News

- Details

- Written by: Quintus Potgieter

- Category: Industry

The battle continues between the FBI and tech industry giant, Apple. The FBI are wanting to access the contents of an iPhone belonging to a terrorist known as the San Bernadino shooter who shot 14 people in the United States. Apple CEO, Tim Cook, is warning against allowing such a bypass of security services because of the prescedent it might set and is also warning against the criminal hackers that could get their hands on the software that would need to be invented to make such a backdoor possible.

In a recent Apple release, they say, "The government says: “Just this once” and “Just this phone.” But the government knows those statements are not true; indeed the government has filed multiple other applications for similar orders, some of which are pending in other courts."

In more recent developments, other tech companies such as Google, Facebook, Amazon and Microsoft have vowed to file briefs to the courts to try and prevent a magistrate's order of forcing Apple's hand and strongarming them into developing the software to allow access to the contents of the phone. It is rumored that Twitter will join the fight as well.

Along with companies voicing their support for Apple, the situation could escalate to a future of hardware and software engineers who would have to build backdoors into devices so that security of state can be ensured in the future.

"Once created, the technique could be used over and over again, on any number of devices. In the physical world, it would be the equivalent of a master key, capable of opening hundreds of millions of locks—from restaurants and banks to stores and homes. No reasonable person would find that acceptable," Tim Cook said.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Facebook has announced their new project that will see tech companies and internet service providers all over the world linking arms to bring the world of virtual reality - and other services that might require the internet - to life. The project they're calling the Telecom Infra Project will be an engineering team effort that will "reimagine the traditional appraoch to building and deploying telecom network infrastructure."

Global connectivity is one of the aims of the project, recruiting a list of providers to kick start the project. The notable preliminary contributions coming from companies such as:

- SK Telecom

- Africa Mobile Network

- Deutsche Telekom

- Nokia

- Intel

- T-Mobile

"“Every day, more people and devices around the world are coming online, and it’s becoming easier to share data-intensive experiences like video and virtual reality,” said the head of engineering and and infrastructure at Facebook, Jay Parikh.

Parikh further said that the world needs to speed up on innovation in telecom infrastructure so that the new technologies emerging operate fully and "unlock new opportunities for everyone in the ecosystem."

These announcements were made at the Mobile World Congress in Barcelona, which has produced a lot of chatter about 5G internet speeds and the internet of things that will connect the world's appliances to the internet.

For more information on the project feel free to visit their website

- Details

- Written by: Quintus Potgieter

- Category: Developments

Researchers in Columbia University Cochlear Implant Center are investigating a way to engineer music so that people who have cochlear implants might actually be able to enjoy music.

Cochlear implants are engineered to make speech sound clearer to people who are past the point of utilizing an amplifying hearing aid, however, it is reported by implantees that they have lost the ability to enjoy music.

The researchers from Columbia University intend to, "test the hypothesis that reengineering music to reduce its complexity can enhance the listening experience for the cochlear implant," they stated in an abstract of their official research article.

The group alleges that it is much simpler for implantees to process speech than the more complex nature of music. Anil Lalwani, MD, a Cochlear Implant Surgeon at Coloumbia University says, "A person who has lost hearing have lost not only some of the hair cells but they've lost some of the nerves that transmit that information to the brain."

The hope is that in the future a specialized type of music can exist for people who have cochlear implants so they could start or go back to enjoying music. Dr Lalwani believes software should exist that reengineers music so that it appeals solely to cochlear implantees.

Les Atlas, a professor of electrical engineering at the University of Washington spoke to NPR, alluding to the fact that it would take a lot of computing power to achieve the encoding of the elements implantees require to listen to music normally.

The fact of the matter is that better implants need to be engineered and designed to facilitate listening to music for cochlear implantees.

For a clearer idea of what music sounds like to a person who has a cochlear implant, check out this video:

- Details

- Written by: Quintus Potgieter

- Category: Developments

The future is here and it might be a little too unnerving to watch.

Boston Dyanmics, an engineering and robotics design company owned by Alphabet (the company that owns Google) has unveiled an upgraded iteration of their Atlas Humanoid. In a new video the 'next generation' robot is seen opening a door and circumnavigating a snowy area in the nearby woods. It has been upgraded to "operate outdoors and inside buildings," Boston Dynamics say in the description of the new viral video. The video shows this when the robot is seen picking up boxes of different weights and placing them on shelves. YouTube comments have reflected negatively at a section of the video where the robot is 'bullied' by a bearded engineer; he shoves the robot down with a stick and then the robot gets up again.

Explaining how exactly the robot is able to mimic human movement, Boston Dynamics explained, "It is specialized for mobile manipulation. It is electrically powered and hydrualically actuated. It uses sensors in its body and legs to balance and LIDAR and stereo sensors inits head to avoid obstacles, assess the terrain, help with navigation and manipulate objects."

Entreprenuer and blogger Jason Calacanis in an interview with CNBC said, "Manual labour is going to end in our lifetime, and in this video you can see how close we really are. It's a huge societal issue with jobs, but it's going to be a huge lift in terms of efficiency of companies that nobody expected."

Check the video out below:

- Details

- Written by: Quintus Potgieter

- Category: Developments

The International Data Corporation (IDC) has announced that it estimates the global spending on robotics and industrial services will grow from $71 billion in 2015 to $135.4 billion in 2019.

This was confirmed in their Worldwide Commercial Robotics Spending Guide which covers industrial markets such as:

- Robot sensors such as cameras, microphones, barometers, and thermometers

- Robot effectors such as end effectors, motors, and speakers

- System hardware

- Command and control software

- Services such as implementation, maintenance, repair, and consulting

In a statement to the press about what the spending guide means for the future of robotics, John Santagate, a Research Manager at IDC Manufacturing Insights said, "Robotics as a technology has really reached its tipping point. Robotic capabilities continue to expand while increasing investment in robot development is driving competition and helping to bring down the costs associated with robots."

Robotics is also becoming a field of study for children who live in slum areas in India. TribuneIndia reports that a start up called Robotics Education World will offer six month courses to train children in robotics. They claim they will be able to offer this for 20,000 children and young adults in New Dheli. The report released by IDC indicates that 65% of robotic spending is in the Asia/Pacific regions and will double by 2019.

- Details

- Written by: Quintus Potgieter

- Category: Education

The engineering industry is being influenced to become more attractive as a field of study to females, with hopes that the male dominated industry might look more equal in the near future.

ExxonMobil - the world's largest publicly traded international oil and gas company - is at the helm of this movement, establishing the Girls Engineering Festival that took place in the Independent School Districts of Conroe, Magnolia and Spring in the United States on the 23rd of February. According to an article written by The Courier of Montgomery County, females only make up 14% of the engineering work force.

ExxonMobil set up teams of female engineers who were able to relay their knowledge to the girls who had attended the festival, to encourage them to consider engineering as a career path. Rick Frankie - an employee of a non-profit organization (Junior Achievement) championing the cause of female engineers - said, "Years ago they said women needed to stay in the house and raise the family; well, that’s not true. You set the example and you have the opportunity.”

HeraldScotland is reporting that Scottish Universities and colleges will be implementing quotas to address the gender imbalance - with specific focus on engineering - ensuring that only 75% of students within a course can lean towards one gender. Online engineering institutions in the tertiary sector are also reporting that 90% of its applicants for the first two months of 2016 were male. The demand for female engineers is growing so rapidly that female-only courses are being considered to lure women into the engineering industry.

- Details

- Written by: Quintus Potgieter

- Category: Education

This week, engineeringcareer.org went searching for the engineers of popular social forum site Reddit. From February 21st to February 27th, National Engineers Week is celebrated in the United States. The week puts emphasis on the need for engineers in society. We interviewed thirteen engineers from the website and asked a few questions about engineering and the industries they currently serve, with focus on graduates. Demographic calculations of the site have shown that the approximate gender and age that is most prevalent on Reddit is 18-29 year old males. Through this survey, students who are currently studying towards their degree will be able to get an idea of the industry they are trying to find a career in.

13 responses filtered in as engineers were honest about their salaries and their happiness when it came to graduating and getting jobs.

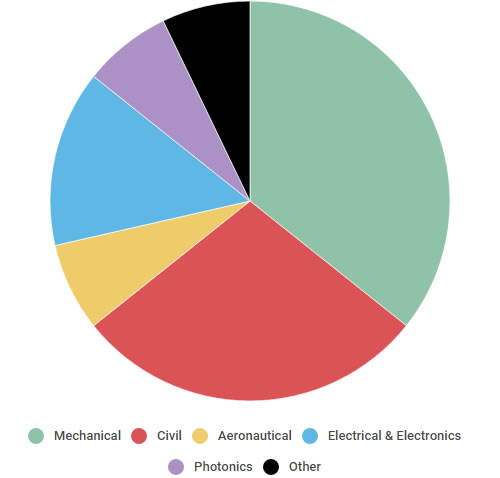

Our first question for the respondents was: What is the nature of your qualification?

Once the category of engineering that they fit into had been established, the job title they were given as a result of being employed in the engineering industry was asked:

- Hardware Engineer II

- Graudate Engineer

- Product Design Engineer

- Design Engineer

- Materials Test Engineer

- Graduate trainee

- Field Engineer

- Construction Manager

- Evironmental Engineer (jnr)

- Electronic Engineer

- Structural Engineer I

- Operations Engineer

- Mechanical engineer

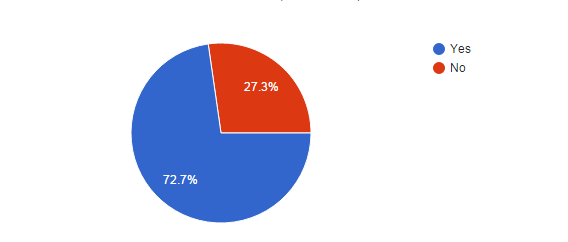

What salaries do these kind of engineering jobs make? Here we will present them in US dollars, showing the average of all of the salaries put together. The option to supply a monthly salary was optional in the survey but does give us an idea of what an engineer in their late twenties can earn. The average salary of all of these jobs put together was $4470.09 per month according to the survey. When asked if the engineers were happy with their salaries, this was the response:

The qualifications that the respondents obtained were all acquired through universities. An encouraging statistic from the respondents when asked whether or not they held qualifications but failed to find a job resulted in a hundred percent, "No." So, if you are pursuing an engineering degree, it is clear that out of thirteen respondents, not one was without work once they had their qualifications. Something to think about.

For all the engineers that might be celebrating Engineers Week along with the US this week, here's a quote to keep you working towards achieving that engineering job: "The scientific man does not aim at an immediate result. He does not expect that his advanced ideas will be readily taken up...His duty is to lay the foundation for those who are to come, and point the way," - Nikola Tesla.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

No one agrees 100% on what makes for plagiarism. Essentially, plagiarism is (generally blatant) copying of someone else’s work without giving them any credit or acknowledgement.

What puzzles me about plagiarism is that in giving credit to the originator of a particular concept or work can enhance one’s own work tremendously. When people read your article and see that it is backed by support from many other experts; they tend to find it more credible.

Dear Colleagues

No one agrees 100% on what makes for plagiarism. Essentially, plagiarism is (generally blatant) copying of someone else’s work without giving them any credit or acknowledgement.

What puzzles me about plagiarism is that in giving credit to the originator of a particular concept or work can enhance one’s own work tremendously. When people read your article and see that it is backed by support from many other experts; they tend to find it more credible.

As opposed to the usual mumbo jumbo subjective rubbish that one reads in the newspaper which is based on anecdotes or someone’s biased opinion with no evidence provided to back up the opinions.

The Guilty Ones

The people who are most guilty of plagiarism are students, journalists and academics.

The rapid growth of the internet now means (for a journalist for example) that it is unnecessary to actually go out and interview people to derive primary evidence for an article. You can actually conjure up many more articles (supposedly derived from you) by simply trawling the internet and rewriting the articles with slight rewording. This is what a lot of newspapers are now doing as they are trying to cut their costs. This is naturally driving some of the good quality newspapers and journals into a frenzy as it is unfair.

Aggregation is different to Plagiarism – most of the time

A practice used by journalists particularly is to grab many pieces written on a particular subject and to rework them in one’s own language and to provide credit from the original sources of the story.

Obviously, simply directly quoting from the original articles without modifying the text is again plagiarism and unless permission has been granted is unacceptable.

Plagiarism by Students can be minimised through Turnitin

When writing a piece, one can check using software such as Turnitin of the degree of plagiarism. This gives one a warm and fuzzy feeling that one is doing the right thing when Turnitin gives one a low probability of plagiarism.

There is also a term called self-plagiarism where one copies previous pieces written by oneself. One should reference the earlier work; although in my opinion this can be somewhat unnecessary.

So….in whatever writing you do – ensure you reference your sources carefully and try and be original in one’s writing. This will give your readership confidence in your integrity as an engineering professional.

Thanks to the inimitable Don Christiansen from the IEEE for an interesting article on Plagiarism. Something which he obviously has thought about a lot as he is an esteemed engineering ‘journo’

Wilson Mizner is perhaps a bit cynical when he says: If you steal from one author it's plagiarism; if you steal from many it's research.

Yours in engineering learning

Steve

Mackay’s Musings – 23rd Feb’16 #588

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

Engineers from the University of Utah have recently discovered a revolutionary type of 2D semiconducting material that will open the door for faster smart phones and computers, while consuming significantly less power.

The semiconductor made from tin monoxide (tin and oxygen) is a layer of 2D material and only one atom thick. This allows the conductor to have electrical charges move through it much faster than silicon and other 3D materials that are conventionally used. This material has the potential to be used in transistors, which are the core component to electronic devices such as CPU’s and GPU’s in computers and mobile devices.

This discovery was made by a research team from the University of Utah, led by associate professor of materials science Ashutosh Tiwari. These findings were recently published in a research journal on February 15 2016 entitled Advanced Electronic Materials.

The many benefits of 2D materials are still being researched, as the field has only opened up over the past five years. Researchers in this field have recently discovered new types of 2D material such as disulphide, borophene, graphene, and molybdenun which only allow the movement of negative (N-type) electrons. In order to create an electronic device, you require a semiconductor material that allows the movement of both N-type electrons and positive charges. The tin monoxide material discovered by the team University of Utah is the first stable positive (P-type) 2D semiconductor material in existence.

Now that the Tiwari and his team have both the P-type and N-type 2D semiconductors, they are confident that manufacturing of transistors that are smaller and faster than those used today is achievable. The transistors Tiwari and his team can make with their semiconducting material could lead to computers and smartphones that are more than 100 times faster than regular devices, won’t get as hot as normal computer chips, and require significantly less power.

“The field is very hot right now, and people are very interested in it,” Tiwari says. “So in two or three years we should see at least some prototype device.”

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Last week one of the true giants in engineering died. His name is Andrew (Andy) Grove (anglicised name from Hungarian) and he drove the microprocessor revolution (amongst other things). Due to the desperate situation in Hungary at the end of the Second World War, he immigrated to the USA and became one of the giants of the semiconductor industry.

One of his stock phrases (which formed the subject of one of his books) was: Only the paranoid survive in business.

Dear Colleagues

Last week one of the true giants in engineering died. His name is Andrew (Andy) Grove (anglicised name from Hungarian) and he drove the microprocessor revolution (amongst other things). Due to the desperate situation in Hungary at the end of the Second World War, he immigrated to the USA and became one of the giants of the semiconductor industry.

One of his stock phrases (which formed the subject of one of his books) was: Only the paranoid survive in business.

Early Days

After arriving in New York from Hungary, he undertook a bachelor of engineering at New York City College; quickly followed by a PhD in chemical engineering at the University of California Berkeley. He was one of the first employees of Intel – I think employee no. 3 - and rapidly became CEO of a fast growing company in the early days of Silicon Valley.

Big Challenges

Intel was originally designing and manufacturing memory chips – initially very successfully. They subsequently had huge challenges with Japanese dumping of memory chips at a low cost. This caused huge stresses for the early Intel. Andrew then swapped the company across to production of Intel microprocessors. A huge gamble at the time but one which has paid off significantly for Intel. Today it has a market capitalisation of $US197 billion and 64,000 employees and is hugely successful.

Andrew Grove’s Philosophies

Andy believed that handling change in business was a key attribute of all firms. He believed that business success contains the seeds of its own destruction. As a company grows you get more stability and you then become complacent and that probably becomes the catalyst for the unravelling of the business.

All corporations are living organisms and they have to continue to sheds their skins and change their methods continuously to survive and indeed, prosper. Andy was a very modest individual preferring a simple office cubicle to a mahogany adult corner office. No reserved parking places at the office, no big cars and no big houses for Andy. He was extraordinarily disciplined, precise and detailed orientated. But coupled with enormous creativity.

He believed in driving a strongly entrepreneurial culture. A notable author and scientist, he was a prodigious writer and ‘technology cheerleader’. One of his texts is still being used by leading universities. A more recent book on management was translated into many languages.

Finally, he is also proof of the enormous value in focussing all businesses globally and embracing people, ideas and cultures from all over the world.

A remarkable man and engineer and someone who we should always remember.

RIP Andy Grove.

Yours in engineering learning

Steve

Mackay’s Musings – 16th Feb’16 #587

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Education

Aerospace company Boeing plans to drastically increase it’s employment of engineers for future endeavours. Boeing Defence Australia’s (BDA) Director of Human Resources Melissa Davidson has announced that the organisation will create 220 new roles this year – including 197 for engineers – due to recently winning two major defence contracts.

Two contracts that are currently driving the employment growth in Boeing are the; Land 2072 Phase 2B system – a battlespace communications network, and the development of a training system for helicopter pilots that requires BDA to not only supply the aircrafts and training devices, but also the training, support, instructors and maintenance itself.

Boeing’s commitment to gender diversity is aiming to achieve at least 30 per cent of it’s new engineering employees to be female.

The projections from the Department of Employment has forecast an extra 1800 electronics engineers and 1600 electrical engineers will be required across Australia in the five years to November, 2019.

You can see if there are any job opportunities with Boeing at: www.boeing.com.au

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Batteries, batteries….that is all we have been hearing of recently. This rapid movement to batteries will undoubtedly impact on the suppliers of electrical power such as power stations and the transmission/distribution networks as the use of batteries at homes will increase strongly. Driven by reducing costs of installations. And some very enthusiastic vendors such as Tesla who are all determined to drive the prices downwards with great vigour. Well, so they claim.

Dear colleagues,

Batteries, batteries….that is all we have been hearing of recently. This rapid movement to batteries will undoubtedly impact on the suppliers of electrical power such as power stations and the transmission/distribution networks as the use of batteries at homes will increase strongly. Driven by reducing costs of installations. And some very enthusiastic vendors such as Tesla who are all determined to drive the prices downwards with great vigour. Well, so they claim.

Microgenerators Galore

This will mean that we are going to be in a position where we have many little micro generators (with photovoltaic cells and batteries) scattered around the suburbs and towns who will sell power back to their local utility particularly whenever there is peak usage of electricity. In other words the power distribution companies have a opportunity to do some trading not only in reselling power from the traditional coal or gas fired power stations but also from all these micro generators scattered around the suburbs who want to sell their power at peak consumption times. The power distribution companies add value in that they have the ‘poles and wires’.

All Systems Green for the Smart Grid

Suddenly distribution companies have a real opportunity to implement the smart grid concept with some significant economic returns. What makes it all very interesting is that generators won't need to build a new power station to handle these peak loads but can merely harness existing power from the individual micro generators scattered around the countryside.

Pricing is a Big Challenge

One of the biggest challenges naturally is to get the price right. So that those living in apartments who don't have solar panels (and batteries) can still find the price of power beneficial. In other words they won’t have to pay as much for their power with the use of micro generators against if they were forced to use the traditional coal fired or gas fired generator power supply exclusively.

Without any shadow of doubt – once we have a burgeoning market of micro generators with the power utilities acting as facilitator – the days of monopoly pricing driven by obscure government agencies will be gone. The genie will have finally escaped.

Big changes are coming. The question for you – whether you work for a power utility or just use power - is this: how do you take advantage of these changes to improve your business/career and life?

Yours in engineering learning,

Steve

Mackay’s Musings – 9th Feb’16 #586

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Education

A recent study by Deakin University (Melbourne, Australia) has shown that majority of engineering graduates actually end up working within the IT industry, rather than the Engineering Industry. Their findings were published in the Australasian Journal of Engineering Education.

The university analysed data on over 200,000 people who have a bachelor-level degree in engineering and found that the degree is extremely valuable to have across a wide range of industries. The study showed that approximately 46 percent of engineering graduates who were under the age of 25 were in an engineering related role, with the figure dropping to 32 percent when the other age groups were counted.

The Deakin research revealed that 14 percent of those with an engineering degree who don’t end up employed within the industry, are employed in the IT and other technology-related industries. Another 12 percent of the people who were included in the study were in general management positions outside engineering, while 10 percent were employed in non-professional jobs.

Engineering graduates’ employability is supported by data from Graduate Carers Australia which identified 80 percent of the graduates who were studied reported that they found employment straight out of university. This is significant, as 70 percent of graduates from other disciplines were unable to find employment immediately after graduation.

Stuart Palmer, lead researcher associate professor of Deakin University has offered the following advise regarding the future and current engineering students:

- It is recommended that engineering students should be better informed about the industry outside of graduation.

- High school (secondary school) students who are interested in studying engineer in the future should be informed that the degree can lead to many more employment opportunities than just engineering and they are more than likely to work outside of the industry.

- The undergraduate engineering curricula should consider the portability of the degree.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

‘The Coming revolution in engineering education’ is always somewhat tedious to read – it is an old worn cliché. We seem to be supposedly having revolutions in everything these days. Certainly there is change coming in engineering education but revolution – I doubt it.

‘The Coming revolution in engineering education’ is always somewhat tedious to read – it is an old worn cliché. We seem to be supposedly having revolutions in everything these days. Certainly there is change coming in engineering education but revolution – I doubt it.

Dear Colleagues,

Dear Colleagues,

‘The Coming revolution in engineering education’ is always somewhat tedious to read – it is an old worn cliché. We seem to be supposedly having revolutions in everything these days. Certainly there is change coming in engineering education but revolution – I doubt it.

Technology Driven Revolutions are Overdone

Over the past century there have been an enormous number of claims of revolutions in education (particularly with technology ranging from TV, computers to the internet). None of them have happened. You can use technology to make learning more efficient but that doesn’t necessarily mean it is more effective. I believe we can all remember the ghastly rote-based computer-based training sessions which were totally useless.

Successful training is really based on how you design the learning, the level of interactivity of the training, the quality of the materials and how good the instructor is. And finally – how this training and education is applied to the job.

Engineering Education Needs to be Dramatically Improved

I am convinced that engineering education at college or university is still extraordinarily poorly done. I still hear of students being subjected to countless hours of boring lectures on meaningless subjects they will never use in the real job market. Universities are still considered an assembly of experts focussed on research (which is where they are rewarded for and where they achieve a level of prestige). The engineering students are often forgotten. It is vital to remember that knowledge and expertise (formerly residing with the professor) is freely available nowadays – esp. on the internet.

In addition, one doesn’t need to demonstrate prowess with advanced mathematics and physics to be able to work as an engineer or technologist these days.

OK – so what is required….?

As you are no doubt aware - a few suggestions on useful education and training for a future engineer or technologist would include:

- Encourage entrepreneurial spirit for students. They should be prepared to experiment and fail often with projects, products and services before being successful.

- Encourage creativity and ‘thinking outside the box’

- Education is a team effort between students and instructors where collaboration and trust is the order of the day.

- Skills such as project management are critical.

- The ability to communicate well is key – whether this is verbal or simply typing up an email.

- Expect and thrive on change. It is everywhere and it will continue.

- Openness and transparency – students and instructors work together collaboratively. The old ‘sage on the stage’for instructors ain’t gonna work any longer with the modern student who wants value.

- The student should absorb a passion for other areas such as the arts, business and law….

Naturally, give students the basic know-how in physics and engineering but encourage them to discover the knowledge they require and to be constantly on a lifelong learning mission. Not necessarily through formal courses but from buddies in discussion forums, on the job or from a mentor.

As we all know – most of what we are taught at engineering school isn’t used in one’s career. There is a great opportunity today, to change this and make engineering education something sought after and engineering graduates admired as real contributors to society.

Bruce Dickinson remarked: Engineering stimulates the mind. Kids get bored easily. They have got to get out and get their hands dirty: make things, dismantle things, fix things. When the schools can offer that, you’ll have an engineer for life.

Thanks to an interesting book: A Whole New Engineer by David E.Goldberg and Mark Somerville.

Yours in engineering learning,

Steve

Mackay’s Musings – 2nd Feb’16 #585

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Quintus Potgieter

- Category: Developments

India’s rapid urbanization and industrial development have overtaken all efforts to protect the environment. This has led two of MIT’s doctoral students in the School of Humanities, Arts, and Social Sciences to begin working on a way to address India’s high levels of air and water pollution issues that pose a threat to human health.

Nick Hagerty, a fourth-year PhD student is designing a cap and trade program with the intention of reducing pollution from industrial wastewater. Ariel Zucker, a third-year PhD student is developing an environmental rating program for industrial smokestack emissions. Both of these projects were developed through MIT’s Tata Center for Technology and Design, whose mission is to address the challenges of communities which are resource-constrained.

Project One: Cap and Trade

Nick Hagerty is working with a team of professors from Harvard University, Yale University and the University of Chicago to provide a financial incentive to polluting companies in India to clean up their act by enabling companies to work together to meet a proposed set of pollution reduction goals.

"What if there were a way to transcend this tradeoff — to reduce pollution without killing off industry? We’ve seen in other parts of the world that there is a tool that can achieve that: It’s emissions trading, or cap and trade," Hagerty says.

Hagerty and the team plan to work with an environmental regulator and a local industry association to monitor the industrial wastewater released by approximately 110 factories that share a treatment facility in the Indian state of Gujarat. They will then provide these factories with pollution permits and enable these companies to trade these amongst themselves.

This project makes it possible for facilities that face high clean up costs to pay another – such as one with cleaner operations and low clean up costs – to take on the emission reductions in order to meet the group goals.

Project Two: Environmental Rating

Ariel Zucker believes that even if you have great technology, you need some incentive for people to reduce pollution. At the moment India has high environmental standards, however the regulations are not very well policed and enforced. This means a lot of the standards are ignored by large organisations.

With the same team of professionals that Haggerty is working with, Zucker is planning to tackle this issue by giving companies a public reputation for environmental performance – for good or poor.

In the state of Maharashtra, Zucker and the team are collecting data on stack emissions from approximately 100 industrial plants and ranking them based on the total amount of particular matter they are releasing into the atmosphere. They plan to assign each plant with a star rating and publish the results online.

Zucker believes strongly in the incentive program as she says "It’s feasible and pretty low-cost for many of these industries to come closer to compliance. If it’s not worth their reputation to do it, they won’t do it. If it is they will.”

This program is planned to go into operation in the spring (northern-hemisphere), when the group will continually monitor smokestack emissions to evaluate the project’s impact.

"I think this project will give industry groups some incentives to start being better citizens," Zucker says. "We see a lot of room for small, low-cost improvements that can have a big impact on pollution."

- Details

- Written by: Quintus Potgieter

- Category: Education

The Oxford Martin Programme on Technology and Employment, in association with Citi recently carried out the Technology at Work v2.0: The Future Is Not What It Used To Be report. The report highlights published data that was featured in the World Bank Development Report 2016.

It was found that fourty-seven percent (47%) of jobs in the U.S. are at risk of automation in the next two decades. The report goes into depth with statistics showing which cities have the highest (and lowest) percentages of jobs at risk. The cities with the lowest risk of jobs effected by automation have a cluster of skilled jobs and a strong technology sector.

The cities with the lowest percentages of jobs at risk of automation are:

- Boston: 38.40% (Percentage of jobs at high risk of automation)

- Washington D.C.: 38.40%

- Raleigh: 39.70%

- Baltimore: 40.40%

- New York: 40.70

- Bridgeport, Ct., : 41.10%

- Toms River. N.J.: 41.20% (Although Toms River is not a big city, this is not an error. The researchers defined labor markets by commuting patterns. Toms River and surrounding towns have a substantial group of commuters).

- Richmond, Va. and Minneapolis: 41.40%

- Denver: 41.50%

- San Francisco: 41.70%

The report found that the cities with the highest percentages of jobs at risk of automation are primarily manufacturing hubs. Carl Frey, one of the researchers and co-director of the Oxford Martin Programme on Technology and Employment said “Without efforts to create new industries, manufacturing cities are likely to experience continued decline,” referring to the decline of manufacturing in the U.S. since the 80’s.

The cities with the highest percentages of jobs at risk of automation are:

- Fresno: 53.8%

- Las Vegas 49.10%

- Greensboro: 48.5%

- Reading: 48.4%

- Grand Rapids: 47.9%

- Oklahoma City and Harrisburg, Pa.: 47.10%

- Los Angeles: 47%

- Dayton: 46%

- Sacramento: 45.9%

- Houston: 45.8%

“The key message of this report is that advanced and developing economies alike will have to shift a larger scale of the workforce into relatively skilled jobs,” Frey noted. “That is going to be the main challenge for China–to make sure that new industries make up for the job loss in manufacturing.”

Frey believes that the greatest growth in the U.S. will be in the healthcare sector saying “Nursing, elderly care, and child care are good examples of where we don’t see that many jobs disappearing in the future”. Other high growth areas noted in the report will be clean energy jobs such as wind energy operations, automotive engineering.

- Details

- Written by: Quintus Potgieter

- Category: Education

The recently released National Employment Report by Aspiring Minds has announced that 80% of India’s engineering graduates are unemployable. The report was based on a study of more than 150,000 engineering graduates in 2015 who attended more than 650 different universities. This has highlighted India’s need to upgrade the country’s education and training system.

CTO of Aspiring Minds, Varun Aggarwal said "Engineering has become the de-facto graduate degree for a large chunk of students today. However, along with improving the education standards, it is quintessential that we evolve our undergraduate programmes to make them more job centric."

The report goes to show that the Indian city that produces the highest number of employable engineering graduates is Delhi, followed by Bengaluru and the western parts of the country. Strong progress in the country is shown as employability by gender is almost equal for engineering graduates.

Methodology

The report is based on a sample of more than 150,000 engineering students from 650+ engineering colleges across multiple Indian states. All these candidates graduated in 2015. The analysis and findings of this report are based on the results of these students on AMCAT: Aspiring Minds Computer Adaptive Test, which is India's largest and only standardized employability test. AMCAT covers all objective parameters such as English communication, Quantitative aptitude, Problem-solving skills, knowledge of domain areas such as Computer Science and Programming, Mechanical Engineering, Electrical Engineering etc. for determining employability in the IT/ITeS & other core engineering roles. The test was conducted under a proctored and credible environment ensured by Aspiring Minds.

Employability has been quantified based on the benchmarking studies done at various companies in different sectors by Aspiring Minds. Currently, AMCAT is used by more than 3500 companies; including seven of the top-ten IT services companies in India, for their assessment and recruitment solutions. The benchmark for employability in a profile and sector is defined by a theoretical understanding and empirical validation of the knowledge, cognitive skills and domain expertise required. The benchmarks established for different profiles ensure both elimination of unsuccessful candidates for a job (elimination of type I error) and inclusion of all candidates who will be successful in the given job (elimination of type II error). The same has been validated among multiple companies in various sectors.

The report also covers a section on aspirations of engineers and a study which attempts to understand the factors which lead to an engineer getting a job in India. The data for the same was captured by means of a scientific survey on a stratified sample of about 27,000 engineers.

Together with the AMCAT scores, the various demographic details of the candidates are also captured by Aspiring Minds' testing platform, which enables a comprehensive and meaningful analysis provided in the report.

Employability by Gender

In India, there are 104 males for every 100 females making the male-to-female ratio (MFR) 1.04. In contrast, the MFR in engineering colleges is 1.68. This shows that a lower proportion of females make it to engineering courses as compared to males. This ratio is better as compared to last year's MFR of 1.72.

Conclusion of Report

One may observe that employability falls drastically towards the beginning and more gracefully towards the middle. This clearly shows that there are certain colleges which have excellent employability; however, other colleges even with close ranking show a drastic drop in employability. This is in line with the perception that certain colleges, such as the IITs and state-run colleges, are much better than others, which may be ranked just as highly. This is not a healthy trend, implying that deserving students in the other colleges find themselves cut off from better opportunities.

To further analyze this hypothesis, the study looked at the employability for the IT product role. One would expect to see a steeper trend, since IT Product employability is more strongly influenced by college education quality (rather than just intake) as compared to employability for IT Services companies.

One can observe that IT product employability falls to less than 10% at Rank 10, down from 32% at Rank 1, which is a fall of three times. On the other hand, for IT Services companies, this fall was only around 1.5 times.

In summary, the study found that the ratio of employability in top 100 colleges versus the rest is between two to six times depending on the role. In spite of this, more than 70% of employable candidates for any role are in campuses other than the top 100. With regard to employability distribution among campuses, the quality of education falls steeply among the top-ranked colleges which implies that colleges that are neighbors in rank have a very different quality of education. There are a large number of colleges with exceptionally low employability: bottom 32 percentile campuses have less than 1 in 100 candidates employable in the IT Product role and the bottom 20 percentile campuses have no candidate employable in the IT product role. Finally, we find that almost 41% of employable candidates for IT Services companies and 18% of employable candidates for IT Product companies are enrolled in campuses ranked beyond the top 750, thus forming an invisible pool to most employers in India.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

The so-called Fourth Industrial Revolution has had a lot of media coverage over the past year. This refers to the big upswing in developments in robotics, artificial intelligence (think of self-driving cars), genetics and cloud-based computing. This list goes on and on, of course.

The so-called Fourth Industrial Revolution has had a lot of media coverage over the past year. This refers to the big upswing in developments in robotics, artificial intelligence (think of self-driving cars), genetics and cloud-based computing. This list goes on and on, of course.

Dear Colleagues,

The so-called Fourth Industrial Revolution has had a lot of media coverage over the past year. This refers to the big upswing in developments in robotics, artificial intelligence (think of self-driving cars), genetics and cloud-based computing. This list goes on and on, of course.

The so-called Fourth Industrial Revolution has had a lot of media coverage over the past year. This refers to the big upswing in developments in robotics, artificial intelligence (think of self-driving cars), genetics and cloud-based computing. This list goes on and on, of course.

The First Three Industrial Revolutions

You may remember from your happy high school day that the first industrial revolution occurred with the mechanization of production using steam and water (often in ‘Satanic Mills’). The second one was when mass production using electrical power arrived (e.g. Henry Ford) and the most recent one was the digital revolution using electronics and IT in the late sixties – starting shortly before I launched myself with blind enthusiasm into my engineering education and career.

The Fourth Industrial Revolution

The fourth industrial revolution is underpinned by six design principles:

1. Interoperability through IoT and Internet of services

2. Virtualization

3. Decentralization

4. Real time access to data

5. Internet of Services

6. Modularity

As a result of this, the predictions are that 47% of workers in USA will lose their jobs in next 20 years; there will be downward pressure on developing country jobs and middle skill professions such as clerical work & customer services will disappear.

The full (sombre) report from the World Economic Forum is contained here: reports.weforum.org/future-of-jobs-2016

Do We See Any Impact?

If you look around you, you can see an impact from various forms of the fourth Industrial revolution from such items as the implosion of publishing newspapers, the demise of traditional printing, streaming music and movies and the drop off in postage services and so forth.

I would say that I doubt that the dire predictions are going to eventuate as there is always inertia in change. But we should certainly be tuned into handling the changes coming to avoid being dumped on the scrap heap. Well, the employment scrap heap that is.

How Best to Deal with these Changes

The suggestion from the pundits is that we need to continually reskill with a focus on STEM (Science, Technology, Engineering and Mathematics). I disagree with this blind assertion.

I somehow doubt that mathematics skills are required as much today as in years past - software does much of this these days. And I have met many highly skilled engineers and technicians who are unemployed or who are earning pitiful salaries. One also only needs to look around town at the enormous number of science graduates who can’t get jobs. So this is patently nonsense.

What I do believe is that the the age-old skills for success are still required – more than ever before - such as being able to communicate well, be pro-active and positive. And in being entrepreneurial and handling failure are also high up on the list of useful skills. We need more small businesses forming – most of which will undoubtedly fail – but in having a number succeed which then grow into larger enterprises which employ people.

What is Really Required

So this is what is really required. More engineering, technology and science entrepreneurs. Visionaries. Experimenters. Triers…..whatever…

I am not sure if Kelly Lynch has considered the impact on our environment but her comment is prescient:I just think we're living in a time of massive, amazing change, like the Industrial Revolution on acid.

Yours in engineering learning,

Steve

Mackays Musings 26th January16 #584

125, 273 readers www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

The PLC is surely one of the workhorses in industry – no matter whether you are in industrial automation, electrical or mechanical engineering, you are likely to be confronted with one of these little beasts - a Programmable Logic Controller or PLC (or indeed, Programmable Automation Controller – PAC)...

Dear Colleagues,

As the truism goes: Over 80% of malfunctions with PLCs are associated with Input/Output modules and field equipment. Frustratingly true for someone who spends most of her time programming the PLC without much regard for the field equipment. Download my presentation entitled: Troubleshooting PLCs and SCADA Systems from my regular Wednesday afternoon online sessions.

As the truism goes: Over 80% of malfunctions with PLCs are associated with Input/Output modules and field equipment. Frustratingly true for someone who spends most of her time programming the PLC without much regard for the field equipment. Download my presentation entitled: Troubleshooting PLCs and SCADA Systems from my regular Wednesday afternoon online sessions.

The PLC is surely one of the workhorses in industry – no matter whether you are in industrial automation, electrical or mechanical engineering, you are likely to be confronted with one of these little beasts - a Programmable Logic Controller or PLC (or indeed, Programmable Automation Controller – PAC). A critical cheap building block for all automated systems.

A few tips on troubleshooting these devices

The first decision is to decide whether the problem is internal or external to the PLC. Bearing in mind that most malfunctions are I/O modules and field equipment. Problems related to a specific I/O module or input/output device are generally external problems while large groups of failures are generally related to the internals of the PLC.

Internal problems - first cab off the rank

- Check that your earthing/grounding is correct. Inspect power and ground wiring. Check that voltage between PLC ground terminal and known ground is actually zero. You may need to log this over time with a scope to find pesky transient (intermittent) changes in voltage.

- Check the power supply to the PLC is operating within the correct ranges for both CPU and I/O modules (and that the ac ripple on your dc supplies is not excessive).

- Check batteries on PLC are still OK.

- EMC/EMI problems get more tricky – look for an EMC/EMI “event” such as motor starting/arc welding in the area or lightning strike which may match up with erratic behaviour of your PLC.

- Check the PLC program hasn’t been corrupted (occasionally on cheaper devices I have seen this happen much to my amazement). Ensure the program is backed up off-site when examining it.

- Check the internal diagnostics for a crash of one of your PLC programs or subroutines or some other error (e.g. divide by zero)

External problems – the more likely problem

The main issue here is to find out why your internal program and data status doesn’t match up with the external situation.

Digital inputs

- Check the power supply to the module.

- Look for where the power to a digital input comes from (not normally from the PLC I/O module).

- Check fuses, breakers and any other cause of power interruption to the digital input

- Check for adequate changes in voltage to the digital input when the external field device is operated.

- If the digital input is operating correctly and the CPU is still misreading it; the problem may lie in the PLC program.

Digital Outputs

- For digital outputs, check where the power is being supplied by. Often not from the PLC output card itself.

- Check the power output from the PLC.

- Check fuses (and fuse blown indicators).

- Force digital outputs on and off.

- Preferably use a test load (rather than open circuit it) when testing the PLC outputs.

Analog Inputs

- For analog inputs; move the field device (an instrument) through the full range of current (e.g. 4-20mA) and confirm this is reflected in the equivalent register in the PLC.

- If there is uncertainty here, hook up a signal transmitter and run through the full range of current (or voltage).

Analog Outputs

- For Analog outputs – in your PLC program force the output to a specific value and observe that the output reflects this. If not; check the external wiring and then the actual output, with a 250 ohm resistor for example.

The hazards of remote troubleshooting

Some of my recent forays increasingly have been into remote troubleshooting of PLCs located thousands of kms away. But this can be a hazardous occupation without enormous care taken with network security to ensure that some one located in Siberia or West Waziristan doesn't hack into your critical industrial control system.

A few thorny transient problems

In my experience in troubleshooting, I have been occasionally exposed to sudden overvoltages which blew a range of variable speed drives and PLC inputs (due to discharge of a capacitor bank with a very sharp transient). Other ones have been horrible harmonics introduced by a new drive. This required isolation of analog inputs to eliminate this (as we then had aliasing problems). Finally, data communications problems traced to common mode voltages surges and fixable by isolation (fiber optics) and improved earthing.

When in doubt; disconnect

And when testing a PLC, ensure that you disconnect any critical high powered equipment when testing outputs. One PLC programmer I know, accidentally started a 1MW ball mill accidentally when testing a tiny digital output from the PLC…...

Particularly true of troubleshooting PLCs is Oscar Wilde's comment: Education is an admirable thing, but it is well to remember from time to time that nothing that is worth knowing can be taught.

The only way to learn is by your own efforts in troubleshooting.

Thanks to Ryan G. Rosandich for a great article on Troubleshooting PLCs.

Yours in engineering learning,

Steve

Mackays Musings 19th January16 #583

125, 273 readers www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

You’re probably tired of hearing the hype about the Internet of Things (IoT). Well, I am getting a little overloaded.

As you probably know – the IoT is the magic carpet that will connect devices (mainly sensors), enabling seamless communications and monitoring/control from anywhere in your plant, home or indeed the world. After I did some initial research last year on what the real magic is, I have become somewhat disillusioned with the flood of articles on the IoT.

Dear Colleagues,

You’re probably tired of hearing the hype about the Internet of Things (IoT). Well, I am getting a little overloaded.

As you probably know – the IoT is the magic carpet that will connect devices (mainly sensors), enabling seamless communications and monitoring/control from anywhere in your plant, home or indeed the world. After I did some initial research last year on what the real magic is, I have become somewhat disillusioned with the flood of articles on the IoT.

There are predictions of massive growth with over 50 billion connected devices within the next five years (with 30% to 50% annual growth required to achieve this). Will this indeed happen and change your life? I have my doubts.

To be quite frank - the IoT is a pretty old concept - remember the good old radio telemetry systems where one connected to RTUs from centralized control systems over a radio network? Thanks to cheaper and smaller hardware and software and the internet, we have simply extended this concept to a wider range of items ranging from medical tracking to fitness to energy management at your home.

Remember the Fieldbus Wars?

Some of you may remember the clash between titans in the instrumentation world in the mid nineties. Essentially, between vendors promising to connect field devices and actuators together with tremendous benefits promised. Solutions proposed ranged from Profibus DP/ProfiNet/ASiBus/Lonworks to Foundation Fieldbus/HSE with Ethernet also being proposed. It was an all or nothing race – only one communication solution was going to work and you had to choose.

It turns out that there are a horde of possibilities being used today ranging from the above with Ethernet/ TCP/IP and the venerable Modbus solution playing a role today. The key has been easy connectivity between the different communications solutions and a focus on business benefits.

Not Everyone Believes the Huge Growth of IoT

There are many who are ‘pooh poohing’ the massive growth in IoT with some pundits saying that if you as a company hitch your wagon to these growth predictions; you are likely to be seriously disappointed and financially out of pocket.

Where does the IoT start and finish?

As usual the home is one of the key areas for IoT. The IoT provides for easy connection between your thermostat, energy and security systems – all connected to the internet and controlled by your smart phone. Inevitably one of the first and major problems with this architecture is the lack of a common communications infrastructure. A veritable Tower of Babel where everyone is using their own protocols to connect their own devices.

There is no evidence that consumers want everything connected together as there are no immediate benefits. Apart from a few vague benefits in connecting remotely to your home to check it out when you are on holiday in the Seychelles.

As has been the case for the past 40 years – solid growth for IoT is undoubtedly in industrial plant, factories, pipelines and utilities where more devices will be installed at far lower costs with seamless connectivity possible. Other opportunities are in tracking parcels, telemedicine and healthcare.

A few Challenges Along the Way

As usual – there is no working business model yet. Hence the hype. And the software to analyze the ferocious amount of data needs to be put in place with demonstrated successful applications. Naturally, one of the issues that fills me with the ‘heebie jeebies’ is the need for solid cyber security to avoid the inevitable remote thugs taking over your plant and doing horrible things to it.

I am sure we will get there with the IoT with a great (business) working model. But it will take a bit longer than is predicted.

Bearing this in mind – keep researching the market and keep up to date with what is happening – you may find an application for your products with great business benefits.

Thanks to Lou Frenzel in Communiqué writing about The Internet of Things: Hype, Hope, or Hit? for an interesting dissertation.

Yours in engineering learning,

Steve

Mackays Musings 12th January’16 #582

125, 273 readers www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

In my bookshelf, I have a marvelous engineering book from 32 years ago entitled: The Robotics Revolution by Peter Scott inscribed in my rather youthful hand: 6th Nov. 1984 London. With fairly minimal mention about software - focussing more on the mechanical, electrical and control aspects. However today at the beginning of 2016 one of the overriding trends are based around ‘The Robots are definitely coming’.

Dear Colleagues,

In my bookshelf, I have a marvelous engineering book from 32 years ago entitled: The Robotics Revolution by Peter Scott inscribed in my rather youthful hand: 6th Nov. 1984 London. With fairly minimal mention about software - focussing more on the mechanical, electrical and control aspects. However today at the beginning of 2016 one of the overriding trends are based around ‘The Robots are definitely coming’. Big time. With a huge focus on software and artificial intelligence.

My modest suggestions on top trends in the technology areas for this year include:

- Machine Learning, artificial intelligence and rapidly increasing robots/automation. Robots will continue to surpass and overtake what we as humans can do esp. in managing the huge amounts of data. From autonomous driving cars to drones to traditional administrative tasks resulting in a hollowing out of middle level jobs with the roboboss (yes!) becoming a reality for many today. Naturally, we need imaginative designers and engineers to create these devices.

- Internet of Things (IoT) and a super-interconnected world – solid growth in connectivity with sensors (and actuators) although (as we can surely remember from the Fieldbus wars) a lack of standardization makes it all very fractured at present. By 2020, 25 billion sensor devices will be generating data (Gartner). How do we handle this volume?

- Cybersecurity and cybercrime. I reckon most of us have been touched by virus attacks, assaults on our bank accounts and IT systems. Security must be built into everything we do rather than as an afterthought. Digital thieves are smarter than ever and are proliferating at an alarming rate. We are under constant attack and need to be vigilant. Esp. with our industrial infrastructure now connected to the internet.

- Smart Phones becoming your primary tool for Everything. They have already become a key mobile tool in our homes and businesses and indeed in our industrial plants. I just wish the batteries would last longer. Have you used your smart phone to measure voltage and current yet?

- Virtual and augmented reality finally working. With the arrival of the Oculus Rift viewer and other related low cost devices, one can get a brilliant virtual experience. Esp. valuable for training and entertainment. All conducted at remote locations.

- Cloud computing working more widely in the industrial world. This will barrel along with greater emphasis where software will be centralized and easily accessible. This will reduce the need for IT expertise (such as networking) at each individual firm as all fixes/configuration will be done at a central cloud-based server. There are still enormous (justifiably I might add) concerns about protection of data in the cloud.

- Drones (or UAVs) being applied to Business. Drones (and hover boards!) growing strongly and being allowed to make deliveries and perform other mundane public tasks.

Can you identify other trends which I have missed?

An interesting comment from Cynthia Breazeal: If you look at the field of robotics today, you can say robots have been in the deepest oceans, they've been to Mars, you know? They've been all these places, but they're just now starting to come into your living room. Your living room is the final frontier for robots.

Take Advantage of these trends in your career, personal life and education. There are huge opportunities for training and education in these areas ranging from virtually free to extensive and expensive.

Thank you BBC News, Gartner (Darryl C Plummer) and Forbes (Peter High) for an interesting summary of your predictions. Please forgive me for not clearly delineating machine learning/artificial intelligence more finely.

All the best for a fabulous 2016 – I hope it meets all your expectations. Above all, stay healthy and maintain your happy personal connections – whether it be family/friends or colleagues.

Yours in engineering learning,

Steve

Mackay’s Musings – 4th January’16 #581

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues,

“The grass is always greener on the other side of the fence” can really gnaw at you. How can you make sure that you’re being paid what you are really worth? Essentially your remuneration is based on the contribution you make to the business you work in. Whilst long hours are commendable, you will inevitably find the firm’s salesman lounging down at the beach during working hours drinking copious cappuccinos and earning double what you earn. Despite your engineering qualification, enormous hours and stress that you work to keep the production facility operating.

Not particularly fair, one would say. But things that impact on pay include: education, formal and informal training, technical experience, size of the company, responsibility level and part of the country you work in, and finally simply – supply and demand.

Education

During the dot com era, many thought a university degree was increasingly irrelevant especially in the IT area. However there is no doubt that a good degree from a good college is an essential ingredient. If you gain the ability to think logically and read and write beautifully and be committed to outstanding project management skills you will have a good future in the earnings stakes. However an advanced degree such as a doctorate may be counterproductive in terms of scaring potential employers off. And you have to find a really niche job to fit this requirement. This may be difficult.

Formal and not so formal Training

Most firms appreciate their staff constantly sharpening their skills by attending (relevant and good) courses. And learning from others in the firm in a more informal way. Actively seeking out new know-how from experts and applying this new found knowledge vigorously to new projects is also highly regarded. All of these are you investing in yourself and making yourself more valuable.

Technical experience

This is often the hardest fought skill you have. Sadly, the technical part of it ages very quickly. Although I would respectfully suggest that the management skills only mature with use and make you even more valuable. So keep sharpening your skills in this area. This must be one of the most important skills you are measured on when you are being offered a job.

The part of the country you work in

Depending on where you live may impact on your income. Some remote locations such as in the Middle East salaries can be high. But your costs are high and life style can be quite challenging compared to suburbia in a “nice western” country. So weigh this up carefully. It always fascinates me when I see Indian nationals returning to India and leaving secure US jobs behind because they prefer to be with family and the local culture, perhaps.

Business experience

Most technical professionals focus on the issues that are near and dear to them. Engineering projects and detailed technical issues. But if you can understand why and how the project is important to your firm and actively ensure the project is aligned with the business issues, the more valuable you will be.

And finally – supply and demand

New trends sweep the job market and engineers with skills in these areas become very valuable. When PLC’s arrived on the scene in the early seventies, any engineer who could program these beasts and mange an entire engineering project was highly sought after. Now electricians can do a lot of this basic programming. During the dot com boom naturally it was engineers with a strong Java and database skills in great demand. So when you have a highly sought after skill you can charge a premium. But watch for more entrants coming into this area and eventually bringing your “value” down.

How do you gauge your worth?

The inevitable source of information on this are the job boards on the internet sites or employment columns. However user groups – of which there are a burgeoning number on the internet, can be a great source of information. If all your engineering peers are on $150 per hour; you can bet your bottom dollar this is the going rate and you had better do something about it if you are earning below this. Many professional magazines publish regular salary surveys and prove interesting reading. The jobs that have large variances are often difficult to interpret but nevertheless worthwhile cogitating on.

To sum up

Overall, I believe having a job is akin to surfing. You can ride a really good wave for a while but eventually when you hit the shore you have to paddle back and look for the new wave. With different characteristics and twists and turns.

So keep your skills broad and deep enough to ride out the changes in the technology that will undoubtedly sweep through your firm. And watch the state of the market as to what is required. I remember leaving engineering school where there was a massive demand for electronics engineers, then software engineers; and then the internet and so forth. Some jobs seem to truck along well through all sorts of economic storms – such as those engineers working in the (perhaps) less exciting power engineering area.

The advice from the US president Theodore Roosevelt on jobs is certainly an interesting one (a reflection of the Yankee “can-do philosophy perhaps?): Whenever you are asked if you can do a job, tell 'em, 'Certainly I can!' Then get busy and find out how to do it.

Thanks and acknowledgements to Patrick von Schlag for his input here.

Yours in engineering learning,

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

In the past few years; we have seen some spectacular collapses of buildings and bridges. This is quite inexplicable to today’s structural designer and engineer who puts enormous effort into the careful use of materials and huge safety margins. However, when a designer is operating at the limit of their expertise; mistakes still occur...

Dear Colleagues,

In the past few years; we have seen some spectacular collapses of buildings and bridges. This is quite inexplicable to today’s structural designer and engineer who puts enormous effort into the careful use of materials and huge safety margins.

However, when a designer is operating at the limit of their expertise; mistakes still occur. One of the questions with the Deepwater Horizon oil rig which exploded with massive damage was in the use of cement (coupled with nitrogen gas) a few kms under the seabed – as to whether it did indeed have the strength required to prevent a massive gas and oil surge. As we know, cement as a proven structural material has been around since Roman times – but for perhaps more predictable environments.

The typical approach a structural engineer follows when assessing materials for safe use and which would give some background to the building you live in, is as follows.

Lab Testing

All materials used are extensively lab tested to determine their structural properties such as tension and compression under loading. The design strength actually used is considerably lower than these figures.

Design Strength Varies Depending on Materials

The calculation of design strength varies from concrete and steel which are fairly predictable and of uniform quality to wood which is rather varied. Wood is considerably more variable in strength as it could have an unusual number of knots or come from a diseased tree. Thus the safety margin has to be considerably higher.

For example, the Douglas fir, has a safety margin of 5.5 (versus 1.4 for Steel). For example, Douglas fir has a compression maximum strength of 51 MPa (7430 psi) and based on the safety margin of 5.5; a design strength of 9.3MPa (1350 psi).

However, (as we know from the Twin Towers disaster) steel can have problems for structural support. As you may recall it is weak in fires and must be protected in all buildings.

Additional Safety Margins

Structural engineers build in additional safety margins by overestimating the dead and live loads and selecting supports one size up from what the design suggests.

Beware when you are at the Limits of Technology

However, despite all this care; you have to be careful about operating at the limits of technology and as to whether you will see sudden loads well in excess of what you designed (DeepWater Horizon) or indeed, your materials exposed to conditions they were never designed for (Twin Towers).

Thanks to 101 Things I learned in Engineering School by John Kuprenas with Matthew Frederick.

Andrew Heller makes an interesting point: Technology is like a fish. The longer it stays on the shelf, the less desirable it becomes.

Yours in engineering learning,

Steve

Mackay’s Musings – 8th Sept.’15 #581

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

When you have a permanent job in a company, your income is pretty certain. But in the cruel but real world of consultant and contractor, life can be considerably more complex and fraught with hazard when dealing with contracts. Remember if you don’t handle these correctly, you will end up considerably poorer despite putting in an enormous amount of hours working...

Dear colleagues,

When you have a permanent job in a company, your income is pretty certain. But in the cruel but real world of consultant and contractor, life can be considerably more complex and fraught with hazard when dealing with contracts. Remember if you don’t handle these correctly, you will end up considerably poorer despite putting in an enormous amount of hours working. So it is worth re-considering the different options here as discussed below.

Simplistically put, as a consultant or contractor, you can bid for work in three ways.

Fixed price contracts. These arrangements lock you into a price. Generally, come hell or high water, whatever happens, this is the price you as the consultant or contractor get paid.

Time and materials. You get paid for both your hours spent on the job as well as the materials supplied to the client.

Two phase contract. In the first phase, you get paid on a time-and-materials basis to define the job to both yours and the client’s satisfaction and then in the second phase you actually perform the contract on a fixed price (or sometimes time and materials basis).

Fixed price can be a Gamble

If you know exactly what has to be done and how long it will take and the project is actually achievable (many aren’t – particularly in software development – and I have been there a few times); then this is a great option. But if the outcomes are uncertain and the project is badly defined, you are playing with fire going for a fixed price contract. Sadly enough, many clients know exactly how difficult and risky a particular job will be and go for a fixed price and “lure” a contractor or consultant in to do the job so that they remove all risk for them personally. They are simply after a rock bottom price.

Interestingly enough on the other side of the coin, I see that many contractors go for fixed price contracts knowing full well that they will be able to “drive a bus through the contract” when it comes to negotiating at the end of the job exactly what they will get paid. We had a particularly tough case recently here with an underground tunneling contract which was fixed price (no matter what the consistency of the earth and rock was); but the contractor actually ended up getting compensated for his risk as he incurred substantial additional costs. The client wasn’t too enthused with the thought of lengthy litigation and inability to use the tunnel for an extended length of time so after jumping around for a while, paid up the additional costs.

If you are forced into going for a fixed price contract and the definition of the job is still a bit uncertain, then ensure that you define exactly what you are going to provide in the contract, in terms of hours and materials and some rate of compensation for when the project specifications change. You may find that if you do this precisely enough, you will end up making more money from the variations to the contract than the actual main part of the contract! A popular strategy followed by some control system vendors who bid a very low fixed price (and thus won the job against fierce competition) with the full knowledge that the variations would compensate them handsomely. If you as the client take on these fixed prices jobs; you will have to spend an inordinate amount of time defining all the terms and conditions and contemplating all eventualities otherwise you are up for considerably more money than originally anticipated.

Sometimes fixed price contracts don’t work too well in odd ways. On one particularly acrimonious job we were advising the client on (for building a Gas Turbine power station); we defined everything extraordinarily clearly and ended up with a fixed price job. Unfortunately the contractor didn’t factor in the risk for writing the control system software and the client had an awkward choice at the end. Either let the contractor go bankrupt and not finish the power station construction or pay more money for the unexpected variations the contractor hadn’t factored in (and thus keep him in business). The client ended up paying well above the fixed price but despite this, after a few months the contractor still went bust. Resulting in the client having to complete the job with the attendant risk now shifted onto her.