News

Unbelievably, inspecting an item considerably more times as against fewer times than required, will both result in more errors being identified. The question is what is a good choice in terms of number of inspections. What are the Statistics here?

Dear Colleagues

Unbelievably, inspecting an item considerably more times as against fewer times than required, will both result in more errors being identified. The question is what is a good choice in terms of number of inspections.

What are the Statistics here?

When inspecting a particular product two types of errors to avoid are a type 1 error where an actual part that is not defective is assessed defective (a Type 1 False Positive Error). Or a Part which is actually defective and which is assessed as not defective (a Type 2 False Negative Error).

In other words, in inspecting items of engineering equipment one can reject a good item (False Positive) or miss a defective item (False Negative).

A False Positive is not too Critical

This is perhaps not too bad apart from the cost and effort of replacing a defective item.

But a False Negative Could be Catastrophic

However, a false negative has to be avoided like the plague. Your critical piece of equipment has been inspected and signed off as acceptable when it is actually defective. This would result in failure during service with often horrible consequences.

Doing Considerably More Inspections to find errors is not the answer either

Theoretically, doing a huge number of inspections could result in nearly every item being inspected being found defective for some reason or other. So, simply increasing the number of inspections is not necessarily the best answer. One has to look elsewhere for solutions here – such as improving (or even in changing) the manufacturing process for the equipment.

The optimum number of inspections is a balancing act between a high level of inspections (costing a lot) against a minimal number where you may fail to uncover real errors (and thus resulting in a major failure of an item of equipment during service). A good knowledge of the process and product will enable you to make the right choice.

Thanks to 101 Things I learned in Engineering School by John Kuprenas with Matthew Frederick.

Although not necessarily good for equipment; this probably applies well to good engineering professionals – thanks to Jenni Rivera for a good quote: Thank you for accepting me as I am, with my virtues and defects.

Yours in engineering learning

Steve

Mackay’s Musings – 15th March’16 #591

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

The Internet of Things abbreviated as 'IoT' is a word that you should familiarize yourself with because you're going to be hearing that word for years to come. Unless, of course, you're up to here with hearing about the Internet of Things.

The definition Oxford Dictionary gives us is: "The interconnection via the internet of computing devices embedded in everyday objects, enabling them to send and receive data."

Making the world's appliances, cars, televisions, radios, houses, malls and anything you could almost think of, a smart object.

The attractiveness of making our everyday objects connect to the internet is that we would be able to control them from a smartphone and access data on how those things are performing and how efficiently they are operating. Everything sent to a cloud, so you would be able to review any data for the rest of your life and it will never go missing.

Could the Internet of Things revolution lead to a cautionary tale about cyber security relatively soon? Perhaps. Cyber security studies will see a major spike in attendance and does need to be stepped up so that hackers cannot compromise the devices that are connected to the internet.

In India, The Financial Express spoke to Ashish Gulati, a manager at Telit India who focus on connecting businesses through the Internet of Things. He said: "Recent research conducted by Forrester in the retails industry found that 96% of retail decision makers are hoping to make the necessary changes to adopt IoT solutions in the near future, but over half are concerned about integration challenges."

Engineering and electronics giant, Bosch, is releasing their own software that will allow the exchange of data on their machines across the IoT networks. CEO Volkmar Denner said: "Many companies and consumers state that security concerns keep them from using cloud technologies and connectivity solutions." However, it seems that Bosch is confident in the IoT solutions they have and says that the progress in this sector - for them - is a milestone for the company.

Even Coca-Cola is getting involved. Derek Myers, a group director of strategy and commercialization said to reporters that the vending machines in the United States are now capturing 100 plus data points a second. The analytics that machines will be able to compute is going to be useful for any company that has a device connected to their IoT network. They will use IoT to display messages to a customer via the screen and could have the vending machines talking to each other as well.

What remains true about the IoT is the complexity of the network that these devices will be connected to. Research corporation, Gartner, estimated that 21 billion devices will be connected to the IoT by the year 2020. According to Crain's Detroit Business there are already 5 billion devices connected.

The possibilities of IoT are endless and more players will be throwing their hats into the ring and will go head to head to be the main provider of IoT hardware and software in the years to come. It is going to be interesting but the necessary cyber security needs to be in place if we are to have 21 billion devices connected by 2020.

Just imagine having the job title: 'Toy Engineer'. Beneath the surface, everyone knows you are a mechanical engineer, however, 'toy engineer' just sounds better. Mario Morello and Peter Spence, co-founder and inventor of Tio, wear the badges of 'toy engineers' with pride.

They have launched an app called Tio that uses a programmable square block that is the "first motorized building block that makes anything smart." Showing off the practical use of this block (which you can see in this video on Forbes.com) shows that you can repurpose old toys, Go Pros and anything that could be turned into a portable, mobile toy. The idea is that you could mount the blocks - through sticky tabs or the magnetic mount - on whatever you could potentially drive around your living room and it will turn it into a connected, mobile vehicle.

The engineers from Tio say that multiple blocks can be coupled together and can work in unison, using the idea of the Internet of Things (IoT) that will be connecting appliances to each other and ensuring they speak to each other. The blocks can be controlled from the Tio app on a smartphone.

Check the video below to see how it all works:

Want to go into a joint venture with Aston Martin? It's not only good-looking cars the company produces, they also design a host of other quality products. Now they are looking to consult and collaborate with companies again.

Aston Martin worked with Foster + Partners to work on the London bus of the future. According to Autocar, they also worked along with Quintessence Yachts to build the AM37 powerboat.

Now, Aston Martin wants further engineering and manufacturing collaboration. They have set up a consulting branch of the company that will operate under the name Aston Martin Consulting.

Aston Martin says it will give companies a platform to engage with their "expertise centered on design, engineering, and manufacturing."

CEO of Aston Martin, Dr. Andy Palmer said, "We are often asked to collaborate on projects with other companies. My belief is that we can expand the provision of our expertise and experience even further. The formation of Aston Martin Consulting means that we can offer a more structured approach to these projects."

The man at the helm of the consulting company will be Bradley Yorke-Biggs who works for Aston Martin as their director of strategy, information technology and governmental affairs. It was clear that he couldn't wait to get started. He said: "We are very excited to extend the reach of the business to include the provision of services across different sectors: both automotive and beyond. We have an incredibly talented and experienced team within Aston Martin and we look forward to expanding our horizons as we work with new clients on interesting new projects."

Contact

Good luck.

Lithium – What is it?

Lithium batteries are commonly used in consumer electronics but the global interest in lithium batteries of late has generated state-of-the-art breakthroughs in lithium battery technology opening up new markets and applications. The trend seems to be moving away from traditional lead acid batteries in favour of lightweight lithium based batteries. The technology is developing so quickly that Standards Australia has recently announced it is forming working groups to update the current standards in relation to energy storage.

Lithium Battery “Megafactories” in China

Production capacities of lithium batteries are on the rise and China seems to be the place it’s all happening. It is anticipated that production will triple by 2020. Previously an expensive option for industry and home consumers, lithium batteries are now well within reach. Large-scale facilities are popping up all over China and this surge in production capability shows that the lithium batteries industry means business and is serious about reducing unit cost and becoming a market forerunner.

Lithium Mining in Australia

Obviously to make lithium batteries one requires the resources. Global technology companies are seeking a reliable supply of lithium for their battery suppliers, electric/hybrid vehicle manufacturing and even some military and aerospace applications. Australia is an emerging lithium market with the potential to be a world leader in lithium production. Australia currently has 14 ASX listed companies with lithium deposits and is already one of the world’s top producers.

Lithium Battery Production in China

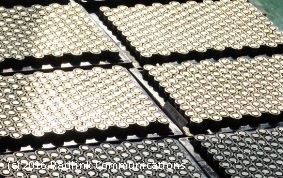

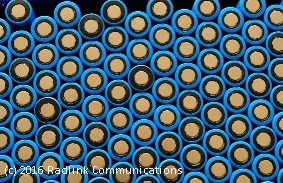

Radlink Communications, a Perth based Telecommunications Company, have been working on an innovative modular and scalable energy storage solution, initially for the mining industry. This has taken them to Melbourne, China and Hong Kong to work with leading edge lithium battery solutions providers and collaborate with them in the development of highly energy dense yet safe battery solutions for extreme industrial temperatures (up to 65 deg C) with extraordinary longevity (up to6000 charge-discharge cycles or about 16 years of daily usage). Radlink’s solution is specifically targeted at parties who require high temperature storage in a robust 19-inch form factor. Radlink have kindly provided some photos from their recent trip to China. In the photos below you can see the lithium battery cells in various stages of production.

Manufactured cells undergo rigorous testing in a controlled environment.

The below image displays 256 cells per cabinet of batteries being tested, and there are about 120 cabinets in the temperature controlled test chamber.

Cells after testing and grading.

Cells are then turned into battery packs by human operators.

Then the lithium batteries are dispatched all over the world for sale to users.

Other areas of interest relating to lithium batteries….

Lithium and Dangerous Goods Safety:

Lithium batteries contain more energy per unit of weight than traditional batteries which is great for energy storage but does create safety concerns as high-energy density can produce hazards if the energy is released at a fast, uncontrolled rate. This is a common concern in the aviation industry.

Lithium and the Electric Car:

In 2016, Tesla Motors plan to bring their new batteries to Australia, which will join Germany as the company's first two markets outside the US. Tesla have already installed electric car charging stations in Victoria and New South Wales called “Superchargers”.

Lithium & Solar:

The lithium & solar market is emerging in Australia. Local energy provider Ergon in QLD is currently running a trial with 33 Toowoomba homes having state-of-the-art rooftop solar and battery systems installed in their homes. It is expected their electricity bills will be significantly reduced as approximately 75 per cent of their power will be generated by the sun. It is predicted that these in-home batteries, such as the Tesla Powerwall could produce not only domestic power but also feed power back into the grid when the network is overextended in the summer months. The desirable combination of solar and lithium has unlimited potential and meets many of Australia’s energy needs. It could very likely be the future of off-the-grid energy, helping to reduce the cost and increase the supply of renewable energy in Australia.

If you want to learn more about the lithium battery industry in Australia then why not attend the upcoming Lithium Batteries Conference in Sydney on May 24th & 25th 2016. The aim of this conference is to explore industry issues and the future of lithium mining and technology advancement in Australia. Lithium industry experts will share their technical knowledge and discuss how the upsurge of lithium battery demand will affect the mining, technology, manufacturing, solar, recycling, electric vehicles and dangerous goods industries. The event will also cover recent research developments and how these can be applied in the real world to benefit industry and the Australian consumer.

Download the full event brochure HERE or register online HERE.

Topics include:

- Lithium Batteries - Past, Present and Future

- The Lithium Rechargeable Battery Supply Chain

- Lithium Ferro Phosphate (LFP) Batteries – The “Safe Lithium”

- Lithium Battery Management Systems (BMS) - Electric Vehicles vs Recreational Vehicles

- Lithium Technology: Overview and as a Replacement for Sealed Lead Acid

- Not all Lithium Batteries are the Same - Lithium Titanate Oxide (LTO) Batteries

- Battery Recycling - End of Life and End of First Use

- Advanced Materials for Lithium-ion Batteries

- Smart Energy Management Opportunities Utilising Li-ion Battery Technology

- Ultra High Power Lithium Opens the way to Increase Efficiency of Power Plants and Reduce Emissions

- Sources and Availability of Materials for Lithium Batteries

- Reconfigurable Utility-Scale Lithium Battery Energy Storage System

- Battery Storage for Recreational Vehicles - Why Lithium is the Next Big Thing

- Update on the Regulations Applicable to Air Transport of Lithium Batteries

- Unearthing Off-Grid and On-Grid Battery Energy Storage

- Making Global Lithium Supply Ubiquitous – New Paradigms in Lithium Exploration to Prevent Lithium Becoming the Next “Oil”

For conference or registration enquiries please contact the conference department at

Teachers and lecturers from The University of Queensland and the Brisbane Grammar School will be bringing STEM subjects to learners all around the world. STEM refers to science, technology, engineering and maths subjects. They will be utilizing the - always growing - Massive Open Online Course (MOOC) method of getting information to learners. Announced at the World Science Festival Brisbane on the 10th of March in Brisbane.

The course is called Question Everything: Scientific Thinking in Real Life and is free to enroll for. University of Queensland Vice-Chancellor, Professor Joanne Wright says that this course will give students the "skills to understand when and how to ask important scientific questions".

The course is focused on students who are in secondary school (grades 9-12) who are in danger of becoming disinterested in maths, science, engineering and technology.

Anthony Micallef, the Brisbane Grammar School headmaster, alluded to the implementing of MOOC technology which would fulfil the intention of becoming an international provider of education in STEM subjects, amongst other "teaching and learning innovations." He added, "Question Everything is a new venture for Brisbane Grammar School and is the first MOOC of its kind in Australia, designed for high school students by high school teachers, working in partnership with a university."

The disinterest of STEM subjects is becoming worrisome, even grabbing the attention of the tertiary sector. This has been corroborated by the Dean of Engineering at the Engineering Institute of Technology, Steve Mackay. In the first episode of Engineering News Network (ENN), Mackay refers to the "engineering valley of death."

"Essentially the concept is when the young adults get to about 12 or 13 years old they lose interest in STEM. This is a tremendous drop-off and then when they get to 18 or 19 there is only a small fraction of the school cohort that actually go into engineering or scientific careers, which is a terrible shame," Mackay said.

This is what the University of Queensland is trying to prevent with their new online courses along with secondary schools. As a possible solution, Mackay suggests "getting good teachers, getting volunteers from the industry involved in schools" and somehow incorporating business with engineering. Through this he hopes the engineering "valley of death" can be overcome and there will be renewed interest in STEM subjects.

Manufacturing fabric is always an interesting industry for engineers to experiment in. There used to be an advertisement on TV from Sasol (seriously watch it, it's a good ad) that asked the question of whether or not there could be a futuristic fabric that could regulate a human's body temperature. Fabric that knew when it was hot and when it was cold and change the body temperature of the wearer accordingly.

MIT have taken it upon themselves to test out the manufacturing of fabric to design the future clothes we wear. Professor Hiroshi Ishii is at the helm of the bioLogic team that have noticed interesting results with an ancient bacteria called Bacillus subtilis natto. The team is putting the bacteria into clothing and due to the expansion and contraction of the natto cells to atmospheric moisture, they could potentially create a fabric that opens vents once an alteration of pressure is felt.

The team say they have invented a "second skin" that feels a body sweat and opens a host of flaps, which will ventilate the suit and regulate body temperature.

A Ph.D. candidate student working with the bioLogic team is Lining Yao. The investigation into creating this new fabric has been ongoing for two years now. She says, "A garment can become an interface that can communicate with your body. The reason we started to explore this bacteria is that we knew that in the natural world there are a lot of smart materials that are naturally responsive. It's very sensitive to even tiny changes in the skin condition, so we thought an on-skin transformable textile would be a really interesting application."

According to MIT's Sharon Lacey, several clothes designers are interested in the developments and that this fabric could soon be introduced to the sports world.

Yao says that the project is revealing "not only how you can be inspired by nature, but how you can collaborate with nature."

For an in-depth look at how the bioLogic is fabric is created check this video out:

Energy storage is a topic on the lips of engineers all over the world, including the ones with the big money like Elon Musk and Bill Gates. Everyone is looking for the next energy breakthrough and the notoriety of redesigning electricity consumption. The United States' Department of Energy claims they have the answer to the question mark of energy storage. The department says it has acquired the 'holy grail' of energy.

A subsidiary company of the Department of Energy, Advanced Research Projects Agency-Energy (Arpa-E) have reportedly made a landmark discovery. They announced this at the Energy Innovation Summit that took place in Maryland on the 29th of February and concluded on the 2nd of March.

In the next ten years, Arpa-E plans to transform America's electrical grid, says Dr Elen Williams, the company's director. Engineers were put to work after President Barack Obama announced funding for the project, and those engineers claim to have "new designs for batteries, and new chemistries which are rapidly bringing down the costs of energy," Williams explained. As of yet there are no physical examples of the 'holy grail' technology they have developed, but will be piquing the interest of companies like Tesla, who have been attempting to build their own energy storage unit called Powerwall.

Australia's Clean Energy Council is also looking for the definitive answer to battery storage. In a recently published paper by the CEC - called Accelerating the Uptake of Battery Storage - the group call for the unlocking of "the full value of storage" for commercial markets but put emphasis on "integrity and safety" of the engineers and the customers that will make use of battery storage.

Safety of the battery storage industry currently booming in countries like America and Australia. In episode 2 of the Engineering News Network (ENN), Dr Steve Mackay, Dean at the Engineering Insitute of Technology, puts the current issues into perspective. He says, "First of all the price of lithium is rising rapidly, supply is not keeping up with demand. Battery energy storage costs are falling as technogy improves. Government is not sure where to go so they are jumping all over the place and training is not certified at this stage."

PV-Magazine claims that currently installers are not regulated, thus, they do not need "qualifications" or "sufficient competency for the installment" of battery storage devices.

What would an installer need in terms of qualifications and competency? Dr Steve Mackay details what training should occur and what needs to be considered with the oncoming wave of battery storage. He said in the ENN video, "With training, not only do you need to have basic electrical theory, you need to look at safe working with photovoltaic cells, batteries, connecting to the grid - which is also interesting - and finally the financial and economic aspects of connecting to the grid."

What do mechanical, aerospace and biomedical engineering have in common at Cornell University? A team of researchers have answered that question with their studies leading to a discovery which could equal sturdier surface treatments on structures for cars, airplanes and more.

In the scientific journal, The Proceedings of the National Academy of Sciences, the team published findings that looked at cancellous bones as a potential answer for surface treatments for engineers to apply on items that could malfunction if cracked or broken.

Cancellous bone is found near joints and the vertebrae and has a spongy exterior with harder interior. The biomedical engineers at Cornell University say that the ingredients that make up these bones are what heals a break or crack in the bones. So, they 'bounce' back into position.

This is making engineers think they can design a similar kind of foam that would bounce back once it develops a crack. Chris Hernandez is an associate professor of mechanical and aerospace engineer at Cornell University. He said, "We used to think we had cancellous bone for the same reasons that use foams in engineering, to absorb energy or make the structure more lightweight. But it turns out that cancellous bone does something different. The way cancellous bone breaks actually makes it heal better."

Another engineer graduate student working on the project, Jonathan Matheny, said, "In the future, this could help in the design of new materials that can take advantage of this ‘function after failure."

Could we be seeing self-repairing car and airplane parts in the future? The insurance companies would have something to say about that - we'd imagine.

Fruit harvesters beware! Robots could be taking your jobs soon. High labour costs are the leading reason given for considering the move to robotics in the horticulture industry. Harvesting with automated, mechanical devices that do the job better than a human hand are becoming the preferred method of harvesting in the world today.

In Australia, labour costs are quickly convincing land owners to make - what they would consider - the smart decision of moving to robotic harvesters. John Lloyd, chief executive of Horticulture Innovation Australia, explains, "We probably have the highest labor costs in the world for horticulture, which is very labor-intensive."

Robotic fleets of workers are not a foreign idea to the engineers of Australia, last year a metals and mining corporation - Rio Tinto - introduced a fleet of autonomous trucks to their fleet. According to AFR.com, it was the Australian Centre for Field Robotics at the University of Sydney which assisted the companies with turning to robotics. The same teams are now working with Horticulture Innovation Australia and developing methods for "avocado, mango and other tree-crop growers" for harvesting, pruning and more.

Professor Salah Sukkarieh, the head of the Australian Centre for Field Robotics at University of Syndey said, "At the moment, I can send a robot out into the field and it can detect an individual weed among the crop and it will spray only that weed and not the crop and it will only spray the right amount of herbicide to kill just that weed. So automatically I've reduced the cost of labour and I can reduce it quite significantly and also cut the chemical cost as well."

If these robots can drive themselves and harvest by themselves we could see something similar to the olive harvesters in Italy, without the manual labour:

The bottom of any vessel that is submerged in seawater is capable of collecting bacteria and marine organisms that have extremely negative effects on the vessels due to corrossion. The process of corrosion on the underbelly of these boats is called 'marine fouling'. It causes costly damages and equals hefty repairs. Those days could be over thanks to the engineers from the A*STAR Insititue of Chemical Engineering Sciences and Institute of Materials Research and Engineering.

According to PHYS.org the team has disovered a "methyl oxazoline polymer" that would avoid microorganisms from attaching themselves to the bottom of the vessels, it is claimed that it will also detach already prevalent microorganisms already on the vessels.

Andbanandam Parthiban, from A*STAR said, "Poly(methyl oxazoline) is the third generation of hydrophilic polymers under focus." He explained the antifouling agents as low-adhesive polymers that form hydration layers on coated surfaces. It is now using the moniker 'PMOx'.

They are now talking to prospective partners in the marine industry to implement the new PMOx coatings and potentially avoid the costly repairs that marine fouling causes.

European-Coatings says, "PMOX coatings effectively reduceStaphylococcus aureus and Escherichia coli adhesion," and admit that it has "great potential" for the future of marine antifouling applications.

Read the official Journal of Photopolymer Science and Technology Vol 18 for more information

The Global Mobile Suppliers Association (GSA) has said LTE and LTE-Advanced connections skyrocketed by 156 million connections in the fourth quarter of 2015. In the last year, LTE connections went up by 552.2 million.

Alan Hadden, VP of research at GSA said, "A daily average of almost 1.7 million LTE subscriptions were being signed up during Q4 2015 and the rate of LTE subscriptions growth is accelerating. LTE technology is now being used by one in seven mobile subscriptions worldwide."

According to Telecoms.com, China is the "dominant market" globally, registering the largest number of LTE subscriptions. They went from 84 million to 386 million subscribers.

The GSA said the amount of global networks offering LTE - which would be 116 operators - will only grow from here on out and reported that 24% of the world's operators are currently facilitating LTE-A connections. According to ITWeb.co.za, 57 countries are using LTE-A, which the GSA says will change soon, they expect 100% global penetration.

There is no denying that LTE and LTE-A give users all over the world a faster connection to the internet but if the networks become over saturated with users, will it slow the networks down? For now, it is a viable technology that is allowing more than a billion people to access the internet and at good upload and download speeds.

Russian automotive engineering company SHERP has shown off its amphibious ATV vehicle in a new video.

According to Top Gear, the ATV has self-inflating tyres that can dominate obstacles of 70cm or more. They also say it has a "Kubota four-pot (so four cylinders) 1.5-litre turbodiesel" inside the beast but only gets a max speed of 27 mph. When driving over water it does 3.7 mph.

The consensus amongst the public is that this is basically a tank.

Weighing in at 2866lbs, the ATV is one heavy vehicle to be carting around town, and you can do exactly that. For about $65,000 you can be the proud owner of one.

The vehicular equivalent of Chuck Norris comes to mind when looking at this ATV. Nonetheless, it is a spectacle of automotive engineering which has military benefits and is just all round awesome

.

Four engineering students at the Indian Institute of Technology-Madras have saved their fellow peers some cents here and there. They developed a campus payment app called Paymint. The app can be used to pay for items on campus and then allow students to get their change in full. The students have highlighted an issue that sees students not getting correct change after a purchase at the university’s outlets.

Rajat Yadav, one of the engineering students who worked on the app said, “A major problem at the institute is getting small change back from shops. There are seven shops on the campus and often, shopkeepers will give us chocolates or some other product. We built a wallet that students can download and use on the campus.”

Yadav and his friend Shubam Jindal are final year students in civil and electrical engineering at IIT-M and put down Rs. 2 lakh ($2976.39) to kickstart the app’s development. They got their friends at the Birla Institute of Technology to assist them in the building of the app.

1,200 students are currently using the app, but that number will rise when they debut the app at an upcoming festival called Ranchi. The app is proof of what happens when engineers put their skill sets together and create something small that can assist the community in a big way.

Engineering in Africa, as we have recently reported, is struggling to produce jobs for engineers in industries like the construction industry. A study in 2013 by the Royal Academy of Engineering found that Africa desperately needed engineers with skills and experience. In the study under a heading named 'The scale and nature of capacity needs,' the academy spoke about the lack of skilled individuals in Africa proving that "there are insufficient numbers of engineers graduating to meet demand in some sub-Saharan African countries".

According to media sources in Kenya, the problem still persists today. four out of ten students are studying degree programmes that are not accredited by the Engineering Board of Kenya (EBK). The Kenya Education Network researched the 2014/15 academic year publishing their findings in a document called The Engineering Baseline Survey. They found that the EBK only recognises 6 out of the 12 universities that offer courses for engineers.

The report also claims that 54 undergraduate engineering programmes are available. Out of those 54, twenty-six of the programmes were not recognised.

Meoli Kashorda, one of the team members of the Kenya Education Network told The Star, it takes two years for an engineering graduate to get a job in Kenya and that no student should be allowed into programmes that aren't accredited.

The South African Institution of Civil Engineering (SAICE) CEO, Manglin Pillay, however, says there is no shortage of engineers in South Africa as a whole. "It's not that there is a shortage of engineers in the country. There's a shortage of engineers in the public sector," he said. Pillay further said that "lack of training opportunities, low salaries and political interference" are discouraging engineers to desire to obtain a degree in engineering.

A new study conducted by body-language expert Dr Harry Witchel, Discipline Leader in Physiology at Brighton and Sussex Medical School (BSMS) believes that computers are able to read a person's body language to tell whether they are bored or interested in what they see on the screen based on the movements on the computer – such as scrolling and clicking.

The research states that it is possible to judge a person’s level of interest by monitoring whether they display the tiny movements that people usually constantly exhibit, widely referred to as non-instrumental movements.

If a person is absorbed in what they are doing or watching on the computer – what Dr Witchel refers to as ‘rapt engagement’ – a noticeable decrease in these involuntary movements will show.

Dr Witchel said: "Our study showed that when someone is really highly engaged in what they're doing, they suppress these tiny involuntary movements. It's the same as when a small child, who is normally constantly on the go, stares gaping at cartoons on the television without moving a muscle.

The study consisted of 27 participants who faced a range of three-minute stimuli on a computer, from fascinating games to tedious readings from EU banking regulation, while using a handheld trackball to minimise instrumental movements, such as moving the mouse. Their movements were quantified over the three minutes using video motion tracking. In two comparable reading tasks, the more engaging reading resulted in a significant reduction (42%) of non-instrumental movement.

The study could have a large impact on the development of future learning applications that are based on artificial intelligence. This is due to the potential that the programme could adapt to a person’s interest in order to re-engage them when signs of boredom are shown. It could even contribute towards the development of companion robots, which would be better able to estimate a person's state of mind and emotional state.

"Being able to 'read' a person's interest in a computer program could bring real benefits to future digital learning, making it a much more two-way process," Dr Witchel said. "Further ahead it could help us create more empathetic companion robots, which may sound very 'sci fi' but are becoming a realistic possibility within our lifetimes."

The World Economic Forum has conducted research which details which country produces the most engineering graduates. Unfortunately, the data they collected left China and India out of the equation due to a "lack of data". Due to the perplexing fact that they left the two countries out, InsiderMonkey.com conducted their own investigations to see which country has the most engineering graduates, factoring in the research done by the World Economic Forum

These were their findings:

The Top 5 countries producing the most engineering graduates per year:

5. Iran: 233,695 graduates. According to Forbes, 70% of the graduates are alleged to be women, which would suggest that they have the most women engineer graduates in the world.

4. The United States: 237,800. InsiderMonkey.com claims that only one in every 20 students majors in engineering in the US of A.

3. Russia: 454,400 graduates.

2: India: 1 million graduates. They might have one of the largest numbers of graduates, however, a report called the Aspiring Minds National Employability Report 2015 (click to download pdf) which surveyed 150,000 engineering students from more than 650 engineering colleges found that 80% of the graduates were unemployable.

1: China: 1.3 million graduates. The huge number of graduates was estimated by UNESCO in 2013. Engineering and Technology Magazine says the statistic should be taken at face value because the number has been disputed.

UNESCO's Institute of Statistics then released another report in 2015 that also excluded India and China from their findings. The official answer that is given is that the countries do not supply their data and so cannot be factored into top 10 lists. The assumption that China and India are some of the most populated areas on earth suggests that they might produce more engineer graduates per capita than any other countries.

The latest results in the tissue engineering and biomaterial development field comes from the Wyss Institute for Biologically Inspired Engineering team that work out of Harvard University. Working with the Harvard John A. Paulson School for Engineering and Applied Sciences (SEAS), the teams have developed a new method of bioprinting "thick vascularized tissue constructs" with the help of 3-D printers.

The tissue constructs consist of human stem cells, "extracellular matrix, and circulatory channels lined with endothelial blood vessel cells," all delivered through a 3-D printer. The team successfully printed a one-centimeter-thick tissue that had bone marrow stem cells as well as connective tissue keeping it together.

When the base for the tissue has been printed, the team then insert fluids, nutrients and cell growth factors into it, which the team claim will, "control stem cell differentiation and sustain cell functions." The future of the project could see a shift in the biomedical engineering industry and what was previously considered the norm in tissue replacement

According to the Printing Vascular Tissue video posted to Harvard University's YouTube page, the engineers admit to the difficulty the industry has had with building tissues and were actively searching for a method to build sustainable vascular tissue.

Zhijan Pei, the National Science Foundation Program Director for the Directorate for Engineering Division of Civil, Mechanical and Manufacturing Innovation, said, "Research such as this enables broader use of 3-D human tissues for drug safety and toxicity screening and, ultimately, for tissue repair and regeneration.” Pei's company should be pleased with the project due to the fact that they have invested the main funding for the project.

Their findings were published in the Proceedings of the National Academy of Sciences journal.

Today, as engineering professionals, we are all lifelong learners if we are to prosper. Technology and indeed life is changing fast and we have to continually learn quickly and effectively new approaches, techniques and systems. Bear in mind that most learning is informal – i.e. through your colleagues and on-the-job. The good old traditional classroom course which we all used to attend is a dim memory.

A week or so ago I attended a superb (free or almost free) online course on learning presented by the University of California...

Dear Colleagues

Today, as engineering professionals, we are all lifelong learners if we are to prosper. Technology and indeed life is changing fast and we have to continually learn quickly and effectively new approaches, techniques and systems. Bear in mind that most learning is informal – i.e. through your colleagues and on-the-job. The good old traditional classroom course which we all used to attend is a dim memory.

A week or so ago I attended a superb (free or almost free) online course on learning presented by the University of California, San Diego entitled: How to Learn: Powerful mental tools to help you master tough subjects. Worth considering if you want to start learning quickly and effectively. It will definitely help you. Many of the suggestions below are probably fairly obvious, but are worthwhile mentioning.

Some Tips on Learning Effectively are:

- It is vital to get good a solid sleep every night. 8 hours. All the toxins surrounding your neurons get washed out when you sleep and enable your memories to be refreshed. So there is definitely a reason to sleep. Even if you are a driven teenager.

- Your brain operates with two parts – the focussed and the diffuse modes. You need to use both when learning. Use the focussed (working) mode to study and rely on the diffuse mode (really your subconscious) to store the stuff you learned and to quickly recall it into your working memory when required.

- Once you have read through a section you are studying; the best way to test yourself is to pause and try and recall it (or even better to teach someone what you have just learnt). This is far more powerful than merely highlighting the text you are rading or sketching out wonderful concept maps of the materials.

- If you have difficulty understanding a section or in tackling a problem try to work through it and then come back later when your diffuse mode has had an opportunity to work through it (in your subconscious). You may find the answer or understanding jumps out at this point.

- Reinforce your materials in your diffuse or subconscious mode by frequently going through the materials and buttressing them in your brain i.e. interleave your study sessions on a specific topic with other activities or topics

- Metaphors and visualization—being able to see something in your mind’s eye—have been especially helpful in storing stuff you have learnt.

- No matter what age you are - new neurons are born in your hippocampus every day. Helped by regular physical exercise and keeping your brain stimulated. These neurons can survive and help you remember things if you learn a new skill (Maxwell Equations?) or work in a stimulating environment. Or indeed try a new route to get to work.

- The best study sessions with others start on time, stay on task and contain a bare minimum of small talk in order to focus on the purpose for the gathering.

- Interleave your learning by alternating your practice with different types of problems--don't waste study time by simply repeating the same technique over and over again.

- Although pretty obvious your understanding is like a superglue that helps hold the underlying memory traces together. One can’t be a parrot and simply regurgitate stuff by rote memory. This can be unreliable and unstable on its own. Understanding is the critical ingredient.

- To prevent procrastination in learning, you want to avoid concentrating on ‘product’ (the end result of your learning session). Instead, your attention should be on building processes. Processes relate to simple habits—habits that coincidentally allow you to do the unpleasant tasks that need to be done. to avoid procrastination you want to avoid focusing on a product, because thinking about completing a product is frequently what triggers the pain that causes you to procrastinate.

- Making your task list for the next day is best done at night before you go to sleep because research has shown that it helps to enlist your subconscious processes to process the list, making them easier to get through the items on that list the next day.

- Use of handwriting (as opposed to typing) appears to help you to more deeply encode (that is, convert into neural memory structures) what you are trying to learn.

Quite a deluge of information you may exclaim – well – it is from a three week course so there is a lot of stuff to cover. My apologies.

As Mahatma Gandhi said: Live as if you were to die tomorrow. Learn as if you were to live forever.

Yours in engineering learning

Steve

Mackay’s Musings – 8th March’16 #590

125, 273 readers – www.eit.edu.au/cms/news/blog-steve-mackay

An alumnus and a team from Oakland University have won $1 million for the creation of possibly the niftiest drone ever invented. The Loon Copter is an "aerial-surface-underwater reconnaissance drone". It can fly, ski on water and even dive down into water.

They built the drone for a competition called Drones for Good that exists to emphasize the use that drones have in the world of today. How drones "improve people's lives and provide positive technological solutions to modern day issues."

The drone utilizes a buoyancy chamber to stay afloat on water but can allow water into it so that it sinks into the water. When it needs to 'come up for air' it releases the water in the chamber and rises back to the surface.

The lead scientist that worked on the drone, Dr. Osamah Rawashdeh told Gizmag.com, "We are looking into acoustic modems, repeater buoys, and some other techniques that could allow streaming of live video for operator feedback as well as data and control commands." The benefits that the drone could have to construction businesses and the like would make this drone a very desired purchase for companies.

The team hopes the drone could be used in search and rescue operations amongst other uses. The drone could be invaluable in assisting engineers complete projects, where the drone would be able to reach those hard to reach places.

The seven engineers were thrilled to win the money at the Drones for Good competiton. Rawasdeh thinks it is a win for drone technology, saying, “Drones have this negative image associated with them now – surveillance and causing problems at airports and so on – but there are a lot of good uses for them, and this competition highlights that."

Students at the University of Washington are focusing on something important, something that affects every person who has ever owned a device that operates on Wi-Fi. Battery drain. Student hardware engineers have developed a new hardware that allegedly uses 10,000 times less power than current Wi-Fi.

According to the students' report they have invented 'Passive Wi-Fi'. "Passive Wi-Fi transmissions can be decoded on any Wi-Fi device including routers, mobile phones and tablets," says the paper.

Unlike traditional Wi-Fi, the passive iteration will transmit a radio frequency which will be relayed to a Wi-Fi enabled device via sensors that utilize near to no power. The sensors recognize the radio signal and sends the less power consuming Wi-Fi to devices that have chipsets within them. They are able to achieve with 'backscatter' technologies.

One of the authors of the paper, Shyam Gollakota told the Daily Mail: "'The passive devices are only reflecting to generate the Wi-Fi packets, which is a really energy-efficient way to communicate."

The discovery is inspiring confidence in companies designing devices for businesses and homes that will make use of and require the Internet of Things (IOT). Communicating with digital devices through the Internet of Things and interconnecting those devices is something that the students at the University of Washington are guarenteeing the 'Passive Wi-Fi' they've invented will do.

The construction industry is fluctuating globally according to multiple news sources this week. IOL reports that in South Africa, the construction industry has been in a decline since the concluding of the 2010 World Cup. Murray & Roberts and Wilson Bayly Holmes-Ovcon - companies that designed and established Cape Town Stadium - have allegedly retrenched staff and are blaming the lack of new projects that require their engineering teams and/or workers.

IOL also claim that the "four largest construction companies" have retrenched at least "20,000 permanent and contract jobs in South Africa over the last two years" in the current slump that the construction industry is trying to survive.

An industry that is still booming in South Africa, or, at least, appears to be, is the shopping centre industry. The Mall of Africa, in Waterfall City in Midrand, is eight weeks away from its launch in April. The mall that is still under construction will be Africa's largest shopping mall development to date and is valued at R4.5 billion. Multiple other malls in South Africa are also going through renovations which have no doubt produced more engineering construction jobs. But, companies are still reporting a slump in the construction industry as a whole.

However, in the United states, according to ConstructionEquipment.com 235,000 construction jobs were made available from December 2008 to February 2016. The site says this a 4% rise, from 2008 when 6,631,000 construction positions were being filled. This reveals the construction industry in the US is doing quite well. The analysis was done by the Associated General Contractors of America. The association's chief economist, Ken Simonson, said, “The overall picture for construction employment is very positive with robust job growth and very little unemployment."

Moreover, Germany is also reporting a growth in the construction sector. Markit Economics estimated that in February of 2016 a reading of the Purchasing Managers' Index showed a fast expansion rate of the industry that was cross-referenced to the last record expansion from March 2011. Their measurements read 55.5 in December 2015 and had grown to 57.9 when another measurement was taken in January 2016. They also revealed that commercial building and civil engineering output had also seen more orders than expected.

Oliver Kolodseike, an economist at Markit explained the growth and the subsequent growth to come for Germany by saying, "House building remained a particularly bright spot in the data, rising at the steepest rate in nine years. With large inflows of refugees and the government planning significant investments to support residential building projects, it is likely that construction activity will continue to expand in the coming months."

.

One small step for quantum technology, one giant leap for MIT. Quantum engineering is always being reupholstered due to newer research that becomes available to the field, it is considered as a relatively new field of engineering. The Massachusetts Institue of Technology (MIT) have been investigating how quantum physics and computing go hand in hand for quite some time, and it seems they've made a breakthrough.

With the assistance of the University of Innsbruck in Austria, MIT has announced that the first five quantum bits of their quantum computer have been tested and proven to be working. The quantum bits solved mathematical equations, giving hope that soon we might see a more secure alternative in encryption of information like credit cards and cloud services. This is explained by MIT's Jennifer Chu: "It’s thought that a single quantum computer may easily crack this problem [encryption of information], by using hundreds of atoms, essentially in parallel, to quickly factor huge numbers."

The researchers claim this is the "first scalable implementation" of a quantum computing algorithm first theorized in 1994 by the Morss Professor of Applied Mathematics at MIT, Peter Shor. The team at MIT say that they've discovered a method of using laser pulses to factor the number 15, which would in the future factor numbers of a much higher value.

Isaac Chaung, a professor of physics and professor of electrical engineering and computer science at MIT, says, "We show that Shor’s algorithm, the most complex quantum algorithm known to date, is realizable in a way where, yes, all you have to do is go in the lab, apply more technology, and you should be able to make a bigger quantum computer."

Chuang admits that the costs of building the computer will be "an enormous amount of money to build" but concedes that it is more an "engineering effort" than a question about physics. So the world might not be seeing the quantum computer soon, however, if banks are able to protect credit card information at a more secure level, they might be the first in line.

According to Computing, the quantum engineering field will be receiving government funding to the tune of £200m to further produce engineers across 40 universities that could assist in the building of quantum computers.

For more information about the mechanics of the computer and the scalability of it for the future: CLICK HERE

Scientists at Cornell University are putting their engineers to work with one of the most fascinating projects of the year. They have designed a stretchy, flexible skin that might fill out many different roles. The skin emits light like a cellphone displays a screen on a phone, or, at least, that's what it looks like. They call it a hyper-elastic light-emitting capacitor (HLEC) and can be stretched up to twice the amount that previous stretchable fabrics were capable of.

In their report on their creation, Chris Larson, Bryan Peele and their colleagues say, "The material could be highly stretched, could emit light, and could also sense internal and external pressure." According to Gizmodo, one of these days, "we can wear it like sleeves or even cover entire robots with it."

Rob Shepard, the assistant professor of mechanical and aerospace engineering at Cornell University says that the skin might see robots change their colour and displays change their shape. On the significance of a robot changing its colour with the skin, Shepard said, "For one thing, when robots become more and more a part of our lives, the ability for them to have emotional connection with us will be important." The medical advantages have been underlined as well. Patients' pulses, temperatures and more could be reflected on the light emitting display. There are endless opportunities with stretchable, light-emitting displays.

The group has released an article called Highly Stretchable Electroluminescent Skin for Optical Signaling and Tactile Sensing detailing how they were able to design the fabric that can survive a strain of up to six times its original size.

According to Cornell University's website, the skin is created by sending electricity in between " layers of transparent hydrogel electrodes sandwiching a dielectric (insulating) elastomer sheet". The elastomer lights up and stores the electric charge and then can be stretched, and in turns makes it a 'soft robot'.

Shepard concedes that there is more work to do due to rubber evaporations on the soft robots during testing but is confident that the future of bendable displays is soon.

Being an engineer is sometimes one of the most rewarding jobs. Not only for the almost guaranteed employment in your field but also because you get to play with some of the coolest 'toys'.

National Engineers Week has come and gone but one of the highlights for engineering students at Placentia-Yorba Linda Unified School District was seeing 'The Echo Ranger' in the flesh. The Echo Ranger is Boeing's submersible 'yellow submarine' - an autonomous underwater vehicle (AUV) - which was shown off in its yellow brilliance to the students, this past week.

Randall Hoover, the senior mechanical design engineer of the vehicle said, "We are using Echo Ranger as kind of a tool," for attracting students to the engineering field. According to WIRED, these vehicles are now being used for "oil and gas surveying, searching for sunken ships and aircraft, and mapping underwater features."

According to an official video of the Echo, the claims are that it can dive to 20,000 feet and can remain submerged, working on an objective for three days.

"It opens a whole new capability to undersea exploration for both military customers as well as the commercial environment," said Mark Kosko, the program manager for Boeing Undersea Systems.

A mechanical engineer at Boeing, Julianne Choy, who is working on a new unnamed, unreleased vehicle for Boeing vouched for engineering as a career. She said, "Engineering is a job where you can make the world a better place,” she told students. “And, while you are doing that, it’s very fun, very collaborative and you get to work with really amazing people."

Chemical engineers in the United Kingdom are researching methods of testing substances at a faster rate than previously conducted to determine whether or not they are regarded psychoactive substances, otherwise known as 'legal highs'.

'Legal highs' (NPS - novel psychoactive substances) refer to substances that stimulate the consumer to the same extent illegal psychoactive drugs do but are easier to purchase due to them being accessible to most people. The substances are not being controlled by law in the UK and are leading to deaths in the country. According to BelfastTelegraph, 101 psychoactive substances were identified in the year 2014. However, with the speed of how many different substances are being produced, a faster screening process needs to be invented.

The Queen's School of Chemistry and Chemical Engineering in Belfast set up a project that is in the process of developing a technology that will screen the new substances and cross-reference them with the newly created substances. At the helm of the project is Professor Steven Bell. He says, "The production of these drugs is constantly evolving and, unfortunately, there have been many instances of highly dangerous variants appearing, causing multiple fatalities before the threat they posed was recognised."

How the screening works

The detecting of legal high drug variants involves screening the "characteristic vibrations of the bonds within the samples by focusing a laser on the sample and measuring the energy of light scattering from it," according to Analyst, the Queen's School of Chemistry and Chemical Engineering's journal. The journal further states that when the chemical signatures of the new compounds of legal highs are found, they then cross-reference them with the already known compounds. Out of 200 samples legal high compounds, 75 percent of them were seized by the Police Service of Northern Ireland.

Bell is hoping that the research they present will be able to assist "the Community, Police and Public Health agencies, with the aim of saving lives and preventing serious injury."

Along with Forensic Science Northern Ireland, the project was given £71,000 from local government to continue the speedy results of what drugs are circulating in the world of legal highs.

According to MedicalXpress.com, the next stage of the project will involve working on "live casework examples."

Tesla and SpaceX CEO, Elon Musk, is hosting a competition for engineering students or any engineers that are up to the challenge. Announced in January, Musk wants to see design ideas for 'The Hyperloop', a super-quick public transport alternative that should aim to travel at speeds of up to 760 miles per hour.

Enter the Auburn Hyperloop Team. The group of mechanical engineers walked away with two awards at the SpaceX Hyperloop Pod Competition Design Weekend. They won best overall subsystem and the design concept innovation award. One of the team's leaders Addison Baitcher was interning for Tesla Motors when Musk announced the Hyperloop competition in 2015 and immediately jumped into a team with a co-founder of the team, Alexander Thompson.

The Auburn Hyperloop Team consists of three different levels. Mechanical engineering, electrical engineering and industrial engineering. They all got to work and started designing elements of the Hyperloop that have now won them the two awards. According to the brief Musk gave to the engineers, the Hyperloop would be "making commutes between San Franciso and Los Angeles cheaper and more efficient than driving or flying."

In an interview with OANow.com ,Baitcher said, “We started designing by simply reading. Papers, books, technical documents — whatever we could get our hands on that would give us a jumping-off point. The more we read, the more refined our design became. The main focus of the design was a control system that worked to keep the pod centered on the track as it traveled. This type of system could be adapted and potentially implemented in applications such as rounding corners and turning.”

Thompson says he is excited about the future of the project and that "competing on an international scale is a testament" to their team's "dedication and knowledge."

Teams will be hoping to be selected for the track test that is being planned for Summer 2016, in the United States. The Auburn Hyperloop Team will be hoping they are going to be there.

For further reading on the Auburn Hyperloop Team's efforts to design the future of transport, visit their website: http://www.auhyperloop.com/

Lithium ion batteries. Are they as safe as they could be? Ankur Jain, an assistant professor in the Mechanical and Aerospace Engineering Department at the University of Texas at Arlington is researching how to make safer lithium ion batteries. He wants to update the technology based on research he has conducted and the contributions of the global community that have reported issues with lithium ion batteries.

The National Science Foundation awarded Jain a five-year, $500,000 Faculty Early Career Development grant to further fund his research.

Jain says, "The end goal is to develop a fundamental understanding of the nature of how heat flows in energy conversion devices such as Li-ion cells and what impedes the flow of heat in those devices." He says that due to the usage of these batteries in electric vehicles, appliances and many other applications, overheating issues arise. "Improvement in heat removal from a battery will directly improve its performance, as well as its safety and reliability."

Elsewhere, Penn State University's Battery and Energy Storage Technology Center have been conducting their own research for the betterment of ion-lithium batteries. They have allegedly put temperature sensors within the batteries to "monitor internal temperatures, detect problems and provide early warning for intervention."

As more appliances are invented that require the power capabilities of Li-ion batteries, what is encouraging is that a method of explode-proofing batteries is being researched by multiple researchers in the engineering field.

Electric cars are one of the focuses where powerful Li-ion batteries that don't overheat to the point of explosion or melting are needed. The Chairman of the Board of Management of Daimler AG - a German carmaker - and head of Mercedes-Benz has said that they are devoting €500 million to building a second battery factory in Germany that will develop stronger Li-ion batteries to power their electric vehicles.

Thus, the research into overheating of Li-ion batteries is now needed more than ever to ensure these batteries are safe to release to consumers.

In the biomedical engineering field, cancer research is an important faculty of study. But, there are questions about the viability of current nanotechnology, in terms of creating cancer treatments. The concerns have been raised by the Purdue University Center for Cancer Research whose work includes the "advancement of new medicines, early detection, and diagnostic methods, more effective treatments, and highly efficient drug delivery systems" as stated on their website.

Purdue University is encouraging "changes in the field" due to the current technology not producing "successful clinical results". The National Cancer Institute in the United States authored the Cancer Nanotechnology Plan 2015 to focus on the "decrease in societal cancer-related morbidity" with the assistance of nanotechnology, a program that is supposed to run for 10 years. Pardue University are now saying that what they've seen in the field isn't working.

Giving further clarity on the criticisms of the current methods used in nanotechnology, Bumsoo Han, a Purdue University associate professor of mechanical and biomedical engineering, said, "The bottom line is that so far there are only a few successful nanoparticle formulations approved and clinically used, so we need to start thinking out of the box."

One of the criticisms relates to using laboratory mice that are not useful in reflecting results that would be useful in measuring what happens in human bodies. Pardue University is pushing for "in-vitro experiments that mimic human physiology" instead.

Earlier this year, in February, biomedical engineers in Wake Forest Baptist Medical Centre claimed they had developed a way to detect "disease biomarkers" with the assistance of nanotechnology. The group of engineers claim they use a new technique that considers nucleic acid sequences and produces an electronic signature to determine the disease biomarkers.

Adam Hall, an assistant professor of biomedical engineering, the main author of the study, said, "We envision this as a potential first-line, noninvasive diagnostic to detect anything from cancer to the Ebola virus."

So, one university is detecting cancer using nanotechnology, and the other one is trying to figure out how to cure cancer with nanotechnology. Pardue University maintains that the creation of cancer treatments through nanotechnology still needs some work so that one day it might make an impact on the globe.

A new supercomputer powered by biological components created by a team of engineers from around the globe is being unveiled to the world. Dan Nicolau, a computer scientist from McGill University, Canada, pioneered the idea of creating a supercomputer that operates on biochemical substance, providing energy to the computer with similar energy that provides human cells with their energy - in the human body.

According to the press release from the university, the supercomputer would run on Adenosine triphosphate - the currency of life - which uses proteins present in all living cells, like the human body.

The bio-supercomputer is smaller than the colossal sizes of supercomputers in the world today, employing less energy from cells that the computer operates on. According to ExaminerGazette, the biological computer would use "up less than 1 percent of the power a current supercomputer does" and is the size of a book.

Nicolau, along with his son and engineering colleagues banded together and built the supercomputer out of "a combination of geometrical modelling and engineering know how" to create a system of protein strings travelling around a circuit with the assistance of ATP.

The model that they have built, however, is not a full proof working prototype but leaves some space for invention on top of the team's discoveries. "“It’s hard to say how soon it will be before we see a full-scale bio super-computer. One option for dealing with larger and more complex problems may be to combine our device with a conventional computer to form a hybrid device. Right now we’re working on a variety of ways to push the research further," Nicolau said.

For more technical information on the first, working, biological supercomputer here are the results of the study: Parallel computation with molecular-motor-propelled agents in nanofabricated networks.

For a visual representation of how this works CLICK HERE

TheEconomist.com estimates that more than a million people have lost their lives due to earthquakes in the last two decades alone. Most of these deaths are caused due to collapsing buildings, which has spurred a fascination amongst civil engineers with earthquake-proofing buildings to ensure less of them fall down during an earthquake.

Engineering students that form part of the Seismic Design Team at the University of California, Los Angeles, are to present their new project focusing on earthquake-proofing buildings at the Earthquake Engineering Research Institute in April. This would form part of a competition called the 2016 Undergraduate Seismic Design Competiton.

The team will construct a 5-foot tall wood model skyscraper that will have to be subjected to simulated ground motions. The judges of the competition will determine which models that are presented respond the best to simulated earthquake movements.

The judges will also estimate how much money a country would spend buying earthquake-proof buildings and the wooden structure should be built in a way that it would attract a potential tenant who would be looking for earthquake-proof buildings.

The teams could also give examples of how to earthquake-proof monuments and buildings that already exist. Kyle Williams, an architectural studies student assisting the civil engineering team said, “Since this year’s competition is in San Francisco, we want to include prominent structures like the Transamerica Pyramid and Golden Gate Bridge.”

The competition encourages civil engineering students to think about the real world they are theoretically designing buildings for. Jian Zhang, one of the civil engineers entering the competition with his team says that they are ultimately striving to "fit the reality" they are trying to "mimic".

Each team gets seven minutes to position rods in their wooden skyscraper clone that will be subjected to earthquake-like conditions atop a shaking table and see if they are able to create a full proof, earthquake-proof building.

For more information on how to get involved with the 2016 Undergraduate Seismic Design Competition, CLICK HERE

A new breakthrough in biological engineering spells good news for several companies who might have been using synthetic, toxic dyes in their products. A natural alternative for dyeing items indigo has been discovered.

Dr. Jixun Zahn - an associate professor of biological engineering - works at Utah State University in the United States and has patented a new method of making a natural blue dye called inigoidine.He is at the university.

Indigoidine is a deep blue dye found in the dyeing of jeans, drinks, paper and even some foods.

Explaining how the process works, Zhan said, "In the original producing strain, there is only one copy of the biosynthetic gene that synthesizes the pigment...But in E. coli. we can make multiple copies of the gene and induce its expression under a stronger promoter."

After this process, it is further "processed and purified" so that it can be used in foods and makeup, amongst other things.

Business development director at Utah State University has applauded the discovery and added, "I’ve had a number of conversations with food- and consumer-product companies that are looking for natural dyes to replace some or all the synthetic chemical-based dyes currently in use — in particular blue.”

It had to happen at some point...right?

Google's self-driving car technology has caused an accident. The company's self-driving Lexus SUV was the first out of the fleet of self-driving vehicles that has CAUSED a crash. The incident occurred on the 14th of February 2016, colliding with the side of a bus near Google's headquarters in Mountain View, California.

The company now has to appear before California's Department of Motor Vehicles, otherwise known as the DMV, to engage in conversation about the incident and investigate what exactly went wrong.

Head of Google's self-driving project Chris Urmson explained the collision to the Associated Press, saying, "We saw the bus, we tracked the bus, we thought the bus was going to slow down, we started to pull out, there was some momentum involved."

Google has released a statement that you can read in full: Click here. They admit to some responsibility but chalk the incident down to "a classic example of the negotiation that's a normal part of driving." They also concede that just like humans are trying to predict each other's movements on the road, that is what their self-driving technology is trying to do as well.

Luckily, there were no injuries reported. This begs the question of whether or not the technology is ready to release to consumers around the world. Earlier in February, it was reported that the artificial intelligence system invented by Google would be considered under the same laws that human drivers are. However, after this incident, there might be some delays in the process.

For more information on how self-driving technology was engineered, here is Chris Urmson's TED talk

The National Aeronautics and Space Administration (NASA) has announced the awarding of a contract that will see the return of a Concorde-like aircraft to the world. Lockheed Martin are the lucky engineers that were given the $20 million order to design an aircraft that utilizes what is called Quiet Supersonic Technology (QueSST).

This would be the first "X-plane" produced for NASA's New Aviation Horizons initiative.

It forms part of NASA's Commercial Supersonic Technology Project that aims to create an aircraft that flies at supersonic speeds but doesn't produce sonic booms that are synonymous with supersonic aircraft. The issue the Concorde had was that it could only go supersonic once they were clear of any populated areas. NASA wants their supersonic plane to fly over populated areas and produce a 'low boom' that doesn't disrupt anyone below the aircraft. This is a strict ban that was introduced by the Federal Aviation Administration.

A NASA spokesperson speaking to The Guardian said, " The company [Lockheed Martin] will develop baseline aircraft requirements and a preliminary aircraft design, with specifications, and provide supporting documentation for concept formulation and planning."

NASA expects that a working flight test might take to the skies in 2020. Prepare for some UFO spotting claims on the internet around that time.

Focus on passenger flight

Are NASA wanting to get passengers on it and fly them around in supersonic speeds?

NASA administrator Charles Bolden says that they are indeed awarding the design contract to Lockheed Martin with, "an aim toward passenger flight."

British Airways and Air France retired the Concorde in 2003 after a slump in profitability, along with the crash of Air France Flight 4590 in 2000 that did not inspire confidence in the minds of eligible passengers.

Jaiwon Shin, an associate administrator for NASA's Aeronautics Research Mission said: “Developing, building and flight testing a quiet supersonic X-plane is the next logical step in our path to enabling the industry’s decision to open supersonic travel for the flying public."

Whilst the fact of shorter air time travel might be attractive, marketing it to passengers might be a hard task for the companies at work considering the history of supersonic passenger jets.

Check the video out for more information on how quiet supersonic air travel might be possible:

CAPE TOWN, SOUTH AFRICA

As fibre-optic networks become more prevalent in South African businesses and homes, Cape Town could be boasting one of the fastest connections in the world. A German telecommunications company called ADVA Optical Networking, this week, tested the capabilities of the service which resulted in 400 Gbps.

Cape Town Business News alleges that these speeds have only been reached four times in the world on fibre-optic networks and that these speeds have never been measured at this speed in Africa.

Xanthea Limberg is the City's Mayoral Committee Member for Corporate Services and Compliance. She praised the network speed test by saying, "‘The trial demonstrates a potential quantum leap in both the speed and the potential performance of our network. At 400 Gbps, it takes less than 0,02 seconds to transfer data equivalent to the capacity of a movie."

The stats will interest citizens who might have been overly sceptical of broadband growth in South Africa. President of South Africa, Jacob Zuma, only mentioned broadband once in his State of the Nation address which took place on the 11th of February, 2016. President Zuma said, "Government will fast-track the implementation of the first phase of broadband roll-out to connect more than five thousand government facilities in eight district municipalities over a three-year period." According to the City of Cape Town's website, R1,3 billion is spent on establishing a broadband network across the city.

Limberg continued by saying that they successfully connect 300 government and public buildings, including a host of municipal buildings on the fibre network.

The project was engineered through a 106km route that stretches between Nyanga and Mitchells Plain.

South African cities are reaping the benefit of constantly improving Wi-Fi access points as well. An infographic released by the Tshwane Municipality showed that they had 630,000 unique users as of May 2015. Their aim is to ensure that by 2017 there will be Wi-Fi in walking distance of every citizen in Tshwane. Cape Town have 190 of their own Wi-Fi points that are being utilized as well.

You may be one of the many engineering professionals not particularly enthused with the idea of making presentations. The reasons may be nervousness, discomfort with strange audiences or simply that you are out of your comfort zone. Often it is not a particularly pleasant experience for both the audience or the presenter. You’re unlikely to ever hear from someone, who has to attend an engineering presentation, that they are really looking forward to it.

Dear Colleagues

You may be one of the many engineering professionals not particularly enthused with the idea of making presentations. The reasons may be nervousness, discomfort with strange audiences or simply that you are out of your comfort zone. Often it is not a particularly pleasant experience for both the audience or the presenter. You’re unlikely to ever hear from someone, who has to attend an engineering presentation, that they are really looking forward to it.

However, doing a high quality presentation is a key part of every engineer, technician or technologist’s box of skills. And helps make your career and job considerably more successful.

A Simple Rule

And by application of one simple rule (sounds like black magic or a quick get rich scheme doesn’t it?); you can dramatically improve your presentations. And that is practice. Practice. And more practice.

Personally, I find practice a bit irritating and unpleasant. Going through one’s slides a few times is often tedious and unrewarding work (like discovering your old smelly running socks in your backpack a few weeks down the track?). But it works; and pays off with great feedback from your audience.

In preparing your actual presentation – ensure that it is simple, addresses the issues in a clear way and is interesting.

Four Reasons Why Practising Your Presentation Helps You