Whatever happened, the law is now firmly linked with Captain Murphy. And the set-up should have been meticulously tested before being put into service (which it wasn’t).

Uncertainty Principle

I reckon this is a reflection of a fundamental principle of engineering about the lack of precision which results in measurement uncertainty. We can never know precisely the value of anything to any arbitrary level of precision. At the sub-atomic level, Heisenberg’s principle makes this point, that for example that the more precisely you try and measure the location of a particle, the less precisely you will measure its momentum (and vice versa for trying to measure momentum precisely). This doesn’t reflect on your ability to measure, but on the nature of the system itself.

Risk Analyses

In Safety engineering, we do what is called a risk analysis where we identify what types of harm could arise from what we are planning to make or do. We can then establish the probability of the occurrence and then multiply this by the severity of the harm (broken finger, to amputated arm) and we end up with the Risk. If the Risk is great enough, we can then apply a $ value to it and determine how much time and money to spend in reducing it to a tolerable risk. It is impossible to make anything totally unequivocally safe. So as far as Murphy’s Law and risk management is concerned, if you have conducted your risk assessment correctly, then you must expect that the consequences it predicts will eventually come to pass.

And remember: “Absence of proof is not proof of absence”. For example, many years ago with the ill- fated space shuttle launch, a proper risk analysis would presumably have shown that the foam chunks falling off its booster and damaging its thermal tiles would have correctly predicted the deaths and destruction of the craft during re-entry due to the defective tiles. However, NASA believed that because they had not seen such problems so far, they would continue not to see them.

So please continue to embed awareness of Murphy’s Law into your daily engineering life and constantly seek to minimise the consequences of risk.

With our constant litany of woe with IT stuff, I think we are all familiar with Murphy’s Computer Laws (Finagles Rules) – well, I certainly am:

What Every Computer Consultant Needs to Know:

- In case of doubt, make it sound convincing.

- Do not believe in miracles. Rely on them.

Thanks to Keith Armstrong for his illuminating article

Yours in engineering learning

Steve

Mackay’s Musings – 27th Sept’16 #619

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

In the past few years; we have seen some spectacular collapses of buildings and bridges. This is quite inexplicable to today’s structural designer and engineer who puts enormous effort into the careful use of materials and huge safety margins.

In the past few years; we have seen some spectacular collapses of buildings and bridges. This is quite inexplicable to today’s structural designer and engineer who puts enormous effort into the careful use of materials and huge safety margins.

However, when a designer is operating at the limit of their expertise; mistakes still occur...

Dear Colleagues

In the past few years; we have seen some spectacular collapses of buildings and bridges. This is quite inexplicable to today’s structural designer and engineer who puts enormous effort into the careful use of materials and huge safety margins.

However, when a designer is operating at the limit of their expertise; mistakes still occur. One of the questions with the Deepwater Horizon oil rig which exploded with massive damage was in the use of cement (coupled with nitrogen gas) a few kms under the seabed – as to whether it did indeed have the strength required to prevent a massive gas and oil surge. As we know, cement as a proven structural material has been around since Roman times – but for perhaps more predictable environments.