News

- Details

- Written by: idc-and-eit-have-launched-their-ebook-library-pdf-format

- Category: Announcements

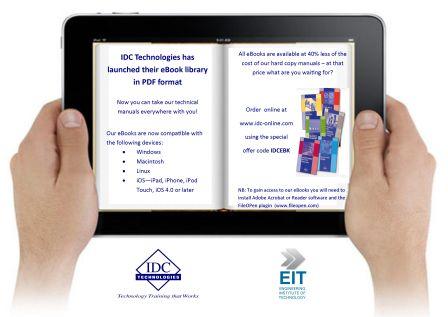

Now you can take our technical manuals everywhere with you!

Our eBooks are now in PDF format and compatible with:

- Windows

- Macintosh

- Linux

- iOS - iPad, iPhone, i-Pod Touch, iOS 4.0 or later

All eBooks are available at 40% less of the cost of our hard copy manuals – at that price what are you waiting for?

Order through the IDC Technologies website using the offer IDCEBK.

NB: To view our eBooks you will need to install Adobe Acrobat or Reader software and the FileOPen plugin (www.fileopen.com).

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

Often you have to write a short summary (referred to as an Executive Summary) for your managers or executives. These fellows (and gals) can be an impatient lot wanting the core ideas imparted with the minimal of technical jargon in action oriented prose. So that they can quickly act on the points you make with minimal cross fire from any one else. Thus you need to be hyper-efficient in your writing.

A few other issues you need to consider

- What do you want to achieve with the executive summary?

- How relevant is the topic to them? Do they have prior knowledge or do you need to give them appropriate background?

- It can be useful to give them some technical details in simple English if they are familiar with the field (being from an engineering background) or you can easily summarise the key assumptions you have made from the technical details.

- Initially do a brain dump of everything you can think of. Don’t worry about the clutter of detail initially. Just write everything down relating to the issue and then work through it after this.

- Choose the key facts from a conflicting maze of others – typically not more than three or four details suffice.

- Write in simple non-jargon based English. Get to the point and don’t get distracted with unnecessary rubbish. Preferably use verbs rather than inactive nouns.

- Review your summary to ensure it is objective with no bias.

- Finally, if you are to present this to a live audience; prepare meticulously beforehand. Practise, practise and also rehearse for any awkward questions that may be thrown your way.

Thanks to Susan de la Vergne of the IEEE for an interesting article.

Please avoid doing this at all costs: An author is a fool who, not content with boring those he lives with, insists on boring future generations. (From Charles de Montesquieu)

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

We all experience setbacks and bad things particularly in our engineering work and our personal lives. I do often. Here are some great strategies to work through these times quickly and effectively. The key is to work through these to increase your likelihood of success in the future.

If you haven’t had a bad moment; you may not be trying hard enough in your job and are stuck in some comfort zone.

Bad things Vary

Often referred to as failures, perhaps you had a bad project outcome; unhappy angry client; missed a deadline; ran over budget or got passed over for a deserved promotion. Or you might have lost the Olympic gold medal by less than one hundredth of a second!

Here are some good strategies to get back from the bad times as quickly as possible:

1. Change Channels

Do something totally different. Disconnect from your current activity and change channels to something different. Watch a good movie, listen to Deep Purple music or walk to a nice quiet spot and scream at the top of your lungs.

2. Work the bad vibes out of your system physically

Often the quickest way to get through this; is to engage in high level physical activity. Where you really sweat it out. A long run on the beach, a work out in the gym or a long hard walk. Or as I did this morning - a hard ride on my bike through the rain.

When you exercise you release the wonderful endorphins; which make you feel better and eliminate the negative emotions and vibes.

3. Breathe deeply

If you are an extraordinarily bad emotional state; then focus all on your energy on taking deep slow breaths by expanding your diaphragm. Concentrate on how the air enters your body and how you inhale and exhale slowly. Do ten deep breaths and contemplate life again. Often you will feel considerably better.

4. Do a post mortem of what went wrong

Contemplate carefully and objectively what went wrong – where did you fail and why? Did you not have sufficient information on your competition; were you overconfident; did you make a wrong calculation; did you depend on the wrong person? Often you need to get an independent opinion as to what happened.

The key is to learn from your mistakes and ensure you don’t repeat this one again.

5. Sweat the stuff you can control

Consider carefully what you have control over and what you don’t or can’t control. Many things in life; we can’t directly control and have to accept the situation. Without losing sleep or simply giving up on everything.

6. Seize the situation

Often things are extraordinarily painful to deal with. The project has gone bad and your client wants you to make some awkward decisions. The supplier of critical components has gone bust. Your key engineer on the project has left to join the competition. But you have to face up to the situation and simply deal with it. Things are not what you wanted and have ended up the wrong way.

But you know what – rarely does life pan out the way we want. Seize the situation and plunge in and deal with it. Now.

You will be the better for it.

William Shakespeare in "The Winter's Tale" suggests: What's gone and what's past help. Should be past grief.

Thanks Andrew May for an interesting article in the Sydney Morning Herald.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

An interesting little (simple) brain teaser for you – no matter whether what discipline or type of engineering professional you are.

The Challenge

A tank at atmospheric pressure contains 1 kg of air. The tank is then pressurized with an additional 3 kgs of air. What is the resultant gauge pressure (in bars) in the tank after this 3kgs of air has been added? Absolute pressure = gauge pressure + atmospheric pressure

A. 1 bar

B. 3 bar

C. 4 bar

You could use the Universal Gas Law in your deliberations:

PV = nRT

Where V is volume; P is absolute pressure; n is the number of moles (‘molecules’); R is a constant and T is the temperature.

Assume atmospheric pressure is 1 bar (the initial pressure) – naturally this is a number which could change depending on what altitude you are at.

Solution (suggested – you could do it in a myriad of different ways)

There is initially 1kg of air occupying V0 initial volume.

With 3kgs of air added; there is now a total of 4kg of air in the tank (thus the final number of moles or particles is effectively 4 times that of the initial number).

The volume (V0) and temperature (TO) of the tank still stays the same.

Thus:

P0 V0 = n0 R T0 (initial state)

P1 V0 = n1 R T0 (final state where n1 = 4 x n0)

Thus – dividing each side of equation 1 and 2 we get:

P1 V0 / P0 V0 = 4 x n0 R T0 / n0 R T0

P1 V0 / P0 V0 = 4 x n0 R T0 / n0 R T0

Thus P1 = 4 P0

Hence, the final pressure P1 = 4 bar absolute or 3 bar gauge pressure (thus answer B above)

Do you agree?

My humble appreciation to Dr Rodney Jacobs and David Spitzer (the flow guru) for their contributions and critique.

Albert Einstein remarked: I never teach my pupils. I only attempt to provide the conditions in which they can learn.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

As we all know, most electronic-based equipment and instruments generally contain some form of circuit board and bits of wire to tie the individual parts together. However, the assembly and manufacturing process in tying these individual wires and circuit boards together and then squeezing them into a tiny space can take considerable effort and consume a huge amount of space.

As we have discussed in earlier blogs, it is now possible to undertake 3-d printing of items ranging from phones to instrument cases – printing one layer at a time. This is possibly the prelude to a personal manufacturing revolution where everything is done on the fly anywhere anytime. Not in a low-paying sweatshop as is often the case.

It is now possible to print electronics in three dimensions to complement this 3-d printing revolution. Printing on circuit boards has been around for a long time. However, we can now do electronics printing in combination with the 3-d personal printing of the case (of the instrument, for example).

Conductive inks are critical

Xerox is currently experimenting with conductive inks to print electronic circuits directly onto plastic or textiles. Although copper is used extensively in circuits; silver is actually better as it is a improved conductor and can easily be used in the printing process. The silver is deposited in a tiny layer (five nanometers thick); thus being cheap. The printing of electronic circuits can be combined with the 3-d printing process thus enabling antennas, sensors and full electronic circuits to be printed “within” or “on” a plastic item (such as phone or instrument).

A Single Machine to make One Product

Instead of considering assembling electronics and building a case for an electronic device as separate processes; one can now do it all in one process. Printing all the millions of transistors contained in an electronic chip is obviously not possible at this stage. So a hybrid approach will be required.

Think of the huge potential possible with your applications…..

The uses of this technology are quite extensive and you can look around at the items you could make smaller or build on the fly and thus respond flexibly to demand and customise to individual requirements.

Thanks to the Economist for a great article on 3-d printing.

David McCullough’s remark is so true: Real success is finding your life work in the work that you love.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

If you have ever been involved with building a start-up firm you will probably realize that a lot of the stuff from business school is next to useless. Start-ups are not simply smaller versions of a standard business but something completely different. Universities have had a mixed record in transferring technology to the market.

It is my sincere belief that driving the creation of start-up firms – particularly in engineering are a critical part of our lives to create new products and services and to improve overall productivity. And we need to nurture and build these “animals”.

Driven only by passion and the smell of an oily rag

Engineering start up firms are driven by passion and belief. Business plans, while nice to have, often change dramatically once you have launched the product and come into contact with your first customer. For every venture that makes it to established small business (or bigger) status, there are hundreds of others that have gone bust. Leaving broken hearts and much financial loss.

There must be ways to improve the success rate of start-ups. Particularly in the critical engineering and technology areas.

We can’t only be focussed on the technology

It is vital to avoid being 100% focussed on the technology we have created with a start-up but to ensure we put solid (and competent) effort into finding customers, working out effective distribution channels, pricing and joint-venture partners. And to handle a ferocious amount of rejection from would-be disinterested customers.

But overall we have to unerringly focus on getting out of the lab or workshop and our product into the real commercial world. After all – no sales and no customers makes for a quick death of the start-up.

Failures are a key part of the start-up

We have to learn from the all too frequent failures in approaching the market. This will require making considerable adjustments to our original premises in how to sell the product – changes to how the product is used/what market should be approached/pricing etc.

We have to run a marathon rather than the 100 m sprint

Start-ups often take considerably longer than anyone ever anticipated and we have to factor in a longer time to get the product out in the marketplace and some degree of profitability creeping in.

A useful template

A successful approach to launching a start-up has come from Mr Steve Blank from Silicon Valley who is somewhat of a serial entrepreneur. He has created two complementary techniques: Business model design (to help understand who your customer really is) and Customer-development (real-world testing of your product in terms of sales and marketing).

If you are considering a start-up – do a google on his approach which is yielding great success.

Thanks to the Economist for an interesting take on a tricky problem.

With respect to start-ups, Benjamin Franklin’s comment should be noted: Energy and persistence conquer all things.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues,

A few weeks ago, I stupidly broke my right wrist (on a beach!) and a few years ago my ankle. Fortunately, after a few plates and screws all is well with no actual loss of a limb.

The purpose of this note is decidedly not to look for sympathy but to talk about the exploding opportunities for engineering professionals working in the field of prosthetics where loss of a limb is the focus.

What is a prosthesis?

A prosthesis, prosthetic, or prosthetic limb is a device that replaces a missing body part. It is part of the field of biomechatronics, the science of using mechanical devices with human muscle, skeleton, and nervous systems to assist or enhance motor control lost by trauma, disease, or defect. Prostheses are typically used to replace parts lost by injury (traumatic) or missing from birth (congenital) or to supplement defective body parts (thanks Wikipedia).

Thousands of new amputees every day

Each day, thousands of people around the world undergo an operation to amputate one or more of their limbs. For example, in the USA, almost two million Americans live with the loss of a limb. Causes of loss of limbs are not only due to trauma or accident but illnesses and cancer. And naturally, military action (although this is a very small component).

The rapidly growing field of prosthetics provides many solutions to those who have lost limbs.

The Feel-good profession

Some have called the field of prosthetics, the ‘feel-good’ profession as it can enable those who have lost limbs to recover much mobility and to operate on an equivalent level to a standard functioning human.

Modern prosthetic devices are highly computerised with microprocessors, sensors and actuators to provide human-like functionality. Experiments are starting to yield brilliant results in interpreting what an amputee actually wants to do with her limb using implants.

How does an engineering professional enter this fast growing field?

There are generally no specific education programs to train engineering professionals in this area. Most people come from a mechanical engineering background; and to a lesser degree also from electrical engineering and software programming. It is vital to know about electromechanical systems, anatomy and physiology and to understand the psyche of an amputee. A slight complication is that the field is quite an inexact science requiring customization to a particular individual and this may drive the more ‘precise’ engineering professional into a frenzy as a result.

Many engineering professionals got their entry into the field by volunteering.

Engineers working in this area have a pretty well 100% employment rate. In fact, there is a growing shortage of expertise in this area.

So think of working in this area if you are looking to put something back into the engineering profession, work at the boundaries of engineering and medical science and to help humanity. Such is the degree of satisfaction working in the area that there are few who enter the field and who leave it.

Thanks to John R. Platt of the IEEE for an excellent article on prosthetics.

It is good to recall John W. Gardner’s comment when dealing with seemingly massively challenging problems: 'We are continually faced with a series of great opportunities brilliantly disguised as insoluble problems'.

Yours sincerely

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues,

The art of negotiation can be a thorny topic. I always remember the comment from a guru who (sadly) remarked: “You don’t get what you deserve; you get what you negotiate”.

We don’t negotiate enough

I believe most of us engineering professionals don’t negotiate enough. We accept the status quo when purchasing or selling something. In our quantitative minds, we accept that the price must be right as it is generally set by others “who know better”. Or we believe it is unprofessional and demeaning to “haggle” over an item. And we often believe that it is about a win-lose scenario - if you beat the price down sufficiently, the other party loses. But believe me, even in established department stores, with a supposedly rigid pricing structure, you can negotiate if you have a reason (imperfections in goods, out of date goods, no spares available). People are looking for reasons to give you a great deal. And a better price. Obviously, you have to justify the reason for the lower price. Simply applying the battering ram approach and demanding a lower price isn’t going to be successful.

Understand the other point of view

It is critical to understand the other person’s point of view almost as well as your own – ensure you are clear about what he/she wants and then look for alternatives to the standard solutions.

Don’t destroy the other party

There is definitely no point in destroying the other party in negotiations. It is better to protect their interests, particularly if you are looking for a long term relationship – otherwise it may come back to haunt you. We were the consultants to the construction of a power station. The client was tough and wasn’t prepared to tolerate any relaxation of the original contract terms (delays in delivering the power station occurred due to unexpected wet weather and labour disputes). The contractor ended up with particularly severe terms in the negotiations for liquidated damages and went out of business shortly afterwards. This resulted in a power station that had to be completed by someone else at an enormously increased cost and with huge delays.

Proven Techniques for Negotiation

A few proven techniques with negotiating – no matter whether you are the buyer or seller:

- Avoid an adversarial – you-lose-I-win approach

- Build trust and co-operation - work as partners

- Try and uncover hidden issues when listening to the other party.

- Research your position and that of the other party thoroughly and work out possible solutions before you negotiate.

- Communicate your position clearly and simply and make sure the other party understands you. Clarify your understanding of the other party’s requirements. Indicate a proven commitment to coming to a win-win solution - What do you have that the other party wants? What can you give away at minimal cost to yourself, but which is worth a lot to the other party?

- Reframe the problem so that it is solvable by a win-win solution. What compromises are possible?

- Wait in silence when you have stated your price - do not talk.

- Look for solutions by “expanding-the-cake.”

- Write down the final agreement and confirm this is what has been understood

As far as negotiation goes, William Shakespeare’s advice (in Much Ado about Nothing) from the 1500’s is timeless, insofar as trusting a third party when interpreting a situation:

Friendship is constant in all other things

Save in the office and affairs of love:

Therefore all hearts in love use their own tongues;

Let every eye negotiate for itself

And trust no agent.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues,

Every successful engineering career involves troubleshooting and fixing at some time. Perhaps mainly remedying your colleague’s mistakes? The trick, I believe, is to keep your mind completely open when tackling the problem - to avoid pre-conceived ideas, as these can throw you off track.

The suggested steps for general engineering troubleshooting are as follows:

1. Identify the exact issue

When someone reports a problem to you; you can bet your bottom dollar this may not be the actual problem. When seen through the eyes of a user the report of the situation may not reflect engineering reality. Ensure you get a careful explanation and if possible a demonstration of the problem. It is your job to ascertain what the real problem is in real engineering terms. Often a problem presents intermittently. Don’t walk away from it, however, presuming it has gone forever – it hasn’t.

Recently, when trying to tune a process control loop, which the operators had complained was sluggish, I unwittingly found that I was actually dealing with high frequency signals (an aliasing problem) - it wasn’t a tuning problem, after all, but a filtering one.

2. Reproduce the problem

It is best to reproduce the problem where possible. You can then observe the full sequence of events, view the error messages and analyse other variables that may be affecting it.

3. Localise, isolate and home in

Now you have to zone in on the equipment or software module that is responsible for the problem. The trick is to zone in on the precise element causing the problem. Penetrate the thicket of equipment and find the precise element. Remember that seemingly unrelated elements can cause problems. It is also vitally important to identify exactly what happened before the problem occurred - was a card changed out and the IP address not updated on the server?

4. Make a Plan

Ensure that you assess what is required carefully. As one of my regular correspondents remarked: Beware the Law of unexpected consequences. The process of fixing something may cause other unexpected problems (a colleague of mine located and remedied severe harmonic problems in a plant network, but blew up three of my precious variable speed drives with overvoltage). When going through your plan, step-by-step, to best remedy the problem, you may find other issues appear that you hadn’t considered.

5. Trace your steps

Ensure that when you fix the problem, you know exactly what you have done in case you need to retrace your steps later to put the equipment back into its original state.

6. Test and retest

Test and retest over a period of time before accepting that the problem has been fixed. If there is any doubt about whether the problem has been fixed or not, there is no doubt. It is, most probably, still a problem.

7. Document for an absolute moron

People who come after you may not be aware of what you have done and how you have solved the problem. The problem may reappear or something similar may happen to another piece of equipment. So - document for someone who may have no knowledge of what you have done.

8. Communicate with the client or user

Often the user is not convinced the problem has been fixed. Your job is to ensure you communicate honestly; what you have done and why the problem has been fixed. Don’t treat the user as a complete idiot, but as a real partner in operating your facility. This is important for your credibility (and for the engineering profession).

I like Anthony J. D'Angelo’s take on fixing things: ‘Become a fixer, not just a fixture’.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues,

Something most of us intuitively grasp; but which is worthwhile mentioning is the inverse relationship between costs of products and services and experience.

In essence, the more experience a firm has in producing a particular product or service, the lower its costs are. Fairly obvious one would think, but something we often don’t consider when planning a large project or job (especially one which has a degree of repetition in it). The Boston Consulting Group noticed that a semi-conductor company’s unit cost of manufacturing fell by about 25% for each doubling of the volume produced. While there are obviously savings due to an increased level of production, a related conclusion was that costs can decline by 20% to 30% in real terms, each time the accumulated experience doubles. This law has been known since WW II when building aircraft. Effectively less labor is required for a given output, depending on the level of experience. Properly managed, experience can facilitate improvement.

Don’t dump your experienced professionals

So this shows the folly of a company replacing experienced engineering professionals with young hacks at (supposedly) far cheaper rates. Experience and a company’s value reside in its human capital. People. And if talent is not recognised, it leaves the firm and takes away a lot of the value and indeed, cost effectiveness of that firm.

Obviously there are ways of bypassing this law in applying new techniques, training staff intensively to pass on the knowledge and hiring more experienced people. And, innovation and change can invalidate the benefits of the experience curve as certain approaches become obsolete. Innovation can thus leapfrog the experience curve. For example, experience in manufacturing black and white TVs is not of much particular advantage today.

However, even with situations such as this, experienced professionals would be refining their skills and knowledge to ride out these technological changes and can thus help the firm to adapt. After all, the basic physics and mathematics underpinning engineering remains the same.

What can you do about it?

The important issue is to realise that you can achieve greater profits at a lower risk by trying to focus on building up your store of experience in your business.

And naturally, you can budget on the hours spent in reviewing/turning around certain repetitive tasks will decline as the project matures.

As the old saying goes: Good judgement comes from experience. Experience comes from bad judgement.

Thanks to the Economist, Joseph Sherman and Rahul Sha for some interesting discussions.

Yours in engineering learning,

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

I was lucky to participate in a recent graduation of eleven electrical engineering students from a major power utility engaged in one of our three year diploma programs (easily equivalent to the first two or three years of an engineering degree and in some respects superior as there was an strong hands-on job-related component).

My speech went as follows….

You (and indeed your partners) have worked exceptionally hard on this qualification over at least three years and we should celebrate. You may have felt that the Engineering Institute of Technology has probably been far more demanding in what we have required from you than most other colleges and indeed universities. This is because we are absolutely determined to build value into your qualifications so that they are marketable and useful on a national and international basis in your engineering career.

We should celebrate your successes from the rooftops as you have achieved a very powerful thing culminating in today’s ceremony.

Power Engineering and specifically the Electrical Supply Industry is typically an area characterised by significant skilled shortages. So your experience and associated qualification will stand you in excellent stead in the future.

A few suggestions relating to your engineering career as you go forward:

Remain positive and in top problem solving mode

Engineering professionals are generally brilliant at identifying problems but not always so good at creating novel solutions to fix problems. You do not want to be known as the ‘Dr No’ of your organisation who is always finding fault with designs and systems; but someone who is proactive about finding practical solutions to problems – often even before they become an issue. Be more foolish in what you do. Experiment with new approaches without fear.

Fit into the organisational culture

Although you may consider yourself to be a huge asset in your company and who can’t be bothered about all the trivial paperwork; you can’t simply ignore company procedures and policies. No matter how irritating they may be. Best to fit into the system and comply with the myriad of administrative procedures and requirements and keep your colleagues happy.

Build Value, innovation and excellence into everything you do.

We’ve all seen the financial crashes and rubbish generated on Wall Street and by people who juggle money without building value. You have a brilliant opportunity to build value into your work as you are working in engineering. Which is all about building value.

Business is a key part of engineering

Costs and financial issues are a critical part of an engineering project. You can’t simply rip out a piece of equipment in your plant and replace it with a new Rolls Royce item because it performs better from a technical point of view. There has to be a justified return on investment. Ensuring that you always consider the financial issues in your engineering career; will add enormous value to the organisation. Profits are what makes a company tick.

Communicate brilliantly and with panache

Engineering professionals are renowned for their love of technology. And are not so enthusiastic about the use of English and in communicating well. However, this is a key part of growing your career. Ensure your written and verbal communications are of the highest possible quality. Not verbose or using large complex words – but simple, thoughtful and clear. Similarly practice your presentation skills – either one- on-one or to a group. And reflect and check on what you write or say before sending your communications out. Overall, soft skills are a critical part of the successful engineering professional.

Value your engineering career more than your firm

We all want to work for a firm or client we love. Forever. However, often your career will develop in a different direction to your firm; especially as far as doing things you enjoy or excel at. You may decide that you have to seek opportunities elsewhere to optimise your career. Often, a firm may be sold to some other entity and they may decide they don’t need your particular skills any longer. Hence it is critical that you keep your engineering skills sharp and relevant to the marketplace. And keep doing outstanding work which not only your firm values but others in the industry notice.

Respect everyone in your firm and get their support

You need every bit of help you can get in your engineering career - from everyone in the firm. Ensure you are friendly and positive with everyone – from the security guard, cleaners, engineering colleagues to the CEO.

Your value is communicated more than only through your work

Sadly, your value to an organisation or client is not only communicated by the fine plant, building or piece of equipment you have designed and built. You need to follow up by clearly communicating why your work is of value to the firm. Remember that email is used frequently but is only one tool to use.

Ensure you have all information before making a decision

As we all know with engineering problem solving – when making a decision one doesn’t always have all the facts. However, you can’t wait forever to make a decision. Try and learn from experts in the field on how they make good decisions. Especially relating to costing’s and scheduling. Always try and look at the worse case scenario here.

Learning is a life-long love affair

Don’t believe your initial degree or diploma qualification is all the learning you need in your career. While problem solving, conceptual and financial skills are often timeless; straightforward technical skills often date extraordinarily fast and you have to keep learning to stay up to date. This can be achieved in an informal way by working closely with your peers and mentors and exchanging know-how in this way. Formal training and education is also useful to keep up to date and aware of the latest engineering trends. Remember that change is one constant in our engineering lives.

Put something back into your profession and help colleagues whether through mentoring or simply technical advice. Ensure you offer advice and support to everyone to improve the engineering (and specifically) the power engineering profession.

Keep learning and sharpening your knife.

Finally, follow your heart in all that you do. Life is extraordinarily short and you have to do what you enjoy. Ensure you keep asking yourself what you ideally want to do and orient your career (and indeed your life) so this is what you do.

Final words

Finally, please keep your alma mater, the Engineering Institute of Technology informed of your progress. We would be delighted to hear of your successes and challenges.

So the choice is all yours - you have complete control of your engineering destiny as to where you are going.

Remember: ‘Only you can change your life. No one can do it for you’.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

One of the concerns I always have when interviewing a stream of people for a job is the impact each of them have on the final decision you make. Or in deciding on the best project when confronted by a list of potential candidates.

Two psychologists, Uri Simonsohn and Francesca Gino, have noted that we are rather poor in using background information in coming to an individual decision. A good example is that of a judge concerned about appearing soft on crime; she would be more likely to send someone to prison if she had already sentenced five other (earlier) defendants to far more lenient sentences that day.

The Interview Situation

How does this work in an interview situation. Well, it has been proven that if you initially interview a number of stronger candidates for an engineering job (for example); you are likely to believe that the next candidate must be a ‘weaker one’.

This problem doesn’t only apply to interviewing people but also in deciding on projects and individual items.

A possible strategy to deal with this

A suggested approach is to assign a rating or score based on what you feel each one is worth without worrying at this initial stage on who is in the ‘pass’ or ‘accepted’ category. You tell yourself that you are merely considering a short list and not a final list. If you find your short list is considerably more than what you were originally targetting; then create a completely new set of criteria (but which are still useful) and apply this to the short list. Arrive at a ranked list in this way and select the top ten or whatever number you are targetting.

The concept is that in going directly from the general to the specific is always liable to bias. This approach described above enables you to avoid this situation.

Thanks to the Economist and Drs Uri Simonsohn and Francesca Gino for detailing this interesting and useful research.

An interesting comment from Olin Miller: To be absolutely certain about something, one must know everything, or nothing about it.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

I know you will recoil at yet another ‘good time’ story but surely James Dyson – the inveterate inventor (remember those bagless vacuum cleaners) - is an inspirational engineer. After I travelled through the UK recently and saw the gloom and damage bought on by the economic downturn; I have to admire this fellow for what he has accomplished in what is generally considered a tough time.

And from a financial point of view, he must surely be one of the most successful engineers with a few billion dollars to his name. Vacuum cleaners, bladeless air warmers and coolers are some of his most successful products. During this recent recession; his private firm has been expanding at a solid rate of over 30% year on year.

I quote from him recently:

I shouldn’t revel in the fact that we are in recession, and I don’t, but it is a time to think really carefully. It is a time to invest in new technology and engineering and good design because the companies that succeed in recession and are able to export are those with products that the world wants. And the world wants new technology, better engineering and products that use less energy and materials.

A poor background was perhaps the catalyst

He came from a poor background – his school teacher dad died when he was nine years old and inevitably there was no life insurance. Fortunately, the school where his dad had taught gave him free schooling. As he couldn’t get any other firms to make the products he designed; he created the Dyson company in 1992. Privately owned so no stock exchange shenanigans.

No stock market shenanigans

Design and engineering work is done in the rural Malmesbury in England but with manufacturing outsourced to Malaysia. Before those from Western countries cry shame on outsourcing manufacturing, bear in mind that he employs 700 highly skilled engineers and associated professionals and is looking for another 200 this year. He reckons the graduates leaving university are still positive, wonderful and wanting to take on the world. He employs them immediately on this basis and encourages them to work on ideas and concepts which have some commercial outcome. Presumably, he is quite ruthless about focussing on solid commercial outcomes rather than too much blue-sky R&D.

A key concept of his is that engineering professionals shouldn’t be making something ‘bigger, noisier or faster with more bells and whistles’ in order to sell it. The theme today is lighter, more energy efficient, less material and less of a carbon footprint. Creativity and thinking laterally is one the key processes encouraged.

Eureka

A good example of their creativity is in transforming a traditional product the ubiquitous hand dryer which evaporates the water off your hands. Why not use a blast of air to scrape the water off your hands instead ? Which formed the basis of Dyson’s successful Airblade hand dryer which I encountered throughout the UK on my recent travels (although I have some reservations about the e-coli possibilities of touching the sides of the dryer - but that is me being picky).

Thanks to The Deal June 2012 for some interesting reading on this topic.

I love this quotation from about 2000 years ago (obviously nothing changes over the millenia):

If you are pained by external things, it is not they that disturb you, but your own judgment of them. And it is in your power to wipe out that judgment now.

Marcus Aurelius Antoninus (121 AD - 180 AD).

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

Even in today’s tough economic times, engineering professionals who are top of their game, are sought after and not easily made redundant. However, companies do morph and change with astonishing rapidity and you may not always feel comfortable with changes in your current firm, and look to alternative opportunities and employment. Sometimes; personal things happen that cause you to decide to move on (something unpleasant at work / death of a close friend /unexpected windfall or a change in life occurring).

Some Suggestions when making the awkward move (or in helping a colleague who has to “move onwards”)

- Develop a pitch that highlights the positives of moving forward to new challenges. Do not become the victim as this ultimately wears you (and your colleagues) down.

- Ensure you build in a support network of a few colleagues who can keep you motivated, aware of other opportunities and in tune with reality.

- Take time out to formally think about who you are; what you have achieved; what your strengths are and what you really enjoy doing.

- Write down specific goals of where you want to go both personally and professionally. Be innovative and creative in your future career.

- Think about career boosts such as further education or training.

- Select a trusted individual to mentor and advise you; and who you can use as a sounding board.

- Redouble your efforts to building up a strong contact network with address and email contact details

- Manage your health well-being with good exercise and especial attention to your mental well-being.

- Support and be kind to your family and friends at this rather stressful time. Try and defuse the stress and uncertainty with fun activities.

- Make your transition interesting and inspirational to others.

- Maximise your entitlements; but while being firm don’t lose your friendliness and respect for others.

- Above all, don’t compromise, as I once did in my haste to leave. Take your time to reflect on where you going and how you are going to do it.

Thanks to Peter Tatham of National Career Development Week for a thought provoking article on the topic of redundancy – An Australian Government Web site.

As Steve Jobs remarked with some prescience: “Remembering that I'll be dead soon is the most important tool I've ever encountered to help me make the big choices in life”.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

The Code of Hammurabi stated 5000 years ago, that ‘If a builder builds a house and the house collapses and causes the death of the owner, that builder shall be put to death’.

Certainly, the Romans were also quite ruthless with execution of engineers who failed in the adequate construction of viaducts and bridges. Penalties are perhaps less harsh today; but consequences of negligence can be far more deadly due to the greater number of people using engineered facilities. Simply put: An engineered system fails when it stops working. And failure is often due to negligence in the design and construction – and often through human factors.

Think of the disasters

Think of some of the disasters that litter the engineering landscape:

- Challenger Space shuttle explodes killing 7 crew. Due to failure of the O-ring leading to the explosion of liquid fuel tanks.

- Bhopal. Piping systems failure leading to toxic vapour linked to the killing of thousands.

- Piper Alpha. An offshore platform exploded, killing numerous personnel.

- Chernobyl. A nuclear cloud is released over Europe.

- Therac-25, a cancer irradiation device. Due to a software bug patients are killed by the doses of radiation.

And recently, some spectacularly ugly train accidents. How on earth; after so much investment in train safety systems; can we still have head-on collisions?

The Primary Causes of Engineering Disasters

The primary causes of engineering disasters (according to SUNY at Stony Brook) are due to (entirely or in part):

- Human factors (incl. both ethical failure and accidents)

- Design flaws (resulting often from unethical practices)

- Materials failures

- Extreme conditions or environments

A recent study pointed out that in 800 structural failures; engineers were at fault with the top four reasons being:

- Insufficient knowledge (36%)

- Underestimation of influence (16%)

- Ignorance, carelessness, negligence (14%)

- Forgetfulness, error (13%)

How do we guard against these human flaws?

So, in our engineering endeavours, how do we guard against these human flaws?

Some suggestions are listed here:

- Build redundancy into design with functionally isolated systems

- Make use of spares especially when components are inexpensive/fail often/can be replaced easily

- Know the details in your design, such as; corners, connections, reinforcements in your design – do not assume anything

- Find trustworthy suppliers and stick to them

- Watch out for problems of scale (and when changing from static to dynamic conditions)

- If people are critical in the operation; then run tests looking at the optimal numbers of personnel needed and the necessary skill levels of the chosen personnel

- Train and retrain personnel; test and retest them if operator error can cause problems

- Use redundant software algorithms to minimize the impact of bugs

- Take care in filtering or allowing alarms to be disabled

- Adjust documentation immediately when changes are made to the operation and design and ensure everyone is aware of the changes

- Exercise management controls for improvement of procedures and changes

- Use real independent verification – not just rubberstamping - in cross-checking work

- Take extreme care in maintenance especially .with the release of stored energy and the removal of energy inputs to a system

- Use materials well within their safety limits

- Only operate equipment within design limits

- Inspect and test to eliminate defective components

- Stick strictly to applicable codes

Hopefully, what Doug Adams says is not true about you and me: ‘He attacked everything in life with a mix of extraordinary genius and naive incompetence, and it was often difficult to tell which was which’.

Thanks to the late Rich Barrett for his thoughts.

Yours in engineering Learning

Steve

Mackay’s Musings – 15th May’12 #477

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

As engineering professionals, most of you will be somewhat surprised to realize that you have a considerable amount tied up in your intellectual property (IP). “What intellectual property?” you may think, with some exasperation. But you will be surprised at how often the simple ideas that you have developed over many years become intensely valuable property. IP represents the property of your mind or intellect.

Surely, Apple – with its plethora of computers, iPads, iPhones and iPads – one of the most valuable companies in the world (if not the most valuable) – demonstrates the incredible driving power of IP.

Various Types of IP

There are various types of IP, such as; patents, trademarks (letters/phrases/logos), designs (shapes or appearances of manufactured goods) and copyright for original material (programs and books). Most of us are familiar with patents, which grant an exclusive license to the patent holder for a period of 20 years (in the US, at least), but copyright is slightly different. A copyright (this can vary from country to country), gives a maximum of 95 years for corporate ownership, or for the life of the author, plus 70 years. It is interesting to note that copyright (and indeed circuit layout rights) are automatically granted to you upon the creation of the material.

Other IP rights (patents being the best example here) have to be registered with local and international governmental organisations. Registration does vary, however, from country to country. For example, in the US, copyrights are registered with “the government”, whereas in Australia, no registration is required. As you know, the global market is becoming increasingly aggressive and shrewd when it comes to stealing valuable ideas and knowledge (let’s not mention countries) - to gain that competitive edge.

Ownership of the IP rights give you the legal recognition of your ownership and goes a long way to protecting it from unfair competition. It is quite an expensive and onerous task, but a worthwhile consideration. A famous example (albeit a simple one) of where things went awry is the Kambrook power board. The product was enormously successful and led to Kambrook becoming a major world player in this consumer business (esp. in the Asia Pacific region). But the IP was not protected. It should have been patented and as a result, within a short time, it was copied unscrupulously and sold throughout the world by aggressively competing firms. The originator of the idea continues to lose tens of millions in royalties every year.

The Main Engine of Growth

There is no doubt that intellectual property is the main engine of growth for any business and is especially advantageous in challenging economic times. Clever thinking and an edge is essential - ranging from innovative engineering designs (e.g. improved efficiencies), to pioneering engineering technologies, such as: deep water drilling or space exploration. In essence, don’t simply give away your intellectual property, but treat it with as much respect as you would cash and your other assets.

A few strategies

- Assess what IP you have. Often this is what gives you and your business a competitive edge.

- Reflect on how you are protecting it.

- Avoid publicizing or telling others about your IP until you have protection in place.

- Implement strategies to harness the development of IP in your firm.

We should always remember the remarks of an old sage when it comes to our most valuable assets: The wise man carries his possessions within him.

Hold your IP close to your chest.

Yours in engineering learning

Steve

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear colleagues

When I was considering studying electrical engineering (many years ago!); my dear father once reminded me with some prescience (although being a teenager it irritated me): ‘Remember my boy, with all your theory and design skills on paper; these are all nothing until you or one of the techies or craftsmen picks up the first screwdriver or soldering iron to start implementing your design’.

In engineering education, we emphasise theory, software and computer design skills to distraction. But sadly we often ignore the importance of experience and even more, the manual skills which build up our engineering experience. We learn a lot of theory at college as engineers and techies. But how many of us need to directly apply a Fast Fourier transform or a Laplace transform to our work today?

Experience seems to be in short supply, particularly if you observe a young engineer at work. In many cases (like a junior officer trying to read a map on the battlefield) he/she is often forbidden from doing any manual work due to concerns that there will be an accident and someone will get hurt. Why? He/she simply doesn’t have the experience.

So was all this theory worth while? I doubt it. But theory is considerably easier to teach than practical know-how - much of which is missing in the engineering curriculum. Admittedly, theory feels far harder to gain than practical knowledge (due to the incredible mental gymnastics one has to perform), but at the end of the day practical knowledge is the key to success in engineering. I was somewhat shocked when I finished engineering school and spent many months on the shopfloor learning basic welding, fitting, turning, milling and how to wield a soldering iron, screwdriver and spanner (to the right level of torque). I did, however, gain considerable proficiency as a result and learnt about real engineering and the difference between theory and practical engineering. And then working in a real process plant, I learnt the hard way about the real practical skills required to run the plant – from the tradespeople who were always thrilled to share their expertise.

There are so many valuable skills, particularly with tools, that are simply not taught in college or university. These skills are handled with panache by craftsmen, but are not easily taught by academics and instructors or books. They can only be gained the hard way - by brutal on-the-job experience, with a very patient mentor (or ‘apprentice master’). Many technicians, who spend their lives working closely with circuits, often develop an incredible and deep understanding of electronic processes – much of this is not easily found in textbooks and dry theory.

As Jack Ganssle rightly pointed out: “Experience is a critical part of the engineering education, one that's pretty much impossible to impart in the environment of a university. You really don't know much about programming till you’ve completely hosed a 10,000 line project, and you know little about hardware till you've designed, built, and somehow troubleshot a complex board”.

As engineers and techies, we are like the blacksmiths of old. We start off as apprentices and through experience learn all our craft. And then when we have acquired all this expertise and know-how we start passing it onto the next generation without holding back any expertise. A sacred (engineering) obligation.

We’re generally paid for what we can do and I would wager a considerable chunk of this is from experience - not from what we derive from theory. So, building up our experience as quickly as possible when we start off, makes considerable sense purely from a mercenary point of view. The top engineers and techies are valued for what experience they have gained over the years.

We have to learn from experience and understand that we will make mistakes in everything we do. As long as we keep trying, we are growing as engineering professionals. We need to ensure that all our young engineers and technicians are involved ‘practically’ and get their hands dirty, when they start their careers. This is to ensure they can relate the excesses of theory that they gained at college or university to the real world.

After all, as Barry LePatner remarks:

‘Good judgment comes from experience, and experience comes from bad judgment.’

My gratitude to Bob Landman and Jack Ganssle for their valuable input here.

Yours in engineering learning

Steve

Mackay’s Musings – 8th May’12 #476

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

We all know that no one is indispensable – companies and people come and go. Even the owner or “boss” of a business is often a fragile commodity. So go a step further and drive yourself and your organisation into becoming more indispensable with a few strategies suggested below.

A few suggestions on being more indispensable in your job:

1. Make sure you are The Expert in your firm on an engineering or technology topic. Pick a “hot useful” topic, learn it inside out and use this know-how to contribute to your firm and clients. Become well known as the local and indispensable expert who takes delight in assisting and educating everyone on this difficult topic - both in your organisation and to your clients. Whether it be in the field of advanced process control, PID Tuning, industrial data communications or electrical harmonics on an oil and gas platform.

2. Write well and document what you do in simple English. Most engineering professionals hate writing and documenting things. Someone technical with this skill, therefore, quickly becomes well known and respected. For example, supplementing your text with clear drawings and diagrams and a neatly-structured spreadsheet listing I/O addresses and interface details would make your work useful and memorable.

3. Communicate brilliantly and passionately. Being able to communicate simply and effectively (avoiding jargon) is always highly regarded. Make opportunities to attend professional development classes that focus on critical thinking and presentation skills or join a group like Toastmasters International which will give you practice.

4. Observe and learn about the changes occurring in your field. Change is guaranteed and not always welcome - especially when you have spent your career investing in a particular skill. For example, a decade or so ago, you had to know about handling a drawing board and 4-20mA process loops. Today you need skills in handling information flow, Gigabit Ethernet, industrial wireless and TCP/IP addressing. So watch for changes, be prepared to change and where possible avoid backing a career dead end.

5. Hitch a lift with a magic carpet rider. There are employees going places in an organisation that can be fairly easily identified. They show clear signs of leadership with their enthusiasm, innovative thinking, competence and involvement in pioneering and ultimately productive projects. Endeavouring to work in their departments is far more intelligent than working for and with dead-end colleagues and managers – those who tend to be cynical, negative and disappointed with the firms they work for and with their own careers.

6. Discuss your career with your manager. Put a plan together of where you want to go with your career over a 6 to 12 month period. In the plan consider; type of work and experience, progress and a forecast, education or professional development and naturally salary. Don’t haggle with your manager on salaries, however, and play your firm off against a job offer from another firm - you are likely to be labelled mercenary and untrustworthy. Keep an eye on salaries, though, with comparable jobs in the market and ensure your management is aware of any discrepancies. In tough economic times flexibility with salaries is more challenging, but you may be able to negotiate on intangible benefits. These include things such as; more time off, longer holidays, opportunities for experience in other areas of the firm, training and education.

7. Make a point of understanding the business side of your firm. This is mainly what your senior managers are interested in - after all. Whether this involves financial, marketing or legal issues – gaining some knowledge in the relevant areas and contributing intelligently will make your managers sit up and take notice - your advice may even become invaluable and sort-after.

8. It is the long haul and persistence that matters. Don’t worry about short term setbacks in your career development. Reassess your direction every now and again, by all means; but ultimately set your objectives and keep trucking doggedly in their direction. Don’t give up or compromise.

Make sure that in your firm and with your clients you are considered one of the best there is in terms of reliability and technical know-how.

With the rapid changes occurring today in engineering, I reckon Theodore Roosevelt was spot on when he remarked: Whenever you are asked if you can do a job, tell 'em, 'Certainly I can!' Then get busy and find out how to do it.

Yours in engineering learning

Steve

Mackay’s Musings – 1st May’12 #475

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

First of all, I would say that this note is not only about getting a better job but also in attracting more work to your firm. Many jobs today are based around a particular project starting up and eventually completing.

Statistically, it is said that up to 80% of new jobs are never advertised. So what you see on the job’s website and in the newspapers is only a poor shadow of the real activity going on below the surface. Similarly, new projects and work, is often not advertised but given to existing suppliers or those who the company knows about.

Unadvertised jobs include jobs that only are created when the right candidate with the right fit of skills (and attitude) comes along. Or there is an impending vacancy that will happen some time in the future and the job is thus not advertised. Or, the hiring manager is casting around internally for someone suitable; and hasn’t got to the stage of formally advertising.

It is thus not routine practice for employers to screen resumes from strangers to find an appropriate candidate. Employers are extraordinarily risk averse these days looking for a solid referral from a trusted individual who can vouch for the ability of the candidate. Sadly, the old adage is true, “It’s not what you know that matters, but who you know”.

I often hear of job candidates applying for a job, being interviewed and then never hearing anything further. They find out later that some internal candidate has then been appointed to the job (or some “mate of a mate”).

So what can one do about this state of affairs?

- Keep actively involved on all the various social networking sites especially LinkedIn (very good for professional activities) and their various job and project forums

- Stay active and involved with your local engineering society and keep vigorously networking and attending presentations by experts

- Keep talking to all your peers in industry about current developments

- Scan newspapers, magazines and web sites for projects starting up and completing

- Keep an eye on people being employed (as advertised in New Appointments)

- And when looking at job adverts – look not only for jobs but details of new projects/services being created by companies

- Form relationships with employers – esp. if you are turned down for a job and stay in touch for other opportunities

Thanks to Debra Feldman and the IEEE for an excellent article.

And remember – no matter how much you already know, as George Santayana remarks so sagely: The wisest mind has something yet to learn.

Yours in engineering learning

Steve

Mackay’s Musings – 24th April’12 #475

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

A key part of every engineering professional’s job is troubleshooting some problem. In fact, arguably many engineers’ sole function (and the reason some are often paid very well) is troubleshooting and fixing intractable problems. Somewhat irritatingly is that it is often identifying and fixing other people’s errors.

The optimum approach is to keep your mind completely open when tackling the problem - to avoid pre-conceived ideas, as these can throw you off track. Naturally, one has to avoid the brute force approach of changing out components randomly in a frantic rush to fix the problem.

The suggested steps for general engineering troubleshooting are as follows. At times it will be tempting to leave some out, but it is worth working through them methodically:

1. Identify the exact issue

When someone reports a problem to you; you can bet your bottom dollar this may not be the actual problem. When seen through the eyes of a user the report of the situation may not reflect engineering reality. Ensure you get a careful explanation and if possible a demonstration of the problem. It is your job to ascertain what the real problem is in real engineering terms. Often a problem presents intermittently. Don’t walk away from it, however, presuming it has gone forever - you can be assured that it will come back at the most inconvenient time. The problem could also be a combination of different issues. Recently, when trying to tune a process control loop, which the operators had complained was sluggish, I unwittingly found that I was actually dealing with high frequency signals (an aliasing problem) - it wasn’t a tuning problem, after all, but a filtering one.

2. Reproduce the problem

It is best to reproduce the problem where possible. You can then observe the full sequence of events, view the error messages and analyse other variables that may be affecting it. If the problem is intermittent, you may need to train the user to do basic diagnostics (such as operate a protocol analyser or vibration analyser) to collect the right statistics and data. A network card, for example, wouldn’t perform erratically until the afternoon sun had warmed up a control room and heated the card up. Without this knowledge it would be difficult to reproduce. Another example is the office network slowing down to a crawl at 2pm every day for 30 minutes, due to someone doing automatic backups at this time.

3. Localise, isolate and zone in

Now you have to zone in on the equipment or software module that is responsible for the problem. The trick is to zone in on the precise element causing the problem. Penetrate the thicket of equipment and find the precise element. Remember that seemingly unrelated elements can cause problems. It is also vitally important to identify exactly what happened before the problem occurred - was a card changed out and the IP address not updated on the server, for example, (a particularly awkward one that caused an aluminium refinery to shut down - the users didn’t understand MAC and IP addressing). Or was there a sudden power surge? Or was the RTU exposed to excessive heat?

4. Make a Plan

Ensure that you assess what is required carefully. Beware the Law of unexpected consequences. The process of fixing something may cause other unexpected problems (a colleague of mine located and remedied severe harmonic problems in a plant network, but blew up three of my precious variable speed drives with overvoltage). When going through your plan, step-by-step, to best remedy the problem, you may find other issues appear that you hadn’t considered. It is worth reflecting on each item of the fix to test for these unexpected consequences. In replacing a valve, for example, you may find the loop controller may need to be tuned again, as the parameters are slightly different. Or a replaced instrument has subtly different ranges, which require updating in the PLC code and SCADA configuration.

5. Trace your steps

Ensure that when you fix the problem, you know exactly what you have done in case you need to retrace your steps later to put the equipment back into its original state.

6. Test and retest

Test and retest over a period of time before accepting that the problem has been fixed. If there is any doubt about whether the problem has been fixed or not, there is no doubt - it is, most probably, still a problem. Many leave this step out and the result is irritating for everyone when the process needs re-commencing. And ensure the user actually confirms he or she is happy with the fix and it all works satisfactorily.

7. Document for an absolute moron

People who come after you may not be aware of what you have done and how you have solved the problem. The problem may reappear or something similar may happen to another piece of equipment. So - document with infinite detail for someone who may have no knowledge of what you have done. This is something which we, as engineering professionals, are not so enthused with. It is, however, critical to the process. Naturally, ensure the documented fix is easily accessible by anyone; and not hidden somewhere in an arcane folder on the server.

8. Communicate with the client or user

Often the user is not convinced the problem has been fixed. Your job is to ensure you communicate honestly; what you have done and why the problem has been fixed. Don’t treat the user as a complete idiot, but as a real partner in operating your facility. This is important for your credibility (and for the engineering profession).

I like Anthony J. D'Angelo’s take on troubleshooting and fixing things. He gives the following exhortation: ‘Become a fixer, not just a fixture’.

Yours in engineering learning

Steve

Mackay’s Musings – 27th March’12 #471

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

I delight in those engineering professionals who have set up incredibly successful businesses (but am saddened by those – the majority – who have failed). In these tough times, I do believe that for our economies to grow we need far more entrepreneurs providing services and products that improve productivity (including safety). The spin-off will be the employment of more people and more opportunities for engineering professionals to practise their skills. Engineers, being highly creative (and making things that are ultimately useful), have an incredible role to play here.

But you can’t suddenly decide to become an entrepreneur. You have to have a genuine passion for a product or service and be prepared to persist. You may have such a brilliant service or product which you reckon has great possibilities and which tempts you to head out on your own. Importantly, though, becoming an entrepreneur does not necessarily entail striking out solely on your own. You can often do it within your existing company structure – genuine owners of businesses delight in welcoming like-minded engineering professionals to extend their businesses with new products and services.

Be ruthless about whether it is a feasible product you are proposing. Many companies have not been able to survive as their key products, whilst useful, have simply never been viable business ventures.

Some suggestions for you:

As engineering professionals we tend to focus on the technical aspects of the product. This is what gets us excited. However, it is the ‘filthy’ business case on which we need to center our attention – “Can this product or service be sold to make money?” - the overwhelmingly important question before launching an idea. Engineers often neglect the business factors as they are less interesting. Sadly, the market will not beat a path to your door because ‘you have designed a better rat/mouse trap’. Ideas are a penny a dozen - it is the business strategy and plan that is critical.

A business plan defining your product and strategy is absolutely essential. And it should fit on a single sheet of paper with all the key thoughts worked through and built in here. If you can’t explain simply what you are doing in a few words to your grandmother, it is probably going to be difficult to make it work. Items to be included in your business plan include; those aspects of the product that are unique, why you will be able to sell it, who your competitors are, the costs and predicted revenue, the cash available to fund the venture, how long it will take to develop the product, the members of your team, an outline of the operations and admin issues and finally, a simple implementation check list with dates.

Initially, try to finance the product yourself and demonstrate that it is workable and bringing in a solid profitability before going to others for funding. Borrowing money from others or getting partners onboard, when the product hasn’t been proven, is fraught with danger.

Put overwhelming effort into your marketing and sales. Persistent communications of your idea to prospects, for your products are essential.

Once you have your product out in the marketplace, you have to listen carefully. You may find that you have to change your strategy considerably as the market might want something else.

It is an extremely lonely mission setting up your own business. Make sure you have oodles of support from your life-partner and that she or he is absolutely committed.

Even when you have a highly successful business, it takes aeons to see the first dollars come in. Often you end up with two years of virtually no income as you build up the business. Can you cope with this and more importantly can your personal life cope with this? Cash flow is always a challenging animal to deal with, but it is always king in business.

And an issue I have tended to scorn in the past (to my detriment), is the operational and administrative side of running the business. You have to put in place systems to deliver your product or service easily and effectively, with a high and continuing level of quality and profitably.

You do need passion and persistence. Persistence is critical as you will get “kicked in the teeth” at least a dozen times a day in the course of running the business.

There is no doubt, that it is enormously satisfying as an engineering professional to run one’s own business, bring new products and services to the market and take control of one’s own destiny. I continue to see so many vibrant engineering businesses opening up that are absolutely inspirational. These range from consulting, to software and hardware development, to electronic product development, to education, to construction and shipbuilding.

When considering entrepreneurial ventures, as the famous General Patton counselled:

‘Take calculated risks. These are quite different from being rash.’

Yours in engineering learning

Mackay’s Musings – 2nd April’12 #472

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

We are flooded on a daily basis with too much data and because we are in such a hurry we often don’t verify the truth of an assertion. And then we take action based on these anecdotal assertions.

Some suggestions in your engineering work:

1. Assess anecdotal information carefully for facts, otherwise file it away as untested.

2. Trace and audit any data which you suspect is second hand - it may have been copied from another source and contain inaccuracies.

3. Use the ‘common sense’ test – this will quickly eliminate the faulty data or statement.

4. Be suspicious of any data or assumptions which appear to be ‘too clean’, predictable, smooth, spherical - nature is unfortunately unpredictable, jagged and bumpy.

5. Apply some quick calculation tests to your newly acquired data to see if it does fit

In the worse case, where the system is ‘infected’ with faulty data or assumptions, ensure you own up quickly and let everyone know so it can be rectified - this is the sign of a true professional - being honest about your mistakes.

Remember that in nature, as the venerable Mark Twain once observed with some exasperation: “Truth is more of a stranger than fiction.”

Yours in engineering learning

Steve

Mackay’s Musings – 9th April’12 #473

125, 273 readers

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

I must thank Andrew Brown for bringing this neat story (which many of you may have heard in the past). It reinforces the need to keep all your designs as simple and effective as possible (applying the famous “Keep it Simple Stupid” – KISS principle) and to apply common sense. Although an engineering design friend of mine often wryly remarks: Common sense isn’t so common around here.

The story goes as follows….

A toothpaste factory had a problem: they sometimes shipped empty boxes, without the tube inside. This was due to the way the production line was set up, and people with experience in designing production lines will tell you how difficult it is to have everything happen with timings so precise that every single unit coming out of it is perfect 100% of the time. Small variations in the environment (which can't be controlled in a cost-effective fashion) mean you must have quality assurance checks smartly distributed across the line so that customers all the way down to the supermarket don't get p....d off and buy another product instead.

Understanding how important that was, the CEO of the toothpaste factory got the top people in the company together and they decided to start a new project, in which they would hire an external engineering company to solve their empty boxes problem, as their engineering department was already too stretched to take on any extra effort.

The Usual Process in a Project

The project followed the usual process: budget and project sponsor allocated, RFP, third-parties selected, and six months (and $8 million) later they had a fantastic solution on time, on budget, high quality and everyone in the project had a great time. They solved the problem by using high-tech precision scales that would sound a bell and flash lights whenever a toothpaste box would weigh less than it should. The line would stop, and someone had to walk over and yank the defective box out of it, pressing another button when done to re-start the line.

Let’s look at the ROI of the Project

A while later, the CEO decides to have a look at the ROI of the project: amazing results! No empty boxes ever shipped out of the factory after the scales were put in place. Very few customer complaints and they were gaining market share. That's some money well spent, he says, before looking closely at the other statistics in the report. It turns out; the number of defects picked up by the scales was 0 after three weeks of production use. It should've been picking up at least a dozen a day, so maybe there was something wrong with the report. He filed a bug against it, and after some investigation, the engineers come back saying the report was actually correct. The scales really weren't picking up any defects, because all boxes that got to that point in the conveyor belt were good.

Now we are all very puzzled