News

- Details

- Written by: Quintus Potgieter

- Category: Education

What's the difference between a Bachelor of Arts degree and a pizza? A pizza can feed an entire family.

Yes, we've all heard the joke and been subjected to the scorn of students who believe their degrees are more superior when compared to humanities degrees. It is no secret; universities are filled with some students who want to degrade certain degrees because they believe they are doing the degree that will guarantee them a job in their respective industry.

McGraw-Hill Education is an educational content publisher, considered as one of the big three educational content providers in the world. They have conducted a study titled the 2016 Workforce Readiness Survey that investigated which industry's graduates exuded the most confidence for postgraduate employment prospects. The study saw McGraw-Hill surveying 1,360 American college students between March 2016 and April 206. They interviewed both undergraduates and postgraduates.

Group president of U.S. education for McGraw-Hill Education said: "Every college graduate deserves to enter the workforce with the confidence that their degree was worth the investment."

Group president of U.S. education for McGraw-Hill Education said: "Every college graduate deserves to enter the workforce with the confidence that their degree was worth the investment."

Their study revealed that 73 percent of students who study science, technology, engineering and mathematics (STEM) degrees believe they are the most employable. The more worrying statistic, however, is that 40 percent of "college seniors" think their "college experience" is instrumental in landing them a job. It's 61 percent of liberal arts students that think their degrees are not worth much once they graduate from university.

When students were surveyed about how they think technology factors into their studies, 85 percent of students said using technology in a lecture and using it as a study tool would further equip them to be attractive to employers. It seems students are hungry for practical work in classes, and less theory.

Furthermore, when graduated alumni were quizzed about the use of technology, 96 percent of them conceded that practically working with tangible technology would definitely lead to better employment options in the current climate of employable graduates. The scary bit is, McGraw-Hill Education says that the number of students actively using "workplace-related" technology is sitting at 26 percent.

Now for the nitty gritty. 62 percent of students said that if they had the chance to choose different major without the heavy tuition fees, they would have chosen different majors.

So, whilst STEM graduates are confident that they are entering the workplace, we're not certain that these graduates have the technical know-how for the industries they're going into. However, engineering students - based on the study - are definitely still the most confident that they have a definite part to play as an employed member of society.

- Details

- Written by: Quintus Potgieter

- Category: Developments

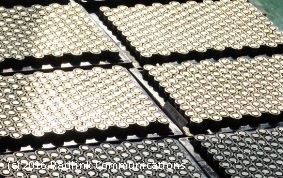

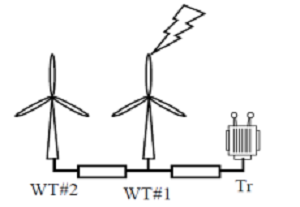

As renewable technologies make their way into our lives, we wonder how we will integrate the newly available technologies with our older technology that we still use to power our homes, our electronics and much more. Ir's hard to imagine calling some sort of firm and asking them to strip your house of its electricity and replace everything with solar cells tomorrow. So what we are left with is buying home energy storage units and saving ourselves some money by using less energy from the old grid in peak times.

Enter, the passive solar building. A building designed with solar energy in mind. A guest blogger for Sturdy Structural defines the passive solar building as a building designed with energy saving elements. We're talking the entire building. From the roof to the walls, to the floors. Solar passive buildings take the climate into consideration, using energy-saving applications to collect any and all energy that the sun is giving to the units.

To see the engineering design principles behind passive solar buildings, check this video out. This uses a house as an example, however, more and more business complexes are building with passive solar technologies in mind:

Cornell University has also gotten wind of further development in passive solar buildings. The university has seen designs that could make their next dormitories the most energy-efficient dorms in the world. The dorms will be a $115 million project and stand at 26-stories high. The passive solar design will ensure that the building uses 70 to 90 percent less energy than buildings of equal size. The engineers behind the building say it will be the largest passive-house building in the world once it is completed. The building will have 550 solar panels on the roof that will power the building. The dorms will be air-tight and will prevent any outside air of making its way in requiring more energy to be used. Special vents will be used to funnel and filter fresh into air into the dorms.

Cornell University has also gotten wind of further development in passive solar buildings. The university has seen designs that could make their next dormitories the most energy-efficient dorms in the world. The dorms will be a $115 million project and stand at 26-stories high. The passive solar design will ensure that the building uses 70 to 90 percent less energy than buildings of equal size. The engineers behind the building say it will be the largest passive-house building in the world once it is completed. The building will have 550 solar panels on the roof that will power the building. The dorms will be air-tight and will prevent any outside air of making its way in requiring more energy to be used. Special vents will be used to funnel and filter fresh into air into the dorms.

- Details

- Written by: Quintus Potgieter

- Category: Developments

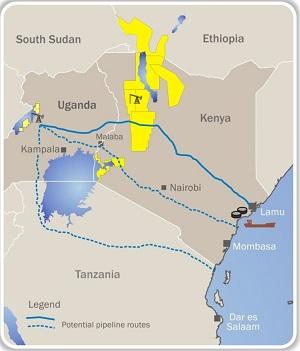

The time for getting your qualifications in engineering for oil and gas facilities has never been better. Kenya is ready to construct a 538-mile crude oil pipeline that will provide oil for a new port being built on the Indian Ocean coastline. This was confirmed by a government official on Thursday.

Pipeline engineers are now in a unique position because they can now apply to be considered to design the front-end engineering design of the pipeline.

Ministry of Energy and Petroleum Principal Secretary Andrew Kamau, speaking to Bloomberg said: "Once we have the pipeline design, the engineering, procurement and construction contract would be awarded in first quarter 2018. It would take us that long as we need environmental impact assessment study conducted to international standards for the project to be able to attract international funding."

Ministry of Energy and Petroleum Principal Secretary Andrew Kamau, speaking to Bloomberg said: "Once we have the pipeline design, the engineering, procurement and construction contract would be awarded in first quarter 2018. It would take us that long as we need environmental impact assessment study conducted to international standards for the project to be able to attract international funding."

The east of Africa is seeing unprecedented successes in oil and gas. This week, a huge helium reserve was discovered in ancient rocks in Tanzania. Kenya is in the eight spot for the list of African countries with the biggest economy. They could jump up a few spots due to this refinery being its first refinery for the country. It will be delivering its first oil in June 2017. Africa Oil has said the South Lokichar basin will produce approximately 1.63 billion barrels of oil. The pipeline is estimated to cost $2.1 billion to build, which is a modest number based on other countries in Africa that have built bigger pipelines. Kenya seems to be playing catch up.

- Details

- Written by: Quintus Potgieter

- Category: Education

If you're an engineering student currently studying towards your dream job, you've probably heard the question asked. When you make it into the industry, what is the dream company you'd want to work for? There's nothing wrong with setting your sights on some of the biggest engineering firms in the world because you never know when you might just get your big break. However, with thousands of fellow graduates getting their degrees and dreaming the same dreams, the industry is a tough one to compete in. Now, we have an idea of the most attractive engineering employers thanks to research group Universum. They have released their report titled The World's Most Attractive Employers 2016.

The study was conducted on 267,084 engineering, business and IT students. The countries included in the report are: Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Russia, the UK and the USA. The Executive Director of CNN Money, Lex Haris, spoke about the legitimacy of the report, saying: "This is a critical time for the global economy and today's grads are the future leaders that will determine its fate. We wanted to hear directly from them. And Universum's survey gives us direct access to thousands of students in a dozen countries.

The study was conducted on 267,084 engineering, business and IT students. The countries included in the report are: Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Russia, the UK and the USA. The Executive Director of CNN Money, Lex Haris, spoke about the legitimacy of the report, saying: "This is a critical time for the global economy and today's grads are the future leaders that will determine its fate. We wanted to hear directly from them. And Universum's survey gives us direct access to thousands of students in a dozen countries.

So, we are looking at the millennials who are making their way into the respective engineering industries after graduating. Who do they want to work for? Here are the top 10 most attractive companies in engineering and information technology graduates' minds:

| Employer | 2015 | 2016 |

| 1 | 1 | |

| Microsoft | 2 | 2 |

| Apple | 3 | 3 |

| BMW Group | 4 | 4 |

| IBM | 6 | 5 |

| General Electric (GE) | 5 | 6 |

| Intel | 7 | 7 |

| Siemens | 9 | 8 |

| Samsung | 11 | 9 |

| Sony | 8 | 10 |

Analysts point out the interesting fact that energy companies are not attractive places for engineering students, as prospective places of employment. It's all about the tech companies in 2016, it seems. Analysts also say the results show that the millennials are aspiring to work for companies that seemingly have well-balanced work and lifestyle image. Interestingly, Google, Microsoft, Apple and BMW Group have retained their positions since last year, and IBM went up one position.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Rutgers University is New Jersey's own state university in the United States. The university's Department of Mechanical and Aerospace Engineering have shown off their new squishy robot. Yes, you read that right. To be more specific, the robot is considered to be a pneumatically driven elastomeric structure robot. The researchers have used the recent bendable robot technology to create a new robot that could have a host of applications in future industries where bendable, 'squishy' robots might be needed.

Bendable elements on robots are not a new innovation. They have been used in deep-sea coral expeditions for the purpose of handling coral with care, due to conventional robotic arms being too forceful. However, now the Rutgers researchers want to grow the innovation of soft robotics. The uses could range from sending the robots into rocky mountains or even driving the robots on different planets. The bendable, flexible material could be invaluable due to its ability to get through terrain that conventional robotics would not be able to do. See the video below to see how the robot navigates rocky terrain.

"If you build a robot or vehicle with hard components, you have to have many sophisticated joins so the whole body can handle complex or rocky terrain. For us, the whole design is very simple, but it works very well because the whole body is soft and can negotiate complex terrain," said Xiangyu Gong, an alumnus of Rutgers University in the mechanical engineering department.

The researchers used silicone rubber to build a wheel and axle assembly and used motors that are engineered to be devoid of metal. On top of that, the researchers had to assemble the vehicle to ensure its safety should it survive some sort of impact.

The team used 3D printers to print the rotors they used. As a result, the researchers were able to create 'squishy' pneumatic internal and external rotors. The external rotors were able to be used as wheels that the researchers used to design a four-wheeled rover robot.

"With no metal components and moisture-sensitive electronics on the vehicle itself, the vehicle is equipped with the actuators. [The rotors] function not only in a dry environment but also underwater as an amphibious vehicle," the researchers said. The researchers also showed that the robot could be dropped from eight times its height and survive the fall.

- Details

- Written by: Quintus Potgieter

- Category: Education

You've got your honours in chemical engineering, you're a junior engineer-in-training, you have less than 4 years of experience at a firm and suddenly you get fired. What do you do? Do you try and get your masters in chemical engineering? Do you try and find a job unrelated to engineering? What can be done? This was a question recently posed to anonymous engineers on a social media site and the reflection of the engineers currently working in the industry could inspire you to take control of your engineering prospects whether you're currently looking for a job or not.

This year has not been kind to chemical engineers. We've seen chemical engineers with BTech degrees begging for jobs on street corners in South Africa, and now isolated incidents of firings of junior engineers in Canada. Employment in these fields is obviously few and far between in 2016. Nonetheless, employment issues are not limited to a certain type of engineering around the world, there are more industries that are struggling to accommodate engineers and the salaries that they demand. It's enough to stress out an educated, employable engineer.

This year has not been kind to chemical engineers. We've seen chemical engineers with BTech degrees begging for jobs on street corners in South Africa, and now isolated incidents of firings of junior engineers in Canada. Employment in these fields is obviously few and far between in 2016. Nonetheless, employment issues are not limited to a certain type of engineering around the world, there are more industries that are struggling to accommodate engineers and the salaries that they demand. It's enough to stress out an educated, employable engineer.

However, fellow engineers have offered their two cents on what to do to keep pushing for the engineering jobs, to ensure that you snag that job:

- Update your resume

- Update your LinkedIn Profile

The Dean of Engineering at the Engineering Institute of Technology (EIT), Steve Mackay, talks about constructing an engineering résumé in the fifteenth episode of the Engineering News Network. Here is a summary with some quotes from the Dean that might strengthen your curriculum vitae:

1. Focus on the job: "Most people think they can use a generic résumé because they are applying for lots of jobs but that is a sure fire path to destruction."

2. Make it simple: "Use simple English, lay it out simply, you don't have to address it to the village idiot but by the same token make it simple and easy and reasonable."

3. Grammar and spelling must be 100%: "Try and look at the English and the spelling to make sure it reads well."

4. Avoid excessive information: "The twenty page CV is long since gone. Employers don't have time to read."

5. Lots of white space and include an executive summary: Mackay says the executive summary should be included because it would state why you think you're the right pick for the job. "Try and be specific, give real employers names...who actually exist...plus your time with them and the job you had and the reason why you left," he said." He further says that you should try and avoid the 'job hopping' approach where your CV shows that you've only spent a few months at a place of employment because that doesn't look good at all.

6. Search for jobs you really want: "It's pointless going for a higher paying job if you hate it. Try and focus on the jobs you are looking for, make sure it's aligned with you."

7. Business strengths: Mackay says it should include 'business wins' from previous employment. Stating what kind of successes you achieved.

8. Experience: "No matter how many qualifications you've got, if you don't have the experience that matches up with the qualifications, you've got a pretty tough job selling yourself. Experience plus qualifications...great match."

- Send your CV everywhere: You never know where you might get a response from

- Find other employment in the interim: This is specifically for engineers who are between jobs or struggling to find the dream engineering job of their dreams. Sometimes, getting a job unrelated to your industry could give you more skills that will assist you once you get into your dream job

- Be prepared to relocate: Engineering experts say that limiting yourself to your city or town is a bad idea, especially if the industry is slowing down in a particular area.

The skills shortages in the STEM industries continue to plague the industry. However, engineers are being influenced to broaden their skill sets in entrepreneurship and other studies so that they are instantly more attractive to businesses who might be interested in hiring them. Keeping a job in the industry means continually learning and applied newly learned skills. It's never too late to learn some new tricks, according to the engineering aforementioned engineering experts.

How do you remain employable in the engineering industry? Let us know in our comments section.

Source: Reddit / The Engineering News Network

- Details

- Written by: Quintus Potgieter

- Category: Education

In March 2015 the Department of Trade and Industry in South Africa committed to funding a program that would see $67.6 million making its way into the industrial sector to create more black industrialists and engineers. The program was set up to further diversify the working force behind industrialists and engineers in the country.

Pricewaterhouse Coopers summarized the basic operations of the program. They wrote: "The concept of black industrialists refers to black people who are directly involved in the origination, creation, high-level ownership (>50%), management, control and operation of industrial enterprises that derive value from manufacturing goods and services on a large scale, thereby acting to unlock the productive potential of our country’s capital assets for massive local employment. Government is essentially looking for black industrialists who not only make long-term commitments to business but are also medium-to-long-term investors."

The sectors that will influence the employing of engineers in the country are as follows:

- Agro-processing

- Manufacturing

- Construction

- Clean technology

- Energy

- Mining

- Automotive components

"We believe there is room for participation of many black entrepreneurs in the manufacturing sector as industrialists," said President of South Africa, Jacob Zuma. "They will be able to benefit from amongst others the incentives provided for in the industrial policy action plan and the host of manufacturing incentives that government provides. We believe the black industrialist policy framework is the right formula to transform the industrial landscape."

"We believe there is room for participation of many black entrepreneurs in the manufacturing sector as industrialists," said President of South Africa, Jacob Zuma. "They will be able to benefit from amongst others the incentives provided for in the industrial policy action plan and the host of manufacturing incentives that government provides. We believe the black industrialist policy framework is the right formula to transform the industrial landscape."

The program is geared towards encouraging black entrepreneurs to broaden their skill sets and find a future in engineering industries. It could also influence black engineers to pursue their dreams and get their competency in industries that are now seeing more job creation due to the move.

The Trade and Industry Deputy Minister, Mzwandile Masina, said that the program would ensure that more black leadership roles would be opened up in industries where black people are normally laborers and factory workers.

The diversification of employees in the STEM industry is an issue that South Africa takes seriously due to its unbalanced past.

- Details

- Written by: Quintus Potgieter

- Category: Industry

The liquefied natural gas market will see demand double by 2030. The latest numbers have grabbed the attention of Chevron and other oil companies who hope to capitalize on LNG sales, due to decreased investment into fossil fuel energy technologies. Millions of dollars will be invested into LNG imports and exports in the upcoming years due to the fact that governments are encouraging cleaner energy. China's LNG demand is also skyrocketing at an annual rate of 15% over the next six years. They will be importing record amounts of LNG as natural gas power becomes more important across Asia. The demand is signaling a rise in prices for LNG that will continue until August.

The growing demand for imports in Asia means that Australia is in the prime position for exporting liquefied natural gas to the region. Chevron's Gorgon LNG export plant in Western Australia was primed and ready to meet the demands from Asia, but then an unplanned shutdown in April caused several issues. Chevron now confirms that the plant is back in operation.

The growing demand for imports in Asia means that Australia is in the prime position for exporting liquefied natural gas to the region. Chevron's Gorgon LNG export plant in Western Australia was primed and ready to meet the demands from Asia, but then an unplanned shutdown in April caused several issues. Chevron now confirms that the plant is back in operation.

"We confirm start-up activities are underway on Gorgon train one with a plan to safely resume production in the coming weeks," a spokesman for Chevron said. The plant cost Chevron US$54 billion to set up.

The Gorgon plant is part and parcel of Australia's efforts in LNG production, making them one of the main exporters. The Sydney Morning Herald estimates that Australia has pumped $200 billion into LNG project investment. The United States has lagged behind in recent history but are dedicating themselves to becoming a big player in exports. With the renewed operations at the Gorgon plant, Australia could be surpassing Qatar as the biggest exporter of LNG. According to government data, Australia will be the biggest exporter by 2019.

Alexandra Heath from the Reserve Bank of Australia said:

The decline in (LNG) prices is unlikely to lead to a significant reduction in production from existing producers because the high fixed costs of building the infrastructure have been paid and marginal production costs are relatively low. Our ability to benefit from rising demand for cleaner fuels will depend on our willingness to invest and innovate. It is important that Australian companies remain at the forefront of developing expertise in these fields, not just for the environmental benefits that they will bring, but to be able to export these technologies to other countries."

The International Energy Agency also recently affirmed the fact that LNG investment will be growing by leaps and bounds. The investment will increase by 45% between 2016 and 2021.

- Details

- Written by: Quintus Potgieter

- Category: Developments

A survey conducted by the Boston Consulting Group has revealed that Germany has shown more interest than the United States in industrial automation technologies. After receiving the opinions of 300 German and US manufacturing executives, the study showed that German executives were more ready for digital solutions in factories. However, only 17 percent of American and German manufacturers have adopted industrial automation. Business Insider confirms that 40 percent of German companies plan to update their factories with current automation technologies however only 25% of US factories feel the same way.

The competition continues. 8% of U.S. manufacturers have autonomous robots and collaborative robots whereas Germans almost double that demand by having 14% of factories equipped with them. The US will want 20% more of those robots working in their factories in the next two years whereas Germans will want 39% more, of what they already have.

The competition continues. 8% of U.S. manufacturers have autonomous robots and collaborative robots whereas Germans almost double that demand by having 14% of factories equipped with them. The US will want 20% more of those robots working in their factories in the next two years whereas Germans will want 39% more, of what they already have.

The report also stated that worldwide spending on IoT connected factory automation technology reached $29 billion by the end of 2015 and will top $70 billion in 2020.

Germany's unique position on Industrie 4.0 has related to 47% of the companies surveyed saying that they have developed IoT strategies for the future of their companies. American companies say only 29% of them have strategies prepared.

"German companies' strong ambitions for Industry 4.0 reflect their need to overcome the challenges of significant factor costs that arise from high wages and a less flexible labor market. These factor costs encourage companies to strive for greater productivity and, thus, promote faster adoption of new technologies. The fast pace of adoption in Germany is also fueled by companies' advanced industrial-manufacturing capabilities. Companies can apply these capabilities to accelerate the introduction of new digital technologies, thereby reducing costs, increasing flexibility, and accelerating the speed of manufacturing," the researchers wrote.

"The early adopters have set a fast pace for implementation and are building capabilities that will enable them to increase their lead. To maintain their competitiveness, all companies will need to accelerate their efforts along the Industry 4.0 journey," the report concluded.

Source: Yibada

- Details

- Written by: Quintus Potgieter

- Category: Developments

The world needs helium. We use it for many things, and then usually waste it by sucking it out of a balloon and putting on a cartoonish voice. Recent reports have indicated that the world is running low on helium due to the lack of new reserves. Thankfully, researchers in Tanzania have discovered a new reserve. Good news for balloon animals but also good news for MRI scanners and nuclear power plants. However, nuclear power plants need a special kind of helium, but the good news continues because the researchers in Tanzania say the new reserve is filled to the brim with "world-class" helium. The researchers have been working with a Norwegian company specializing in helium named Helium One. The researchers are from the University of Oxford and Durham University.

"This researcher shows that volcanic activity provides the intense heat necessary to release the gas from ancient, helium-bearing rocks. Within the Tanzanian East African Rift Valley, volcanoes have released helium from ancient deep rocks and have trapped this helium in shallower gas fields," said the University of Oxford in a statement.

"This researcher shows that volcanic activity provides the intense heat necessary to release the gas from ancient, helium-bearing rocks. Within the Tanzanian East African Rift Valley, volcanoes have released helium from ancient deep rocks and have trapped this helium in shallower gas fields," said the University of Oxford in a statement.

The researchers use similar drilling techniques used in oil and gas discovery. Chris Ballentine, chief of geochemistry at Oxford who worked on the team that discovered the new helium, spoke to the Washington Post. He said: "We look for source rock, we look for a mechanism to release the gas from the source, and we look to understand how gases migrate and looking for trapping structures."

We also use helium in semiconductor manufacturing. Rodney Morgan, the vice president of procurement at the Semiconductor Industry Association said: "Although the semiconductor industry consumes only a small amount of the overall quantity of helium used today, it remains a critical, irreplaceable input into our manufacturing process."

Helium is also used to clean NASA's space shuttle engines. So, we imagine Elon Musk is probably doing the same. This means, we need a lot of helium in the world, without even considering what uses the most helium, which is, of course, helium balloons.

So, good thing we've found more, then. Diveena Danabalan of Durhan University's Department of Earth Sciences spoke to CNN, saying: "We are now working to identify the 'goldilocks-zone' between the ancient crust and the modern volcanoes where the balance between helium release and volcanic dilution is 'just right."

The researchers say that the new discovery could see more than a million MRI scanners being filled. Professors at Oxford say the discovery is a "game-changer" and will lead to more discoveries through the same methods soon, ensuring that society never runs out of helium. The researchers say the discovery comes at the right time, due to a helium price escalation of 500% in the last 15 years.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Emissions testing company Emissions Analytics have written a report indicating that Diesel cars produce more emissions during winter. The group says that once the outside temperature reached below 18 degrees centigrade (65,4 Fahrenheit) cars began to release more emissions. The company reportedly tested 213 different models from 31 different auto engineering companies. The group found that cars built in the 2009-2011 bracket have produced the most emissions.

The tweaking of the engine in colder conditions has been proven to underreport the number of emissions the cars produce. Chief Executive of Emissions Analytics, Nick Molden, said: "If we were talking about higher emissions below zero, that would be more understandable and there are  reasons why the engine needs to be protected. But what we've got is this odd situation where the temperature threshold has been set far too high, and that is a surprise." The group found that the Euro 5 vehicles (manufactured between 2009-2011) produce 4.6 times the legal parameters for Nitrogen Oxides (NOx) when the outside temperature dropped.

reasons why the engine needs to be protected. But what we've got is this odd situation where the temperature threshold has been set far too high, and that is a surprise." The group found that the Euro 5 vehicles (manufactured between 2009-2011) produce 4.6 times the legal parameters for Nitrogen Oxides (NOx) when the outside temperature dropped.

The group did, however, say that the Euro 6 cars manufactured from September 2015 onwards reported better numbers, only reaching 2.9 times above the legal NOx limits.

Engineers say without the pollution controls partly switching off under colder temperatures, engines would undergo amounts of damage. The carmakers say it is a necessary method to ensuring that vehicles don't break down.

These revelations come at a time of an ongoing emissions scandal that has rocked the automotive engineering industry. Volkswagen has confirmed that they will use $15.3 billion to buy back vehicles from consumers. The carmaker admitted to developing software that underreported the amount of emissions their cars did.

VW will also be focusing on cleaner, more efficient technologies. According to Reuters, VW will be paying $2 billion over 10 years to a Californian company who specialize in electric vehicle charging infrastructure.

However, what are the automakers doing to shake off the pointing fingers, forcing their engineers to admit their years of underreporting? According to BBC:

- Vauxhall says that it is using diesel cleaning systems to prevent emissions

- Suzuki says it will be altering 3,200 cars' software to report more accurate emissions performance

- Renault has committed to buying back cars sold from September 2015 to July 2016. They will also change software to report accurate emissions

- Mercedes will tweak 26,000 A class and B class models in the UK to lower emission levels.

The Society of Motor Manufacturers and Traders spoke to the BBC, saying: The temporary reduction or switching off of some emissions control systems under certain temperatures is allowed by law and necessary to avoid damage to vehicles’ engines.Without it, there could be a significant cost to the consumer for major repair work. In its recent report, government recognised the need for such technology and was satisfied with how vehicle manufacturers were using it. Manufacturers are investing billions of pounds in developing ever-more-advanced technology, and this along with new Real Driving Emissions regulation from next year will see significant lowering of emissions across a full range of driving conditions and temperatures."

- Details

- Written by: Quintus Potgieter

- Category: Education

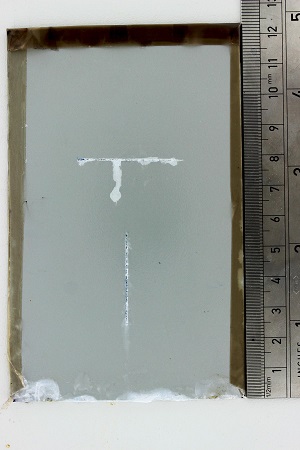

Chinese engineers have unveiled the world's longest and highest glass-bottom bridge in the Zhangjiajie Grand Canyon. The bridge serves as a skywalk from one side of the canyon to the other. And it's very strong. So strong that they decided to hold an event to show off its strength that included a journalist taking a sledgehammer to the glass walkway. To add to the anxiety of standing on a glass bridge, the engineers allowed a car to be driven on the glass surface.

The glass bridge is suspended 300 metres (984 feet) in the air and 430 metres (1,411 feet) long and 20 feet wide, suspended in Zhangjiajie's National Park. Chief engineer of the project, Ma Liang, said: "We use a  method of gluing together every panel to tighten the area between them. The thickness of every glass panel is 1.5 centimetres." They then took the Volvo XC90 SUV to the bridge with 11 passengers inside of it and drove it across the bridge, amounting to two tons. Some of the glass panels did shatter under the sledgehammering and the car driving over them but the panels are easily replaced. The chief design engineer on the project said that the bridge can withstand up to 100 MPH winds.

method of gluing together every panel to tighten the area between them. The thickness of every glass panel is 1.5 centimetres." They then took the Volvo XC90 SUV to the bridge with 11 passengers inside of it and drove it across the bridge, amounting to two tons. Some of the glass panels did shatter under the sledgehammering and the car driving over them but the panels are easily replaced. The chief design engineer on the project said that the bridge can withstand up to 100 MPH winds.

The bridge can take the weight of 800 people and will be opening in July. It was supposed to be opened in May, however, weather conditions slowed the engineers down. The man behind the design of the bridge was Israeli designer, Haim Dotan. The bridge cost approximately $37.4 million to construct. Dotan said he wanted to build a bridge that was second in beauty to the nature that the area is known for. The film Avatar was filmed in the canyon.

to be opened in May, however, weather conditions slowed the engineers down. The man behind the design of the bridge was Israeli designer, Haim Dotan. The bridge cost approximately $37.4 million to construct. Dotan said he wanted to build a bridge that was second in beauty to the nature that the area is known for. The film Avatar was filmed in the canyon.

- Details

- Written by: Quintus Potgieter

- Category: Developments

What is a dark warehouse? It's not a warehouse with its lights off if that's what you're wondering. No, the dark warehouse, or otherwise known as the "lights-out facility", is a factory that runs completely through automated means without any human intervention. Warehouses are opting in for self-driving forklifts, robots equipped with vision cameras, automatic storage and retrieval systems and more. Adidas recently announced a lights-out facility in Germany that would see robots in charge of manufacturing shoes.

Other factories that currently use fully automated systems include cold storage and freezer warehouses where food is frozen and stored. And soon, electronics companies will be using dark warehouses in the manufacturing of electronic devices. The truth is, humans don't need to do those jobs anymore. A hand-tailored cell phone doesn't make anyone jump out of their seats with pride and joy. But a hand tailored Rolls-Royce is a different thing.

However, lights out facilities are becoming more and more sought after in the industrial world. "A lights-out facility is more possible in less-variable parts of logistics, where people are moving a large portion of the same types of objects," said Matt Engle, an employee for Cognex Corp, a company that specializes in vision systems for factory automation.

However, lights out facilities are becoming more and more sought after in the industrial world. "A lights-out facility is more possible in less-variable parts of logistics, where people are moving a large portion of the same types of objects," said Matt Engle, an employee for Cognex Corp, a company that specializes in vision systems for factory automation.

The dark warehouse is becoming a goal for some factories. The efficiency of a fully automated factory is becoming somewhat of a bragging right for some companies. However, if it isn't cost-effective, then is it truly worth it? The answer to that question lies in co-bot (collaborative robots) technology. Cobots are cheaper than fully automated industrial robots and cost small and medium-sized enterprises - who want to go into automation - much less. However, collaborative robotics alludes to the involvement of human instruction. Thereby, eliminating the truly dark warehouse.

However, for big industrial facilities that are looking to fully automating and going 'dark', DC Velocity has compiled a comprehensive three-point checklist that companies can follow in their pursuit for fully automated systems:

- Automated storage and retrieval systems: facilities that handle high volumes of inventory moving and out of storage

- High-speed sorting equipment

- Warehouse robotics: guided by wireless instruction from a warehouse management system or warehouse execution system

- Details

- Written by: Quintus Potgieter

- Category: Education

Engineers have to work in teams. It's seldom that an engineer won't have to face a team dynamic at some point. The problem some people have is behaving accordingly when working with a team. You either do well at teamwork or you don't. The issue is, sometimes it is unavoidable. An engineer might end up working with other hot-headed engineers and suddenly a conflict arises. The shocking fact is that sometimes conflict might be a good thing. All you have to do is read Steve Jobs' biography to see how many times he clashed with his fellow engineering pals but look at Apple today. So yes, conflict can be good, but sometimes, conflict can derail an entire project.

Scott Dietzen, the CEO of Pure Storage, a company that lends itself to all-flash solutions for demanding business and IT problems works with engineering-types. He recently wrote a Top 10 list of the top 10 things you need to do to be a successful engineer. It was published on Forbes' website. The first one was, an engineer should choose meaningful problems. The second one was, build or join an outstanding team. The question is, whether or not that outstanding team will survive a conflict that arises. Is conflict necessary in an 'outstanding' team? Is being part of a team the deciding factor in making someone a good engineer?

Scott Dietzen, the CEO of Pure Storage, a company that lends itself to all-flash solutions for demanding business and IT problems works with engineering-types. He recently wrote a Top 10 list of the top 10 things you need to do to be a successful engineer. It was published on Forbes' website. The first one was, an engineer should choose meaningful problems. The second one was, build or join an outstanding team. The question is, whether or not that outstanding team will survive a conflict that arises. Is conflict necessary in an 'outstanding' team? Is being part of a team the deciding factor in making someone a good engineer?

"It's an issue we have all the time and let's face it conflict is actually a good thing," says the Dean of Engineering at the Engineering Institute of Technology, Steve Mackay. He opens up about the conflict prevalent in the engineering industry in his video series the Engineering News Network. "Whenever you have a conflict in your team, the trick is always to deal with the problem as quickly as possible and also to try and focus on the issue, not the person. So, focus on the issue, try and deal with the issue, dissect it very carefully and try and listen carefully to all parties," he added. He also says the action and decision on a certain issue should be swift as well," he added.

Mackay ends his video off with a quote from Garth Brooks. The quote reads: "The greatest conflicts are not between two people but between one person and himself."

Paul J Breaux at the Southwest Research Insitute wrote a guide to handling conflict in engineering teams that was published in the IEEE Xplore Digital Library. He wrote: "Conflict must be managed both locally and globally to assure the success of any engineering organization in its target industry. How an engineering organization manages conflict can directly impact its success or failure." He alludes to the fact that ignoring conflict is not an option.

Dietzen's other principles one should stick to - if they want to be a good engineer - are:

- Work hard

- Tell your story well

- Be optimistic

- Be realistic

- Be contrarian

- Trust your instincts

- It's a marathon, not a sprint

- Have fun

- Details

- Written by: Quintus Potgieter

- Category: Industry

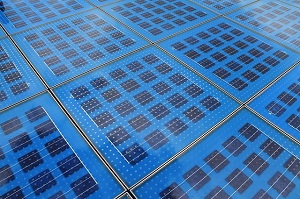

Australia, The United States, and Britain. Who is winning the renewable energy race? Who is doing more to secure green energy in their country? The answer is Germany. They have installed and are achieving 38301 MWp (Mega Watt peak) with photovoltaic devices. They have strategies in place to ensure that their country could run fully renewable energy by 2030. However, how close are the other superpowers and forward thinking countries? Those aforementioned countries that are considered to be big players in the renewable energy game. Let's take a look.

Australia's Labor Government has established a Strategic Industries Taskforce to further the renewable energy conversation in the country. The taskforce wants to set up a Strategic Industries Reserve Fund that would see AUD $300 million to encourage renewable energy in "emissions intensive industries". This would include modernizing companies that are still operating with a big carbon footprint. The money will also be funneled into research in STEM fields to further investigate ways of making Australia's energy reach its renewable energy goals.

Australia's Labor Government has established a Strategic Industries Taskforce to further the renewable energy conversation in the country. The taskforce wants to set up a Strategic Industries Reserve Fund that would see AUD $300 million to encourage renewable energy in "emissions intensive industries". This would include modernizing companies that are still operating with a big carbon footprint. The money will also be funneled into research in STEM fields to further investigate ways of making Australia's energy reach its renewable energy goals.

Bill Shorten, the Opposition Leader for the Labor Party, spoke to media recently, saying: "Renewable energy is not just a fringe industry anymore. It is a key strategy in delivering jobs in Australia delivering investment into Australian industry. That is why we are prioritising our goal of 50 percent of our energy mix by 2030 will be derived from renewable energy sources such as these remarkable solar farms [referring to the Royalla Solar Farms]."

The United States are set to commit to a new clean power goal at a summit being held in Ottawa this week. Countries set to co-sign the bill are Canada and Mexico as well. They're calling it...and wait for it, it's worth it...The Three Amigos Summit. The summit will see the three countries agreeing to power their country through renewable means by up to 50% by the year 2025. A senior advisor in Barack Obama's camp said that the goals are aggressive but they are certain the three countries will be able to do it, making it a continent-wide agreement. According to The Guardian, a third of America's power is already being produced from renewable energy sources. Interestingly, Canada already produces 81% of its energy through renewable means.

And now for the inevitable news. Britain has been told that the exit from the European Union will amount to less renewable energy technology making its way into the country. The offshore wind industry is rumored to be impacted by the Brexit as well. After the Brexit results were unveiled, Siemens halted wind power investment in the UK due to uncertainty in the market. Dong Energy is also one of the bigger investors in UK offshore wind. Their spokesperson told the Guardian: "We will await clarity over the implications of the vote to leave the European Union. However, we don't believe that UK energy policy is dependent on EU membership." Therefore, the UK should say a collective, "Whew!" What is apparent, however, is that time will tell what the Brexit's impact on British energy policies is. Hopefully, for the engineers who work in the industry's sake, everything will be fine. It depends on the change in leadership and what those leaders have in mind for renewable energy in the UK, a country who was tipped to be the dark horse in the renewable energy game before the Brexit.

Source: Renew Economy / The Guardian

- Details

- Written by: Quintus Potgieter

- Category: Developments

We know it's going to play a big part in our future, but how big are we talking here? Lithium seems to be on everyone's lips these days due to being in the driver's seat in the push for renewable energy. Needless to say, it powers most home electronics as it is. It is also leading the charge in home energy storage units. So what does the demand for lithium look like?

Experts say that as of 2015, the global lithium supply was approximately at 160,000 tonnes of lithium carbonate equivalent (LCE). Those are the ones we are using every day of our lives which power the lithium-ion batteries, that are also making their way into electric vehicles.

Francis Weldin, executive technical director at a company named Dakota Minerals Ltd was interviewed in a recent report on global lithium demand. He says that for every 1% of new electric vehicles making their way to market, 70,000 tonnes of lithium is in demand. These numbers were originally published by Goldman Sachs, who called lithium-ion the new gasoline, showing just how much demand has grown. So, needless to say, the numbers aren't inspiring much confidence. Sodium-ion batteries, anyone?

Francis Weldin, executive technical director at a company named Dakota Minerals Ltd was interviewed in a recent report on global lithium demand. He says that for every 1% of new electric vehicles making their way to market, 70,000 tonnes of lithium is in demand. These numbers were originally published by Goldman Sachs, who called lithium-ion the new gasoline, showing just how much demand has grown. So, needless to say, the numbers aren't inspiring much confidence. Sodium-ion batteries, anyone?

According to ABC News, only five lithium mines have been fully developed in the last 20 years due to the low demand. However, then Elon Musk and his soon-to-launch Tesla Gigafactory hit the scene and is using lithium-ion propaganda to instil the anxious feeling that everyone should have a lithium-ion battery in their car and in the house, or be left in the Stone Age. Musk's factory, if successful, will be the world leader in lithium battery power producing.

Goldman Sachs further projected that lithium-ion batteries' use in electric vehicles alone would grow 11-fold, making the demand reach 300,000 tonnes by 2025. Elon Musk isn't the only philanthropist wanting to get his hands on the world's lithium production, China is interested too. A study conducted by Infiniti Research Limited entitled Global Lithium Market 2016-2020 estimates that the electric vehicle market in China. The demand for EVs in China will grow the market at a CAGR of 7.84%, making the country a contender for lithium-ion battery usage. All we know is the more lithium mining that occurs the more there will be for the world, and that's what engineers are working towards. A world powered by renewable energy with the assistance of lithium-ion technology.

- Details

- Written by: Quintus Potgieter

- Category: Industry

A cyber-takedown of the Ukranian electricity grid in December of 2015 has sent the cybersecurity industry spiralling. Since then, governments across the globe have been equipping themselves with cybersecurity firms that will try to ensure a takedown of a similar nature doesn't occur. What is apparent is that governments need some pretty efficient firewalls to ensure that criminals can't take down their country's power grids with complex lines of code. Industrial control systems being interceptable by outside forces poses a big risk for the future of ensuring the safety of grids. It's all about the smart-grid now, but is it smart enough to ensure that hackers don't take them down?

The United States' Office of Electricity Delivery & Energy Reliability said: "Addressing cybersecurity is critical to enhancing the security and reliability of the nation's electric grid. Ensuring a resilient electric grid is particularly important since it is arguably the most complex and critical infrastructure that other sectors depend upon to deliver essential services."

So what have the US government done to secure that a virtual takedown doesn't happen? They put the U.S. Department of Homeland Security's Industrial Control Systems Cyber Emergency Response Team (ICS-CERT) to work and learned from the loopholes that allowed hackers to take down the Ukranian power grid.

So what have the US government done to secure that a virtual takedown doesn't happen? They put the U.S. Department of Homeland Security's Industrial Control Systems Cyber Emergency Response Team (ICS-CERT) to work and learned from the loopholes that allowed hackers to take down the Ukranian power grid.

Robert Lee, a former cyber warfare operations office for the U.S. Air Force spoke to Spectrum, saying: "Everything about this attack was repeatable in the United States. While their security wasn't awesome, it definitely wasn't below the industry standards."

America has a Critical Infrastructure Protection standard that protects the country's important SCADA systems. But professionals are saying more powerful firewalls are needed to make sure the SCADA systems never get touched. Experts warn that the more "smart meters, electric car chargers, rooftop solar installation, and other intelligent devices" open the grid up for attack.

DNP3 protocols allowing communications across substations and field devices are the entry points that need to be continually monitored for potential hacking. Using open source extensions like DNP3 SCADA, the utility can set up alarms. Alarms enable utilities to monitor intrusion on a network that is in the process of being hacked. However, experts say the willingness of utilites to embrace DNP3-compatible extensions that monitor intrusion have only been adopted by four or five utilities in the US. Experts also warn that not enough utilities are taking cybersecurity seriously.

- Details

- Written by: Quintus Potgieter

- Category: Education

Engineering failures continue to plague African countries. Nigeria, Kenya, and Ghana have been under heavy scrutiny by both its people and its governments due to unsafe civil engineering practices that have left many dead in the last few years. In Nigeria, the lack of a structural engineer was one of the reasons given for the collapse of the Synagogue Church of All Nations that left 115 people dead. In Kenya, after the collapse of a six-storey building, the Deputy Governer of Nairobi said that seventy percent of buildings in the country are erected without proper certification. There is an engineering ethics problem in Africa, but nothing is being done to change it.

Ghanaian publication, Graphic Online, has berated their president, John Dramani Mahama for not doing anything about the annual floods that occur in Accura due to what the publication claims are 'engineering failures'. They wrote: "Mr President, we appeal to you apply the whip on your appointees, especially metropolitan, municipal and district chief executives who fail to use the statutory authority of their assemblies to compel the people to respect the laws."

The engineering experts in Ghana have said that Accra is located in low-lying areas that are susceptible to flooding due to where the houses had been constructed in the first place. Furthermore, the draining systems are overcrowded with rubbish due to the residents who dump their rubbish into the drainage systems. The experts are saying a proper, effective drainage system is needed and then the city can address problems with litter and other issues. The publication thinks that underground drainage systems would be better for the area because open drain systems have been a target for the city to turn the drain into a landfill.

The engineering experts in Ghana have said that Accra is located in low-lying areas that are susceptible to flooding due to where the houses had been constructed in the first place. Furthermore, the draining systems are overcrowded with rubbish due to the residents who dump their rubbish into the drainage systems. The experts are saying a proper, effective drainage system is needed and then the city can address problems with litter and other issues. The publication thinks that underground drainage systems would be better for the area because open drain systems have been a target for the city to turn the drain into a landfill.

However, whoever first constructed the drains must have known that at some point there was going to be a problem with waste management. Why would they build it in any case? It becomes an ethics issue. From the process of awarding the contracts to construction companies to the unethical building of unsafe drainage networks and buildings around Africa.

The Dean of Engineering at the Engineering Institue of Technology, Steve Mackay has broached the topic of engineering ethics in the latest episode of his YouTube series, Engineering News Network. He said: "Ethics for engineers means engineers in the fulfillment of their professional duties shall uphold paramount the safety, health and welfare of their fellow citizens. That should be the highest possible consideration. It's a very expensive process if you want to rip the system but ethics is something that we as engineers and technical professionals have to do all the time."

Mackay outlines what the American Society of Civil Engineers believes are the fundamentals of ethical engineering. They're something that engineering entities in Africa should be focused on, but regrettably, are mostly ignoring.

- Hold safety, health and welfare of your fellow citizen in high regard

- Only work in areas where you are competent. Don't build bridges if you're an electronics design engineer for circuit boards. Focus on your areas of competence

- Be truthful and objective in everything you do. Be honest, tell the truth and be objective when you communicate and talk to others.

- Try and hold the highest professional standards in whatever you do. Don't take shortcuts, don't go for the cheap and nasty approach.

- Avoid conflicts of interest

- Ensure that your professional reputation is built on real, objective successes.

- Have zero tolerance for fraud, corruption, bribery. Say no.

- Always focus on enhancing your skills

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

As we know – engineering professionals often hugely underestimate their contribution and role in industry and society. Safety in the workplace especially when it comes to electricity is something we have to constantly keep our eye on and can continue to make a huge contribution.

Dear Colleagues

As we know – engineering professionals often hugely underestimate their contribution and role in industry and society. Safety in the workplace especially when it comes to electricity is something we have to constantly keep our eye on and can continue to make a huge contribution.

Engineering professionals should be proud

As engineers and technical people we are proud to make things happen and but it’s important that in this desire to produce an outcome, the technical solutions properly take into account:

- The relevant technical and safety requirements of a statutory nature (the legal requirements, contained in Acts, Regulations and referenced technical standards/codes);

- The possible need for additional measures to protect people and property (moral issues that arise because simple compliance with local laws may not deliver an adequately safe outcome for people and property – this is where issues such as good risk management and “good industry practice” come into play); and

- The wider corporate responsibility and also the impact on corporate image (and thus shareholder value) should a major deficiency with the outcome become evident. For example, the capacity and means for ensuring the ongoing safety of facilities in the long term need to be considered, where relevant.

An Energy Safety checklist

I believe these three issues need to be seen as part of the “energy safety checklist” that practitioners apply as part of their work, in their endeavour for continuous improvement, whether working on infrastructure (e.g. electricity or gas transmission lines, power stations etc) or industry installations (of mine sites, process plants or large buildings).

Massive Energy Safety failures

There have been some very newsworthy energy safety failures in recent times and two come to mind (besides the Gulf of Mexico rig explosion, of course). Firstly during early June 2010 there was a substation explosion and fire in Dhaka, Bangladesh which resulted in the death of at least 117 people and many more injured people, as the substation was next to a building storing various flammable chemicals. Secondly, during August 2010 it was announced that British Petroleum had agreed to pay a record OSH law fine of US$51m for failing to correct safety hazards at its Texas City oil refinery after an explosion killed 15 workers in 2005. The latter failure to comply is now not only costing BP a huge amount of money, but is also seriously hurting the company’s image and credibility.

Safety short cuts are expensive

It highlights that taking safety shortcuts to save some dollars doesn’t really save money in the long run. It also highlights that engineers should not be afraid to make sure the right information goes “up the line” to CEOs and also the directors of company boards, since many now take pride in reporting corporate performance through a triple bottom line – known as people, planet & profit.

Thanks to Al Koenig for this useful commentary.

In undertaking your day-to-day work, especially as far as safety is concerned, Howard Newton sagely observed: People forget how fast you did a job - but they remember how well you did it.

Yours in engineering learning

Steve

Mackay’s Musings – 28th June’16 #606

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

The 3rd Generation Partnership Project is a collaboration that involves multiple telecommunications companies who were behind the expansion of third-generation (3G) mobile phone system technology. The collaboration now wants to focus its efforts on Industrie 4.0 and focus on communication for the Internet of Things. This involves working on fifth generation technology. The group has released the first specifications for a new radio technology that will be ready to be used in devices by June 2018.

They will be finalising the architecture of systems that will run on fifth-generation communications by December of 2016. The result will be narrowband Internet of Things (NB-IoT) supporting two-way communications that will have low throughput and will be able to function on low-cost devices. Furthermore, the technology will be able to support up to 150,000 devices per single cellular cell. The release will also be able to run alongside existing 2G and LTE networking. This means, finally, GPRS will be quicker as well. Don't you just hate it when your phone barely manages to get internet on GPRS? Now, Release 13 allows for a 20db link budget improvement that will see GPRS perform better under terrible conditions.

Dino Flore, chairman of 3GPP said: "It took us only nine months to standardise the new technology after the study phase. Once again 3GPP demonstrated the ability to quickly respond to the emerging market needs."

Dino Flore, chairman of 3GPP said: "It took us only nine months to standardise the new technology after the study phase. Once again 3GPP demonstrated the ability to quickly respond to the emerging market needs."

Meanwhile, a company named u-blox has released a chip that will be compatible with 3GPP Release 13 (the new 5G standard) that will assist with communications in "smart buildings and cities, utilities metering, white goods, asset tracking, and agricultural and environmental monitoring." It is being considered the world's first cellular NB-Iot (Narrowband) technology. The chip will be the first one to be used by industry leaders Vodafone, Huawei and more. It will be the standard for NB-IoT and the future of the 5G world. It is called SARA-N2 module

Vodafone will be using NB-IoT as soon as 2017. The technology will go by the name LTE-Advanced Pro.

Alex Sinclair, CTO of the GSMA, said: "We are pleased that the industry has moved so quickly to adopt them and that they have now been ratified by 3GPP. Mobile operators have already started a number of pilots around the world and this agreement over common standards will help accelerate the development of commercial solutions and ensure they are in market much faster, providing customers with more choice."

The Internet of Things is going to need lightning-speed communications between devices and this standardisation of communications technology is a good step forward.

Source: PR Newswire

- Details

- Written by: Quintus Potgieter

- Category: Education

The world is moving at a fast pace in the twenty-first century. It's easy to have mastered the skills necessary to do a job, just to find yourself years down the road with a whole set of new skills you have to learn to remain employable to a company. It happens in many engineering industries due to how technology is constantly updated, software changes, hardware gets replaced, a robot takes the repetitive task you used to do. etcetera. You could even be fresh out of high school not knowing where to start on your road to becoming an engineer. Perhaps a MOOC could be your saving grace.

MOOC is short for Massive Open Online Course. A free online course that is offered by top universities that introduce students to the type of work that tertiary level institutions teach or lets you brush up on your skills that you might require for a certain type of job. To find a list of MOOCs that specialize in Engineering, you can look at this website: MOOC LIST.

MOOC is short for Massive Open Online Course. A free online course that is offered by top universities that introduce students to the type of work that tertiary level institutions teach or lets you brush up on your skills that you might require for a certain type of job. To find a list of MOOCs that specialize in Engineering, you can look at this website: MOOC LIST.

In South Africa, students recently led a protest against the hiking of university admission fees, which quickly turned into an argument for free tertiary education. Now, The University of the Witswatersrand is offering three new massive open online courses that could get students started on building towards their engineering career. The University will be the first in Africa to offer MOOCs along with with the edX program. The three courses are:

- Research Methods: An Engineering Approach

- Results-Based Project Management: Monitoring and Evaluation

- System Dynamics for Health Sciences

Deputy Vice Chancellor at Wits says: "There is no doubt that there is dire need for more places at South African universities and for access to quality post-school training. Wits is proud to be the first African university on the edX platform, where we offer free online courses unique to South Africa."

It is a good move for the university that is trying to do everything it can to at least offer something to a country that is demanding tertiary education be made free and available to every student. And it is encouraging to see they are engineering-inspired courses. However, if you wanted to, you could also do some MOOCs that get you started through industry big-hitters like MIT, Stanford and more.

The University of New South Wales Australia has also launched their own MOOC, named Through Engineers' Eyes: Engineering Mechanics by Experiment Analysis and Design. The professors behind the MOOC say learning foundational engineering concepts is invaluable to the future studies that a student pursues.

- Details

- Written by: Quintus Potgieter

- Category: Developments

The civil engineering industry is desperately wanting to use automated drone technology in the United States. Current unmanned vehicle laws from the Federal Aviation Administration have limited some of the automated operations that could be run on construction sites, which would perform site monitoring, mapping, and inspection. Now, they are updating the laws but have still left out amendments that would benefit the engineering companies.

Companies in the US that want to use drones, want to implement automated systems. Amazon and Alphabet have both engineered automated drone delivery systems that will not be able to fly under the new FAA regulations. Another regulation that could stunt the growth is the fact that drones would not be able to fly during the hours of the night.

The new laws demand that a drone must always be in "eyeshot" of the pilot controlling it. However, as more and more automated drone delivery systems are proposed, the FAA could alter these laws. This would mean that automated site mapping, monitoring or inspection drones are a pipe dream for now, but so long as a piloted inspection drone can be seen by its pilot, those seem to be allowed for now.

U.S. Transport Secretary Anthony Foxx announced the new regulations on the FAA's website, saying: "We are part of a new era in aviation, and the potential for unmanned aircraft will make it safer and easier to do certain jobs. We look forward to working with the aviation community to support innovation, while maintaining our standards as the safest and most complex airspace in the world."

The FAA says the new regulations could create up to 100,000 new jobs in the industry over the next 10 years. They also say that the money generated by companies using drone technology could top $82 billion, according to their industry estimates.

There are many other uses UAS's could be used for in the engineering community and now that the laws have been altered, those uses can finally come to fruition. However, the lack of support for the automation of those systems sets some industries back. Good news for drone operators whose employment is guaranteed until the FAA decides to review the law on a pilot being necessary.

Automated drones flying pre-planned paths is invaluable to civil engineering industries and the safety of those sites, as shown in this video below:

The new drone laws are summarized

Source: Federal Aviation Administration

- Details

- Written by: Quintus Potgieter

- Category: Industry

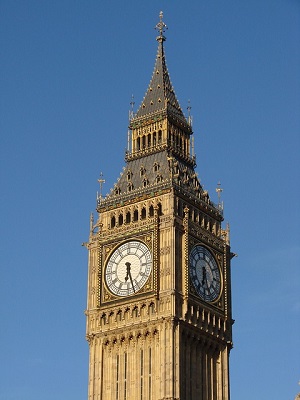

Heartbreak, dismay, disappointment. Just some of the words that academics are using to express themselves with after the British public decided that the United Kingdom would not remain in the Europe Union. Universities are now saying they anticipate considerable changes in the future of studies in engineering and science.

When the referendum's results were announced the Institution of Engineering and Technology immediately demanded discussions be held to measure what kind of damage a Brexit will have on the engineering industries. The group says the vote comes at an inconvenient time due to the shortage of engineers the country has. They say the vote will impair the economy

According to a poll, the publication The Independent ran, 56 percent of students believed that leaving the EU would lead to "detrimental effects" on career prospects in the country. What academics are worried about is the loss of the European Union research funding. £687 million ($907 million) is made available for research and a lot of that is used for engineering and science research and innovation.

According to a poll, the publication The Independent ran, 56 percent of students believed that leaving the EU would lead to "detrimental effects" on career prospects in the country. What academics are worried about is the loss of the European Union research funding. £687 million ($907 million) is made available for research and a lot of that is used for engineering and science research and innovation.

President of Universities UK, Julia Goodfellow said: "'Leaving the EU will create significant challenges for universities. Although this is not an outcome that we wished or campaigned for, we respect the decision of the UK electorate. We should remember that leaving the EU will not happen overnight – there will be a gradual exit process with significant opportunities to seek assurances and influence future policy.

However, Patrick Flaherty, Chief Executive of AECOM UK said that due to the fact that no nation has ever left the EU before, the long-term impact couldn't be measured as of yet.

However, students are anxious about what the Brexit means for the high-ranking British universities. Five percent of students in the UK are from EU territories, and the exit could have implications for them, depending on what politicians decide about immigrating students. Universities UK wants to ensure that EU student exchange stays in place.

"Our first priority will be to convince the UK Government to take steps to ensure that staff and students from EU countries can continue to work and study at British universities in the long term, and to promote the UK as a welcoming destination for the brightest and best minds. They make a powerful contribution to university research and teaching and have a positive impact on the British economy and society. We will also prioritise securing opportunities for our researchers and students to access vital pan-European programmes and build new global networks," Goodfellow concluded, in her statement after the Brexit results were published.

Source: Universities UK

- Details

- Written by: Quintus Potgieter

- Category: Developments

The European Union has been reading some Isaac Asimov novels, it seems. The expansion of industrial robotics has made the EU question whether or not to finally give robots the "electronic persons" classification. We are seeing robots in factories around the world furthering the fourth industrial revolution and slowly making their way into households around the world. The fact of the matter cannot be denied, robots being considered "electronic persons" is soon not going to be the stuff of science-fiction novels anymore.

The draft document by the Legal Affairs Committee of the EU to give intelligent robots that title "electronic persons" has gotten the engineers who develop and equip factories with these 'robotic persons', talking. VDMA, a German engineering association, says this is the kind of overeager chatter that will slow the fourth industrial revolution down. The European Union are trying to force regulation on technologies that they assume already exists, says VDMA chief executive Thilo Brodtmann.

VDMA robotics and automation head Patrick Schwarzkopf told Reuters that a legal framework for electronic persons should only be happening in the next 50 years and not in the next ten years. "We think it would be very bureaucratic and would stunt the development of robotics," he said.

VDMA robotics and automation head Patrick Schwarzkopf told Reuters that a legal framework for electronic persons should only be happening in the next 50 years and not in the next ten years. "We think it would be very bureaucratic and would stunt the development of robotics," he said.

The draft proposal has come after news that factories all over the world are continually replacing human workers with a robotic workforce. The rise in industrial automation is something that Europe does quite well, and in Germany specifically. Perhaps that is why the EU wants to jump on the issue so quickly.

The activist behind the proposal is an MP Mady Delvaux. She was interviewed by the EU's actual website, saying that robots need a classification of some sort because of the many different kinds of robots that exist today, i.e. service robots, industrial robots, drones, cars, etc. She said: "There are various reasons for this. We need a new European standardisation. We also need to consider liability, the protection of personal data and the prevention of hacking...The US, China, Korea and Japan have very ambitious projects. If we do not create the legal framework for the development of robotics, our market will be invaded by robots from the outside. Also, the European Parliament will be the first parliament in the world to discuss and create such a legal framework." She also alludes to the fact that the robot revolution will "destroy certain kinds of jobs" but is confident that Europe will be creating new ones to counteract the loss of employment.

Other robot manufacturers like Kuka have also rubbished the claims that an "electronic persons" classification for robots is necessary right now and would rather delay the process to see where robotics lands up in the upcoming years.

Here is the entire draft report on the recommendations to the commission on Civil Law Rules on Robotics

- Details

- Written by: Quintus Potgieter

- Category: Education

The engineering world wants hard-earned academic qualifications. It's no lie. A degree from a well-known, respected university can get you a job. However, do you have experience? This is where engineering apprenticeships come in. A student studying towards their Masters Engineering levels could see themselves taking part in an apprenticeship and equipping themselves with even more engineering skills which will lead to a lucrative career. Learning practical skills in an industry-specific apprenticeship will give you invaluable background information and skills that will equip you to go further and do more in the career you are building towards.

Engineering UK said in 2013 that there would be a demand for 69,000 qualified people in an engineering apprenticeship positions from the years 2010-2020. However, only 27,000 apprentices get their qualifications per year in the UK. The bigger picture is that by 2020, the UK expects to have seen 1.86 million jobs to have been made available in the engineering industry.

Furthermore, there is the nasty business of seeing the gender imbalance statistics in engineering apprenticeships. The issue of men outnumbering women in engineering is unavoidable these days, and it obviously affects the apprenticeship numbers as well. The Young Women's Trust compiled a report that revealed there are 25 male apprentices in a program and only one female. They have also highlighted that men apprentices get paid more than female apprentices. Aecom has also recently warned the industry that the gender gap needs to be addressed due to less than 8% of manufacturing and engineering technology apprenticeship programs being given to women candidates. Those numbers were made public by the Department for Business, Innovation & Skills in the UK.

Furthermore, there is the nasty business of seeing the gender imbalance statistics in engineering apprenticeships. The issue of men outnumbering women in engineering is unavoidable these days, and it obviously affects the apprenticeship numbers as well. The Young Women's Trust compiled a report that revealed there are 25 male apprentices in a program and only one female. They have also highlighted that men apprentices get paid more than female apprentices. Aecom has also recently warned the industry that the gender gap needs to be addressed due to less than 8% of manufacturing and engineering technology apprenticeship programs being given to women candidates. Those numbers were made public by the Department for Business, Innovation & Skills in the UK.