News

- Details

- Written by: Isabella Foster

- Category: Perth Activities and Events

Whilst it can be tempting to rush home and into bed as fast as possible on Perth’s gloomy wintry days, the cooler months are the perfect time of year to explore our bustling city, just without the bustle!

Perth comes alive in winter, from film and art festivals to pop-up bars and ice skating in the city centre, there is never a shortage of new things to try. Here is a list of activities that we are sure will keep your body temperature up this winter.

Ice-skating at Elizabeth Quay

It’s back by popular demand for the third year in a row! From 28 June to 21 July, Perth’s pop-up skating rink is open to people of any skill level and is conveniently located in the city centre at Elizabeth Quay. With world-class entertainment, music performances, rides and food trucks, there is no better way to spend your winter nights than on the ice.

It can get pretty busy so we recommend buying tickets online to secure your spot.

Explore Northbridge

Rug up in your best scarf and coat and get ready to explore the kaleidoscope of food, arts and nightlife in Northbridge. Commonly referred to as the ‘cultural hub’ of Perth, Northbridge is bursting with things to eat, drink and watch. We recommend checking out Lucky Chan’s Laundry + Noodle Bar, where their spicy bowls of soup are sure to keep you warm on a cold night.

Northbridge is highly accessible with Perth busport and train stations nearby. Take a look at their menu.

Explore the ocean with AQWA

Winter isn’t great beach weather, however, we can do you one better. At the Aquarium of Western Australia (AQWA), you are able to get up close and personal with the beautiful marine species of Western Australia. With exclusive adults-only evening events, one of the world’s largest living coral reef exhibits and a 98 meter long moving walkway, plan your next day trip to this oceanic marvel.

Find out more and book tickets.

Experience the theatre at the State Theatre Centre of Western Australia

Housing the Heath Ledger Theatre, this 575 capacity building is a defining architectural landmark in the city of Perth. The Centre is consistently busy hosting events ranging from theatre to dance and music performances that feature both local and global talent. With brand new world-class facilities, there is no better way to spend a special evening.

Check out their schedule and book tickets on their website.

Take your sporting skills indoors

The rain is no excuse to stop getting active this winter. Perth is home to an endless number of indoor games and activities. From mini golf and bowling to trampolining and rock climbing, there is something for everyone. We recommend checking out Holey Moley, Perth’s craziest and most unique mini golf venue. Test your skills against the infamous windmill and ‘shark infested’ waters.

Find out more today.

Embrace the cold at Winter Fest

The city is guaranteed to light up this year with Winter Fest. Running from 24 June to 21 July, this myriad of events will be heating up your social calendar. From incredible light showers, delicious comfort food, magicians and a pop-up cinema there is almost too much to choose from.

Check out the full list of happenings.

Fremantle Markets

One of the leading tourist destinations in WA, the Fremantle Markets is something you just can’t miss this winter. With an incredible of sights, smells and sounds to take in, there is something for everyone within the array of local talent the market showcases. Buy the latest piece of hand-made clothing or treat yourself to a piece of cake and coffee. Fremantle Markets is alive with culture and a great way to spend a winter weekend.

Go for a drive outside of the city

It takes less than an hour’s drive to escape the city and be amongst the rolling Perth hills. With beautiful stretches of road, valleys, trees and lookouts, a winters drive through the country is the perfect escape during a wintry weekend. With the recent rainfall, the city has endured, we recommend checking out Bells Rapids. This beautiful picnic and bushwalking spot is home to white water rapids which thrive during the winter season.

Find out all you need to make it a day trip.

Art gallery

Located in the heart of the Perth Cultural Centre, the Art Gallery of Western Australia is a peaceful and serene escape to the busy nature of the city. The Collection, associated programs and stimulating exhibitions offer Gallery visitors a unique and exciting experience of historic and contemporary Australian artists. The gallery is also in close proximity to a number of cafes to rest and enjoy lunch at.

Kings Park

One of the largest inner city parks in the world and visited by an astonishing 6 million people each year, Kings Park is an outstanding collection of Western Australian flora and an ideal place for picnics and walks. With stunning views of the city and surrounding areas, it’s ideal for a winter’s drive and a great spot to get your next Instagram photo of storm clouds rolling in.

- Details

- Written by: Quintus Potgieter

- Category: Education

The traditional engineering qualification is going through changes. Universities and technical vocational educational institutions are coming to grips with the changing nature of engineering. The world’s problems need solving, and they cannot be solved with one engineer from one discipline from one university anymore.

Some universities and institutions understand that, and are determined to bridge the gaps between engineering disciplines. Other universities do not seem to grasp the idea of changing educational offerings at all - and produce future-proof-less engineers.

With technology advancing at a rapid rate, universities are having to update their curricula with the most cutting edge research and technical information. What universities are wanting to do is instruct the prospective engineers in the kinds of knowledge that can help them help the world.

One subindustry engineering has produced is the assistive technologies industry. This is an industry that sees engineers developing technologies for disabled and elderly people in hopes that it might make their lives easier. The industry has heated up to such an extent that entire degrees are being compiled.

There are over one billion people living with a disability. Accessibility to technology is thus extremely important.

The universities that are meeting this challenge head on are the University College London (UCL), Loughborough University London and the London College of Fashion. They have just added the Master of Science in Disability, Design and Innovation to their offerings. It will be a multidisciplinary approach to creating assistive technologies. The curriculum is ready to go, with expert instructors ready to teach, at the Global Disability Innovation Hub (GDI) based at the Queen Elizabeth Olympic Park.

The GDI Hub is pumping £10 million that will see the Life Changing Assistive Technology For All programme reach over 3 million people.

Dr Catherine Holloway, Academic Director of the GDI Hub told Eureka Magazine:

“The global potential for disability innovation is huge. New technologies provide opportunities for scalability and access, but to accelerate this movement we need a new generation pioneers. The Disability, Design and Innovation Masters is the world’s first course in this rapidly growing area of expertise. Students will be taught in a uniquely multidisciplinary environment, learning from global experts, live research projects and high-profile global collaborations. We’re looking for exceptional students with the drive and determination to push the boundaries of this new area of study.”

The market is ripe for some innovation in the tech sector for the specific task of creating truly innovative technologies for the disabled and the elderly. As a result, engineering startup companies with budding engineering entrepreneurs have been developing to get them to the market.

Even big tech is getting in on the game. Google has gotten its engineers to develop a subtitling function to its new operating system Android Q. It will be very helpful to hard of hearing and fully deaf people when activated on the smartphone. The function named Live Caption can transcribe podcasts, videos, audio and even video chat on the fly, as it happens. It is accessible via one tap.

The MSc in Disability, Design and Innovation has modules on entrepreneurship, engineering skills and understanding of the global policy and societal contexts of disability. Consequently, the industry could see more software and hardware entering the world that will positively assist those with disabilities.

Works Cited

“Google's Impressive Live Caption Will Add Subtitles to Any Audio on Your Phone.” Android Authority, 7 May 2019, www.androidauthority.com/google-live-caption-983562/.

Ucl. “Disability, Design and Innovation MSc.” UCL Graduate Degrees, 11 Feb. 2019, www.ucl.ac.uk/prospective-students/graduate/taught-degrees/disability-design-innovation-msc.

- Details

- Written by: Quintus Potgieter

- Category: Industry

The offshore oil and gas industry is an industry well known for its high risk nature. Not only are the employees who work on the rigs putting their lives in danger, but so are the employees who work under it. These employees are the oil rigs’ deep sea saturation divers. They have one of the most dangerous jobs in the world, walking on the bottom of the ocean floor.

Deep sea diving operations are important to offshore oil and gas operations around the world. Engineers need them for oil well checks and changes, installation of new wells and decommissioning of old ones.

Humans are utilized when diving up to depths of 200 meters. For anything past those points, specially engineered vehicles are required. These divers are subjected to ten times the atmospheric pressure humans experience every day.

The dive support vessels are built around a pressurized saturation system. On the vessel itself, specialized living chambers are set up for the divers to sleep in. The vessel houses smaller vessels called “Bells’ that take the divers down to the seabed. Divers are lowered into the sea, tethered to the ship above. The divers essentially live underneath the ocean for 28 days.

When living on the Bell, divers breathe a helium-oxygen mixture (named Heliox) to prevent nitrogen narcosis, which makes the crew’s voices go high pitched just like the effects of breathing in air from a helium balloon. The divers say living underneath the ocean is just like living on the International Space Station, just under water.

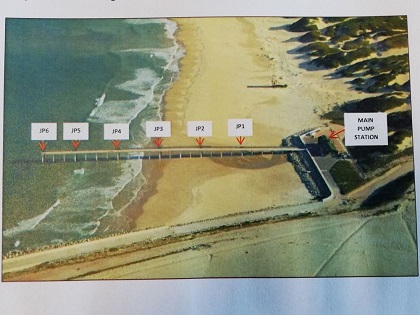

A computer system is run in a mode named Dynamic Positioning mode that locks the vessel over the exact point on the seabed. They then lower the Bell down from the ship in the exact location and the engineers dive from the Bell into the ocean.

Engineers facilitate the functioning of all the important on-board computers. A Dive Supporter, who sits within the vessel atop the sea, also monitors all of the divers in real-time underneath the ocean. Cameras track their every move.

Inside the Bell, there is a man who does not dive down, but rather regulates the gases of the divers and the feeding of the ‘umbilical cord’ that tethers the divers to the Bell under the ocean. The umbilical cord feeds hot water into the diving suit to keep the diver warm, and provides gas to breath - while being the physical tether to the boat.

Last Breath

Saturation diving has become the subject of a new BBC documentary that has made its way to Netflix named ‘Last Breath’. It follows the true story Chris Lemons, a saturation diver who was deployed to the middle of the North Sea to dive down and perform some changes to an oil well there. In September of 2012, the dive support vessel Lemons was on was traversing the North Sea Oil Fields, 127 miles east of Aberdeen.

On the 18th of September 2012, Lemons was at the bottom of the North Sea, but little did he know that a storm was brewing above the water. The storm was so powerful that it knocked out and overrode the GPS systems on the vessel, leaving it to float away from the location the divers were doing their maintenance at. It resulted in Chris Lemons’ umbilical cord being severed. He only had five minutes of oxygen left in a reserve tank on his back.

The crew was unable to get the vessel under control and find Lemons as the storm threw the ship off course. Once they had managed to get the ship’s automated control systems rebooted it returned to its previous GPS locations, however more than a quarter of an hour had passed. They eventually managed to track Lemons down, he was assumed dead. But after Bellman Duncan Allcock performed CPR, Lemons was resuscitated.

Chris Lemons was without oxygen for 33 of the 38 minutes he was under the ocean for. Experts are still trying to explain how he survived. The documentary is definitely a must-see for engineering enthusiasts and those who want to see a truly miraculous story of survival.

Works Cited

“Last Breath.” Netflix, 6 May 2019, www.netflix.com/watch/80215139?trackId=13752289&tctx=0,0,918ad4a9fe2b7784d8c79439f0ec1e1c83f2fc41:4f43e0538969a387426f5910f8d43f377769aa91,.

Peter Stanford For The Daily Mail. “How Did a British Diver Stranded 300ft under Sea Survive with NO Oxygen for 38 Minutes? .” Daily Mail Online, Associated Newspapers, 10 May 2019, www.dailymail.co.uk/news/article-7013143/How-did-British-diver-stranded-300ft-sea-survive-NO-oxygen-38-minutes.html.

- Details

- Written by: Quintus Potgieter

- Category: Industry

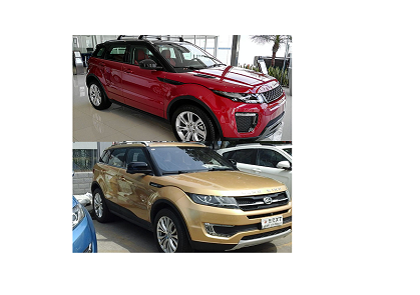

Huawei. You have probably heard of them - you may even own one of their smartphones. They are the second largest multinational technology company in the world, coming second only to Samsung. With the enormous size of the company, and tremendous force of national pride in China, there are thousands of engineers working for them around the world.

Huawei have been instrumental in implementing mobile internet technology infrastructure in many countries across the world, making them the world’s biggest supplier of networking technologies. However, U.S. intelligence figures are beginning to suggest that Huawei’s technology is being used to spy on its users on behalf of the Chinese government, a controversial finding when thinking of the growing trade war between China and the American government under the Trump administration.

The US and China’s escalating trade war took a recent turn on the 17 May 2019. The Trump administration signed an executive order that drew a line in the sand of the tech world. Businesses are now banned from buying Huawei networking equipment, and Huawei themselves have been blocked from utilizing American companies’ resources for their technology. Huawei had effectively been blacklisted on the US market.

One of the biggest problems on the consumer level was clear: smartphones need Google. Google is the home of the Android operating system and the owner of many online resources accessed by people all over the world. As a result of the executive order, Google had to revoke the licensing granted to Huawei to utilize the Android operating system.

Huawei’s past and present devices were issued a ninety day exemption that would see the Huawei devices getting updates from Google. Once the ninety days are over, Android upgrades would not be available for those devices. The blacklisting will also leave the phones unable to use Google Play Services. Apps like Gmail, YouTube, and the Google Play Store, rely on Google Play Services to function.

If the blacklisting continues, Huawei will need to build their own app store to be implemented in their smartphones. But software aside, it’s the engineered hardware that Huawei might lose out on if this ban continues.

A global technology dilemma

The problem Huawei faces is that they need U.S. components to build their smartphones if they want to keep manufacturing them at the pace they usually do.

UK-based (with American origins) chip designer ARM was directed to halt ‘all active contracts, supporting entitlements, and any pending engagements’ with Huawei. ARM produces vital mobile devices processors, so if the blacklisting continues, Huawei might need to find a new provider for its processors or even start developing their own.

Huawei seemingly foresaw the ban and stockpiled troves of chips and vital components to keep the business producing technology while the uncertainty grows. Huawei may be hoping that the blacklisting is revoked before they run out of the components, because manufacturing without American components will pose a whole new set of problems for the company.

The blacklisting will also slow the rollout of global 5G, which Huawei was busy with globally before the controversy. Huawei had seemingly been pushing forward faster than the United States at their rollout of 5G technologies, which also could have aggravated the trade war.

The trade war further highlights how engineers are caught in the middle of political escapades. The blacklisting affects many different companies across the globe, and impacts those who work for them.

Huawei, however, remains optimistic that this will all be wrapped up in due time. They said:

“We value our close relationships with our partners, but recognize the pressure some of them are under, as a result of politically motivated decisions. We are confident this regrettable situation can be resolved and our priority remains to continue to deliver world-class technology and products to our customers around the world.”

Works Cited

“Google Pulls Huawei's License for Android, Apps After US Blacklisting.” Interesting Engineering, 20 May 2019, interestingengineering.com/google-pulls-huaweis-license-for-android-apps-after-us-blacklisting.

Lee, Dave. “Huawei: ARM Memo Tells Staff to Stop Working with China's Tech Giant.” BBC News, BBC, 22 May 2019, www.bbc.com/news/technology-48363772.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Engineering and politics are intricately linked. The prioritization of certain engineering disciplines and technologies may depend on where leading political parties lie on the political spectrum.

In the United States, the Democrats were not supportive of the construction of a new phase of the Keystone Pipeline (an oil pipeline system between Canada and the United States), whereas the Republicans were practically racing to get it built. When Donald Trump won the Presidential Election, the hurdles that were keeping the Keystone construction back, were effectively cleared.

Climate change, and the engineering technologies that cause the phenomena, have been heavily politicized - which left-leaning parties have been using to try and sway voters with.

A similar situation recently played out in Australia. Two years ago, Australia’s then Treasurer Scott Morrison taunted the Opposition by carrying a lump of coal into the House of Representatives. It was to mock what they were saying were Labor’s hasty plans to move away from fossil fuels, which they said would result in thousands of job losses.

Scott Morrison is today the Prime Minister of Australia. He emerged victorious in the 18 May 2019 election, in what he described as a ‘miracle’ victory. The industries that are invested in coal, have welcomed the appointment.

Minerals Council of Australia (MCA) CEO, Tania Constable, told media:

“The Coalition government’s strategic economic reform agenda to keep taxes low, in conjunction with responsible 2019/20 Budget measures, provides opportunities for large and small business to be successful. It also means that the mining industry will continue to develop the nation’s minerals for the benefit of everyone. This is a win for regional jobs, particularly in the big resources states of Queensland, New South Wales and Western Australia. There is now a clear mandate for resources projects that have lawful approvals to proceed, such as the Adani coal mine in central Queensland and the Yeelirrie uranium mine in Western Australia.”

Adani Group has seen a lengthy delay on their mega coal mine in the north of the Galilee Basin in Central Queensland. They are seeking to generate 60 million tonnes of coal per year, with a total capacity of 2.3 billion tonnes over 60 years. It is expected to be the largest coal mine in Australia and one of the largest in the world.

On a federal level in the election, the people of Queensland seemingly voted in favor of the Coalition government, which to engineering bodies and the Adani Group specifically pointed to the fact that they think the coal mine should go forward. Appealing to jobs seemingly worked handsomely. Lucas Dow, Adani Australia Chief Executive Officer said in a Twitter video after the election results:

“When there is an opportunity like the Carmichael Project ready to deliver thousands of jobs today in a manner that is both commercially and environmentally responsible, people cannot fathom why the Queensland Labor government refuses to get behind the Carmichael Project.”

The Adani Group had its eye on getting the ball rolling on the mine in 2010. It took a couple years to grow legs, and by 2017 the regional headquarters of the mine were opened and the promise of construction was on the way. It was only in November 2018, that any indication the mine might be finished started to show. Soon after, it became an environmental bone of contention on the lead up to the election.

From the affect the coal mine will have on the climate, to the endangerment of the black-throated finch bird population, were among the issues being hurled at the Adani Group’s impending mine. There have also been protests under a movement known as #StopAdani.

Despite the national election results, voters were resolute in their intention to vote against the alleged climate denying politicians - most notably in Warringah. Exit polling in Warringah, where Tony Abbot from the Liberal Party was unseated by Independent Zali Stegall, indicated that climate change was voters’ top issue.

Thus, it seems like it will not be plain sailing for Prime Minister Scott Morrison as opposition parties and groups seek to continue to oppose the leading government on the topic of climate change. However, regional miners and engineers in the line of benefitting from a coal-friendly Prime Minister are welcoming the election results.

Works Cited

Cave, Damien. “It Was Supposed to Be Australia's Climate Change Election. What Happened?” The New York Times, The New York Times, 19 May 2019, www.nytimes.com/2019/05/19/world/australia/election-climate-change.html.

Karp, Paul. “After the Climate Election: Shellshocked Green Groups Remain Resolute.” The Guardian, Guardian News and Media, 19 May 2019, www.theguardian.com/australia-news/2019/may/20/after-the-climate-election-shellshocked-green-groups-remain-resolute.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Temperatures in Nairobi, Kenya, reach 35 degrees centigrade in the summer months. Over five hundred kilometers away is the town of Malindi, where a brand new photovoltaic solar project is kicking off. If Kenyan engineers are looking to work in renewable energy, their chance has arrived.

The Malindi project will be the first utility-scale independent power project the country will see. Globeleq is a company hailing from the United Kingdom, and is heading up the project. They are also investing in renewable energy solutions in South Africa.

The company will be selling electricity to Kenya’s national electricity provider Kenya Power, recently agreeing to a 20-year deal.

Paul Hanrahan, Globeleq’s CEO, told media:

“The attractive investment climate combined with strong local community support sets the stage for this important project as well as future investments in Kenya. We are extremely pleased to be making this investment into the Kenyan energy sector.”

The construction will be complete and in operation by mid-2020, producing up to 40 megawatts of power. The rights to the land, the environmental impact assessment and the necessary permits needed for constructing have all been procured. The project’s construction has received nearly $100 million dollars AUD in funding from investors, who will all be enjoying a cut of the eventual profit. The engineering companies behind sourcing the necessary technology and constructing the actual plant are Sterling and Wilson Solar.

Kenya, unlike many of its other neighboring countries, is opening their energy market up to whatever entities may be able to provide electricity to its people. They intend to rely less on coal powered power stations and move to more renewable sources. It is all a part of the government’s National Electrification Strategy which aims to power Kenya by completely green energy by 2020.

A recent coal power plant construction reaching completion in Kenya is undergoing scrutiny for purportedly lying about the price of the electricity that will be produced at the power plant. The plant in Lamu, Kenya, is seeing a big level of pushback after the revelations were made public. Experts are saying the entire project should be scrapped.

The Kenyan government and the World Bank set up a $67 million dollar AUD facility under a project named Kenya-Off-Grid-Solar to further develop the private solar sector, in hopes that they can bring electricity to 14 communities that have been lacking energy solutions.

Principal Secretary of the Ministry of Energy, Joseph Njoroge, said:

“The country has made great strides in achieving connectivity with access to electricity standing at 75% though both grid and off-grid options. However, access to electricity is low in the 14 marginalized counties, which represent 72% of the country’s total land area and 20% of the population.

Works Cited

“Kenya in $47m Financing to Provide Solar Solutions.” Journal Du Cameroun, 11 June 2019, www.journalducameroun.com/en/kenya-in-47m-financing-to-provide-solar-solutions/.

“Kenya: First Utility-Scale IPP Solar Project Achieves Financial Close.” ESI, 3 June 2019, www.esi-africa.com/industry-sectors/renewable-energy/kenya-first-utility-scale-ipp-solar-project-achieves-financial-close/.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Triton Submarines have taken man to where no man has gone before...to the bottom of the ocean.

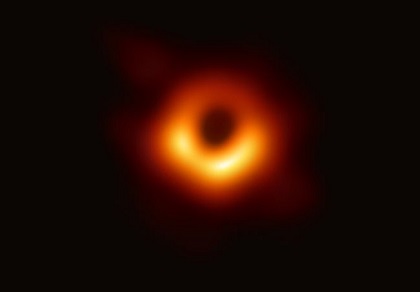

Businessman and amateur pilot, Victor Vescovo, went down to what is believed to be the deepest point of the ocean a human being has ever travelled to. Its name is the Challenger Deep, located in the Pacific Ocean at the southern end of the Mariana Trench. From surface to seabed the underwater marvel is 10,928 meters deep and is the deepest point in the Earth’s hydrosphere. The vessel would have to sustain pressure equal to 50 buses pushing down on it. Descending nearly 11km in April 2019, Vescovo now holds the record for the deepest ocean dive made by a human. What he found on the ocean floor will shock you.

Triton has recently been working on creating prototypes of submersibles that are able to withstand incredible amounts of pressure atat significant ocean depths. And they have struck gold - or should we rather say titanium - with the Triton 36000/2 Hadal Exploration Systems. They explain how the submersible came to life on their website:

“Three years ago, an American client came to us with a dream. He had climbed the seven summits, the tallest peaks on each of the seven continents, and next he wanted to dive to the deepest point in each of the five oceans. The challenge was set. Only two manned submersibles have ever dived to full ocean depth, and each made only a single dive. Could Triton design and build a submersible capable of repeat dives to the most remote, hostile and unexplored region of our planet? The answer, a resounding “yes”.”

The company spent every weekday (and probably weekends) working on designing and engineering feasibility studies of the submersible. Then, in 2016, the last design was decided upon and a manufacturer was chosen. They were off to the races.

The submersible’s alloy would be made of titanium, and surrounding the vessel, glass-bead based ‘syntactic’ foam to allow for buoyancy. The two materials are able to withstand immense pressures - whilst making enough space for two passengers. But, what made this submersible novel was the lack of welding work required. One of these submersibles can be purchased for just US $48.7 million.

Triton eventually settled on a name: The DSV (Deep Submergence Vehicle) Limiting Factor. A fully commercially accredited full ocean depth (FOD) manned submersible. And the plan was to take it on a journey that would see it visit the bottom of all the five oceans - a mission entitled Five Deeps Expedition. He has since completed four out of five of the expeditions and is to complete his mission in the Arctic Ocean in September 2019. His entire journey has been filmed and will be made into a documentary to air on Discovery networks.

Filming the documentary also required some engineering. The team had to design cameras that could sustain the pressure down at 10,000m below sea level. Unmanned vehicles would also be sent out onto the seabed to scan the surface so it could be recreated in virtual reality - which too had to be built out of the robust materials the Triton 36000/2 was made up of.

Here is a video from Triton that shows some of the engineering work around the testing of the submersible before they took on the five oceans.

<iframe width="702" height="395" src="https://www.youtube.com/embed/bTuKBeG1bRE" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

At the bottom of the Challenger Deep, Vescovo made a chilling discovery on the seafloor… plastic waste. After spending four hours hovering above the seafloor, he said he observed a plastic bag and sweet wrappers. Manmade waste was at the deepest levels of the ocean.

Nonetheless, the expedition is an amazing feat of engineering. Upon returning from the Challenger Deep expedition, Vescovo (talking to the BBC) said:

“It is almost indescribable how excited all of us are about achieving what we just did. The submarine and its mother ship, along with its extraordinarily talented expedition team, took marine technology to a ridiculously higher new level by diving - rapidly and repeatedly - into the deepest, harshest, area of the ocean.”

Works Cited

“Hadal Exploration System.” Triton Submarines, tritonsubs.com/hadal/.

Morelle, Rebecca. “Mariana Trench: Deepest-Ever Sub Dive Finds Plastic Bag.” BBC News, BBC, 13 May 2019, www.bbc.com/news/science-environment-48230157.

- Details

- Written by: Quintus Potgieter

- Category: Industry

We are only five months into 2019 and America has already seen 693 tornadoes tear across their sky. Just over the last couple of weeks, the American Midwest has been battered by over 100 tornadoes that have left several states with billions of dollars of damage to recover from. And so, with many buildings left destroyed, civil engineering is quick to come to into action.

The immediate concern when any storm hits is flash flooding. Over the last 12 days Oklahoma has witnessed rivers and dams rise to levels that have never been seen before.

Their streets were flooded due to drainage systems being overloaded and the natural earth simply not being able to absorb the amount of water falling from the sky. However what follows the flash flooding is far more worrying. When the sky turns an eerie shade of green, Americans known all too well what follows…a tornado.

Last Wednesday, late in the evening of 24 May, a maximum strength EF3 tornado touched down in Jefferson City, Missouri. Tearing across 32 miles of country, the tornado resulted in immense amounts of heavy damage. Dr Giuron (Grace) Yan, a Missouri S&T assistant and professor of structural engineering, made a trip to Jefferson City to study the destroyed structures, and their structural integrity after the tornado

Yan currently operates a wind hazards laboratory named the WHAM lab at Missouri University of Science and Technology. Sending a number of drones into the sky, Yan and her team were able to assess the damage left behind in the wake of the storm, observing some houses with their roofs completed taken off but some with only partial damage.

Yan will be using the data gathered for research purposes in hopes that her and her team can develop guidelines for tornado-resist construction. The ultimate goal would be to have these guidelines standardized and used to improve the official building codes in the area.

She notes that the extensive damange is due to the municipal building codes for residents not enforcing a rule that homes must be able to withstand rotating winds. She says some homes in Jefferson City are only built with ‘straight-winds’ in mind. She is thus planning to recommend the municipality implement residential building codes that will force residents to build with more than just thunderstorms in mind. Yan told STL Public Radio:

“If the tornado intensity is not that high, and if we have improved our building code to recommend tornado-resistant design, the damage would be much less. For example, a number of buildings, the entire roof has been blown off but if we performed tornado-resistant design, the damage can be minimized to just the shingles.”

The civil engineering lessons Yan and her team are learning are useful. Yan points out that the Missouri State Penitentiary didn’t withstand the force of the tornado but just across the road, a house seems virtually untouched. Residents of the town are in awe of the tornado, effortlessly carrying away blocks of concrete with the wind.

The research is important, especially when considering that in the future it could save lives when future tornadoes hit. Unfortunately, some damaged buildings in the wake of tornadoes can never be repaired, and some lives are ultimately lost. Nonetheless, Americans are resilient, and their rebuilding spirit has kicked in, in a country that has seen this carnage many times before.

Works Cited

Chen, Eli. “Missouri S&T Engineers Inspect Jefferson City Tornado Damage To Make Houses Stronger.” St. Louis Public Radio, news.stlpublicradio.org/post/missouri-st-engineers-inspect-jefferson-city-tornado-damage-make-houses-stronger#stream/0.

Ktul. “UPDATE: Officials Pull Back on Water Release from Keystone Dam.” KTUL, 29 May 2019, ktul.com/news/local/keystone-release-could-be-dropping-as-resilient-community-fights-back-flood-water.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Engineering is transforming Kenya into an innovative hub of new technologies that are both helping the poorest of the poor and assisting the growth of the business sector.

A startup from the Penn State College of Engineering, Kijenzi, has been training Kenyans in the art of 3D printing. The startup also helps address several key issues encountered in the rural medical facilities in Kenya.

In Kenya, clinics are being faced with many issues like outdated machinery, unrefined supply chains, and limited access to equipment they need to ensure a healthy environment for patients. On Kijenzi’s website they explain how their 3D printers work:

“At the most basic level, 3D printing is a form of additive manufacturing - the process of adding material to a product. The printers used by MK take computer-generated 3D models and, with a series of programs, translate the models into a form readable by the printer. With this formatted file, the printer can then use fused deposition modelling (laying down many thin layers of material, in this case plastic filament) to actualize the model. With this process, a huge variety of products can be generated, printed in many materials, and from infinite designs.”

The useful element of Kijenzi’s 3D printers is that it can use a versatile PLA plastic filament. This certain type of filament can be made up of recycled plastics as well. Thus, collected and recycled plastic in Kenya could make up filaments that can be changed into new products by 3D printers in the country.

The printer itself is put together by Kijenzi, and is fabricated out of affordable but durable materials. The printer can produce “simple knobs and brackets needed for maintaining appliances and machinery to unique application medical items”, Kijenzi says. It can also print frames for bifocals, hearing apparatuses and more.

Entrepreneurship & Business

Hobbyists have taken up 3D printing globally, but entrepreneurs have also started opening their doors to the public offering to print items customers want as well. A 3D printing service in Nairobi named Objet Kenya is a 3D printing service provider showing Kenyans what is possible in the 3D printing industry.

Farai Mashambanhaka, who worked with Objet Kenya, wrote in 3DPrint.com:

“There are several other companies offering 3D printing services in Kenya and the country has a great entrepreneurial and innovative spirit. This has made 3D printing a very sensible and lovable technology and if there is something that fires it all: it is the Kenyan will provide homegrown solutions.”

Another 3D printing service provider in Kenya is Ultra Red Technologies. They print ‘customized canopies for wildlife exploration vehicles’. They are also printing parts for solar powered desalination devices that will provide clean, purified water for Kenyans.

Another company offering training in 3D printing for Kenyans is a place named Kenya Connect. It is a not for profit organization offering STEM classes to help Kenyans learn the basics.

Works Cited

“3D Printing.” Kijenzi, 26 June 2017, medtechkijenzi.wordpress.com/3d-printing/.

“3D Printing in Africa: Kenya & 3D Printing.” 3DPrint.Com | The Voice of 3D Printing / Additive Manufacturing, 1 May 2019, 3dprint.com/242729/3d-printing-in-africa-kenya-3d-printing/.

- Details

- Written by: Quintus Potgieter

- Category: Student Stories

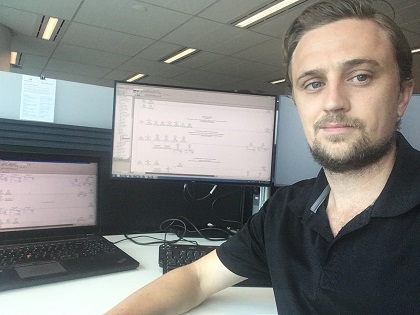

Sam Bates is a graduate of the Engineering Institute of Technology who recently earned his 52708WA - Advanced Diploma of Industrial Automation. He works in the automation industry in the United Kingdom and is employed as a controls engineer. But, it has been a journey to get to where he is today. Sam says:

“I left school at the tender age of 16 and went to engineering college to learn the very basics in engineering. While I was there, I got offered an apprenticeship at a local engineering company called Finishing Design Services. They build special purpose machinery and wanted to employ me as a panel wirer with the option to progress in future years if I had the right attitude.”

Leaving school as early as he did, and needing experience, he took the apprenticeship. He would go on to be a panel wirer for four years while he completed his National Vocational Qualification (NVQ) and apprenticeship.

“As promised, the company offered to pay for me to complete a HNC in electrical and electronic engineering at university for one day and evening a week for two years. I accepted and continued to develop, now doing more skilled work at my company, such as editing electrical drawings, powering up machinery and getting introduced to software.”

Once he had completed his Higher National Certificate (HNC), he decided to slow down on studying and continued to gain work experience and develop his skills in the workplace. He began designing the electrical schematics for small projects and writing PLC software for them.

He spent seven years at Finishing Design Services and was ready to move on. Sam moved to London. There, he worked as an engineering technician at a company named Suncombe Ltd. The company manufactures process machinery. However, he had a feeling that the qualifications he had earned were not quite enough to reach the career aspirations he had.

“I progressed within that company to commissioning the software and servicing existing machinery. This is where I decided to take up the Advanced Diploma of Industrial Automation to develop my knowledge.”

Upon graduating from the course, Sam was looking to level up once moreso he began looking for controls engineer jobs. He eventually landed a job at a new company named ATM Automation.

He has since been with the company for six months, writing and commissioning software for automation machinery.

Sam believes the engineering industry has changed his life and encourages young people to heavily consider going into engineering. He said:

“I cannot understand why young people do not want to jump into any kind of engineering type of work. I would encourage young people to get an apprenticeship once finishing school, or after their A levels* - and to study part time while they work. This would give them the practical experience that employers desire and the opportunity to develop their knowledge.”

Equipped with his Advanced Diploma, he is confident in his job and ready for more challenges that the engineering industry can throw at him. As he continues growing his skill set, Sam expects to become a senior controls in engineer in the next ten years.

*a public examination requiring advanced knowledge in a subject and taken at the end of secondary school in the United Kingdom.

- Details

- Written by: Quintus Potgieter

- Category: Industry

In the 1800s the United States was industrializing to the point where New York and San Francisco, states that were quite literally on opposite sides of the country, needed to figure out a central point at which they could trade with each other. They would, via their respective railroads, meet in the middle at a trading port in New Orleans. However a lake stood in their way, Louisiana’s Lake Pontchartrain.

The railway, at over nine kilometres long, is the longest railway crossing over water on earth and the longest railroad bridge in the United States. Engineers completed the bridge over 130 years ago. Back then, it was entirely made of wood. Now it is a concrete ballast deck bridge.

The bridge provides a pathway into New Orleans and is still to this day a vital piece of infrastructure for the trading of goods within the United States.

However, with a low lying concrete deck bridge comes a problem; boats can not pass underneath the bridge. In solution to the issue, engineer William Donald Scherzer came up with the idea of the rolling bascule bridge. A 66 meter long Scherzer bridge fitted to the railway raises the span by rolling on a track with a 830-tonne counterweight that takes the bridge skyward.

Patrick Weldon, an Assistant Division Engineer of Bridges on the Norfolk Southern Railway, talking to the television programme Impossible Engineering, explained:

“We have machinery at the top of the bridge that is powered by two electric drive motors. There are two pinions and those pinions rotate across a rack system. Essentially what happens is, it applies force to open the bridge.”

In 2005, the bridge was put through its biggest challenge yet; Hurricane Katrina. It led to the damaging of 7.5 kilometers of railway was swept off the bridge and into the bottom of the lake. Maintenance teams had to use cranes to pull the railway back onto the bridge deck. Only 16 days after Katrina made landfall, the engineers managed to get train services restored

India’s engineering marvel

At the end of 2018, Indiaopened their latest dazzling marvel of engineering; the longest combined rail and road bridge. It is named the Bogibeel Bridge. It crosses over the River Brahmaputra, sitting between the Dibrugarh and Dhemaji districts of the northeastern state of Assam. The bridge stretches to a length of 4.94 kilometers.

It has been a long process from laying the foundation stone of the bridge in 1997 until its operation in 2019. The bridge was delayed due to a plethora of issues, ranging from lacking the appropriate technology, subsequently missing deadlines as a result, and the rising costs of construction.

Engineers have essentially changed the lives of the people of Dhemaji with the construction of the bridge. The bridge has provided easy access to hospitals, education institutes and the Dibrugarh airport. The railway also bypasses 705 kilometersthat passengers would have had to endeavour before the bridge’s construction.

When all the delays were figured out, the bridge’s construction went ahead. Standing atop 42 pillars which were constructed using state-of-the-art Germany engineering technology, the bridge was welded together. The welding of the bridge has ensured it is significantly lightweight when compared to riveted girders. Engineers also had to account for the rising of the Brahmaputra river which swells during rainy seasons. Consequently, they built the bridge 32 meters above the river water level.

The bridge has a lifespan of 120 years, and is the second longest bridge in Asia. And now, it is the darling and pride of India.

Works Cited

“‘Impossible Engineering’ Beasts of the Bayou.” IMDb, IMDb.com, 1 May 2019, www.imdb.com/title/tt10121906/?ref_=ttep_ep1.

“All You Need to Know about Assam's Bogibeel Bridge - How Special Is the Bogibeel Bridge.” The Economic Times, economictimes.indiatimes.com/news/politics-and-nation/all-you-need-to-know-about-the-bogibeel-bridge/good-governance-day/slideshow/67241699.cms.

- Details

- Written by: Quintus Potgieter

- Category: Developments

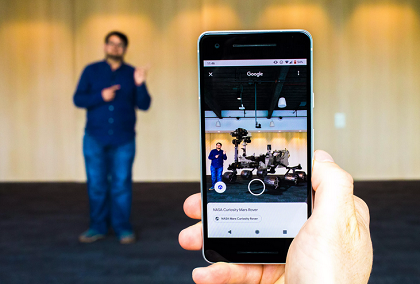

Google I/O has kicked off in Mountain View, California. A keynote speech opened the conference, which will see software and hardware developers from all over the world descend on Silicon Valley to watch and learn how Google do what they do.

Google CEO Sundar Pichai kicked the proceedings off by outlining Google’s Mission, which is to “organize the world’s information and make it universally accessible and useful”. They continued on to announce a plethora of notable additions to their product lines including new smartphones, and smart home devices, but it was an addition to their search engine that raised eyebrows.

Google announced that they would be implementing augmented reality into their search engine through what is known as Google Lens. Google initially launched ARCore in 2018, a platform for building augmented-reality experiences, and now they have finally shown what is possible.

At the conference, Google showed how the functionality work, but CNET has shown, in more detail, how useful the addition is:

The benefit for school children and general scholars is immediately apparent. Searching for an object and seeing it in action right in front of you while you are learning is valuable for those who are audio/visual learners.

With this new search tool, when you find an item that can be shown in augmented reality you are able to click ‘view in your space’ and a 3D model of whatever you have chosen will be projected into your camera’s field of view. The CNET video above shows what seems to be a NASA rover in augmented reality.

Thus, for prospective engineers specifically, the virtual simulation technology that Google has developed could be very beneficial to their learning. Engineers could see in 3D the technologies mentioned in their textbooks, learning its intricacies and getting an idea of what they might see in their future employment.

Google now joins the league of companies like Microsoft who are trying to bring the virtual world into the real world specifically for learning purposes.

Clay Bavor, Vice President of Virtual and Augmented Reality at Google said:

“We think, with the technologies coming together in augmented reality in particular, there’s this opportunity for Google to be vastly more helpful.”

Works Cited

Lardinois, Frederic, and Frederic Lardinois. “Google Brings Augmented Reality to Search – TechCrunch.” TechCrunch, TechCrunch, 7 May 2019, techcrunch.com/2019/05/07/google-brings-augmented-reality-to-search/.

- Details

- Written by: Quintus Potgieter

- Category: Developments

In 2017, the world got its first taste of the future of electric mobility and looked like something straight out of a science fiction film. An unmanned remote-controlled electric ‘jet’ prototype that took to the skies and experts were more than impressed. The engineers at Lilium, a Munich based startup, were providing the world a glimpse of what might one day be possible - a fully electric jet taxi.

Fast forward to 2019 and the company announced their fully electric five-seater prototype jet, flying up to impressive speeds of 300km/h. On 4 May 2019, the engineers took their new unmanned prototype out to a launch pad in Germany to test the groundbreaking vehicle. It was a successful launch.

The electric jet takes off like a helicopter, going straight up without the need for a runway - making it a more accessible technology for companies wanting to purpose these aircraft. The company’s aim is to build an ‘Uber-of-the-skies’ mobility service that they intend to have operational in various cities around the world by 2025.

Co-Founder Matthias Menier said:

“This is the first time that we have a full-scale, full-weight prototype of that five-seater version. This is the next step in mobility as we perceive it. What we are trying to achieve is an air mobility revolution. We look at what is possible by the laws of physics. Our principle of maximum simplicity combined with a level of safety is really something that makes us unique.”

The Lilium jet is fitted with 36 all-electric engines on the flaps of the jet that produce minimal noise. The company says the low vibrations will mean a smooth and quiet ride for passengers, but most importantly not generate any carbon emissions. The company says they are the first electric jet engines in commercial certification.

The engineers working on the project say the fixed wing design of the aircraft only utilizes less than 10% of the maximum 2,000 horsepower the plane is capable of while cruising. The company says:

“This efficiency, which is comparable to the energy usage of an electric car over the same distance, means the aircraft would not just be capable of connection suburbs to city centers and airports to main train stations, but would also deliver affordable high-speed connection across entire regions.”

Now comes the hard part of refining the prototype and seeing if humans can actually travel inside the cabin. The company, however, do say that if they get their aircraft operational by 2025, a pilot will most likely be aboard helping fly the aircraft. But, they are not ruling out an autonomous aircraft in the future. The even harder part for the engineers and the company as a whole is getting safety approval in Europe and the USA, which the company is now in the process of doing.

Works Cited

Hawkins, Andrew J. “Electric Air Taxi Startup Lilium Completes First Test of Its New Five-Seater Aircraft.” The Verge, The Verge, 16 May 2019, www.theverge.com/2019/5/16/18625088/lilium-jet-test-flight-electric-aircraft-flying-car.

“Home.” Lilium, lilium.com/.

- Details

- Written by: Quintus Potgieter

- Category: Developments

Anglo American’s coal mining operations in Mpumalanga, South Africa, are becoming more efficient and safer. They are starting to roll out underground Wi-Fi and equipping their miners and engineers with smartphones. It’s a setup that will cost only $690,000..

Currently in South Africa, telephones are used inside mines to communicate above and below the mine, but they are not immediately available to everyone involved in the mining operation. Communications is just one of the many benefits of the new underground Wi-Fi. Miners can now send photographs and videos to fellow miners and engineers so they can troubleshoot any problems in the mine.

Anglo American’s Edgar Simfukwe told the media:

“We’re working in an environment where safety and productivity are paramount. The introduction of underground Wi-Fi is a game-changer. It allows our miners to communicate more easily, thereby making mines more productive. The main benefit is that breakdowns can be reported and resolved faster - in some cases, by contacting equipment manufacturers on the spot.”

Safety is another vital benefit. Miners can now be tracked throughout the mine which will also aid rescue crews if accidents happen. In the future, miners will also wear wearable technologies that can track their vitals whilst they do the heavy work - giving the mining company incredible oversight over its workforce’s wellbeing.

Once they successfully implement a communications mesh network, the company can also look into fleet management that can be automated utilizing Wi-Fi technology. This has been happening in some technologically developed mines around the world for some time now.

Automation in the mine a success?

Many mining operations around the world are creating interconnected networks of miners and mining technology through Industrial Internet of Things technologies.

In Western Australia, iron ore mining producer Fortescue Metals Group since 2012 had coupled their trucks up to an automated system that actually drives the trucks autonomously. The company calls it the Autonomous Haulage System (AHS). They are connected via a Wi-Fi system as well. In February 2019, however, a pair of the trucks collided into one another.

Since then, the technology has shown its reliability over time and avoided more accidents than it has caused. Chief Executive of Fortescue, Elizabeth Gaines, explained:

“Since the introduction of the first AHS truck at Solomon in 2012, AHS trucks have safely travelled over 24.7 million kilometres.”

Nonetheless, a preliminary investigation into the collision allegedly revealed that the trucks apparently lost Wi-Fi coverage in a certain location inside the mine. Thus, it seems, the mine’s mesh network was not properly communicating dynamically.

Anglo American is on track with their implementation of networked technologies. In 2017, they began their rollout of technologies into the mining sector. With a more than $34 million USD investment into technology like drones, remotely controlled drills and novel software, Anglo American has begun its revolutionizing of their operations.

Progress is being made in making mines all across the world with the implementation of Industrial Internet of Things technologies that are making for a safer environment for engineers and miners alike.

Works Cited

“Anglo American Heads up Underground WiFi.” ENCA, 20 May 2019, www.enca.com/news/anglo-american-heads-underground-wi-fi.

“Not so Autonomous: Wifi Outage Results in Driverless Truck Crash at Fortescue Mine.” MINING.com, 15 Feb. 2019, www.mining.com/driverless-trucks-not-flawless-two-crash-fortescue-mine-australia/.

- Details

- Written by: Quintus Potgieter

- Category: Student Stories

Jessica Ann Mckenty is an Apprentice Communications Technician at Ergon Energy. She is a noteworthy graduate of the Engineering Institute of Technology. In October of 2018, Jessica graduated with a 52782WA - Advanced Diploma of Industrial Data Communications, Networking & IT.

Jessica completed the Advanced Diploma in the final eighteen months of her apprenticeship at Ergon Energy. Through her academic endeavors and her apprenticeship, Jessica became equipped with everything she needed to make sense of the industry she was entering into. She said:

Jessica completed the Advanced Diploma in the final eighteen months of her apprenticeship at Ergon Energy. Through her academic endeavors and her apprenticeship, Jessica became equipped with everything she needed to make sense of the industry she was entering into. She said:

"I have been fortunate enough to get exposure to a wide range of applications of communications. This includes fiber splicing, tower rigging, mobile vehicle installation, radio communications maintenance and installation. I have also worked on upgrades of protection signaling paths (microwaves and fiber), removal of old SACS systems and installation of RTU's in their place, as well as installing and configuring communications modems and switches at remote sites."

Previously, Jessica had acquired an Electrical Trade certificate and had a reasonable grasp on some of the necessary information in her industry, but she says the Advanced Diploma presented her with ‘greater understanding and appreciation of industrial data, communications, networking and IT.'

“The highlights of the course would have been the DNP and SCADA modules, as many faults I encountered in my work involved these topics. Once I was able to breakdown the knowledge provided by EIT and use it in my fault finding methods, I did feel a sense of success.”

The fault finding, Jessica says, was made more accessible through the first four modules of the course: Physical Media, Industrial Data Coms, Wireless, and Ethernet. It was all systems go after she began familiarizing herself with the kinds of systems she came to know through her studies. She had newfound confidence when working at configuring switches and modems.

However, Jessica did find some aspects of the course difficult; specifically, the group work aspect of it. Being used to traditional ways of learning, Jessica found that the online method of learning that EIT provides took some getting used to. But soon after, she realized that she could re-watch lectures and found written summaries of past webinars.

Nonetheless, Jessica notes that she really thrived in her work while working through her Advanced Diploma. Her future outlook is one of ultimate optimism. She said:

"In relation to career progression, I feel I am a more valued member of my workgroup. The foundational knowledge that this course provides is priceless. I have been successful in being signed off early as to take on a Communications Paraprofessional role within Ergon, and I look forward to continuing my studies and having a successful career in this field.”

Jessica is considering studying towards a CISCO accredited course or pursuing an advanced networking course to further her knowledge in network operations. Equipped with the skills and the know-how thanks to the 18-month Advanced Diploma, Jessica feels that she is exactly where she needs to be — building a career in the engineering world.

EIT would like to honor her for never giving up on her course and persevering. That is why she is a runner up finalists of our EIT Graduate of the Year 2018. We hope she continues to take her engineering career from strength to strength and succeeds in everything she does.

- Details

- Written by: Quintus Potgieter

- Category: Student Stories

At the end of the 80s, in the far west of outback New South Wales, in an inland mining city known as Broken Hill, Cindy McGeorge embarked on an Electrical Fitting apprenticeship. And now, with a 52726WA - Advanced Diploma of Applied Electrical Engineering, she is an alumnus of the Engineering Institute of Technology.

Her life has been defined by becoming a mother, relocating, pursuing further education and her dreams in the electrical engineering industry. What follows is an interesting window into the world of a woman in the energy distribution world.

After her apprenticeship Cindy worked both above and underground at the local mines in Broken Hill and graduated to working with the mines’ SCADA systems. After spending some years there she felt it was time to move on. She said:

“After 10 years I went to work in the south west Queensland oil and gas fields as a contractor as well as working part time on a cattle station. I was lucky during this time to give birth to two boys. My eldest child and his nanny would travel with me to my jobs. When the second boy came along, it was time for a change.”

Cindy moved to a nearby town, Tibooburra. She continued to contract on a smaller scale, but also spent time raising her children and running a local shop.

But she was due for another shake-up. She said:

“After a few years in Tibooburra, I found myself contracting to the local utility Essential Energy and this turned into a casual position. Some of my jobs included all remote meter reads, fault and emergency work and meter installation.

“After 6 years I relocated to obtain a full-time position within Essential Energy, but also to access a better education for my children. This landed me in a town in the middle of New South Wales, where I continued as a full-time Electrical Technician with the distribution company.”

She then began studying through the Engineering Institute of Technology to further her knowledge and skills. She has since moved to Griffith in New South Wales, and is excited to see what the future will bring.

Cindy notes that it is interesting to see how technology is transforming the industry she has come to know and love. She adds that the introduction of small and large-scale solar and wind energy projects have been an impressive and exciting addition and believes these advances will, and should, attract young, passionate people to the electrical industry.

Cindy is not stopping or slowing down. She is determined to achieve great things, and further her career in engineering. She concluded:

“I have spent 30 years in the trade and always had a passion to do things better and different. Engineering will hopefully open the doors that can allow me to achieve this. With the aid of more study, I will see myself move towards a job that allows me to be creative and productive.”

All of us at EIT wish Cindy everything of the best. We know that her career will continue to be defined by the passion she brings to her work and her further studies.

- Details

- Written by: Quintus Potgieter

- Category: Industry

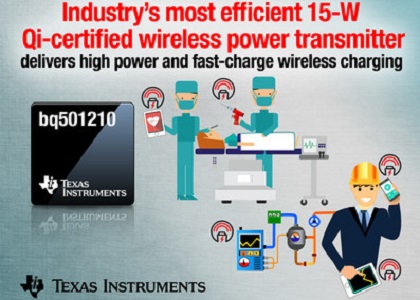

Wireless charging technology has had a serious hit or miss relationship with the mobile industry. With some standards being cleared, some technology being engineered and some being still stuck in pre-production, it’s hard to know what’s going on sometimes. However new developments might mean we are closer than we think.

Qi is the charging standard that defines wireless power transfer using inductive charging methods. The increasing development of this technology has gotten engineers minds inventing at a million miles an hour. If smartphones will be able to charge their batteries without the need for wires, what else could be charged wirelessly too?

In 2016, a company named Texas Instruments, who specialize in wireless technologies, began experimenting outside the smartphone and branching out to other industries. They released the industry’s first Qi-certified 15-W wireless power transmitter.

“Industrial equipment such as electronic point-of-sale devices and handheld medical equipment reap the benefits of 15-W wireless power. This breakthrough in technology enables wireless models and reduces overall end-application size by helping eliminate bulky wiring.”

However the smartphone industry is still leading the way in the wireless charging revolution. There are rumors currently circulating that the next generation of iPhones will employ what is called bilateral charging. This form of wireless charging allows one charged up phone to transfer some of its battery power to another device that requires charging.

Electronic Vehicles

Electric vehicles (EV) are another industry where wireless charging could revolutionize the technology used. However, whilst the industry has taken many leaps forward; EVs are still stuck in the development phase.

The company Qualcomm develops wireless charging technology for electric vehicles under the name HALO and has subsequently just sold their technology off to MIT-founded business WiTriCity. WiTriCity has now started the process of formalizing a wireless charging standard for automakers. Their aim is to make ‘EV charging easier than refueling’.

They are working on park-and-charge bays and power transfer grid-to-battery technologies that would charge cars through surface or in-ground placements placed in asphalt, cement and more.

Encouragingly for WiTriCity, the joint venture with Qualcomm gives them access to incredible patents and pending patent applications.. Now the companies can work to improve the technologies and could lead to some breakthroughs for electric vehicles.

Alex Gruzen, CEO of WiTriCity, in a press statement, wrote:

“WiTriCity’s wireless charging technology is key to the future of mobility which is clearly electric, and is increasingly shared and autonomous.”

Qualcomm’s HALO technology has also been embedded into an electric vehicle charging road. The road was also a joint venture - this time, with automaker Renault. Their tests saw an electric vehicle being charged at 20kW while travelling 100km/h.

Robert Lassartesses from Renault said:

“If you compare fast charging with gasoline, it’s not equivalent. Even in our best dreams [EV charging] is 300kW. We are 20 times below what you can do with gasoline and it’s important to keep this in mind. Equivalent service between electricity and [traditional] fuel cannot be expected.”

300kW could be attainable with an 800V battery, the experts said, but the battery would be far too heavy. Thus, the development of batteries, and their wireless charging applications, is ongoing across engineering industries. The benefit for the consumer is clear: batteries that last longer and go further.

Works Cited

“TI Announces the Only Qi-Certified 15-W Wireless Power Transmitter.” News, news.ti.com/ti-announces-only-qi-certified-15-w-wireless-power-transmitter.

Ward-Foxton, Sally. “'Electronic Road' Charging For EVs Moves Forward.” EETimes, EE Times, 23 May 2017, www.eetimes.com/document.asp?doc_id=1331778.

- Details

- Written by: Quintus Potgieter

- Category: Industry

Nokia wants to show the world what is possible with 5G networks and automated factories. Not only is the company now manufacturing mobile technologies with 5G embedded within their architecture, but they are also using it to automate their factories.

Based in the Finnish city of Oulu, Nokia has built a factor which they consider to be the future of modern industrial production and manufacturing. Whilst the plant has always belonged to Nokia, the company has now retrofitted the plant with new llot-powered technologies.

Nokia wanted to make a factory that was “conscious”, a self-thinking and always learning factory of the future. 5G, in general, will transform engineering industries; industries that have been trying to take the workforce out of harm's way by replacing repetitive tasks in industrial operations.

President and Chief Executive Officer of the Nokia Corporation, Rajeev Suri said:

“It possesses unique characteristics that make it socially and economically transformative: low latency (in other words, almost imperceptible lag when carrying out remote orders); fast speeds (around 10 times faster than today’s networks); connection capability (enabling up to 1 million linked devices per square kilometer); and unparalleled reliability (allowing new precision-based applications).”

To show how the lower latencies work with 5G, Nokia tested advanced real time quality control with their 5G system powered by Intel. The engineers intentionally made errors in a manufacturing process, which the 5G monitoring system with a camera attached to it flagged the error immediately, suggesting course corrections for the process. See it in action here:

Nokia is incorporating the characteristics of ‘flexibility, versatility and productivity’ into the factory. They are also processing all of the data generated by the factory in the cloud. Suri writes:

“The vast majority of the factory is now automated. Its temperature and humidity automatically change to keep machines in prime condition. Parts are delivered using autonomous vehicles. Equipment carries indoor GPS, allowing managers to see exactly where it is, what it’s doing and whether it could be used or positioned more efficiently.”

Nokia does not only believe that the adoption of 5G is good only for manufacturing plants, they believe it will transform all humans’ lives. The factory itself has worked well on their 4G network, proving that many companies can start with the technology already available to companies around the world. But 5G is the next frontier. Suri writes:

“This is only a first step. More are necessary. Governments in particular need to step on the gas and prioritize 5G adoptions. But if ever something was worth working for, it’s this. I firmly believe that the sooner governments, businesses and individuals have access to 5G, the sooner the Fourth Industrial Revolution can help people all over the world enjoy safer, happier, more productive lives.”

Works Cited

“Industry 4.0 Use Case over 5G at Nokia Oulu Factory.” Nokia, www.nokia.com/about-us/news/media-library/industry-40-use-case-over-5g-at-nokia-oulu-factory/#1.

Suri, Rajeev, and Nokia Corporation. “5G Will Redefine Entire Business Models. Here's How.” World Economic Forum, www.weforum.org/agenda/2019/01/5g-will-redefine-entire-business-models-here-s-how/.

- Details

- Written by: Quintus Potgieter

- Category: Industry

It was a story of ineptitude, willful ignorance, and oncoming catastrophe. But that didn’t stop civil engineers in the state of California from bouncing back and rectifying what had been neglected. In February 2017, Oroville Dam’s main and emergency spillways were damaged due to heavy rains which exposed the ill maintenance and general corrosion of the main and emergency spillways.

The reservoir is California’s second-largest provider of water. The dam’s capacity is 4.363537 km3, which equates to 1.75 million Olympic swimming pools. During the crisis, more than 190,000 people had to be evacuated from Oroville and the surrounding counties due to fears that the concrete weir of the dam could collapse and send water flooding into the regions.

Thankfully, there was no collapse in Oroville, but extensive repairs were needed. The Department of Water Resources’ engineers went to work and began a repair project that would see some impressive work done. On the 2nd of April 2019, it opened for the first time after the crisis.

The repair

On the main spillway, every 5 minutes, a dump truck would place 19 cubic meters of roller-compacted concrete onto the main spillway. They would eventually lay over 100 thousand cubic meters of concrete for the repair of both spillways. They utilized 16,000 feet of drainage pipe, which is equivalent to 500 Olympic swimming pools. And to keep everything in place? Five million kilograms of reinforcing steel.

The engineers constructed a secant wall out of reinforced concrete piles for the emergency spillway. The wall, in length, was just four feet shorter than the height of the Empire State Building.

It was initially thought that the repair work would only cost $400 million USD, but the final number was much larger. The final repair bill weighed in at $1.1 billion USD. Speaking to the Sacramento Bee, Joel Ledesma, the deputy director of the California Department of Water Resources said:

“We are prepared; we’ve spent the last two years restoring full functionality. The industry has learned a lot since this dam was built 50 years ago.”

They reopened the spillway and began pushing water at 3,300 cubic feet per second down the newly repaired spillway on its first day of operation.

Joel also told the media that the new spillway was ‘designed and constructed using 21st century engineering practices and under the oversight and guidance from state and federal regulators and independent experts’. Below, is a video that shows the rebuilding process:

Works Cited

Caraccio, David. “Enough Concrete to Pave from Oroville to Texas, and Other Facts about Oroville Dam Repair.” Sacbee, The Sacramento Bee, 5 Apr. 2019, www.sacbee.com/news/state/california/article228890254.html.

Pedroncelli, Rich, et al. “$1.1B Oroville Dam Spillway Repairs Put to Test.” Construction Equipment Guide, Construction Equipment Guide, 10 Apr. 2019, www.constructionequipmentguide.com/11b-oroville-dam-spillway-repairs-put-to-test/44557.

- Details

- Written by: Quintus Potgieter

- Category: Developments

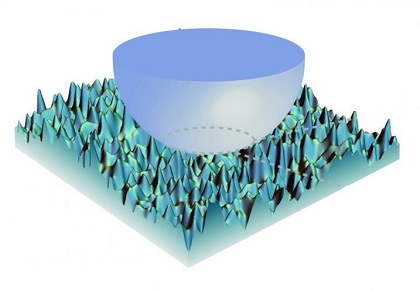

Engineers and scientists have embarked on the race of a lifetime to perfect energy efficient refrigeration technologies. At this point in time, refrigeration technologies are a large contributor to greenhouse gases due to their amount of electricity consumption.

A group of international researchers at the Chinese Academy of Sciences have reported that they have come closer to perfecting a new form of refrigeration that achieves a cooling effect utilizing crystal plastics.

Instead of compressing gas in the traditional way refrigerators do it, the researchers attempted to apply pressure to the plastic crystal. The result is a change in the molecular structure of the crystal plastics, which rapidly absorbs any heat.

Dr Bing Li, one of the researchers of the study, speaking to The New Scientist said:

“We identified plastic crystals as promising materials for solid-state refrigeration. A tiny pressure can switch the materials between the disordered state and the ordered state, resulting in a large change in energy.”

Within the crystal, the molecules compress and decompress which in turn produces a cooling effect. Dehong Yu of Australia’s Nuclear Science and Technology Organisation (ANSTO) speaking to ABC News said:

“One cycle will cause a 50-degree difference in room temperature with very little pressure. This is a perfect example of where we use our fundamental research to lead into a real thing that can benefit our everyday life.”

One of the plastic crystal compounds known as neopentyl glycol reportedly has an ‘energy change tens of times greater than other potential solid refrigerants’. The compound can absorb much more heat than solid coolants at the same pressure.

The researchers are calling it ‘atomic refrigeration’ and it could make its way into range of other consumer products. It could especially be used in air conditioners.

However, there is still some innovation required with the plastic crystals. The researchers point out that some more trial and error is needed to make them more viable as a refrigerating alternative. They write:

“Nevertheless, plastic crystals are not perfect caloric materials. For instance, given their organic nature, they have relatively low melting points (typically about 300-400K) which is not desirable for refrigeration applications. In addition, the properties that make plastic crystal highly deformable mean that these materials lack the mechanical resilience to endure many refrigeration cycles.”

Thus, the crystal in its current form still requires some further development before it replaces traditional cooling methods. This is where traditional refrigerators have an upper hand; gases can be cycled without end and determination.

However once plastic crystals has been perfected, cooling technologies could microchip-sized. It is now up to the engineers and scientists to figure out how to ensure multiple cooling cycles and scale the technologies appropriately.

Works Cited

Cazorla, Claudio. “Refrigeration Based on Plastic Crystals.” Nature News, Nature Publishing Group, 27 Mar. 2019, www.nature.com/articles/d41586-019-00974-5.

Lu, Donna. “Fridges Made from Plastic Crystals Could Help Cut Carbon Emissions.” New Scientist, www.newscientist.com/article/2197805-fridges-made-from-plastic-crystals-could-help-cut-carbon-emissions/.

Weule, Genelle. “Your Fridge Is Bad for the Environment. Here's What Could Someday Replace It.” ABC News, Australian Broadcasting Corporation, 28 Mar. 2019, www.abc.net.au/news/science/2019-03-28/plastic-crystals-could-keep-us-and-the-planet-cool-in-the-future/10943796.

- Details

- Written by: Steve Mackay

- Category: Blog - Steve Mackay

Dear Colleagues

I would respectfully suggest that most people and their companies go about their day-to-day work without a strong sense of purpose. However, in achieving success and fulfillment it is absolutely critical for both you and the business you work for to seek an overriding purpose.

Research Shows

Research clearly shows that the finest companies are those that have a deep sense of purpose and employ people who similarly derive meaning from this purpose. This overarching sense of purpose drives everyone on a day-to-day basis and gives meaning to their work.

As Nicholas Pearce (Professor from the Kellogg School of Management) remarks: The 'why we are here' drives the 'what we will do to achieve this'. Unfortunately, most companies in today's highly competitive landscape are driven simply by profit maximization. The financial pundits would fall about laughing if as CEO you indicated that you weren't particularly interested in profits but in providing meaning to your employees (and to the firm).

Obviously, you need profits to be sustainable as a business to pay the bills, to grow and to withstand the inevitable financial ups and downs. But this should not be the main reason why the firm exists. A firm should have some underlying purpose and provide meaning to its employees.

Purpose is a Powerful Driver

Most companies tend to indicate that they want to stay in existence and keep making profits. And most people are in auto mode and tend to front up to work without asking what they are doing besides earning a dollar to pay the bills. This makes their commitment to a company fairly shallow.