Developments

- Details

- Written by: Quintus Potgieter

What is a dark warehouse? It's not a warehouse with its lights off if that's what you're wondering. No, the dark warehouse, or otherwise known as the "lights-out facility", is a factory that runs completely through automated means without any human intervention. Warehouses are opting in for self-driving forklifts, robots equipped with vision cameras, automatic storage and retrieval systems and more. Adidas recently announced a lights-out facility in Germany that would see robots in charge of manufacturing shoes.

Other factories that currently use fully automated systems include cold storage and freezer warehouses where food is frozen and stored. And soon, electronics companies will be using dark warehouses in the manufacturing of electronic devices. The truth is, humans don't need to do those jobs anymore. A hand-tailored cell phone doesn't make anyone jump out of their seats with pride and joy. But a hand tailored Rolls-Royce is a different thing.

However, lights out facilities are becoming more and more sought after in the industrial world. "A lights-out facility is more possible in less-variable parts of logistics, where people are moving a large portion of the same types of objects," said Matt Engle, an employee for Cognex Corp, a company that specializes in vision systems for factory automation.

However, lights out facilities are becoming more and more sought after in the industrial world. "A lights-out facility is more possible in less-variable parts of logistics, where people are moving a large portion of the same types of objects," said Matt Engle, an employee for Cognex Corp, a company that specializes in vision systems for factory automation.

The dark warehouse is becoming a goal for some factories. The efficiency of a fully automated factory is becoming somewhat of a bragging right for some companies. However, if it isn't cost-effective, then is it truly worth it? The answer to that question lies in co-bot (collaborative robots) technology. Cobots are cheaper than fully automated industrial robots and cost small and medium-sized enterprises - who want to go into automation - much less. However, collaborative robotics alludes to the involvement of human instruction. Thereby, eliminating the truly dark warehouse.

However, for big industrial facilities that are looking to fully automating and going 'dark', DC Velocity has compiled a comprehensive three-point checklist that companies can follow in their pursuit for fully automated systems:

- Automated storage and retrieval systems: facilities that handle high volumes of inventory moving and out of storage

- High-speed sorting equipment

- Warehouse robotics: guided by wireless instruction from a warehouse management system or warehouse execution system

- Details

- Written by: Quintus Potgieter

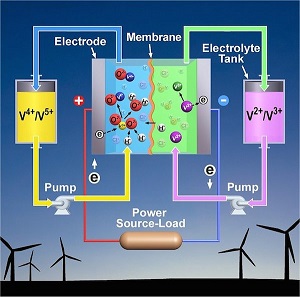

We know it's going to play a big part in our future, but how big are we talking here? Lithium seems to be on everyone's lips these days due to being in the driver's seat in the push for renewable energy. Needless to say, it powers most home electronics as it is. It is also leading the charge in home energy storage units. So what does the demand for lithium look like?

Experts say that as of 2015, the global lithium supply was approximately at 160,000 tonnes of lithium carbonate equivalent (LCE). Those are the ones we are using every day of our lives which power the lithium-ion batteries, that are also making their way into electric vehicles.

Francis Weldin, executive technical director at a company named Dakota Minerals Ltd was interviewed in a recent report on global lithium demand. He says that for every 1% of new electric vehicles making their way to market, 70,000 tonnes of lithium is in demand. These numbers were originally published by Goldman Sachs, who called lithium-ion the new gasoline, showing just how much demand has grown. So, needless to say, the numbers aren't inspiring much confidence. Sodium-ion batteries, anyone?

Francis Weldin, executive technical director at a company named Dakota Minerals Ltd was interviewed in a recent report on global lithium demand. He says that for every 1% of new electric vehicles making their way to market, 70,000 tonnes of lithium is in demand. These numbers were originally published by Goldman Sachs, who called lithium-ion the new gasoline, showing just how much demand has grown. So, needless to say, the numbers aren't inspiring much confidence. Sodium-ion batteries, anyone?

According to ABC News, only five lithium mines have been fully developed in the last 20 years due to the low demand. However, then Elon Musk and his soon-to-launch Tesla Gigafactory hit the scene and is using lithium-ion propaganda to instil the anxious feeling that everyone should have a lithium-ion battery in their car and in the house, or be left in the Stone Age. Musk's factory, if successful, will be the world leader in lithium battery power producing.

Goldman Sachs further projected that lithium-ion batteries' use in electric vehicles alone would grow 11-fold, making the demand reach 300,000 tonnes by 2025. Elon Musk isn't the only philanthropist wanting to get his hands on the world's lithium production, China is interested too. A study conducted by Infiniti Research Limited entitled Global Lithium Market 2016-2020 estimates that the electric vehicle market in China. The demand for EVs in China will grow the market at a CAGR of 7.84%, making the country a contender for lithium-ion battery usage. All we know is the more lithium mining that occurs the more there will be for the world, and that's what engineers are working towards. A world powered by renewable energy with the assistance of lithium-ion technology.

- Details

- Written by: Quintus Potgieter

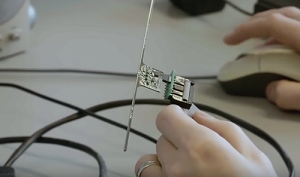

The 3rd Generation Partnership Project is a collaboration that involves multiple telecommunications companies who were behind the expansion of third-generation (3G) mobile phone system technology. The collaboration now wants to focus its efforts on Industrie 4.0 and focus on communication for the Internet of Things. This involves working on fifth generation technology. The group has released the first specifications for a new radio technology that will be ready to be used in devices by June 2018.

They will be finalising the architecture of systems that will run on fifth-generation communications by December of 2016. The result will be narrowband Internet of Things (NB-IoT) supporting two-way communications that will have low throughput and will be able to function on low-cost devices. Furthermore, the technology will be able to support up to 150,000 devices per single cellular cell. The release will also be able to run alongside existing 2G and LTE networking. This means, finally, GPRS will be quicker as well. Don't you just hate it when your phone barely manages to get internet on GPRS? Now, Release 13 allows for a 20db link budget improvement that will see GPRS perform better under terrible conditions.

Dino Flore, chairman of 3GPP said: "It took us only nine months to standardise the new technology after the study phase. Once again 3GPP demonstrated the ability to quickly respond to the emerging market needs."

Dino Flore, chairman of 3GPP said: "It took us only nine months to standardise the new technology after the study phase. Once again 3GPP demonstrated the ability to quickly respond to the emerging market needs."

Meanwhile, a company named u-blox has released a chip that will be compatible with 3GPP Release 13 (the new 5G standard) that will assist with communications in "smart buildings and cities, utilities metering, white goods, asset tracking, and agricultural and environmental monitoring." It is being considered the world's first cellular NB-Iot (Narrowband) technology. The chip will be the first one to be used by industry leaders Vodafone, Huawei and more. It will be the standard for NB-IoT and the future of the 5G world. It is called SARA-N2 module

Vodafone will be using NB-IoT as soon as 2017. The technology will go by the name LTE-Advanced Pro.

Alex Sinclair, CTO of the GSMA, said: "We are pleased that the industry has moved so quickly to adopt them and that they have now been ratified by 3GPP. Mobile operators have already started a number of pilots around the world and this agreement over common standards will help accelerate the development of commercial solutions and ensure they are in market much faster, providing customers with more choice."

The Internet of Things is going to need lightning-speed communications between devices and this standardisation of communications technology is a good step forward.

Source: PR Newswire

- Details

- Written by: Quintus Potgieter

The civil engineering industry is desperately wanting to use automated drone technology in the United States. Current unmanned vehicle laws from the Federal Aviation Administration have limited some of the automated operations that could be run on construction sites, which would perform site monitoring, mapping, and inspection. Now, they are updating the laws but have still left out amendments that would benefit the engineering companies.

Companies in the US that want to use drones, want to implement automated systems. Amazon and Alphabet have both engineered automated drone delivery systems that will not be able to fly under the new FAA regulations. Another regulation that could stunt the growth is the fact that drones would not be able to fly during the hours of the night.

The new laws demand that a drone must always be in "eyeshot" of the pilot controlling it. However, as more and more automated drone delivery systems are proposed, the FAA could alter these laws. This would mean that automated site mapping, monitoring or inspection drones are a pipe dream for now, but so long as a piloted inspection drone can be seen by its pilot, those seem to be allowed for now.

U.S. Transport Secretary Anthony Foxx announced the new regulations on the FAA's website, saying: "We are part of a new era in aviation, and the potential for unmanned aircraft will make it safer and easier to do certain jobs. We look forward to working with the aviation community to support innovation, while maintaining our standards as the safest and most complex airspace in the world."

The FAA says the new regulations could create up to 100,000 new jobs in the industry over the next 10 years. They also say that the money generated by companies using drone technology could top $82 billion, according to their industry estimates.

There are many other uses UAS's could be used for in the engineering community and now that the laws have been altered, those uses can finally come to fruition. However, the lack of support for the automation of those systems sets some industries back. Good news for drone operators whose employment is guaranteed until the FAA decides to review the law on a pilot being necessary.

Automated drones flying pre-planned paths is invaluable to civil engineering industries and the safety of those sites, as shown in this video below:

The new drone laws are summarized

Source: Federal Aviation Administration

- Details

- Written by: Quintus Potgieter

The European Union has been reading some Isaac Asimov novels, it seems. The expansion of industrial robotics has made the EU question whether or not to finally give robots the "electronic persons" classification. We are seeing robots in factories around the world furthering the fourth industrial revolution and slowly making their way into households around the world. The fact of the matter cannot be denied, robots being considered "electronic persons" is soon not going to be the stuff of science-fiction novels anymore.

The draft document by the Legal Affairs Committee of the EU to give intelligent robots that title "electronic persons" has gotten the engineers who develop and equip factories with these 'robotic persons', talking. VDMA, a German engineering association, says this is the kind of overeager chatter that will slow the fourth industrial revolution down. The European Union are trying to force regulation on technologies that they assume already exists, says VDMA chief executive Thilo Brodtmann.

VDMA robotics and automation head Patrick Schwarzkopf told Reuters that a legal framework for electronic persons should only be happening in the next 50 years and not in the next ten years. "We think it would be very bureaucratic and would stunt the development of robotics," he said.

VDMA robotics and automation head Patrick Schwarzkopf told Reuters that a legal framework for electronic persons should only be happening in the next 50 years and not in the next ten years. "We think it would be very bureaucratic and would stunt the development of robotics," he said.

The draft proposal has come after news that factories all over the world are continually replacing human workers with a robotic workforce. The rise in industrial automation is something that Europe does quite well, and in Germany specifically. Perhaps that is why the EU wants to jump on the issue so quickly.

The activist behind the proposal is an MP Mady Delvaux. She was interviewed by the EU's actual website, saying that robots need a classification of some sort because of the many different kinds of robots that exist today, i.e. service robots, industrial robots, drones, cars, etc. She said: "There are various reasons for this. We need a new European standardisation. We also need to consider liability, the protection of personal data and the prevention of hacking...The US, China, Korea and Japan have very ambitious projects. If we do not create the legal framework for the development of robotics, our market will be invaded by robots from the outside. Also, the European Parliament will be the first parliament in the world to discuss and create such a legal framework." She also alludes to the fact that the robot revolution will "destroy certain kinds of jobs" but is confident that Europe will be creating new ones to counteract the loss of employment.

Other robot manufacturers like Kuka have also rubbished the claims that an "electronic persons" classification for robots is necessary right now and would rather delay the process to see where robotics lands up in the upcoming years.

Here is the entire draft report on the recommendations to the commission on Civil Law Rules on Robotics

- Details

- Written by: Quintus Potgieter

I can sometimes be seen on a rod but I'm not a fish. I can be forked but I'm not a tongue. I'm bright but I'm not the sun. I'm electric but I don't have any wires. I'm seen during a storm but I'm not a cloud. What am I? Seeing as though it's Friday, I'll let you off the hook and give you the answer. It's lightning.

In this article, two industries that seem to produce conductive elements that attract lightning, will be focused on. However, here is a list of just some of the objects that need earthing and grounding:

- Standby generators

- LV and HV supply systems

- Technical Earthing for equipment sensitive to fault currents

- Transformers

- Feeder Pillars

- Telecommunications Systems

- Wind Farms

- Deep drilled boreholes with conductive aggregates

- Rail and tram earthing

- And many more

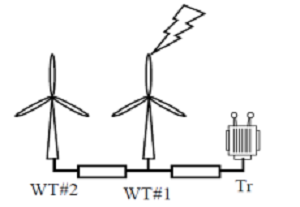

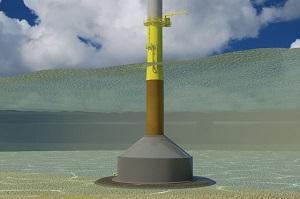

Wind turbines are behind a lot of the clean energy production that is sticking to governmental agreements to minimize the amount of greenhouse gases, especially in Europe. Ensuring the turbines aren't hit by lightning is an enormous undertaking due to the very pole-like nature the turbines have, including the electromagnetic fields the turbines produce. They are a glaring target for lightning. Reports of damaged blades and the electronic equipment inside the turbines have been seen in the industry due to bad grounding practices.

Wind Farm Bop writes that there are 3 main characteristics of an earthing system:

- Ensure that living beings in the vicinity of the earthing system are not exposed to dangerous potentials

- Retain system voltages within reasonable limits in case of faults

- Provide a sufficiently low impedance

He further says mechanical technology solutions for grounding wind turbines has a bigger failure rate than other more solid grounding applications such as exothermic or compression grounding technology. Exothermic grounding technology is able to survive vibrations and disturbances, whereas mechanical technology can shake and come loose.

A new solution to grounding wind turbines has been an invention out of Spain named the Halo Lightning Suppressor. It deionizes the space around an electricity generating turbine. The technology boasts a 100% guarantee that lightning will be avoided.

Jay Kothari, the president of EMP Solutions - the company who has developed the Halo Lightning Suppressor - has underlined the problems wind turbines have. He said: “The first issue is the problem caused by atmospheric lightning, and second, because the turbine is spinning, it generates its own electrical field. So you have the static from the turbine as well. The solution is to deionize the air passing overhead and dissipate the static charge generated by the spinning blades. For that, we install a unit inside the tower to pull some the static electricity off the blades and send it to ground. And we install a unit on top of the turbine to dissipate the charges generated by the storm cloud. The two devices provide a huge area of protection. A single device can protect a 100-m radius or about 337,000 ft2 of space."

Jay Kothari, the president of EMP Solutions - the company who has developed the Halo Lightning Suppressor - has underlined the problems wind turbines have. He said: “The first issue is the problem caused by atmospheric lightning, and second, because the turbine is spinning, it generates its own electrical field. So you have the static from the turbine as well. The solution is to deionize the air passing overhead and dissipate the static charge generated by the spinning blades. For that, we install a unit inside the tower to pull some the static electricity off the blades and send it to ground. And we install a unit on top of the turbine to dissipate the charges generated by the storm cloud. The two devices provide a huge area of protection. A single device can protect a 100-m radius or about 337,000 ft2 of space."

Therefore, instead of trying to predict where lightning is going to strike, EMP Solutions tries to ensure that lightning doesn't strike at all. However, the company does admit lightning areas prone to lightning do require ground earthing systems regardless of their 'wonder-tool' that claims to undercut lightning.

Meuller also gives a nod to the grounding work that telecoms do in their fight against lightning. Data communications and telecommunication industries religiously ground their equipment and do it well. Something that could be shaking up the need for grounding in data communications and telecommunications is the introduction of fiber technologies.

The Dean of Engineering at the Engineering Institue of Technology, Steve Mackay, in a new episode of the Engineering News Network has spoken out against the myths of lightning. Talking about fiber, Mackay said: "If you're ever working with daily communications systems in lightning prone areas, always try and use fiber. Fiber gets rid of all the problems because fiber, of course, doesn't conduct lightning and of course, is immune to any electromagnetic interference. So, it's a really good solution." Mackay further warns that the misconception of lightning not striking twice is also a nonsensical myth due to the Empire State Building being struck multiple times a year, and emphasizing that lightning is unpredictable in that way.

- Details

- Written by: Quintus Potgieter

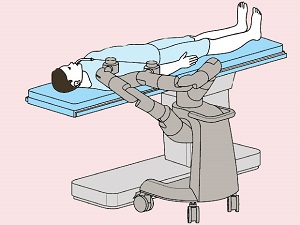

Robots are expensive. Some companies can overlook the fact that installing industrial robots would be an expensive endeavor because they have the funds available. But, what about start-up companies that can't exactly put down a lot of money for industrial robotics? The International Federation of Robotics has said that by 2018, there will be 2.3 million industrial robots at work. However, that number could be adjusted upwards if robotics becomes affordable by then.

This would be possible with collaborative robots, or 'cobots'. These are industrial collaborative machines that are cheaper to buy than a full-fledged industrial robotic setup  but helps with factory efficiency. The average price for one is $24,000 but there are some that go for $10,000. So, the prices aren't bad for small companies who want to get into manufacturing or automate some of their assembly lines. The cheaper collaborative robots are single arms that do repetitive tasks like picking and placing or packaging. And they are becoming more attractive to companies and fast.

but helps with factory efficiency. The average price for one is $24,000 but there are some that go for $10,000. So, the prices aren't bad for small companies who want to get into manufacturing or automate some of their assembly lines. The cheaper collaborative robots are single arms that do repetitive tasks like picking and placing or packaging. And they are becoming more attractive to companies and fast.

The cobot market itself, according to Barclays, was sitting at $116 million last year, but will shoot up to $11.5 billion by 2025. Speaking to Reuters, Stefan Lampa, the head of robotics at Germany's Kuka spoke about collaborative robots: "By 2020 it will be a game-changer"

The leader in collaborative robotics sales is Universal Robotics, who say they are doubling the number of sales yearly due to the fresh demand for collaborative robots.

Collaborative robots are seeing a massive sales hike in not only the manufacturing industries but also the food industry. Barclays released their report that showed the UK would be spending $1.6 billion on automation in the next year. The report says that beverage and food companies would see "productivity improvements" of 25% and would also see jobs being creation despite more automation being implemented. This relates to the fact that more collaborative robots are being purchased that still make space for humans within jobs.

- Details

- Written by: Quintus Potgieter

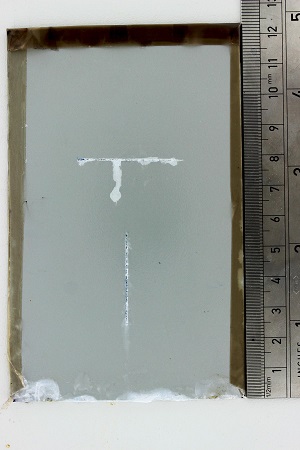

Getting your professional certificate in 3D printing and design could take you many places. After all, additive manufacturing is becoming an important part of a lot of industrial endeavours in the world of engineering today. However, the biomedical field is always an interesting one when it works in tandem with 3D printing. We've seen everything from artificial arms to tracheas get printed and used for biomedical purposes. But now bioprinting has taken another step forward. And it's got to do with stem cell research.

Researchers from the University of Bristol have developed a material named bio-ink. The 'ink' lays the material foundation for stem cell growth to be facilitated. Thereafter, living tissue can be 3D printed. The revelations come from the School of Cellular and Molecular Medicine who have published their findings in the Wiley Online Library under the title: 3D Bioprinting Using a Templated Porous Bio-ink.

To explain, Dr Adam Perriman, from the School of Cellular and Molecular Medicine, said: "Designing the new bio-ink was extremely challenging. You need a material that is printable, strong enough to maintain its shape when immersed in nutrients, and that is not harmful to the cells. We managed to do this, but there was a lot of trial and error before we cracked the final formulation. The special bio-ink formulation was extruded from a retrofitted benchtop 3D printer, as a liquid that transformed to a gel at 37°C, which allowed construction of complex living 3D architectures."

To explain, Dr Adam Perriman, from the School of Cellular and Molecular Medicine, said: "Designing the new bio-ink was extremely challenging. You need a material that is printable, strong enough to maintain its shape when immersed in nutrients, and that is not harmful to the cells. We managed to do this, but there was a lot of trial and error before we cracked the final formulation. The special bio-ink formulation was extruded from a retrofitted benchtop 3D printer, as a liquid that transformed to a gel at 37°C, which allowed construction of complex living 3D architectures."

The bio-ink consisted of polymers extracted from seaweed and another unnamed synthetic polymer. The seaweed polymer is reportedly the answer to sustaining cell nutrients once they are heated up to the specific temperature.

"What was really astonishing for us was when the cell nutrients were introduced, the synthetic polymer was completely expelled from the 3D structure, leaving only the stem cells and the natural seaweed polymer. This, in turn, created microscopic pores in the structure, which provided more effective nutrient access for the stem cells,” Perriman concluded.

The printing of complex tissue structures could see the future of printed body parts actually becoming more than fiction. This would add even more uses to the already impressive feat of engineering that is the 3D printer.

How about it engineers? Want to get your hands on some bio-ink and develop something that could improve the engineering world through 3D printing?

Source: PHYS

- Details

- Written by: Quintus Potgieter

BMW have finally revealed that they intend to get into the energy storage system market and compete against manufacturers like Tesla, Daimler (Mercedes Benz) and Nissan. BMW will be repurposing their i3 model batteries for home storage systems once the batteries have served their purpose inside the car. Once an electric vehicle has used a percentage of a lithium-ion battery's recharge cycles, it is illegal to keep it inside a car, however, the battery retains enough of its power to act as a solar energy storage unit for households. Nissan will be putting their Leaf vehicle's batteries on walls once they are past their prime as well.

The product was announced at BMW's very own electric vehicle facility in Montreal, Canada. The company pointed out that their offerings stand out above the crowd due to being a repurposed car battery and not a full battery pack like Tesla has developed. The technology has recently been branded 'car-to-grid' technology.

The unit gets its electricity from solar panels and is able to provide that electricity to households during peak hours to save consumers some of their hard-earned cash once the cost of energy provided by the grid is at its highest. It can also power the household once an outage occurs. Along with PV module and the storage unit, you get the converter and equipment that will all be inclusive in the installation rates.

How much juice are we talking here? BMW will be selling stackable 22-kWh or 33-kWh packs. This would definitely be able to power most of the appliances in a house for a 24 hour period. The average household in the United States uses 30kWh per day. BMW also confirm that the battery can be used to charge electric vehicles.

Cliff Fietzek, manager of Connected eMobility at BMW USA, said: "The remarkable advantage for BMW customers in using BMW i3 batteries as a plug and play storage application is the ability to tap into an alternative resource for residential and commercial backup power, thus using renewable energy much more efficiently and enabling additional revenues from the energy market."

An update to our wall of competitors is in order:

| Tesla PowerWall | Mercedes | Nissan xStorage | BMW |

| Stores 6.4kWh | Stores 2.5kWh | Stores 4.2kWh | TBD |

| Storage stacking: 9 PowerWalls can be connected to equal 58kWh | Storage stacking: 8 Mercedes batteries to equal 20kWh | Storage stacking: 8 batteries to equal 20kWh | Storage stacking: 22kwH or 33kwH |

| Price: Up to $7,000 each including installation | Price: Up to $10,000 each including installation | Price: $4,500 each including installation | TBD |

Source: Autoblog

- Details

- Written by: Quintus Potgieter

The Internet of Things is growing at an exponential rate, faster than some companies can keep up. The Internet of Things also emphasizes the need for faster internet connections. The impending future interconnectivity of 50 billion devices around the world has inspired a slew of 5G network tests in the United States, in attempts to handle the speed necessary to facilitate the Internet of Things. Faster internet speeds will be good for the Internet of Things so data and analytics can be quickly calculated and ready for data analysts to peruse.

However, there has been a kink in the wire that has been slowing IoT data and analytics analysis down. The problem lies within the sensors a certain IoT setup contains. For example, a factory could have industrial robots and automated machines that have thousands of sensors within its manufacturing. Those sensors are responsible for monitoring how the machines are working and allow for the data to be exported and perused by the analysts. Researchers at the Georgia Tech Research Institute (GTRI) say they have developed a "flexible, generic data-fusion software" that will allow the data from all Internet of Things connected sensors to be shown at once.

Another challenge that could slow down the process of making sense of IoT sensor data, are the formats that they could be encrypted in. Finding a one-fits-all answer to communication protocols is what GTRI are trying to do.

The FUSE data-fusion software has been developed to serve the following purposes:

- Providing users with online forms that let them define the sources they need in the form of “domains” – abstract descriptions of how the targeted data interrelate;

- Gathering incoming raw data according to user specifications and mapping them into the specified domains. The data can then be transformed and manipulated using “tasks,” which are user-defined JavaScript functions or legacy software that run inside the FUSE service;

- Displaying the processed data to users on-screen via an interactive data visualization, exploration and analysis dashboard that supports most data types including numeric, logical, and text data. Users can also devise their own custom dashboards or other interfaces.

"One of the advantages of FUSE is that it can be broken up and distributed to accommodate any sensor and server architecture. So it can grow and change as a business, facility or campus changes over time," Adams concluded.

The researchers at Georgia Tech are trying to automate the processes behind perusing data of automated systems, which would make every element of the Internet of Things more efficient. Now, there are still manual processes that need to be followed with acquiring the data produced by the sensors in an IoT setup. FUSE would be assisting with this, and could be an invaluable addition to automated setups.

Source: Georgia Tech News

- Details

- Written by: Quintus Potgieter

When getting your qualifications in science, technology, engineering and mathematics, it is easy to lose track of skills that could be easily attainable that might assist your job hunt in the future. There are a number of engineering experts that are warning students to further explore entrepreneurial and business skills that might complement their engineering degrees.

In the United Kingdom, in Newcastle, STEM experts are trying to implement a student-focused course named The Hunter's Smart Specialisation Strategy. The strategy tries to fuse both STEM careers and entrepreneurship, as well as digital literacy, in an attempt to grow the skill sets of STEM  career professionals.

career professionals.

The Massachusetts Insitute of Technology (MIT) also recently launched entrepreneurship courses that specifically teach engineers entrepreneurial skills for the closing of business deals. The course is called Entrepreneurial Negotiations: The MIT Way.

Moreover, the University of Illinois Urbana-Champaign's College of Engineering have also launched a program that sees business-savvy skills being taught to engineering students. The university wants to launch the course by this September. The program will focus on "Innovation, Leadership and Engineering Entrepreneurship."

"We lead the pack in entrepreneurship and by creating this degree we are recognizing that innovation leadership and engineering entrepreneurship are not just satellite, extracurricular activities but we bring them front and center. Students can come to Illinois, engage their passions, and receive mentorship, education and guidance as they part in our highly entrepreneurial ecosystem on campus," said Andreas Cangellaris, dean of engineering at UIUC.

UIUC have high-ranking engineering alumni who have gone on to start build and contribute to companies like PayPal and YouTube.

Sydney Morning Herald contributor Tony Featherstone has also commented on the need for entrepreneurship education in Australia amidst a shortage of mathematics education and entrepreneurship education. He writes:

Australia needs more scientists who think like entrepreneurs, information technology students who can turn their software into a fast-growth growth ventures, mathematicians who can turn algorithms into commercial ventures, and engineers who can build big businesses. But it will take generational change to achieve it and the push must start at school.

- Details

- Written by: Quintus Potgieter

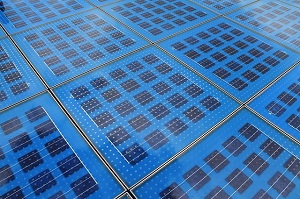

Photovoltaic cells are not reaching their full potential. Recently, we reported on a method that could lead to more efficient photovoltaic cells from the University of Utah. The revelations included subjecting semiconductors to light sources before the manufacturing process. This reportedly, allowed semiconductors to work more efficiently, especially for applications in solar technology.

The improvement of solar technology will be important in the photovoltaic cell industry in the next few years. Increasing solar efficiency is paramount to the future of renewable energy. The University of Utah's work is largely theoretical as it stands. A sure-fire solution to making solar panels more efficient is needed, here and now.

"The problem occurs in series-connected solar panels (which is one of the most common ways of connecting solar panels for distributed PV systems) when solar modules are experiencing varying levels of irradiation or temperature. This can result from sporadic cloud, dust accumulation on the PV panels, or uneven air ventilation. In these instances, the current generated by each module is different," said Masdar Insitute Research Engineer Omair Khan.

"The problem occurs in series-connected solar panels (which is one of the most common ways of connecting solar panels for distributed PV systems) when solar modules are experiencing varying levels of irradiation or temperature. This can result from sporadic cloud, dust accumulation on the PV panels, or uneven air ventilation. In these instances, the current generated by each module is different," said Masdar Insitute Research Engineer Omair Khan.

The engineers say that low-performing photovoltaic panels covered by shade cause panels that are exposed to the electricity giving sun to produce less energy. Therefore, the engineers came up with a novel solution.

The device was developed by Khan and the Masdar Institue of Electrical Engineering and Computer Science. The device connects the solar panels and optimizes their output. The device takes the series-connected solar panels and feeds each of them independently instead of the usual load-share, photovoltaic panels are synonymous for.

The device was developed by Khan and the Masdar Institue of Electrical Engineering and Computer Science. The device connects the solar panels and optimizes their output. The device takes the series-connected solar panels and feeds each of them independently instead of the usual load-share, photovoltaic panels are synonymous for.

"The low performing solar modules affect the energy output of the entire string of solar panels, as the maximum power output is governed by the lowest current in the system. This means that if one solar module is shaded and thus generating a low current, and is connected in series to several good, high-performing modules, then the high-performing modules cannot operate at higher currents," Khan said.

The device undercuts the "lowest current" limitation prevalent in photovoltaic cells today and rather uses the strongest output a panel may be receiving.

"By employing a dedicated converter to independently perform maximum power point tracking on each submodule, rather than the string of modules as a whole, means that the operating point of each submodule has no effect on the rest of the submodules in the system. Each converter extracts the maximum power possible from each submodule, thus maximizing the PV system's energy-efficiency," Khan concluded.

- Details

- Written by: Quintus Potgieter

We've all seen them. A video that is sped up by about 2 times its normal rate, showing an industrial robot performing some sort of complicated task. The main issue is the speed at which the robot is actually operating at. Industrial robotics can't be fully implemented if what we're left with are slow robots working at a slow pace. That's where motion planning comes in. Researchers at Duke University explain: "Motion planning is the problem of finding a path to move a robot from its current position to some goal position without colliding with any obstacles."

Essentially, collision detection software needs to be built into the robot's processor so that it knows what to avoid and what to pick up. The processor has collision detecting circuits, according to an engineer which assisted in the building of the chip.

"Although motion planning has been studied for decades, existing techniques take seconds on general purpose CPUs and hundreds of milliseconds on power-hungry GPUs to create a single plan. This is a major obstacle to the practical use of robots in unstructured environments as there are often long delays between the desire to execute a motion, and actually having a plan to execute," said the researchers in their video.

The researchers are trying to save the day with the processor they have developed. They have published their findings in a journal titled Robot Motion Planning on a Chip. They claim they are able to speed up the motion planning three times over and say that it would use 20 percent less power than robots do for motion planning as it is. The researchers have tested a robot arm out on their motion planning chip and have revealed that the motion planning takes less than a millisecond to motion plan.

The researchers use multiple Microsoft Kinects put in four different locations around a robotic arm, which then calculates 3D volumes in its path, which are called voxels. The algorithm then calculates what is considered an object due to a pre-existing instruction and avoids anything that it is programmed to avoid.

As a result, the robot looks to be working as quick as a human would in terms of noticing what obstacles are in its way, and circumnavigating around them to obtain the item it is looking for. In other words, it is motion planning in real time much like a human brain would. Of course, it isn't completely full-proof yet but the research indicates that robots will be extra efficient in the future.

Watch the video below to see the impressive engineering feats that the engineers over at Duke Robotics have perfected:

- Details

- Written by: Quintus Potgieter

Researchers from Swansea University could be sitting on a gold mine. The team has just been awarded £25,000 (about $37,000) from the Worshipful Company of Armourers and Brasiers. What? Who are we worshipping? The researchers have apparently made breakthroughs in corrosion inhibitors that prevent rust and corrosion, especially on steel products. They have developed this inhibitor to address the issue of a previous inhibitor which will be banned from the EU in 2019. That specific inhibitor is named "hexavalent chromate".

Hexavalent chromium is being banned for health reasons. According to the Occupational Safety and Health Administration in the U.S. the chromium is unsafe to work with. OHSA said: "The evidence in the record for rulemaking indicates that workers exposed to Cr(VI) are at an increased risk of developing lung cancer. The record also indicates that occupational exposure to Cr(VI) may result in asthma, and damage to the nasal epithelia and skin."

So, the University of Swansea's breakthrough that can be coated onto steel products to prevent their degradation is coming at the best time possible for the steel industry.

The researchers reportedly used aggressive electrolyte anions that were implemented into the coating. The coating then reacts and triggers a release of an inhibitor. They say the alternative they have come up with can be considered a "smart release coating" that outperforms hexavalent chromate.

Professor Gaint Williams, who is at the helm of the team at the University of Swansea's College of Engineering, said: "This is a significant breakthrough, showing a smarter and safer way of reducing corrosion. The new product is environmentally sound, economical, and outperforms the market leader in laboratory tests. It illustrates that Swansea, with its close links between research and industry, remains at the heart of innovation in steel."

The steel market is reportedly worth £3 billion ($4.4 billion) in Europe alone. Therefore, the corrosion inhibitor could make the researchers quite a bit of money based on coming up with a safer alternative to what steel is coated with today.

"The system has been shown to prevent the onset of corrosion for over 24 hours compared to less than two hours for the current market leader. We also have been able to demonstrate that the rate of corrosion can be slowed down significantly once it has started. This is by far the best result seen in 15 years of research on this topic," said Patrick Dodds, a doctoral student at the Univeristy of Swansea.

- Details

- Written by: Quintus Potgieter

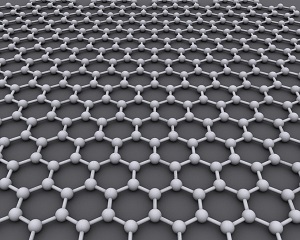

Photovoltaic installations are all the rage in 2016 but are they cost-effective and efficient? Right now, getting a storage system could be a little bit of the price range of most consumers. If households want to shave their peak-time energy bills, getting a storage system makes sense, however, if there is no subsidization for storage systems, you could expect to part with $3,000 for a Tesla PowerWall. The price goes higher in other countries due to shipping costs and general installation of any sort of storage system for individual households.

Three United Kingdom research organizations noticed this problem and have all banded together to develop a solution to the price tag on storage. The organizations - of which one includes the assistance of The University of Warwick - agreed to lend their top engineers to build sodium-ion cells that would serve as low-cost

alternative to lithium-ion batteries. Lithium-ion's development is ongoing and is becoming one of the standards for powering vehicles, energy storage systems and still used for powering electronics.The researchers are certain that their sodium alternative would be 30% less expensive to produce.

Faradion's CEO Francis Massin, said: "This partnership with Moxia Technology and WMG offers a great opportunity not just for Faradion, but for global CO2 reduction. Solar energy storage is an important growth market of the next five years and this partnership means that the UK has the opportunity to be at the forefront of the technology development."

Each company brings something different to the table. Faradion brings their sodium know-how. Moixa has a vast knowledge of energy storage and WMG brings some of the best engineers together to work on the newly developed cells.

Faradion was awarded a £38.2 million ($55 million) grant to further develop the sodium-ion batteries back in May. The company is expected to show how the battery could be implemented into electric vehicles by 2018. By 2025, the company estimates that multiple cars across the UK will have sodium-ion batteries installed inside of them.

The question is will sodium-ion be the battery of choice in the future if it remains cheaper than lithium-ion? Lithium batteries seem to have some sort of monopoly over the game now due to manufacturers using it for EVs, storage systems and other applications. However, by 2018 we could see a battle of the batteries.

- Details

- Written by: Quintus Potgieter

Industrial automation is growing in popularity as the fourth industrial revolution continues to charge ahead into the future. The Robotics Industries Association has reported that in 2015, the demand for industrial robotics grew by 14% and was valued at $1.8 billion. The International Federation of Robotics also chimed in with their projections. They say that by 2018, there will be 1.3 million industrial robots in use around the world.

President of Force Robots, Steve Somes, said: "Collaborative robots are going strong, and you will see a larger role in force sensing and control. Responding to external forces not only makes robots safer collaboration, it also enables more tasks like assembly, grinding and deburring."

Now, in new developments for robotic sensors and cameras, Robotiq has released a vision-guidance system for pick and place robots; the kind of robots you'd find in an industrial factory.The company currently supplies Universal Robots with "2-finger and 3-finger grippers". The camera fits onto a module that surrounds the robots arms and then gives the robot vision, to see what it the shape of something it is picking up. The company says it only takes five minutes to install. Automated location of objects of an object on an assembly line, thanks to the vision guidance system will improve the turnaround time of production, no matter what industry. It would ensure a safer work space as well, for human colleagues using collaborative robots.

Explaining how the Robotiq camera system works, the manufacturing engineer at Continental Automotive, Victor Canton, said: "The Robotiq Camera breaks all the integration barriers that we are used to seeing with vision systems in manufacturing automation. We could think of many pick & place robot tasks that can now be programmed very fast. We will need this solution for upcoming projects with UR robots."

- Details

- Written by: Quintus Potgieter

Cement. Can't live without it...can't live without it. Concrete is important in the civil engineering world, but, sustainable, environmentally non-harmful applications of concrete are becoming even more important. However, how do we make cement cooler? Researchers from the Michoacan University of San Nicolás de Hidalgo have the answer. Glow-in-the-dark cement. The researchers have used phosphorescent materials to make the glow-in-the-dark cement which would be more eco-friendly than using normal cement.

How does it work? It absorbs radiation during the day and then lights up at night. It's a phosphorescent cement that acts as an alternative to cement. The researchers explained: "By using additives, scientists are able to prevent the formation of crystals that occur normally during the production of cement, creating a material with a noncrystalline structure - similar to glass - that allows passage of light inside. Varying the proportion of additives added while manufacturing the cement regulates both its luminescent  intensity and colour."

intensity and colour."

The 'cement' could be used in many towns for high visibility and eco-friendliness. The researchers say the cement could be lit-up for 12 hours. The big problem comes with the durability of the cement. Right now, further testing is required. The researchers are looking to the future. They want to hypothetically build entire walkways or bicycle lanes out phosphorescent cement . Additionally, if the cement is eco-friendly, companies may be interested. Minimizing the amount of GHG in the air bodes well for any company or entity, thereby shrinking carbon footprints in the cement industry.

The picture to the left of the article is not phosphorescent cement but stones. The future applications of the cement would be full walkways and bicycle lanes. The stones were positioned in such a way that it resembled Van Gogh's Starry Night, and is nothing more than a small project in the Netherlands.

Source: Futurism

- Details

- Written by: Quintus Potgieter

The world produces a lot of plastic every year. That plastic usually finds it way to landfills. Some of it even lands in our oceans. According to World Watch, the world produces 299 million tons of plastic per year. If you live in Asia, the amount of plastic used by a single person is 20 kilograms per year. Needless to say, there is a lot of polyethylene being used and discarded every day. But once it's discarded, it doesn't serve many purposes. Science fiction kind of changed that when Doc Brown chucked some garbage into his fuel tank in the end of the first Back to the Future movie and powered his vehicle with enough fuel to blast him and Marty McFly into the future. Oh, imagine that, chemical engineers!

The Shangai Institute of Organic Chemistry and the University of California have reportedly developed "efficient and selective degradation of polyethylenes into liquid fuels". The researchers are cognizant of the methods used to produce fuels from plastic today. They, however, say that those methods are low-energy and are not efficient. Additionally, the burning of plastic contributes to harmful emissions. Converting plastic waste into fuel, without creating fossil fuels would be a step forward for  the world.

the world.

The researchers created a process called cross alkane metathesis (CAM). The researchers split the properties of the already manufactured plastic and were left with Ir-H2. They say that splitting of the plastic's properties can then be used with further cross alkane metathesis to produce hydrocarbons that can be used as diesel fuel that is "suitable for transportation". The researchers say the process is highly efficient and inexpensive.

The research implies that plastic and bottles and grocery store plastic bag might be able to be used to make liquid fuel. And we have a lot of those in the world today. You can read the researchers' published works in the Science Advances journal. Their contribution to the journal is titled: Efficient and selective degradation of polyethylenes into liquid fuels and waxes under mild conditions.

- Details

- Written by: Quintus Potgieter

Substation design has changed over the years. Now, with the upcoming push for renewable energy, the technology that operates substations needs to keep up with the times or eventually just call it a day. The issue with old substation design? It tends to leave some people in the dark...for hours. Just ask Michigan. 25,000 people were recently subjected to power outages due to unknown reasons. The Executive Director of Public Affairs at Lansing Board of Water & Light Steve Serkaian indicated it was the age of the substation the utility was utilizing.

"When you have a facility that's more than 50 years old, I mean, try driving a vehicle that's more than 50 years old," Serkaian said. That is really the only explanation that might describe most substation failures these days. He further went on to say, "Technology is not flawless."

What do engineers do to guarantee substation design reliability? They build automated systems that can quickly restore power if an unplanned outage occurs. Some utilities use self-healing solutions that assist with some of the challenges they experience today. Newly automated systems have fault detection, isolation, and load restoration (FDIR).

One of these automated solutions is available from ABB Group, who specialize in Automation and Power Technologies. Explaining FDIR, they write: "FDIR enables the utility to quickly identify the location of a fault, isolate it, and restore power during an unplanned outage by rerouting the flow of power on the distribution grid through, unaffected areas."

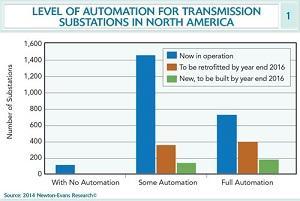

But the question is, how many utilities have automated systems or reliable, new, technologies that ensure power continues to flow when an unexpected outage occurs? The answer is...not enough. The smart-grid future, some think is here, is a bit further away.

According to Newtons-Evans Research, as of 2014, the number of fully automated substations is significantly lower to substations that have some automation. The number of substations to be built with full automation by the end of this year is also low. The situation is worse in third-world countries where the old technology of eras past is used to supply electricity to their respective towns and cities.

Automated substations would ensure real-time data and analytics and is far more useful than the old substation technology that goes down without an indication of what caused the outages.

The main issue with upgrading substations with automated technology is whether to replace the remote terminal units or just retrofit pre-existing RTUs in the utility. Replacing RTUs might not address the problems some utilities have and can be overly costly, so retrofitting solutions could be implemented.

Miles Dupuis, an engineer from an electrical services company named Cleco Corp, spoke to Utility Products and explained the divide between replacing the legacy RTUs or retrofitting on the old technology. He indicated that there was no comparison between a full RTU replacement versus a retrofitted RTU system. He said: "Using a vendor that allows us to retrofit RTUs in one day while using only one person in the field is far less costly than what other vendors offer. Some solutions offer the option to replace old, outdated RTUs with replacements to modernize your substations ; however, it usually takes three people and two to three days to complete the task, at a much more significant cost."

- Details

- Written by: Quintus Potgieter

Here is one for the PC master race. The University of California, Davis, is in the news for creating a new 1000-core "kilo-core" processor. Say what? Yes. The university's Department of Electrical and Computer Engineering have created a processing chip that is able to handle 1,000 independent processors. This would be considered the world's first kilo-core processor, the engineers said. Unless there is someone else out there who can take them up on the challenge and prove that something as impressive has already been built. The chip completely destroys the last record that saw only 300 processors on a multi-core chip.

The researchers also ensured that the chip is energy efficient. They say it can be powered by a single AA battery. The researchers showed their creation off at the 2016 Symposium on VLSI Technology and Circuits.

Bevan Baas, a professor of electrical and computer engineering at UC Davis, who was at the helm of the project, said: "To the best of our knowledge, it is the world's first 1000-processor chip and it is the highest clock rate processor ever designed in a university."

Bevan Baas, a professor of electrical and computer engineering at UC Davis, who was at the helm of the project, said: "To the best of our knowledge, it is the world's first 1000-processor chip and it is the highest clock rate processor ever designed in a university."

So who funded the thing? Unsurprisingly, IBM did.

But how fast does it really go? Baas said that 1,000 processors could handle 115 billion instructions per second. Another benefit of the independent processors being powered individually, the processors could shut themselves off to save battery life when they aren't being utilized.

So what do we do with a kilo-core processor? What can we use it for?

The truth is a lot of processes, however, it wouldn't be consumer-ready (for now) due to a hefty price tag. The team is certain it can be used for "wireless coding/decoding, video processing, encryption" and other large data applications. IBM already has a supercomputer that is on a top 5 list of the fastest computers in the world. Research into these kinds of microchip processors could see their computers becoming even faster.

Source: UC Davis

- Details

- Written by: Quintus Potgieter

The University of Michigan knows how important nanotechnology is. Engineers all over the world are actively busy with nanotechnology, that can be worn outside of the body, but also exist inside a body. Biomedical applications of nanotechnology have a long list of advantages if perfected. Now, researchers from the university have begun to work an injectable computer that uses radio frequencies to communicate with machinery outside of the body. Fancy having a WiFi connected body?

The engineers say that an injectable computer could help measuring tumor pressure inside the body, as well as other medical applications. At the helm of the project is David Wentzloff, an associate professor of electrical and computer engineering at the University of Michigan. The battery-operated computer was crafted for a project the university was running that encouraged students to build something that could "boost the evolution" of the Internet of Things.

So, what the engineers at the University of Michigan have done, is connected our bodies to the Internet of Things. As facetious as that sounds, it is a legitimate statement for the future of the Internet of Things.

David Blaauw, a professor of electrical engineering and computer science at the University of Michigan, and another researcher attached to the designing of the injectable computer said: "We have incorporated in our system, a radio. Typically in the past, we've only been able to go a couple centimeters of distance. That's really small. Now, what we've done here is made a new type of antenna that can go much longer distances but is still small enough that it can be put inside a syringe."

Wentzloff said that the computer would be able to definitely measure the pressure of tumors if the computer was injected into a patient. It could also track how well chemotherapy is working inside a patient. He said: "The size of a tumor is directly correlated to the pressure of the tumor. When you are administering chemotherapy, you can use pressure as a way of measuring the progress of the treatment. The primary challenge there is when you inject a device to try and measure the pressure, which scar tissue forms you are not getting a good reading. These millimeter-scaled injectable sensors are a minimally invasive way to measure the pressure inside a cancerous time."

The issue that researchers have had in the past is that the human body absorbs most of the electromagnetic radiation previously making it difficult to connect devices together through radio frequencies. The engineers went to work and produced a radio that can speak to another device by up to a foot outside of the body.

Source: The University of Michigan

- Details

- Written by: Quintus Potgieter

Efficient, renewable, cost-effective and...did we mention renewable? What are these words? Well, they are words that you hear in almost every single engineering industry in the world today, but these words specifically haunt the engineers who work with light-emitting diode technologies. Scientist and engineering associate professor, Mike Scarpulla has to grapple with these words daily. The professor from the University of Utah is actively involved in creating LED technologies. A recent breakthrough he made, could lead to more renewable, brighter, LEDs.

What he found is, before the LED light becomes an LED light, something can be tweaked in the manufacturing of the semiconductors that allow light emitting diodes to do what they do. The theory allegedly comes out of the National Renewable Energy Laboratory in Colorado, who suggested adding light during the manufacturing of semiconductors. The study could also assist with the building of more efficient photovoltaic cells.

Scarpulla explains that defects in semiconductors alter the conductivity of the material. He says this affects how the technology converts sunlight into electricity or causes LED lights to emit less light than they are capable of. The defects in semiconductors were thought to have been caused by the temperature or the conditions in which the semiconductors were manufactured. The researchers then introduced light in the semiconductor manufacturing phase and now have something interesting to report back.

Scarpulla explains that defects in semiconductors alter the conductivity of the material. He says this affects how the technology converts sunlight into electricity or causes LED lights to emit less light than they are capable of. The defects in semiconductors were thought to have been caused by the temperature or the conditions in which the semiconductors were manufactured. The researchers then introduced light in the semiconductor manufacturing phase and now have something interesting to report back.

"We ran simulations of what happens. If you put a piece of a semiconductor in a furnace in the dark, you would get one set of properties from it. But when you shine light on it in the furnace, it turns out you suppress these more problematic defects. We think it may allow us to get around some tricky problems with certain materials that have prevented their use for decades. The exciting work is in the future, though -- actually testing these predictions to make better devices," said Scarpulla, in a conversation with Science Daily

The team is now testing different semiconductors from different engineered products to see what effect introducing light in the manufacturing stage has. The researchers are confident that they could build more efficient semiconductors that power cellphones, solar panels, and LED light bulbs.

- Details

- Written by: Quintus Potgieter

Potholes are a global problem. Wherever there are roads, it's likely, that you'll eventually see a pothole. Some countries have it worse off than others when it comes to road maintenance, and could see potholes remain unfilled for a long period of time. Civil engineers all around the world are adamant to find a 'one size fits all' approach to ending the problem of potholes in their respective countries. One of the countries that suffer from unrepaired potholes is South Africa. $3.3 billion is spent every year on vehicle repairs and medical injury costs due to potholes.

The Council for Scientific and Industrial Research (CSIR) unveiled a new technology they had developed at the end of 2015. It is called the Visual Surveying Platform (VSP). The research had been done by a group of researchers at the CSIR and they published their findings under the title: Visual surveying platform for the automated detection of road surface distresses.

"To improve the efficiency of maintenance and reduce the cost thereof, the Visual Surveying Platform (VSP) is being developed that will automatically detect and analyze road distresses. The VSP consists of a vehicle-mounted sensor system, consist of a high-speed speed camera and a Global Positioning System (GPS) receiver, and an analysis and visualization software suit," the researchers wrote.

"To improve the efficiency of maintenance and reduce the cost thereof, the Visual Surveying Platform (VSP) is being developed that will automatically detect and analyze road distresses. The VSP consists of a vehicle-mounted sensor system, consist of a high-speed speed camera and a Global Positioning System (GPS) receiver, and an analysis and visualization software suit," the researchers wrote.

The system is inexpensive and efficient, the researchers say. One can be produced for just $33,000. The system video records the road surface and then analyzes the recordings through automated analysis which would be able to flag which roads have defects and require repairing.

"The VSP automatically detects and classifies road distresses using a two-stage artificial neural network framework. Video frames first undergo hue, saturation, and value (HSV) color conversion as well as a spatial frequency transformation before being used as inputs to the neural network.

It's an impressive step forward for the country and for the technology of pothole prevention and pothole repair.

The United Kingdom has also improved the efficiency of pothole repair, with similar technology the CSIR uses, but actually built into the pothole repairing vehicle. Some municipalities have invested into the Archway Roadmaster 295. The vehicle is able to patch up a pothole in three minutes. A front mounted boom extends out from the face of the truck and is used to spray the bitumen mix onto the road surface and patch up the pothole. To see the Roadmaster in action, take a look at the video below:

If you are in the civil engineering industry, let us know how you plan on tackling the global problem of potholes. Use our comments section and let us know.

- Details

- Written by: Quintus Potgieter

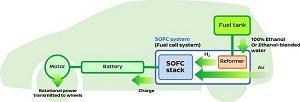

Nissan continues to innovate in the automotive industry. The company said they were working on a fuel cell vehicle (FCV) technology that would ethanol as a hydrogen source. The company hopes to have overhauled their entire fleet of vehicles to work on cleaner energy sources by 2020. The company indicated that they would be using sugar cane and corn crops to produce the ethanol.

Nissan's Executive Vice President Hideyuki Sakamoto said: "The cost and energy required to produce hydrogen can be very high, and it also requires significant investment in fuelling and storing infrastructure. Compared with that, ethanol is very easy to procure, it is safer to store and lower cost. These are its merits."

The move to ethanol would be an industry first, and would be very efficient. Nissan implied you would be able to drive at least 372 miles on a single tank. This would be competing with the Tesla Model S's estimations. The Tesla is rumored to only being able of reaching 253 miles before it needs a full recharge.

The move to ethanol would be an industry first, and would be very efficient. Nissan implied you would be able to drive at least 372 miles on a single tank. This would be competing with the Tesla Model S's estimations. The Tesla is rumored to only being able of reaching 253 miles before it needs a full recharge.

The official name of the technology is Solid Oxide Fuel-Cell (SOFC) technology. In their press release, the company said the system is powered by the e-Bio Fuel-Cell (the ethanol) and is driven by the SOFC power generator that turns the fuel into electricity.

"In addition, the e-Bio Fuel-Cell car's distinct electric-drive features -- including silent drive, linear start-up, and brisk acceleration -- allow users to enjoy the joys and comfort of a pure electric vehicle (EV).

So, it's lithium-ion vs ethanol in the future, then? Perhaps. Manufacturers are lining up to see what the preferred method of powering electric vehicles will be. However, both technologies are leading to a zero-emissions future and that's a good thing. Which technology looks most promising to you? Let us know in the comments section. You can also read Nissan's press release announcing the ethanol fuel cell: HERE

- Details

- Written by: Quintus Potgieter

Everything's bigger in Texas. Even the engines inside the big pickup trucks. However, petrol heads have become more conscious about how much fuel they consume as prices continue to dance around uneasily. It's all about fuel efficiency in the twenty-first century. However, with gas guzzling cars, getting the most out of your tank had been difficult, until now. An engineer out of Texas has claimed to have developed an engine that would be able to do 100 miles per gallon.

Cars are currently able to reach 60 miles to the gallon if the driver shuts off everything else that potentially utilises the car's energy-producing fuel, and just drives. However, Josh MacDowell, the budding inventor, has said that using a Stirling engine and thermopile technology has shown some interesting results. He has tested a hybrid electric car that

charges the car while it drives. He is venturing forward with putting one of the engines into a Ford F-150 and securing 58 miles to the gallon. MacDowell says smaller SUVs will be able to achieve 100 miles to a gallon,

Stirling engines are 200 years old and are powered by the exchange of hot and cold air. The engines are apparently able to use 50% of the power they produce, whereas the engines we use in our cars can only utilise 14% of the energy they produce.

Nonetheless, taking MacDowell's claims at face value, Texas A&M University, San Antonio, have now invested into the project, and will be assisting him in obtaining a patent for the new engine design.

Macdowell spoke to KHOU and said: "I imagine in 20 years the only place you will see an internal combustion engine is on a Harley-Davidson motorcycle because people like the way they sound. He is so confident in his new creation that he is prepared to do a cross country trip on only 40 gallons of fuel, and is expecting to achieve. He says once he achieves that the automotive industry will be knocking on his door to try and get involved with the technology.

Will the Stirling engine be the future of the automotive engine? We'll keep an eye on the news for you, and track the progress of MacDowell and his seemingly revolutionary engine.

- Details

- Written by: Quintus Potgieter

Countries like India and Africa have poverty-stricken areas with people who need food just like the rest of the world. In these impoverished areas, the burning of unstable gas stoves is commonplace, which has its own dangers due to shack fires that could occur. Burning charcoal is out of the question indoors, due to carbon monoxide. Burning a wood fire also causes unhealthy amounts of smoke if it were to be burned indoors. However, a group of engineers at a company named BioLite have banded together to bring a smoke-less clean burning wood stove, that is now available to these impoverished nations.

Additionally, the engineers have made sure that the stove is able to regulate heated and cooling temperatures with causing minimal damage to the stoves over time. The engineers say the stove can run twenty-four-seven without much damage to the pot.

So how does it work?

Ryan Gist, senior combustion engineer at BioLite. "In this lab mechanical engineers with electrical engineers and combustion engineers to develop our stoves and other products. We burn test every day and go through a lot of wood."

The answer is in the fans, which ensures more oxygen powers the fire instead of just burning the wood and creating wasteful smoke. Smoke is the indication of fuel for the fire that is being wasted and emitted, a fuel that could assist a fire in burning.

"The fan is really the heart of our home stove and camp stove products. It's important because it's doing two jobs at once. The fan is providing oxygen to the fire to make it burn clean and efficiently but it's also cooling the thermal-electric generator which allows us to make power," Gist said.

The team has 3D printed fan molds so that they can test an assortment of different fan sizes to measure how the fire can be manipulated inside the home stove. After the fans are tested they implement them into the full system.

The researchers use what they refer to as 'burn hoods' which test the amount of emissions being released by the stove. The emissions analyzers then produce data

"We measure the particulate smoke with a really cool method using a laser. By shooting a laser into the sample we can see the scatter back of the particulate smoke that's in the stream," Gist added.

The researchers claim that 90 percent of the smoke that conventional stoves produce - in poorer areas in India and Africa - is completely eliminated. The team says their target audience are the 1.2 billion people who do not have access to electricity.

"It's a really tough balancing act, the fans doing double duty, providing the air to the fire but also cooling the thermal-electric generator and you can imagine we can put more power into the fan to generate more electricity but we've taken more electricity to do that. At the same time, we have to balance the amount of air and oxygen the fire needs. It's that balancing act that we work so hard on doing in the lab," Gist said.

Source: QZ.com

- Details

- Written by: Quintus Potgieter

Fancy living in a 3D printed house? What used to be a far-fetched pipe dream might actually come to fruition sooner than you think. A Chinese company named WinSun had claimed to have printed 10 concrete houses in under 24 hours, in 2014. The company's concrete 3D printer has only been seen by employees. Therefore, there was no concrete evidence that the company factually printed the houses in under 24 hours, or even printed them at all.

As 3D printing technology progressed, the introduction of live, on site printings have increased. Dubai has printed their own office cubicle, in a construction project that took 17 days. Now, another Chinese  company claims to have printed a 400-square-meter villa in 45 days. The print happened completely on-site and manufactured in one place. The print is an encouraging look into the future of 3D printing houses which have been proven to be faster in construction that regular house building. The company behind the print is HuaShang Tengda Industry and Trade.

company claims to have printed a 400-square-meter villa in 45 days. The print happened completely on-site and manufactured in one place. The print is an encouraging look into the future of 3D printing houses which have been proven to be faster in construction that regular house building. The company behind the print is HuaShang Tengda Industry and Trade.

WinSun printed their parts off-site in 2014, whereas Huashang have completely printed and erected their villa out in the open. The company used C30 grade concrete with their concrete printing technology to construct the foundation and the walls.

An employee for Huashang Tengda said: "Our house 3D printing equipment combines four seperate systems: an electronic ingredient formulation system, a concrete mixing system, a transmission system and a 3D printing system. We have used a traditional reinforced concrete material to 3D print the villa, without any additives. The material does not need to be specially customized, so users can simply use locally-produced cement to greatly reduce material transportation costs."

3D printing now results in quicker build times, less labour costs, accurate structural design and efficiency across the board. 3D printing will irrevocably change civil engineering and construction for years to come as the technology is continually improved. Entire villas, offices and more are being printed, what else could we see printed in the upcoming years? The skies the limit, it seems, especially in Singapore ; the country has begun designing skyscrapers that are bound for 3D printing. Additionally, Dubai aims to print 25 percent of building projects by 2030.

Source: Engineering.com

- Details

- Written by: Quintus Potgieter

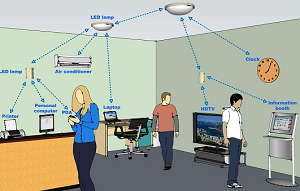

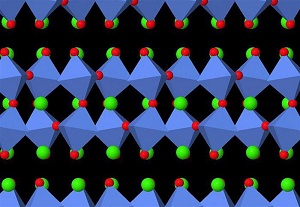

Data communications just got a bit more interesting thanks to lasers. Visible light communications abbreviated as VLC - no not the video player - is a technology that utilizes visible light to carry data from one device to the other, unlike radio frequencies that are used today. A new paper on the subject has been published in the ACS Photonics journal. The authors are from the King Abdullah University of Science and Technology (KAUST).

VLC technology makes use of lasers or LEDs which appear as normal lights. The catch is that the lights are turning on and off faster than the human eye can observe. Reportedly, the light sends data in binary code to a receiver that deciphers it. A converter changes the laser light into colors that  receive the transmission and decodes into "white light" that then captures the data being sent.

receive the transmission and decodes into "white light" that then captures the data being sent.

Osman Bakr, one of the researchers on the team developing a VLC color converter, said: "In this work we break the record for data communication using visible light, and more impressively produce white light with a very high color rendering index of 89, by designing a special color converter based on hybrid perovskite nanocrystals. Our work demonstrates white light as both a lighting source and a system for ultra-high-speed data communications."

The researchers' color converter allegedly has 40 times the bandwidth for transmission, compared to already available commercial converters. The team was able to reach 2 gigabits per second, trumping data transmission technology like WiFi.

"In this bandwidth-hungry era, there will be a continuous push by consumers for VLC systems with higher bitrates. We believe that white light generated by semiconductor lasers will one day replace the LED white light bulb for energy-efficient lighting. To achieve this objective, we set our long-term goal to develop nanocrystals that can convert high-energy excitation photons from the semiconductor lasers to Red-Yellow-Green-Blue (RYGB) lights at ultra-short photon lifetime," said Boon Ooi, one of the researchers and inventors behind the new converter.

The future of smart lighting that could produce data connection points which could transmit data to devices could be here sooner than we think. Engineers have been working on Li-Fi technologies that would make this possible. However, visible light communication could replace Li-Fi as a data transmitter in buildings with lighting fixtures, without the need of radio frequencies.

Source: PHYS

- Details

- Written by: Quintus Potgieter

Australia is now powering an entire gold and copper mine with solar energy. The DeGrussa mine in Western Australia is powered by one of the largest off-grid solar and battery storage facilities in Australia. The photovoltaic cells are producing 7MW of electricity and will reach 10MW by the end of summer. The plant will serve as a test for the implementation of clean energy powering of other mines around the world.