Developments

- Details

- Written by: Quintus Potgieter

Concrete batteries? It seems that civil engineering and mechanical engineering have met in the middle for a new type of energy storage.

A Swiss startup named Energy Vault has showcased an unorthodox experiment — they have stacked concrete blocks via an electric crane, and in doing this, stored energy.

The startup compares the phenomena to pumped hydroelectric energy storage. Quartz reports that 96 percent of the world's energy storage capacity comes from pumped hydro. This means whenever there is a surplus of electricity, the excess is used to pump the water up into a dam. Then when there is a demand for electricity to be generated, the water falls with the help of gravity. As it descends, the water turns the turbines to produce potential energy.

However, this method can be problematic. What about areas that don't have access to dam water and the subsequent turbines that enable pumped hydro? Well, Energy Vault says stacked concrete could be the answer.

Simply put: when you elevate something against gravity, it stores energy. When it falls, you recover that energy. This is the theory behind Energy Vault's

new system. A crane, with an electric motor, picks up concrete blocks and stacks them in a tower, storing excess energy. Then, the blocks can be dropped from the stack while the motors are run backward and a generator shaft is used to produce the electricity. The startup envisions a 120 meter (400 foot) tall crane that lifts and stacks blocks all around it. The crane is powered by renewable energy like solar or wind — a computer then tells the crane where the concrete blocks are, and a camera assists, too. The block is then lifted, and a stack of concrete blocks begins.

The total energy in a full tower of concrete blocks as pictured above is 20 megawatt-hours (MWh). Quartz reports that it's enough to ‘power 2,000 Swiss homes for a whole day'. The startup is confident that a lower quality concrete can be produced for the plants specifically so they can continue generating energy all day long.

The experimentation is still in its early stages and being performed on a small scale. But, any energy storage applications that could be applied worldwide would be welcomed by governments who are trying to rely less and less on fossil fuel technologies to keep the lights on.

Gravity trains

Some electrical engineers on social media have questioned how viable the concrete block stacking is. Some other engineers point to train regenerative braking as a better option. In California, a company named ARES (Advanced Rail Energy Storage System) has implemented a grid-scale energy management system that is capable of providing utility balance when it is needed.

The system utilizes 300-tonne autonomous train-like vehicles on a train track. When a power utility is in need of power, the vehicles - who would have made their way uphill when the utility had an excess of power - would begin their descent downhill. Their motors then become energy generators and generate electricity in the act of traveling downhill and then braking. The cabs have rocks in them so that they are weighted down and faster when coming downhill.

Here is an example of what it looks like:

Works Cited

Rathi, Akshat. “Stacking Concrete Blocks Is a Surprisingly Efficient Way to Store Energy.” Quartz, Quartz, 30 Aug. 2018, qz.com/1355672/stacking-concrete-blocks-is-a-surprisingly-efficient-way-to-store-energy/.

“Surplus Energy Rides the 'Gravity Train' - BBC News.” BBC, BBC, 28 June 2018, www.bbc.co.uk/news/av/technology-44549962/surplus-energy-rides-the-gravity-train.

- Details

- Written by: Quintus Potgieter

Electrical engineering professionals will have to roll with the punches as new technology takes over the quarrying business and sends the industry into the future. Volvo Construction Equipment and partner Skanska are testing an Electric Site project — a quarrying operation of the future that will look completely different to anything that has come before it.

It's all going down at Vikan Kross quarry. The group is experimenting with new concept machines, work methods, and brand new site management systems, which have never been tested at a quarry before. They are focusing on electromobility and automation to meet new emissions targets — a move that will set the bar for the mining industry for some time to come.

Gunnar Hagman, CEO of Skanska Sweden said:

“This is the first time that anything like this has been attempted in the quarrying industry and, if successful, Electric Site could serve as a blueprint for transforming the efficiency, safety and environmental impact of quarries around the world.”

On 29 August 2018, the engineers were ready to debut their new Electric Site. For ten weeks, the autonomous Volvo machines will engage in production. They will only emit 95 percent of the emissions that a normal mining setup would produce. The companies will also spend 25 percent less than they would have with the old technology. The engineers have electrified each level of the transport stages in the quarry. Hagman said:

"We have to completely rethink the way we work and how we look upon machine efficiency — pushing the boundaries of our competence. The total site solution we developed together with our customer Skanska is not a commercial solution for sale today and we will evaluate the outcome of the tests but we have learnt so much already, elements of which will be fed into our future product development."

The quarry is utilizing eight prototype HX2 autonomous battery-electric load carriers. These fully electromobile vehicles will carry the extracted resources from the quarry. The engineers had initially tested out a first iteration of the load carrier called HX1. Once they had confirmed the electric drivetrain was capable of being driven by the battery technology they went ahead with producing the HX2.

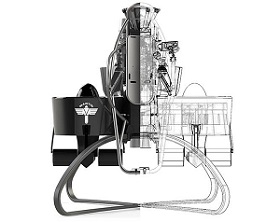

The engineers then went on to fit previously emission-emitting technologies with electric motors. A primary crusher excavator prototype was born, ready to work on the site. One benefit of electric motors is that the site is much quieter than a normal quarrying site. But Chief Project Manager for Electric Site at Volvo CE Uwe Muller explains just how complicated an electric upgrade to an excavator is:

"To fit the new components in the machine without increasing its size required a significant amount of repackaging work. However, in terms of the operator interface and controls, nothing has changed - it's operated in exactly the same way as a conventional Volvo extractor. If the cable is connected, the machine will automatically start in electric mode. If it's not, it will start in diesel mode. Because the machine will be relatively static - only moving a few meters once or twice a day as the excavator works its way through the blasted rock - it's ideally suited as a fully electric machine on a cable."

The thinking behind this reflects the kind of renewable energy setups at mining setups. Some mines have solar panels and diesel setups so that when the renewables cannot pick up the slack, it can default back to diesel generators and continue powering the mining operation. Muller continues:

“This has allowed us to make it a zero-emission excavator when it’s plugged into the grid. However, we’ve designed it with flexibility in mind, so that we can have the option of using the diesel engine when it’s needed, for example, to reposition the machine or quickly movie it prior to blasting.”

Works Cited

Casey, JP. “Volvo and Skanska Begin Tests at Prototype All-Electric Mining Site.” Mining Technology, 4 Sept. 2018, www.mining-technology.com/news/volvo-skanska-begin-tests-prototype-electric-mining-site/.

“Testing Begins at World's First 'Emission-Free' Quarry.” Volvo Construction Equipment, www.volvoce.com/global/en/news-and-events/news-and-press-releases/2018/testing-begins-at-worlds-first-emission-free-quarry/.

- Details

- Written by: Quintus Potgieter

A lot of infrastructure lies underneath bodies of water. Take, for example, the SEACOM Subsea Cable system that provides Internet infrastructure to the African continent — any maintenance on it is done undersea. Presently, a fleet of ships remain ready to be sent out when a fault occurs, with repairs performed by divers.

Underwater bridge and structure inspections are also vital activities conducted by engineering specialists. Oil rigs and wind turbines are no different — they too need to be studied and maintained underneath water.

In future, underwater infrastructure monitoring, maintenance, and repair will — and probably should — be conducted by waterproof robots.

However, what robots face underneath the ocean surface is often treacherous. There are many factors that they have to deal with when undersea, such as; waves, currents and eddies.

Professor of Mechanical Engineering at Stevens Institute of Technology, Brendan Englot, said robots naturally struggle to get their bearings underwater, which presents a unique challenge for artificial intelligence.

“There are so many difficult disturbances pushing the robot around, and there is often very poor visibility, making it hard to give a vehicle underwater the same situational awareness that a person would have just walking around on the ground or being up in the air,” he said.

Englot and his team have decided that instead of programming robots to achieve outcomes, they will let the machine do the learning instead. They purportedly do this through the use of an algorithm.

The team puts a robot in the water with the task of mapping a particular area. They collect the data and design an algorithm that provides the robot with new situational awareness when it is put underwater again.

Despite the changing underwater environment, the robot does indeed traverse the area more ably. This method is known as ‘reinforcement learning’ — a method that doesn’t rely on finalized mathematical models and Englot’s team concedes there is still room for improvement.

Utilizing sonar technology, the robot emits high frequency noises and calculates its position with reference to the sounds bouncing off surrounding objects. The team of engineers indicates that the robot could be sent for a second pass-by, utilizing a camera as well. They believe that combining the sonar measurements, corroborated by what a camera can see, could lead to some pretty efficient situational awareness for underwater robots.

Englot recently sent a robot to map out a pier in Manhattan.

“We didn’t have a prior model of that pier. We were able to send our robot down and it was able to come back and successfully locate itself throughout the whole mission,” he explained.

The algorithm is still in its early stages and the technology is still developing, but the future looks bright for self-learning robots that can be sent into dangerous underwater situations.

Works Cited

Editor, Ryan Daws. “AI Robots Will Solve Underwater Infrastructure Damage Checks.” AI News, 20 July 2018, www.artificialintelligence-news.com/2018/07/20/ai-robots-underwater-infrastructure/.

Loughran, Jack. “Robots Taught to Navigate Complex Sea Currents with Algorithms.” RSS, 20 July 2018, eandt.theiet.org/content/articles/2018/07/robots-taught-to-navigate-complex-sea-currents-with-algorithms/.

- Details

- Written by: Quintus Potgieter

Those kids with their laptops could just change the world!

Millennials are the first generation to have the best of technology at their fingertips. Some are using it to tackle projects in a world of aging and often inadequate infrastructure.

With climate change overwhelming drainage systems all over the world, for instance, a downpour can lead to flooding. South Africa, Japan, and the United States have recently seen flooding in areas with infrastructure that was designed for more moderate weather patterns. Storm water drains simply can’t keep up with the volume of water in a climate worsened by fossil fuel emissions and general climate change.

The Department of Civil Engineering at McMaster University in Canada in 2015 released a report in the Journal of Hydrology. Author James D. Miller wrote:

“A number of future climate projections indicate a likelihood of increased magnitude and frequency of hydrological extremes for many regions around the world. The urban storm-water management infrastructures are designed to mitigate the effect of extreme hydrological events. Changes in extreme rainfall events will have a significant implication on the design of stormwater management infrastructures.”

Startups, millennials and entrepreneurship

Brazil is a country facing such challenges. And even if there was a solution, the country would not be able to afford to implement it.

Enter two engineers based in São Paolo, Brazil: Diogo Tolezano and Pedro Godoy. They have initiated a startup called Pluvi.On. They have developed a weatherproof tool that can measure rain and predict if floods are expected — a type of rain gauge called a Pluvi. If a flood is forecast, preventative measures can be taken or warnings can be given, based on the data recorded by the device.

They outlined the dire situation in Brazil and provided some insight into their own motivation:

“….today approximately 30 million Brazilians are directly impacted by floods every year. And there is a projection…. by 2030 a loss of US$4 billion...lost homes, furniture, vehicles…”

The startup is being assisted financially through the Red Bull Basement hacker residency. The residency develops projects that offer solutions to issues in urban spaces. They assist with spaces to create, mentorships and more.

Their foresight and funding of projects for engineering startups will help empower other millennials endeavoring to create technologies that could greatly help the globe.

Tolezano and Godoy were determined to act rather than wait for their government to do something. They decided to develop the technology themselves and get extra backing from Red Bull to implement the technology and test it out. The engineers told Red Bull:

“When we look at the impact of floods, it really is a relevant problem. We wanted to use our knowledge to make a positive impact on cities. If we don’t get our hands dirty, it’ll take a long time before anything happens.”

They developed the rain gauge and opened it up to the public as an open source project. Now members of the public can find all the information necessary to create a Pluvi of their own.

The gauge is made up of a plastic box that allows rain in. The water goes into a plastic bucket that measures the amount of rain coming down. Using an ESP chip inside the box, data is generated and sent to the cloud, ready to be perused. The tilts of the plastic bucket inside the enclosure are measured, the number that is generated assists with the flood predictions.

In the two months of the Red Bull residency, they built the enclosure, put in a data integration platform, and ensured that they could get the data forwarded to the people who needed it most.

When their first prototype debuted the entire setup cost US$190. This was subsequently reduced to US$130. Development of the fourth prototype only cost US$50. Thanks to these inventive, proactive and community-spirited men, a network of 20 gauges around the city are generating and uploading data.

Being an entrepreneurial engineer is within reach. Starting with very little, as Tolezano and Godoy have shown, improvements to one’s immediate community are possible.

Diogo Tolezano said:

“The idea is to have real time information. So, as soon as the rain starts we can identify its behaviors and patterns, and then, mainly according to its intensity, we can let the population know with some time in advance.”

Works Cited

Red Bull, www.redbull.com/za-en/projects/red-bull-basement.

“The Impacts of Urbanisation and Climate Change on Urban Flooding and Urban Water Quality: A Review of the Evidence Concerning the United Kingdom.” Egyptian Journal of Medical Human Genetics, Elsevier, 8 July 2017, www.sciencedirect.com/science/article/pii/S2214581817300435.

- Details

- Written by: Elyse Simich

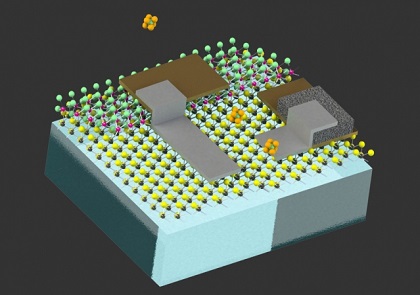

Robots the size of a human egg cell, with the ability to sense their environment, have been created by researchers at the Massachusetts Institute of Technology (MIT). It’s hoped that they can eventually be used to monitor pipelines in the oil and gas industry to check for leaks and other issues. It’s also possible that they could be used for diagnostic purposes, by passing through the digestive track to check for inflammation or other signs of disease.

These robots consist of tiny electronic circuits made from two-dimensional materials, which piggyback on miniscule particles, known as colloids. These insoluble particles can be anywhere from one millionth to one billionth of a metre across. Their tiny size enables them to stay suspended indefinitely in liquid or air.

These robots consist of tiny electronic circuits made from two-dimensional materials, which piggyback on miniscule particles, known as colloids. These insoluble particles can be anywhere from one millionth to one billionth of a metre across. Their tiny size enables them to stay suspended indefinitely in liquid or air.

Senior author of the study Michael Strano said the research team had wanted to find a way to graft complete electronic circuits onto colloidal particles.

“Colloids can access environments and travel in ways that other materials can’t,” he said.

While they may be the smallest robots ever, they have the ability to store data and complete computational tasks. They are self-powered by a simple photodiode, which provides them with enough electricity to function. This means they don’t require an internal battery or an external power source.

Currently, leaks and other issues within pipelines are found when crews physically drive along them using expensive equipment. In theory, these new robots could be inserted into one end of a pipeline, carried along with the flow, and then removed at the other end. During that time, they would have recorded the conditions they encountered, such as contaminants or the location of problem areas.

Right now the devices don’t have a timing circuit with the ability to indicate the location of the data readings. However, this is something the research team is working on.

Other research teams have been working on creating similar robots; however, Strano said their focus is on developing ways to control movement. For example, may teams have worked on creating tail-like flagellae; inspired by the way some microbial organisms propel themselves. Strano said he believes this isn’t the best approach as these movement systems are mostly used for local-scale positioning rather than for significant movement. He suggested it’s more important to make these robots functional rather than mobile.

- Details

- Written by: Quintus Potgieter

Battery life. If we could figure out how to lengthen it exponentially, the world would be a better place. And that seems to be what the researchers at the National University of Singapore (NUS) have - almost –achieved. They have invented a smart microchip that can continue powering a device even when the battery of the said device has been depleted.

In the not-so-distant future the technologies associated with the Internet of Things (IoT) will demand connectivity around the clock; to assure the safety and efficiency of businesses’ hardware.

Sensors, for example, are technologies that require 24/7 uptime; they need power sources to continue running. Because any number of sensors are required in a single process, they also need to be as small and as unimposing as possible – a significant challenge because smaller batteries do not have the capacity of their bigger counterparts.

The engineers from NUS designed a microchip to circumnavigate the battery life problem in batteries - and they’ve called it ‘BATLESS’. Using a tiny chip with an even tinier solar cell placed on top of it, the microchip uses light (even if its dim) to continue powering itself when the battery is depleted.

Associate Professor Massimo Alioto from the Department of Electrical and Computer Engineering at the NUS Faculty of Engineering said:

“We have demonstrated that batteries used for IoT devices can be shrunk substantially, as they do not always need to be available to maintain continuous operation. Tackling this fundamental problem is a major advancement towards the ultimate vision of IoT sensor nodes without the use of batteries, and will pave the way for a world with a trillion IoT devices.”

The batteries that these microchips can help power are ten times smaller than existing IoT node batteries and are consequently ten times cheaper to produce.

How it works

The battery and microchip power management solution is truly fascinating. The battery works as a normal battery would: The battery utilizes all its energy when powering something. However, when the battery life runs out, the smart-chip switches into a mode known as ‘minimum-power’. The chip then uses half a nanoWatt until a new battery can be replaced, but continues to power optimally.

Professor Alioto says:

“BATLESS is the first example of a new class of chips that are indifferent to battery charge availability. In minimum-power mode, it uses 1,000 to 100,000 times less power, compared to the best existing microcontrollers designed for a fixed minimum-energy operation. At the same time, our 16-bit microcontroller can also operate 100,000 times faster than others that have recently been designed for fixed minimum-power operation. In short, the BATLESS microchip covers a wide range of possible energy, power, and speed trade-offs, as allowed by the flexibility offered through the two different modes.”

The engineers say that the BATLESS microchip will be a perfect fit for ‘smart buildings, environmental monitoring, energy management, and adaptation of living spaces to occupants’ needs’. Utilizing the minimum power mode, the microchip can still ensure that data gets sent to the relevant mechanisms even when battery life isn’t present.

Works Cited

NUSingapore. “NUS Engineers Invent Smart Microchip That Can Self-Start and Operate When Battery Runs Out.” EurekAlert!, www.eurekalert.org/pub_releases/2018-05/nuos-nei050318.php.

“Smart Microchip Keeps Going When Batteries Run Dry.” Futurity, 26 June 2018, www.futurity.org/smart-microchip-batless-1794752/.

- Details

- Written by: Quintus Potgieter

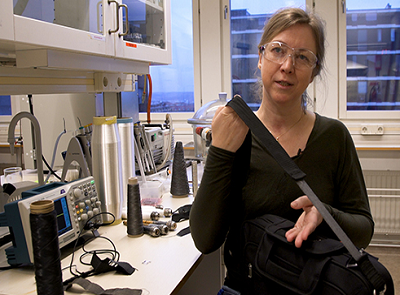

In the 22 March edition of the Nature Partner journal of Flexible Electronics, a report was published that might just redefine our clothing of the future.

The Swedish School of Textiles and research institute, Swerea IVF, conducted studies on how electrostatic power can be generated from textiles. Researchers from Chalmers University of Technology put those studies to the test.

The researchers used what is known as a piezoelectric material. These are materials that generate an electric charge when put under mechanical stress. Cigarette lighters utilize Piezo ignition by slamming a hammer into a crystal that then ignites the gas. It also powers camping stoves, gas lights, and gas grills.

Engineers have envisioned, for some time, a world where piezoelectricity could power everyday items through kinetic energy.

Researchers at Chalmers University of Technology have designed a fabric that converts kinetic energy into electric power using piezoelectric means. Using piezoelectric yarn the researches have designed a textile which carries an electric current when stretched (this applies the mechanical stress to the material).

One of the researchers, Anja Lund explains:

“The textile is flexible and soft and becomes even more efficient when moist or wet. To demonstrate the results from our research we use a piece of the textile in the shoulder strap of a bag. The heavier the weight packed in the bag and the more of the bag that consists of our fabric, the more electric power we obtain. When our bag is loaded with 3 kilos of books, we produce a continuous output of 4 µW. That’s enough to intermittently light an LED. By making an entire bag from our textile, we could get enough energy to transmit wireless signals.”

The researchers say the stretching of the textile has generated a charge that produces enough power to ‘light an LED, send wireless signals or drive small electric units such as a pocket calculator or a digital watch’. The only problem? The signals are intermittent.

Using a heavy bag with the piezoelectric textile fitted to the shoulder strap, the researchers demonstrated how they could power an LED. Lund believes that sensors can be ultimately powered by the textiles.

The textile works even better when it becomes wet and therefore heavier. It follows then that when exercising and sweating while wearing these textiles, they have the potential to power sensors and generate enough power to connect via Wi-Fi to an Internet of Things network (freely available around every corner in the future).

Works cited:

Electric textile lights a lamp when stretched. https://www.chalmers.se/en/departments/chem/news/Pages/Electric-textile.aspx

- Details

- Written by: Quintus Potgieter

Imagine for a second the kinds of innovation that could occur if MIT (Massachusetts Institute of Technology) and BMW joined forces. Well, stop imagining. The two have joined forces. But, not necessarily in the way you might have thought. The university and the car manufacturer have linked arms, and are ready to harvest their latest obsession: air.

The engineers from MIT’s Self Assembly Lab and BMW have created a new 3D printed structure utilizing a process known as ‘Liquid Printed Pneumatics’.

The interdisciplinary collaboration between engineers and labs has created the first material that can morph from one shape into another shape - thanks to air...and rapid liquid printing. The printer emits the necessary liquid material into a mould which then hardens.

The printer is able to print 100 percent silicone rubber into sophisticated structures, structures like air chambers. These ‘air pockets’ can inflate or deflate based on how they are ‘programmed’. Traditional 3D printers have struggled to perfect sizeable prints and have stuck to small-time hard plastic prints. But now, with the new fabrication process, bigger prints are guaranteed.

Skylar Tibbits, the co-director and founder of the Self-Assembly Lab refers to the work they do as ‘4D printing’; 3D printed objects that can adapt, morph and assemble based on necessity. Talking about their new air-bubble 3D printed innovation, Tibbits spoke to FastCompany, saying:

“It’s programming it with air. Instead of zeros and ones, you’re sending different pulses of air.”

The result is a material that appears to be alive and moving. Now, BMW just needs to find a use for the technology on the inside or outside of their cars. But something tells us they won’t have a problem coming up with a concept.

Historical adaptive designs

This isn’t the first time BMW has flirted with the idea of a vehicle that could adapt to the needs of the driver, and even the needs of the environment it is driving in. In 2008, the company introduced a concept car that had a body of fabric.

The car’s name was GINA (Geometry and functions in ‘N’ Adaptations). Flexibility and stretchability was a big focus for the engineering team - which had begun work on the car as far back as 2001. The idea, however, is a novel one. If a car’s exterior was stretchable, flexible and non-rigid, it could - if the technology was more fleshed out - heal itself after an accident.

Aerodynamics was also a focus. The car would change shape at different speeds to make the car as aerodynamic as possible, literally morphing and adapting on-the-fly.

What is apparent is that BMW has been attempting to innovate within the exterior and interior designs of cars for ten years now. The engineers at BMW and MIT believe that the inflatable materials they have recently designed could be used in the interior of the vehicles in the future - an adaptable material that could be tailor made for the customer.

Tibbits explains that the customer could ‘programme’ the kind of interior design they would want on any given day inside their car. He said:

“The interior could be different every time you got in, for every person who got in. By using pressure differential inside and out, you can make it morph around a human or object.”

Thereby, when cars are autonomous and the driver felt like having a nap, they could program the many airbags in the interior to morph into a more relaxing environment for the passenger inside.

Works Cited

Schwab, Katharine. “MIT and BMW Are Building the Stretchy, Inflatable Future of Cars.” Co.Design, Co.Design, 22 May 2018, www.fastcodesign.com/90173037/mit-and-bmw-are-building-the-stretchy-inflatable-future-of-cars.

Squatriglia, Chuck. “BMW Builds a Shape-Shifting Car Out of Cloth.” Wired, Conde Nast, 10 June 2008, www.wired.com/2008/06/bmw-builds-a-ca/.

- Details

- Written by: Quintus Potgieter

Last month we took a look at the (new) tallest building in the world which belongs to the Kingdom of Saudi Arabia. It is The Jeddah Tower, which is set to trump the previous record holder for the tallest building in the world - the Burj Khalifa. But, this isn’t the only impressive feat of civil engineering currently solidifying its place in the history books.

The projects detailed here are all projects that are utilizing new technologies, using new design philosophies, or simply becoming the biggest of their kind in the world. What remains clear is, civil engineering, globally, is ‘reaching new heights’ every year.

Hong Kong-Zhuhai-Macau Bridge

This year marks the opening of the Hong Kong-Zhuhai-Macau Bridge which crosses Lingdingyang in China. It has been dubbed the Longest Sea-Bridge ever built - it spans 34 miles (55 kilometers).

How long does a bridge like this take from the idea phase to the final construction phase? Only 15 years. The Chinese government tasked the engineers with testing the feasibility of a bridge that would traverse the Pearl River Delta in 2003. The bridge would be essential to China’s Greater Bay area and lead to economic prosperity. The bridge has been completed and is ready for use this month.

The bridge utilizes a bridge-tunnel system, which consists of a series of three cable-stayed bridges, and one undersea tunnel. There are also three artificial islands that now link Hong Kong, Macau, and Zhuhai - three metropolitan cities.

Normally, the commute from one city to the next would take commuters three to four hours. Now, with the bridge in place, the travel time between cities will only be 30 minutes. The bridge construction cost: an estimated USD$15 billion.

The engineers of BYME Engineering brought together the latest in bridge building materials to construct the bridge.

Central Park Tower

A project that will also reach the billion dollar mark when completed is set to be Manhattan’s new jewel in its crown. It’s the Central Park Tower. It is located at 217 West 57th Street.

adrian__smith__and__gordon__gill__architecture(1).jpg)

The building is set to be a mixed-use building of the future. The architects and engineers have been closely following a construction philosophy called ‘Global Environmental Contextualism’ - a philosophy that will become increasingly popular. The idea is to design and construct with the natural environment in mind; using nature as an inspiration for designing.

The building, still under construction, will reach ‘supertall’ status (which is above 985 feet or 300 meters) upon completion. The Shanghai Municipal Investment Group and the Extell Development Company are behind the construction.

The construction will use the latest in cutting-edge engineering technologies and ensure the carbon footprint is as small as possible. It is expected to open in 2020.

Heathrow

The United Kingdom intends to expand Heathrow International Airport; an airport which has been in existence for 100 years. The expansion will officially make Heathrow the biggest airport in the world.

The airport will add a third runway. Heathrow currently has 80 million passengers through it every year; the expansion will see the number rise to 110 million passengers by 2030. This will also make the airport the busiest in the world. According to CNN Travel, the airport is currently only the 7th busiest in the world.

The UK government obviously foresees an increase in the number of people flying locally and internationally and it will be a necessary injection of funds in a post-Brexit UK. British members of Parliament have just given the go-ahead for the new Heathrow runway, despite historical opposition.

The expanded Heathrow is expected to cost £14.3 billion (US$20 billion) and another hurdle: the houses that are presently located where the build is proposed. The villages of Longford, Sipson and Harmondsworth would need to be demolished if the airport goes ahead.

The expansion has been hotly contested, understandably. But the civil engineers are gearing up to start building this state-of-the-art runway at Heathrow. The move will generate many temporary and some permanent jobs too.

Works Cited

“11 Civil Engineering Projects That Might Define the Future.” Interesting Engineering, 26 June 2018, interestingengineering.com/11-civil-engineering-projects-that-might-define-the-future.

“11 Civil Engineering Projects That Might Define the Future.” Interesting Engineering, 26 June 2018, interestingengineering.com/11-civil-engineering-projects-that-might-define-the-future.

- Details

- Written by: Elyse Simich

The world’s first driverless ferry is set to replace footbridges in the Norwegian city of Trondheim. Soon pedestrians will be able to cross the canal that separates the Ravnkloa fish market and the Vestre Kanalhavn dock much quicker than they’ve ever been able to before.

With the population growing steadily, engineers have been faced with the challenge of creating more river and canal crossings — however bridges can be costly to build and obstruct the flow of boat traffic. A team at the Norwegian University of Science and Technology (NTNU) has designed a self-propelled Autoferry to solve this problem.

There’s currently a small number of unmanned cable ferries located at various locations in Norway. However, this project aims to remove the cable, which will reduce operating costs and revitalize coastal areas.

So how does this ferry work? An on board Global Navigation Satellite System (GNSS) will help the vessel to self-navigate from one bank to another. Four integrated light sensors — a radar unit, an infrared camera, an optical camera and a Light Detection and Ranging (LiDAR) unit —will allow the ferry to detect and avoid kayakers and other boats. If it’s on the opposite side of the canal to waiting passengers, they can call it over with the press of a button.

While researchers at NTNU have been working with autonomous vessel management systems for years, they’ve never trained a computer to predict movements or read complex traffic scenarios in such great detail before.

The Autoferry takes approximately one minute to cross the canal, which is just less than 100 metres wide. It currently takes pedestrians 10-15 minutes to cross using the footbridge. The watercraft will be able to hold 12 passengers, plus bicycles and baby strollers.

Speaking to Gemini Research News, the head of NTNU’s department of engineering cybernetics Morten Breivik said the project has had its share of obstacles.

“One of the challenges of the project is that all these systems need to work well together. We also want to have sensors on land that can monitor blind zones,” he said.

The Autoferry isn’t quite ready to carry members of the public across the canal. Engineers are currently conducting a series of tests to ensure its safety. In phase one, the boat traffic in the canal was monitored and recorded. Phase two saw the construction of a half-scale ferry (five metres long). The propulsion systems, batteries and charging systems were all tested. Researchers are now developing the navigation system, automatic docking and testing the ferry’s anti-collision sensors.

Phase three will commence soon: it will involve putting the full-scale ferry into action and final testing of the technology.

NTNU’s head of department of electronic systems associate professor Egil Eide is in charge of operations for the Autoferry. He told Gemini Research News that he believes the driverless ferry will improve the quality of life for citizens.

“Driverless ferries can help develop regions that previously haven’t been linked to cities and towns due to a lack of infrastructure, for example,” he said.

“We believe that an industry will evolve from this project. The driverless ferries can become a new tool in community planners’ toolboxes.”

Researchers hope these ferries can one day connect to a city’s existing forms of transport and be used as an alternative form of emissions-free passage. They are also optimistic that these ferries could revitalize small island communities by providing a cheap form of transport. Researchers are now investigating a way to make the technology scalable, so ferries can be used over longer distances in rural areas.

- Details

- Written by: Elyse Simich

The Tottenham Hotspur Football Club has recently announced their new stadium has been “future-proofed” to accommodate safe standing, should the legislation in the UK change.

Standing during games has been banned at in the top two divisions of English football since

As a result, the Football Supporters’ Federation launched a petition to overturn the ban and give football clubs a choice to implement safe-standing areas for fans. The now-closed petition garnered over 112,000 signatures and sparked a debate in Parliament on June 25.

The English Football League and the Premier League both hold the position that clubs should have a choice as to whether their fans can sit or stand during a match. The Labour Party has also called for the law to be changed.

The Hillsborough Justice Campaign (HJC) was established in order to seek justice for those who were injured or killed in the crush, and their families. In a blog post for metro.co.uk, HJC campaigner Sheila Coleman expressed her concern that some people are against safe-standing because of the Hillsborough disaster. She said this is disingenuous as it implies that standing was a factor that led to the tragedy.

“It remains the collective view of the HJC that standing never killed anyone at a football match,” she said.

“Within the

Tottenham Hotspur executive director Donna-Maria Cullen echoed these sentiments in a press release from the club.

“As a Club, we did not engage on this until the Hillsborough Inquiry was concluded, which showed that the tragedy in April 1989 had not been caused by standing,” she said.

“We then conducted research with our fan base which showed overwhelming support for safe standing. The main reasons given were choice and atmosphere - fans cannot sing sitting down.”

Designing the new stadium to accommodate safe standing has sparked the question as to whether it’s possible to convert seated areas to standing areas in old stadiums. These safe standing areas are characterised by rail seating — fixed rail barriers with attached fold-up seats to designate each standing slot.

Speaking to New Civil Engineer WSP UK’s head of stadium Peter Chipchase said this shouldn’t be an issue provided the stadium passes a number of stress tests first.

“In terms of converting an existing

“Modern stadia are designed at 4kN/m² but currently only holds 2kN/m², so increasing capacity would be no

Dynamics would also need to be tested, according to Chipchase, to avoid the stands from vibrating underneath the crowd.

“In Frankfurt, the Eintracht fans know that if they all jump at the same time they can get the stands to move up and down with them. It is pretty scary to watch and they could be resonating the tier to collapse,” he said.

“They are able to get it going because the stands are designed with a frequency of 2Hz. That wouldn’t be possible in a modern stadium, as they are all designed with a frequency of 6Hz.

“I can’t think of a single stadium in the UK that would have an issue with dynamics, but they would still have to be tested before being converted.”

While dynamics and capacity may not be a problem, sightlines and old terraces could cause issues.

Mott MacDonald technical director Nick Ling told New Civil Engineer that visibility of the field could be reduced, as people wouldn’t necessarily be able to see over the person in front of them.

“Standing sections increase the risk of reduced C values or even negative values,” he said.

“So sightline and C value issues could mean that tiers need reprofiling which could result in a change to the structure and retracing.

“It is feasible for some stadia, but more difficult for others. If sightlines are tight, it could be difficult to make the alterations required.”

Another issue he flagged was that fixing barriers to old terraces could be structurally challenging and require more capital investment.

These rail seats have been trialled at Scotland’s Celtic Park and across Europe, where they are particularly popular in Germany. Reasons for this are that they increase the stadiums’ capacity and allow fans to safely stand throughout the game if they choose to.

The new 62,000 seat stadium is set to open later this year.

- Details

- Written by: Quintus Potgieter

Some highways (and most sidewalks) in the United States are made out of concrete. Mark Weaver, a Professional Engineer in California, writing on website Quora, explains:

“The main reason is that highways have much higher volumes of traffic than surface streets. Highways also have much heavier vehicles traveling on them than surface streets. The combination of higher volumes and higher weights of vehicles causes serious durability issues for asphalt concrete pavement.”

The problem with concrete? It isn’t very flexible. For building roads, the material of choice is usually asphalt due to its flexibility - but concrete is cheaper to install. A lot of other U.S. infrastructure is made with concrete - and it is starting to show its age.

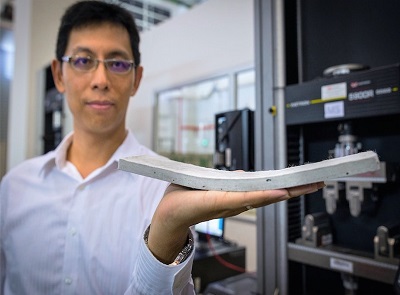

The brittleness of concrete is not one of its favorable attributes, but what if engineers could cheaply install concrete and it could last longer than any rival material?

Bendable concrete would contribute to more stable bridges and it would help prevent them from collapsing. Sometimes it’s not the older bridges that are in trouble of collapsing, but the new ones.

In March 2018, a bridge collapsed at Florida International University in the United States that unfortunately led to loss of life. Engineers had discussed a crack that had formed on the bridge hours before the bridge collapsed. The crack has still not been confirmed as the root cause of the collapse, however, a bendable concrete that could survive more stresses may have prevented a collapse. The bridge is said to have been built via a quicker construction method and utilized a new form of concrete known as ‘self-cleaning concrete’.

Solutions

Engineers at the University of Michigan believe they have the answer to offsetting the brittleness of concrete. Their discovery was inspired by seashells. In their Conversation article, they write:

“To develop ductile concrete, our laboratory borrowed ideas from nacre, also known as mother of pearl - the iridescent material on the inside of abalone shells.”

Mimicking the nanoscale architecture of an abalone shell - which the engineers say looks like a brick wall - makes what seems to be a small shell, quite rigid.

“The ‘bricks’ are thin layers of aragonite platelets, and the ‘mortar’ between them is a natural polymer that is very elastic. The polymer holds the rigid aragonite layers together, but allows them to slip from side to side under stress. This structure makes nacre both strong and flexible.”

Their new concrete has been given a name: Engineered Cementitious Composite (ECC) or strain-hardening cementitious composite. When using tiny fibres within concrete that is under pressure, the composite emulates the flexible rigidness of the nacre.

Scientists in Singapore’s Nanyang Technological University have also been experimenting with putting ‘thin-as-human-hair’ fibres into their mix of concrete. The result? A new material known as ConFlexPave. The distribution of the polymers reportedly makes the concrete stronger and more durable.

The researchers say instead of pouring the concrete on site, the concrete could be prefabricated at a factory and transported to the construction site and simply laid in place. The engineers will test the concrete around their campus over the next three years.

Professor Yang En-Hua from NTU’s School of Civil and Environmental Engineering, leading the charge on the research said:

“The hard materials give a non-slip surface texture while the microfibres which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in a concrete that is tough as metal and at least twice as strong as conventional concrete under bending.”

Works Cited

Coxworth, Ben. “Next-Gen Concrete Bends Instead of Cracking.” New Atlas - New Technology & Science News, New Atlas, 17 Aug. 2016, newatlas.com/bendable-concrete-sidewalks/44950/.

Li, Victor C. “Bendable Concrete, with a Design Inspired by Seashells, Can Make US Infrastructure Safer and More Durable.” The Conversation, The Conversation, 11 June 2018, theconversation.com/bendable-concrete-with-a-design-inspired-by-seashells-can-make-us-infrastructure-safer-and-more-durable-93621.

Weaver, M. (2018). In the United States, why are most highways made of concrete, while most streets are made of asphalt?. [online] Quora. Available at: https://www.quora.com/In-the-United-States-why-are-most-highways-made-of-concrete-while-most-streets-are-made-of-asphalt [Accessed 11 Jun. 2018].

- Details

- Written by: Quintus Potgieter

With population numbers expected to rise exponentially, and the global growth of the middle class to continue, the topic of the sustainability of resources becomes more pertinent. More cities are needed, functioning infrastructure must be available, and it must all reflect the hallmarks of modern civilization.

However, it has become apparent that populations are growing faster than cities can be constructed.

Some philosophers and thinkers have started looking to the sea to solve some of these problems. And if their ideas are to become reality, it should present civil engineers some unique challenges. The main challenge: how to build a floating city.

The result is a futuristic movement blending civil engineering and marine engineering; seasteading.

A case for floating

Blue Frontiers, a Singaporean startup has linked arms with a California-based nonprofit named the Seasteading Institute to make seasteading a reality in the near future. They are formalizing their efforts on a project dubbed ‘The Floating Island Project’.

Thanks to their unique governing frameworks, these floating cities will create utopias, says the company’s promotional material.

“Seasteaders plan to provide you with the technology to found your own floating nation on the ocean. And seasteading is already happening,” said president of the Seasteading Institute Joe Quirk, at a futurism conference named Voice & Exit in 2015.

Quirk explains that floating cities are not a new idea - engineers have been engaged in building floating communities for a variety of reasons.

Shell has a floating liquefied natural gas (FLNG) facility 475km north-north east of Broome, Western Australia. It is the largest floating facility ever built and is an indicator that a floating life at sea is possible. The floating facility employs 260 local workers. The facility will produce liquefied natural gas for the next 25 years.

Similarly, cruise ships are commonly referred to as floating cities. The existence of floating nuclear-powered military submarines, ships and even floating nuclear power plants are becoming a reality.

“Nearly half the world’s surface is a blank slate, unclaimed by existing governments, and we want to create a thousand startup governments on the sea,” Quirk said. A floating city might also have a unique advantage that may just attract the environmentalists; solar power.

Engineers are currently building an energy producing system utilizing a process known as ocean thermal energy conversion (OTEC). Essentially, it turns the ocean into one big solar panel.

With seawater absorbing a lot of the sun’s emitted energy, the thinking is that the heat at the surface of the ocean can be captured and converted into electricity. The process includes deep cold seawater, heat exchangers, refrigerants, and a turbine. The lead engineers of Makai Ocean Engineering explain in this video:

Soon a reality?

In January 2017, the Seasteading Institute and the government of French Polynesia signed a Memorandum of Understanding, setting the stage for a seastead to be constructed. Blue Frontiers, the company spearheading the project, alongside the Seasteading Institute, must, however, raise all the funds.

The company in charge of constructing the floating city s a company named DeltaSync. Quirk says that humanity could be uplifted because of future floating cities. He is advocating a mantra of ‘ocean first, space second’.

He also reflects on rising sea levels in French Polynesia, thanks to global warming. A future which includes floating cities could save entire communities from being swept away by the ever encroaching sea.

“Is it doable? We walked on the moon 45 years ago. It’s easier to float than fly. It’s cheaper to build seastations than space stations.”

Blue Frontiers has even created its own crypto-currency for the floating city they plan to build in French Polynesian waters. They hope to have a functioning example by 2020, but still have a long way to go and a lot more money to raise before the project truly sees the light of day.

Quirk believes they could have a functioning floating city completed by 2050 if all goes according to plan.

However, Silicon Valley billionaire investor, Peter Thiel, is a little skeptical, he feels that the seastead is “not quite feasible from an engineering perspective”. He previously invested $1.7 million into the Seasteading Institute but has since extricated himself from the project.

Nonetheless, engineers are at the forefront of creating sustainable solutions to the world’s most pressing problems. With technological growth experiencing great leaps every decade, which in turn is making technology much more affordable, solutions to dire infrastructural problems are being presented.

Works Cited

“Atlantis Rising: Why Floating Cities Are the Next Frontier (Joe Quirk).” YouTube, 16 Mar. 2015, youtu.be/Jr8Iw4o7Gic.

“Prelude FLNG.” Shell Global, www.shell.com/about-us/major-projects/prelude-flng.html.

- Details

- Written by: Quintus Potgieter

As Vladimir Putin gets another six years in the seat as the Russian President, Russian engineers tow something through the Baltic Sea, something the world has never seen before.

The metal giant in tow has the symbol of an atom tattooed to its exterior, which onlookers know can only mean one thing; it’s nuclear. The Russians correctly assert that it will be the world’s only functioning floating nuclear power plant. Floating nuclear technologies are not new, but this is an impressive feat of engineering.

Russia’s state nuclear power company Rosatom is behind the construction of the unit.

Construction on the unit began in 2009 - the first stage of the build does not include any nuclear fuel. But, in 2019 it will reach stage two. The Deputy Head of the Directorate for the Floating NPP Construction and Operation Dmitriy Alekseenko said:

“At the first stage, the FPU with no nuclear fuel on board will be towed from the territory of Baltiysky Zavod to the landing of Atomflot FSUE in Murmansk. Then, at the second stage - roughly in the summer of 2019 - it will be sent from Murmansk to the seaport of Pevek, loaded with nuclear fuel and with the crew on board.”

Its final destination will be the Arctic town of Chukotka.

Critics abound

Russia is not a stranger to media coverage, much of which is overly negative. As a consequence this new floating nuclear power unit has been dubbed the ‘floating Chernobyl’. Greenpeace went as far as calling it ‘Chernobyl on ice’.

Some critics have said taking a nuclear reactor to an Arctic town may pose a danger to the environment. But Rachel Becker, writing for the Verge, makes a pertinent point - some critics are making risk assessments on the project, but conveniently overlooking the fact that submarines have been powered by nuclear means for 60 years.

Furthermore, experts warn that judging one nuclear plant by heavily publicized historical plant meltdowns is damaging the future of an energy source that should be part of a country’s energy mix.

Usefulness

According to Rosatom, the floating nuclear unit would be providing electricity for 100,000 people through its 70 megawatt capability. After the nuclear unit goes live in the coastal town of Pevek, it will be the most northerly located nuclear plant in the world.

The Russian government doesn’t intend slowing down; the Akademik Lomonosov is one of many mobile transportable low-power units planned to provide electricity. The mobile units can be used to power “remote industrial plants, port cities” and offshore gas and oil platforms.

The mobile unit currently traversing the Baltic Sea is a Floating Nuclear Thermal Power Plant (FNPP). The nuclear reactors the plant will utilize include technologies first devised in 1980 to power Russian icebreaker ships.

Bringing ship building and nuclear technologies together is now the pride of Russian engineers. To attempt to quell critics of the technology, the engineers of the state-run nuclear company put out some assurances in a press release:

“The FNPP is designed with the great margin of safety that exceeds all possible threats and makes nuclear reactors invincible to tsunamis and other natural disasters.”

Works Cited

Becker, Rachel. “The Scary Part of the Russian Nuclear Power Plant Isn't That It Floats.” The Verge, The Verge, 2 May 2018, www.theverge.com/2018/5/2/17313174/floating-nuclear-power-plant-russia-academik-lomonosov-chernobyl-titanic.

“The World's Only Floating Power Unit 'Akademik Lomonosov' Takes the Sea.” Benefits of Nuclear Energy, www.rosatom.ru/en/press-centre/news/the-world-s-only-floating-power-unit-akademik-lomonosov-takes-the-sea/.

- Details

- Written by: Quintus Potgieter

1969 was a big year for the engineers and scientists at NASA; the year they enabled humans to reach the Moon. Next year, it will be 50 years since Apollo 11 touched down on that lunar surface.

This year the goal is Mars, although the players look a little different to 50 years ago. Now it seems that billion dollar private companies and government agencies are all competing in the space race.

SpaceX, the aerospace engineering company headed up by Elon Musk, is soon to launch their BFR (Big Falcon Rocket); the test before sending astronauts to Mars.

SpaceX has been innovating feverishly in the aerospace engineering industry. They have perfected the landing of rockets after launch, and they have mastered the reusing of previously launched rockets. They have also been firing rockets into space at almost a tenth of the cost of those sent by NASA.

Instead of remaining the stuff of dreams and science fiction tales, Elon Musk believes that a human colony on Mars will become a reality one day. He predicts SpaceX will be sending spacecraft to Mars in 2019.

Human missions

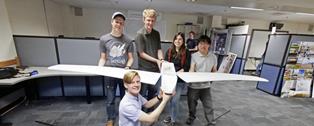

Getting spacecraft to Mars is one thing, but getting humans there is quite another. At the Mars Desert Research Station (MDRS), in the small US town of Hanksville, in Utah, engineers and scientists are collecting data that will be used on future Mars missions. The research station and program were set up by the Mars Society.

Zac Trolley is a Canadian Electrical Engineer and future Mars settler. Since childhood he has dreamed of reaching the Red Planet. He has been close; he was part of a two week Martian Simulation at MDRS in February 2018. During this time his engineering skills were used to help the team prepare for a future Mars mission. Zac tells us:

“Mars was the original target for the consecutive missions after Apollo, but that all got canceled. So, the architectures are all there, what’s missing is political will and funding. A lot of that political will is coming from the private sector, you know, with these billionaire entrepreneurs who are bringing their billions of dollars with them.”

He says that the conceptual ideas are finally moving into the engineering feasibility phase; these were missing from the science fiction pipe dreams of the past. Zac worked as the Crew Engineer for the project; he was tasked with maintaining the infrastructure of the Habitat. The Habitat (or Hab) is a two story 8 meter cylindrical building that houses the spacesuit simulators, has an exterior airlock, offers a shower room, toilet room and rear airlock. The rear airlock opens up to tunnels that lead to other structures at the research station.

During the two week simulation he also assisted others in their research projects. He explained:

“We conducted research on NASA plant growth systems, dust accumulation, material abrasion for space suits, and participated in many outreach activities including recording 360 video for VR applications.”

Donning some Hollywood-prop-esque space suits, Zac and his fellow team members navigated the desert areas of Utah, pretending to be astronauts. The location was picked due to its geology - it is similar to Mars’ dusty surface.

Everyone should be an engineer

Zac was part of the 188th iteration of the Martian simulation. He says that the knowledge being harvested from the Mars simulations will be invaluable to future missions. He explains:

“When a Mars mission happens, the engineers, the assembly team, and all the people that are involved, all the surrounding teams; they’re going to have to have an intricate knowledge of the mission as well. The more people that go through these simulation missions, and get an idea of how they operate and the mindset of the crew, even if they don’t go to Mars, their designs and their decisions regarding the rockets and the Habitat are going to be influenced by that. And it makes a better mission.”

Zac, as the Crew Engineer, had to keep the power grid working, the water system functioning, and all the other “bits and bobs and bolts” maintained. Nonetheless, Zac stresses that everyone who travels to Mars will need basic engineering knowledge so they can troubleshoot any on-board technologies. They will also have to master first aid training!

He believes that the first mission to Mars will need to be made up of members who are well-versed at working as a team. Zac noted that the MDRS simulation mission focused on the social aspects of working in a team more than the technical engineering feasibility.

Zac may be a little more conservative than Musk, he believes that aerospace engineering is still two decades away from putting humans on Mars. He believes firmly, however, that when a mission is at last undertaken, the technical and human elements must be aligned.

When asked what engineering education can do to fully equip engineers for future Mars missions, Zac said that engineering education should inject creativity and risk tolerance into the curriculum. He said:

“When I was doing my engineering degree, one of the most valuable things to me was extracurricular activities. I joined some clubs and I did some things outside of class and that was where I was able to really show my creativity.”

Works Cited

Applied Futurism, zactrolley.com/.

“Mars Desert Research Station.” Mars Desert Research Station, mdrs.marssociety.org/.

“There's a Starman, Sitting in a Car ... and It's All to Do with Elon Musk.” ABC News, 7 Feb. 2018, www.abc.net.au/news/2018-02-07/spacex-rocket-takes-sports-car-into-space/9403618.

- Details

- Written by: Quintus Potgieter

Engineers wait with bated breath for a call they may never get. Earlier this year, the United Kingdom’s Foreign Secretary, Boris Johnson, proposed a 22-mile bridge to span the English Channel.

Eleven tunnel boring machines and engineering expertise created the 50.45 kilometer (31.35 mile) Channel Tunnel link between England and France.The tunnel took five years to build with a total of 13,000 workers from both England and France. If the building of a bridge is announced it would mean a sizeable payday for engineers attached to the project.

Some have dismissed Johnson’s intention to build the bridge - calling it a fantasy that will never come to fruition. However, Channel Tunnel operators Eurotunnel have expressed interest in the project.

Speaking in the House of Commons, Johnson said:

“It is a curiosity that two of the most powerful economies in the world, separated by barely 21 miles of water, are connected by only one railway line. And I think it is a matter for legitimate reflection by our two countries on the way forward.”

The bridge would be an impressive feat, not just considering the engineering prowess it would involve, but because it would be a post-Brexit achievement for the country which is due to leave the European Union, but still retain its business connections with France.

What they’ll need

If the plan to build the bridge goes forward, engineering professionals will either be tasked with creating a cable stayed bridge or a suspension bridge. There is just one glaring problem that is already causing speculators some consternation: boats.

Wanda Lewis, Emeritus Professor in Civil Engineering at the University of Warwick took to The Conversation, to explain. She writes:

“The channel is between 40m and 60m deep and some passenger ships are more than 70m tall. So to let ships pass underneath, the pylons supporting the bridge would have to be around 150m tall. To support the cables you would have to add pylons above the deck, which would mean a total pylon height well above 500m. Again, nothing this tall has ever been built.”

If the bridge does get built, it will be the world’s tallest bridge, and may just get recognition as a marvel of the modern world. However, with height comes wind and this strengthens with greater height. The bridge could be poised to deal with a number of wind-related engineering challenges.

With the longest bridge in the world as a case study, the Danyang-Kunshan Grand Bridge in China, the Daily Mail estimates that the bridge would cost approximately £824 million (USD 1.150 billion).

The Boris Bridge - as it has now been humorously dubbed - has received a great deal of backlash. The UK Government may indeed scrap the idea, but they are not ruling out the possibility of another tunnel.

Eurotunnel maintain that building a second link to England is not a matter of ‘if’ but a matter of ‘when’. Chief Executive of Eurotunnel Jacques Gounon wrote in a letter:

“The idea of a second fixed link is something that we regularly consider in our long term plans, and we would be delighted to engage with your officials to explore the possibility further.”

Works Cited

Lewis, Wanda. “Boris Johnson's English Channel Bridge: an Engineering Expert's View.” The Conversation, 12 Mar. 2018, theconversation.com/boris-johnsons-english-channel-bridge-an-engineering-experts-view-90409.

Ravenscroft, Tom. “Eurotunnel ‘Very Interested’ in Boris Bridge between England and France.” Dezeen, Dezeen, 14 Feb. 2018, www.dezeen.com/2018/02/14/eurotunnel-channel-tunnel-interested-boris-bridge-england-france/.

- Details

- Written by: Quintus Potgieter

The speed at which a lithium-ion battery charges, remains a unique scientific and engineering challenge. Historically, slow charging has been responsible for limiting the development of vehicles and technologies that need to constantly recharge. This is, however, changing as technology advances.

The safety of lithium-ion batteries has also been a sore point in the history of battery technology. But with new sensor technology these batteries are becoming less risky.

Ensuring no thermal runaway occurs in Li-ion batteries is important for the future of vehicles and other technologies dependent on them. In fact temperature control, the speed of charging and general battery safety is paramount.

Interestingly University of Warwick researchers claim that Li-ion batteries already sold in commercial settings can be charged faster than previously thought. They also assert that this could improve their safety. With new sensor technology embedded into the battery a speedier charge and reduction in risk will result, they believe.

The researchers have published their findings in a journal named Electrochimica Acta under the title: “Understanding the limits of rapid charging using instrumented commercial 18650 high energy Li-ion cells.”

18650 high energy Li-ion cells are the ones found in our electronics, future electric vehicles and our energy storage units. Now, with new sensor technology, the inner-workings of the Li-ion battery can be monitored and will open a new pathway to battery flexibility.

Lead researcher Dr Tazdin Amietszajew says:

“This could bring huge benefits to areas such as motor racing, which would gain obvious benefits from being able to push the performance limits, but it also creates massive opportunities for consumers and energy storage providers.

The Warwick University researchers say the new sensor technology will allow for flexible charging functionality, but has revealed that we have been charging the batteries more slowly than necessary. Amietszajew said:

“Faster charging as always comes at the expense of overall battery life, but many consumers would welcome the ability to charge a vehicle battery quickly when short journey times are required and then to switch to standard charge periods at other times. This technology is ready to apply now to commercial batteries, but we would need to ensure that battery management systems on vehicles, and that the infrastructure being put in for electric vehicles, are able to accommodate variable charging rates that would include these new precisely tuned profiles/limits.”

It may even ensure that the Li-ion batteries do not overcharge. There are already measures in place to prevent electronics’ Li-ion batteries from overcharging, although it still occurs in certain Li-ion applications.

The Battery University explains:

“Prolonged charging above 4.30 volts on a Li-ion designed for a 4.20V/cell will plate metallic lithium on the anode. The cathode material becomes an oxidizing agent, loses stability and produces carbon dioxide (CO2). The cell pressure rises and if the charge is allowed to continue, the current interrupt device (CID) responsible for cell safety disconnects at 1000-1,380kPa (145-200psi). Should the pressure rise further, a safety membrane on some Li-ion bursts open at about 3,450kPa (500psi) and the cell might eventually vent with flame.”

The research into how to get Li-ion batteries performing more efficiently, being charged up more quickly and living longer, is important research. This glimpse into the future, thanks to Li-ion batteries, has already signaled a new ‘gold rush’ - with lithium being the gold. The future of clean, renewable energy applications may indeed depend on Li-ion batteries performing better than they already do.

Works Cited

“Charging Lithium-Ion Batteries.” Charging Lithium-Ion Batteries – Battery University, batteryuniversity.com/learn/article/charging_lithium_ion_batteries.

Posted March 11, 2018 by Travis Horesh & filed under Newswire, The Tech. “New Li-Ion Battery Sensor Tech Promises 5x Faster Charging.” Charged EVs, chargedevs.com/newswire/new-li-ion-battery-sensor-tech-promises-5x-faster-charging/.

- Details

- Written by: Amber Allen

It is difficult to train for outdoor sports indoors. We can try to replicate naturally occurring factors such as hills, valleys, wind and rain; but nothing can adequately imitate what the outdoors is capable of producing (even when training outdoors). Cycling is no exception. Training is regularly conducted indoors, to control things such as resistance and drag when slopes are sparse. Or, when practise riding into a headwind is required and there’s not a breath of wind outside.

Previously, an ergo (stationary bike) was the option, where gears were simply changed to add resistance to the ride, slowing a cyclist down and causing him/her to push harder to achieve the same speed. A relatively new product has emerged, however; it is completely changing the training game.

AIRhub is a revolutionary cycling training device produced by Terrain Dynamics. It is an electromagnetic braking system which adds watts to your ride without adding mass. The AIRhub connects to your smartphone via Bluetooth, with the AIRhub app controlling your output in real time. “AIR” stands for automated integrated resistance, and hub of course being the 1.5kg physical attachment to the front wheel of the bike.

The aptly named Terrain Dynamics is the brainchild of Perth man Michael Freiberg, a gold and silver Commonwealth Games medallist himself and 2011 Omnium World Champion. Freiberg developed this remarkable feat of engineering after years of training for both track and road cycling. He was finding he couldn’t control and manipulate his training schedule exactly to his needs with the technology that was previously available; his routine was often dictated by his location or the weather on the day. As this inventor and managing director Freiberg says:

"With the AIRhub, we've created that. A smart, one-of-a-kind electromagnetic braking system that works with you and can be customised to suit your program and your terrain.”

AIRhub has a series of different modes to select from, each regulating the system in a different way.

- Manual mode: it can add up to 100 watts while riding. This mode is ideal when riding with slower cyclists; it allows for a slower speed, but with the use of more power.

- Heart rate mode: it monitors the heart rate and automatically adjusts resistance to keep the training in a specific zone. This mode is ideal if riding in a large group – it increases resistance when positioned in the middle/back of the pack and decreases it if at the front; it is designed to maintain a consistent heart rate.

- CDA mode: it increases coefficient of drag to simulate headwinds.

This product is versatile. It can be utilised by leisurely weekend riders - wanting to increase average speed by a couple of km/h, all the way up to elite athletes – wanting to hone in on specific heart rate targets, oxygen intake and output wattage. Sitting at a current price point of $1950 per unit, the AIRhub is a fairly significant financial investment, but one that when used correctly, can dramatically improve results in very broad or very specific areas.

“I hope everyone who's ever struggled to take their performance to the next level, whether it be because they live in a flat area, don't have safe roads to train on or have to train solo just to get in those hard sessions, can find their answer in the AIRhub.” M. Freiberg

The results speak for themselves, with riders demonstrating a 10-15% improvement in riding power with no additional effort.

References:

En.wikipedia.org. (2018). Michael Freiberg. [online] Available at: https://en.wikipedia.org/wiki/Michael_Freiberg [Accessed 12 Mar. 2018].

Rainmaker, D. (2017). Hands-on: The AIRhub on-road cycling resistance unit. [online] DC Rainmaker. Available at: https://www.dcrainmaker.com/2017/01/airhub-cycling-resistance.html [Accessed 12 Mar. 2018].

Terrain Dynamics. (2018). AIRhub. [online] Available at: http://terraindynamics.com.au/airhub [Accessed 10 Mar. 2018].

- Details

- Written by: Quintus Potgieter

Electricity, seemingly abundant in our world today, is something that we take for granted. The reality, however, is very different in the world.

It is estimated that 1.3 billion people still do not have access to electricity.

Electricity can mean many things for communities. Once electricity is established within a community, the access to power can lead to better health care, education, and self-determination. And prosperity soon follows.

Powering rural areas is an engineering work in progress. The remoteness of some communities means that relying on the grid is impossible.

The technologies that have been used to bring power to remote villages have historically been those which impact negatively on the environment; diesel generators have been a common source of power.

Powering the remotest villages on earth

Ladakh is inside the Indian state of Jammu and Kashmir in the Kunlun mountain range within the Great Himalayas. A small number of inhabitants brave the cold in the area; Ladakh is 12,400 feet above sea level. Until a few years ago they had never used electricity.

A team known as the Global Himalayan Expedition trekked to the remotest village in Ladakh: the village of Shadé.

These wonderful and courageous volunteer engineers installed a Solar Nano-Grid to provide the inhabitants with electricity in 2017. This complimented one previously placed in the village. The first installation had never been robust enough to power the entire village.

It took the team four days to travel the 56 miles before reaching Shadé Village. The Kashmir Monitor wrote:

“The village has never received any grid based electricity. The villagers have been using Solar Home Lighting Systems and old kerosene oil lamps. In winters, the village remains cut-off from the outside world for about six to seven months. There is one satellite phone in the village, which was installed in 2013 and remains the only medium of communication between the village and the outside world.”

The team intends to provide nanogrids to surrounding villages as well. They have been working to electrify a dozen other villages in the Himalayas in an expedition that started in 2013. The citizens of the villages are understandably delighted.

The government has, however, signed a Memorandum of Understanding with the Centre of Development in India to get two mega solar parks built in the region of Ladakh. This will be enormously valuable to the inhabitants in the region; securing them with a sustainable supply of electricity.

To see more of the work being done in the Himalayas, here is a documentary on the projects from NDTV:

Works Cited

“Remotest Village in Ladakh Gets Electricity for the First Time.” Kashmir Monitor, 14 May 2015, kashmirmonitor.in/Details/129269/remotest-village-in-ladakh-gets-electricity-for-the-first-time.

- Details

- Written by: Quintus Potgieter

If you don’t have steel you don’t have a country - so says the President of the United States Donald Trump. And, based on an investigation conducted by the American government, their country had drawn the short straw when it came to steel imports and exports. To ensure it did not impact the elusive ‘American Dream’l import tariffs were back on the table.

President Donald Trump has announced a 25 percent tariff on steel articles exported to the United States. In an official proclamation, he said:

“This relief will help our domestic steel industry to revive idled facilities, open closed mills, preserve necessary skills by hiring new steel workers, and maintain or increase production, which will reduce our Nation’s need to rely on foreign producers for steel and ensure that domestic producers can continue to supply all the steel necessary for critical industries and national defense.”

And yet American steelworkers have been wondering where they fit in into the future of the metalworking industries - the increasing automation of steel factories will inevitably hollow out traditional roles. Barack Obama, before the end of his presidency, was quizzed on the return of jobs to the steel sector. He was less optimistic than his successor.

President Donald Trump is making a concerted effort to refocus attention on metalworking factories; the new tariffs will add 25% to steel imports and 10% to aluminum. Tariffs on foreign washing machines and solar panels were also recently imposed by his government.

Trump, on March 7th, tweeted:

“From Bush 1 to present, our Country has lost more than 55,000 factories, 6,000, manufacturing jobs and accumulated Trade Deficits of more than 12 Trillion Dollars. Last year we had a Trade Deficit of almost 800 Billion Dollars. Bad Policies & Leadership. Must WIN again! #MAGA”

Car manufacturing and beyond

Whilst most people would decry the tweets as Trump’s notorious ‘alternative facts’, a CEO of multiple engineering companies on the cutting edge of modern day engineering agrees that American business has not been getting a fair deal.

CEO of Tesla Motors, Elon Musk, also took a seemingly pro-tariffs stance. Responding to Trump on Twitter, Musk tweeted:

“Do you think the US & China should have equal & fair rules for cars? Meaning, same import duties, ownership constraints & other factors. For example, an American car going to China pays 25% import duty, but a Chinese car coming to the US only pays 2.5%, a tenfold difference. We raised this with the prior administration and nothing happened. Just want a fair outcome, ideally where tariffs/rules are equally moderate. Nothing more. Hope this does not seem unreasonable.”